HONDA INTEGRA 1998 4.G Repair Manual

INTEGRA 1998 4.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/6069/w960_6069-0.png

HONDA INTEGRA 1998 4.G Repair Manual

Trending: tire type, air condition, manual radio set, fuel additives, fuel tank capacity, load capacity, headlight aiming

Page 61 of 1681

Page 62 of 1681

I

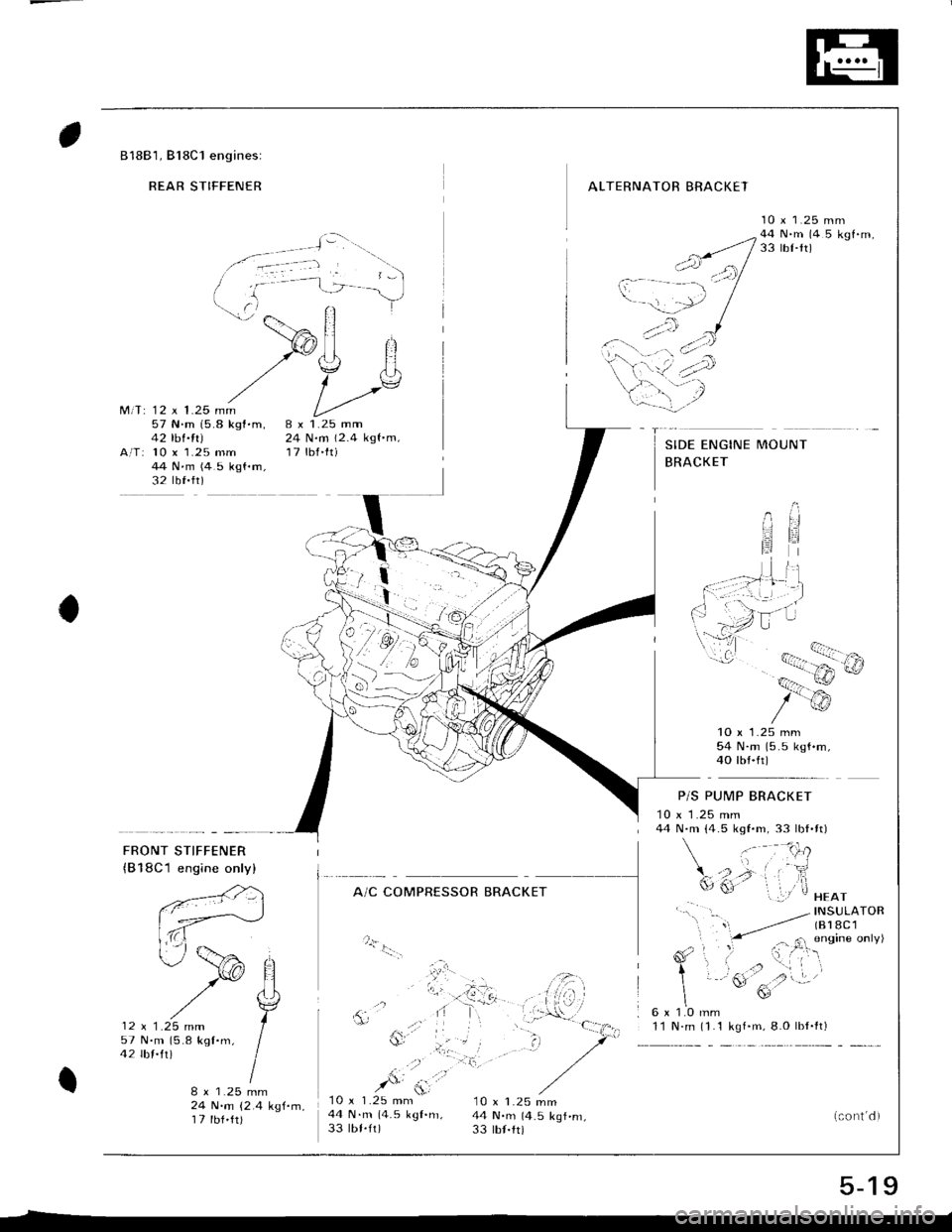

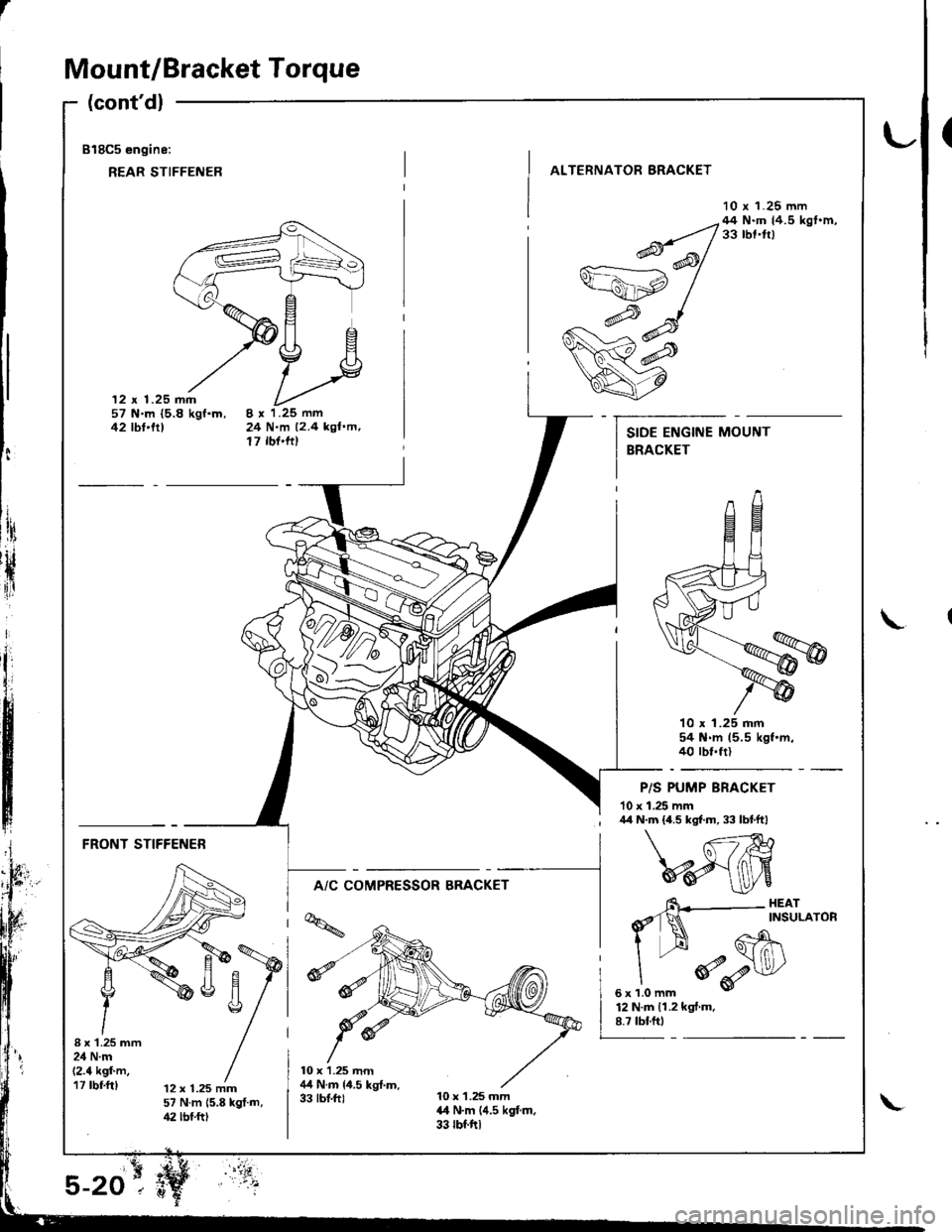

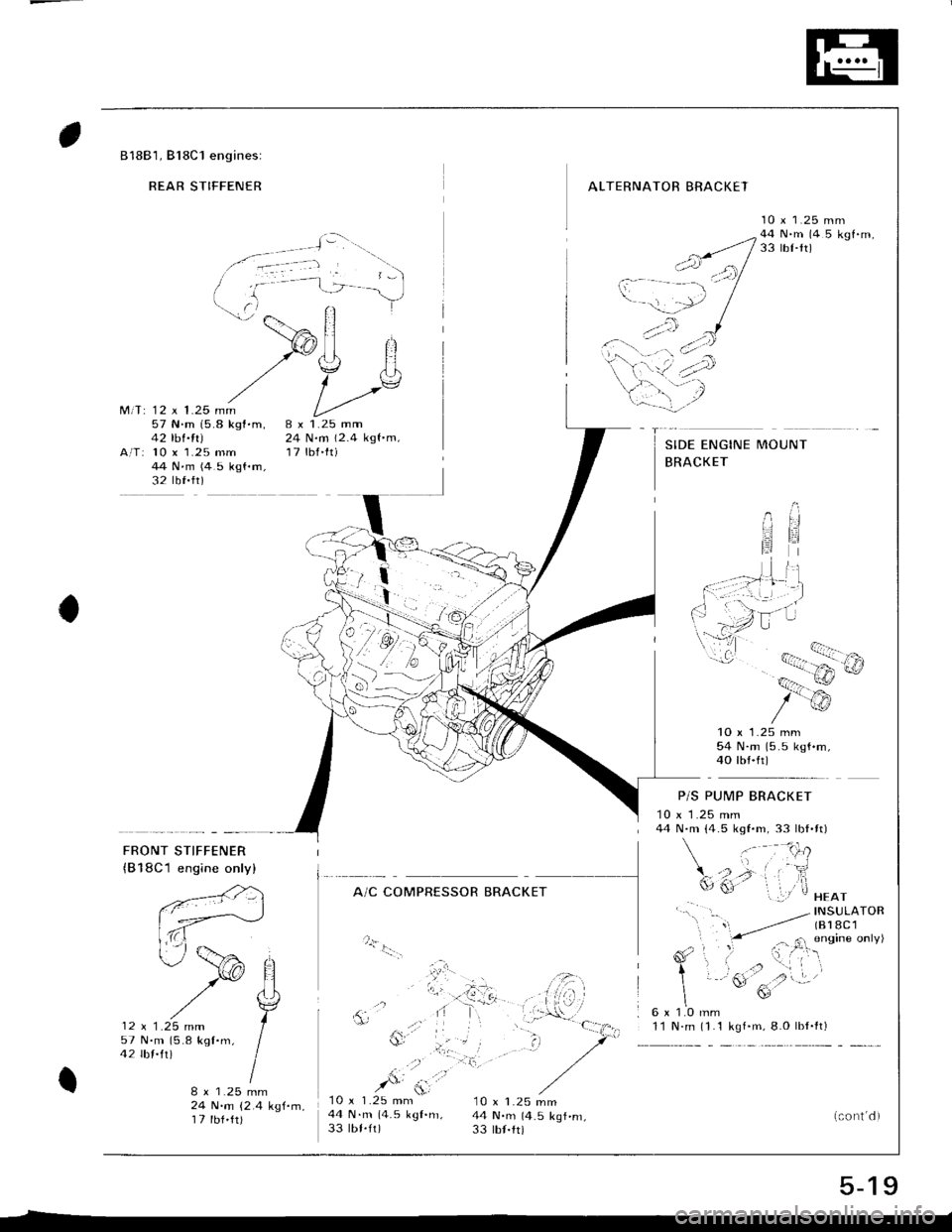

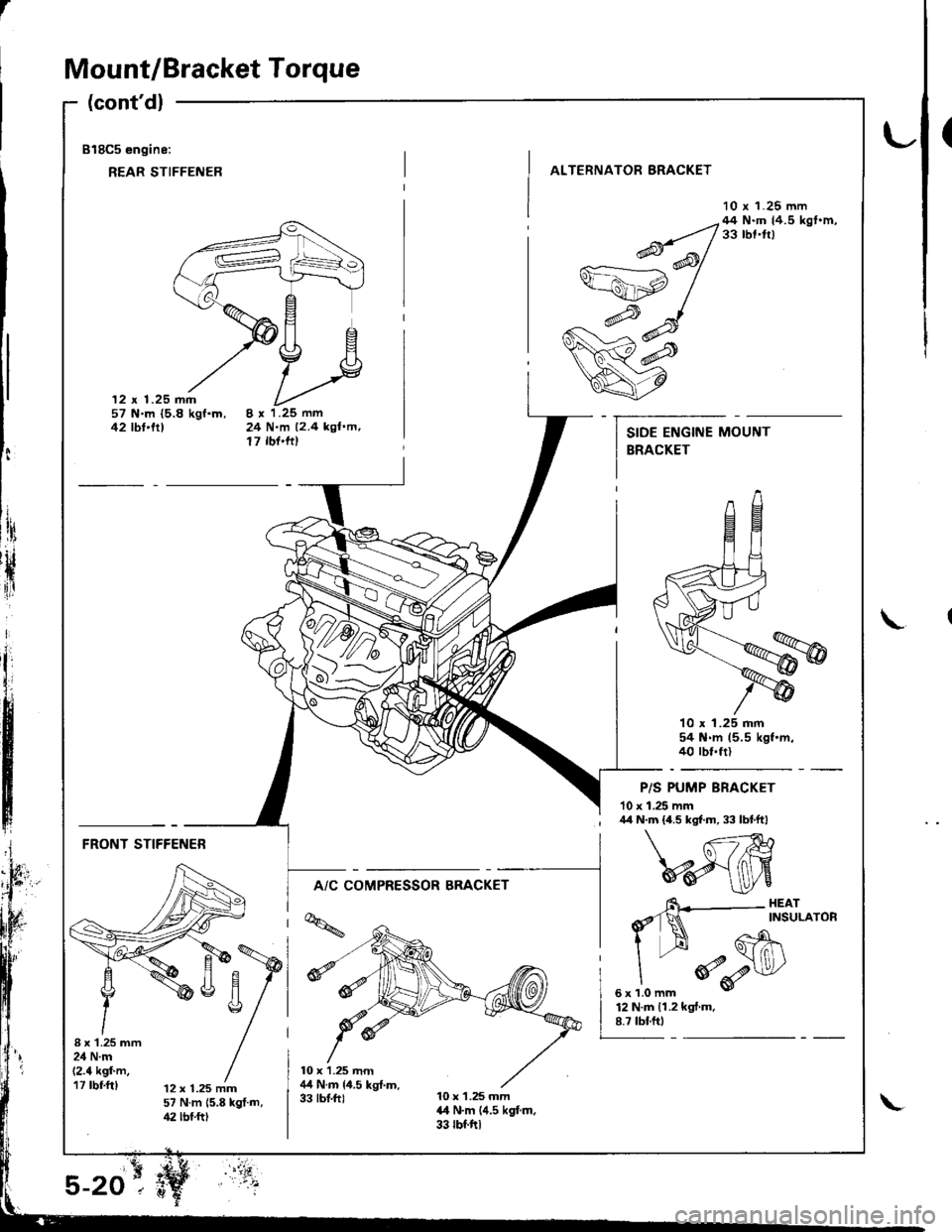

Mount/Bracket Torque

(cont'dl

818C5 engine:

REAR STIFFENER

(

ALTERNATOR BRACKET

10 r 1.25 mm

12 x 1.25 mm57 N.m {5.8 kgf.m,42 tbt'trt24 N.m 12.4 kgl.m,17 rbf'ftt

--q;;/44N'mtr.5kst'm'v=ahp /

w#

q7

10 x 1.25 mm54 N.m 15.5 kgf.m.40 rbt.frl

P/S PUMP BRACKET

10 x 1.25 mm

t:

ltri

rH

{ir

I\

; /r/r N.m {4.5 kgf.m, 33 lbtftl

FRONT STIFFENER

A/C COMPRESSOR BRACKET

I x'1.25 mm24 N.m(2.4 kgf'm,17 rbf.ft)12 x 1.25 mm57 N.m 15.8 kgt.m,42 lbf.ftt

6\--- HEAr

d'1N ^rNsuLAroR

I --H Gh\

"

*o-r$l/

sxrlomm v

12 N.m 11.2 kgf.m.8.7 tbf.ftt

Page 63 of 1681

Page 64 of 1681

Page 65 of 1681

r.lJ

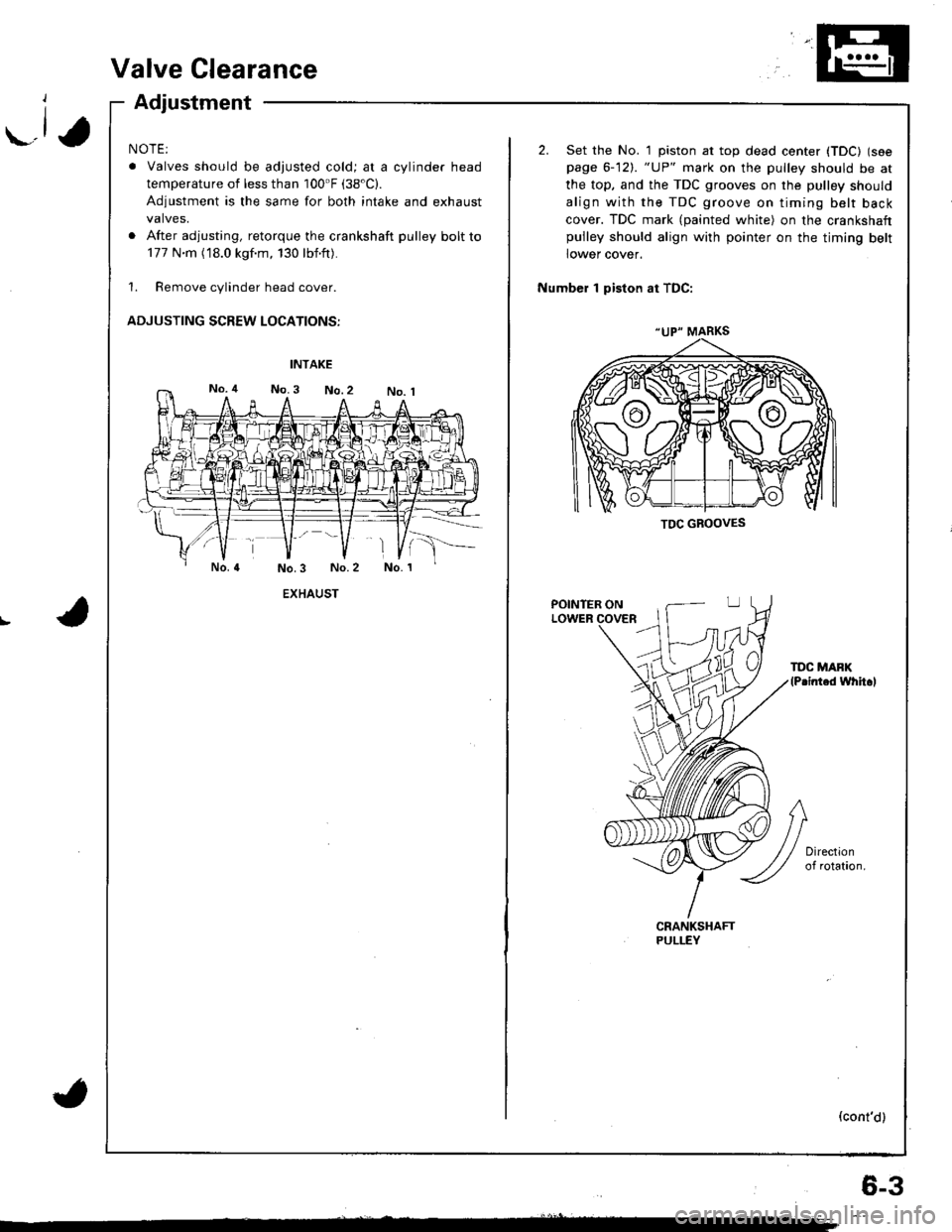

Valve Clearance

Adjustment

NOTE:

. Valves should be adjusted cold; at a cylinder head

temperature of less than 100'F (38"C).

Adjustment is the same for both intake and exhaust

valves.

. After adjusting, retorque the crankshaft pulley bolt to

177 N.m (18.0 kgf.m, 130 lbf'ft).

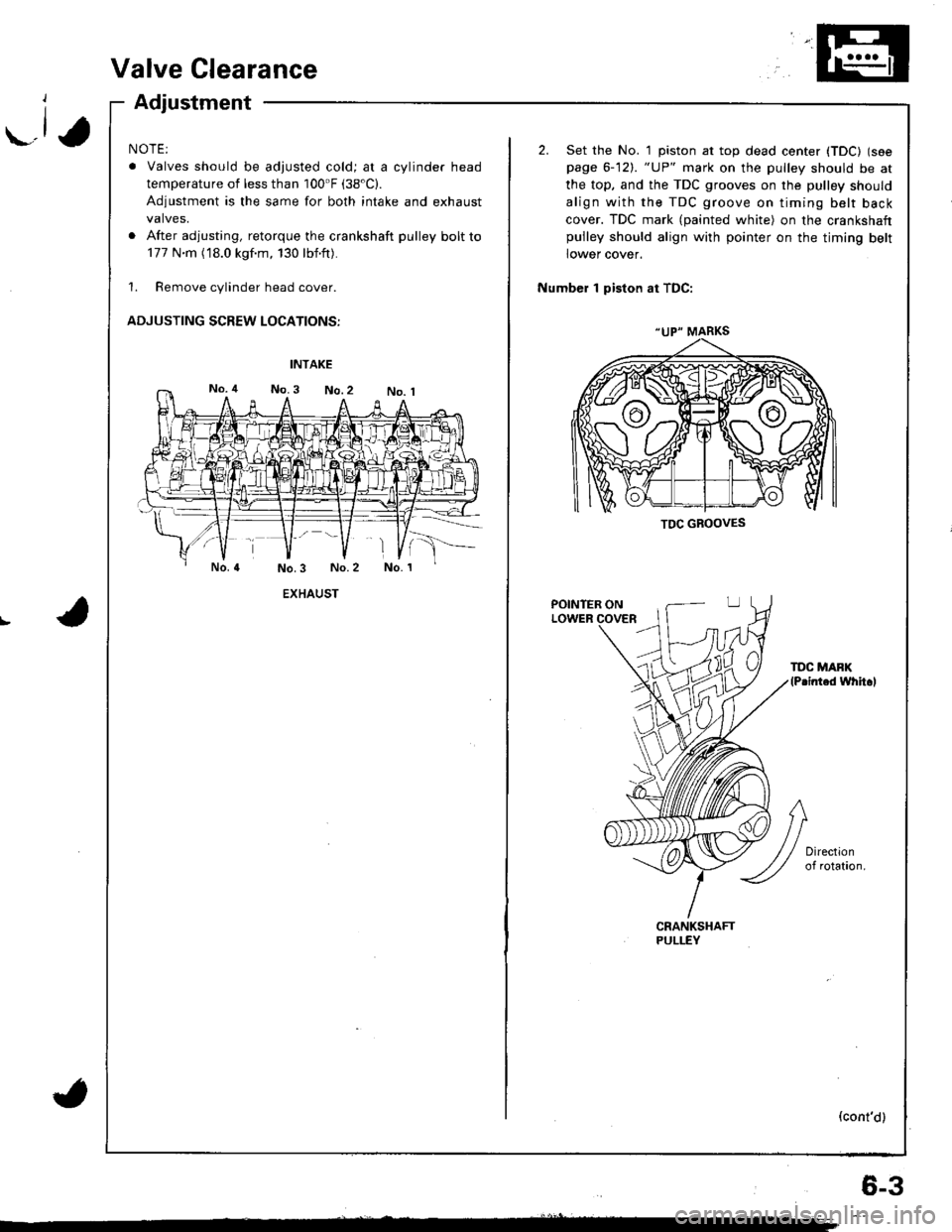

1. Remove cylinder head cover.

ADJUSTING SCREW LOCATIONS:

EXHAUST

(

"UP" MARKS

TDC GBOOVES

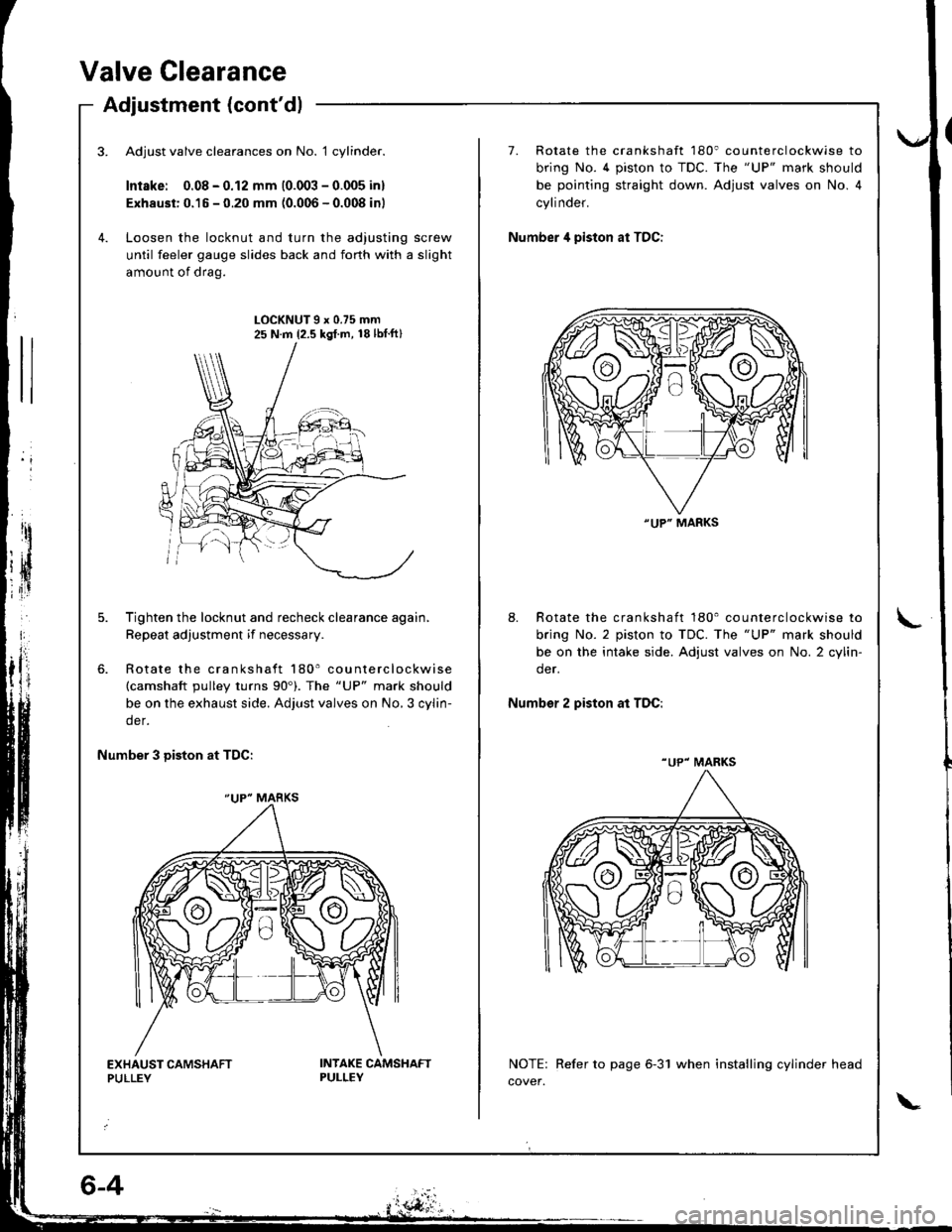

2. Set the No. 1 piston at top dead center (TDC) (see

page 6-12). "UP" mark on the pulley should be at

the top, and the TDC grooves on the pulley should

align with the TDC groove on timing belt back

cover. TDC mark (painted white) on the crankshaftpulley should align with pointer on the timing belt

lower cover.

Number 1 piston at TDC:

POINTER ONLOWER

TDC MAFK(P.inted whh.l

(cont'd)

6-3

Page 66 of 1681

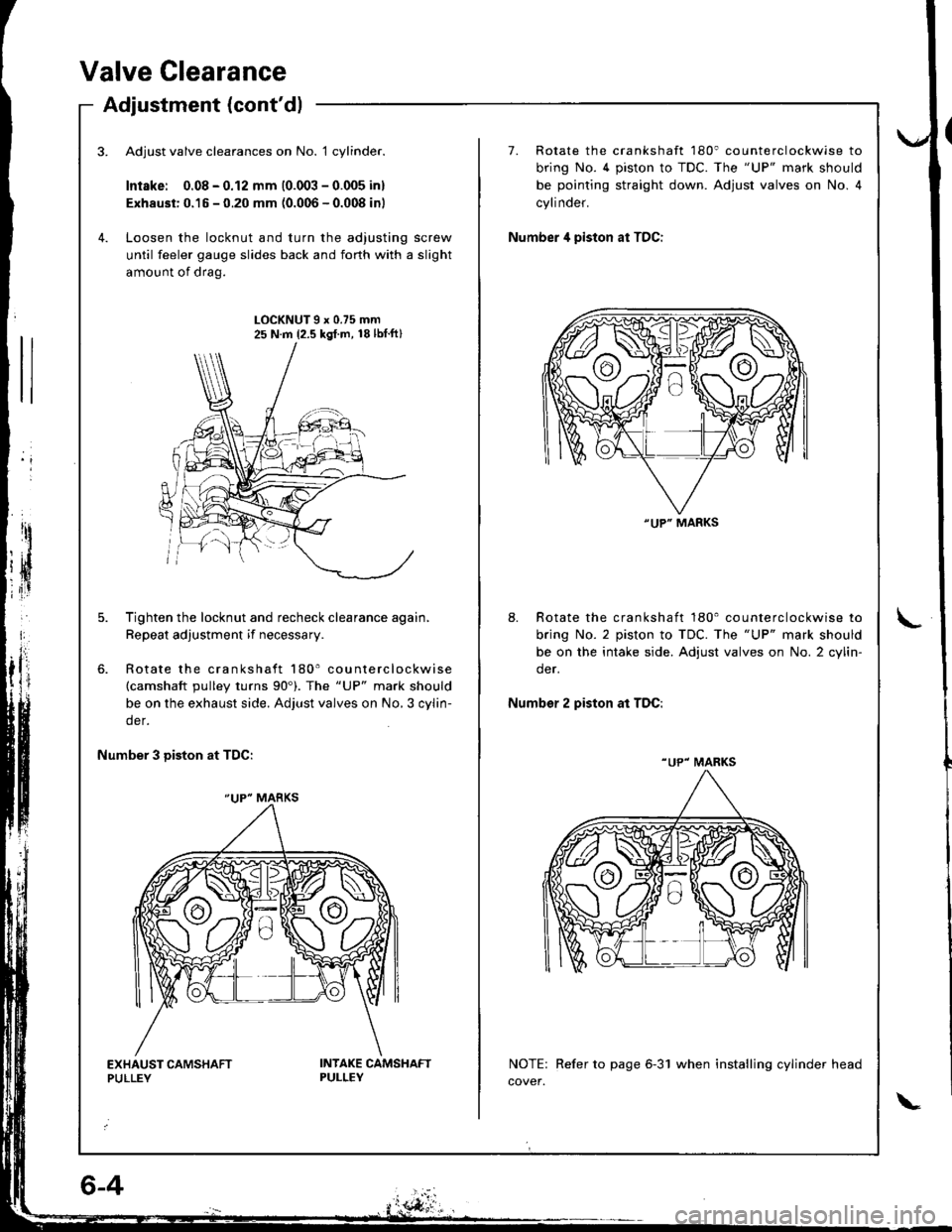

Valve Clearance

Adjustment (cont'dl

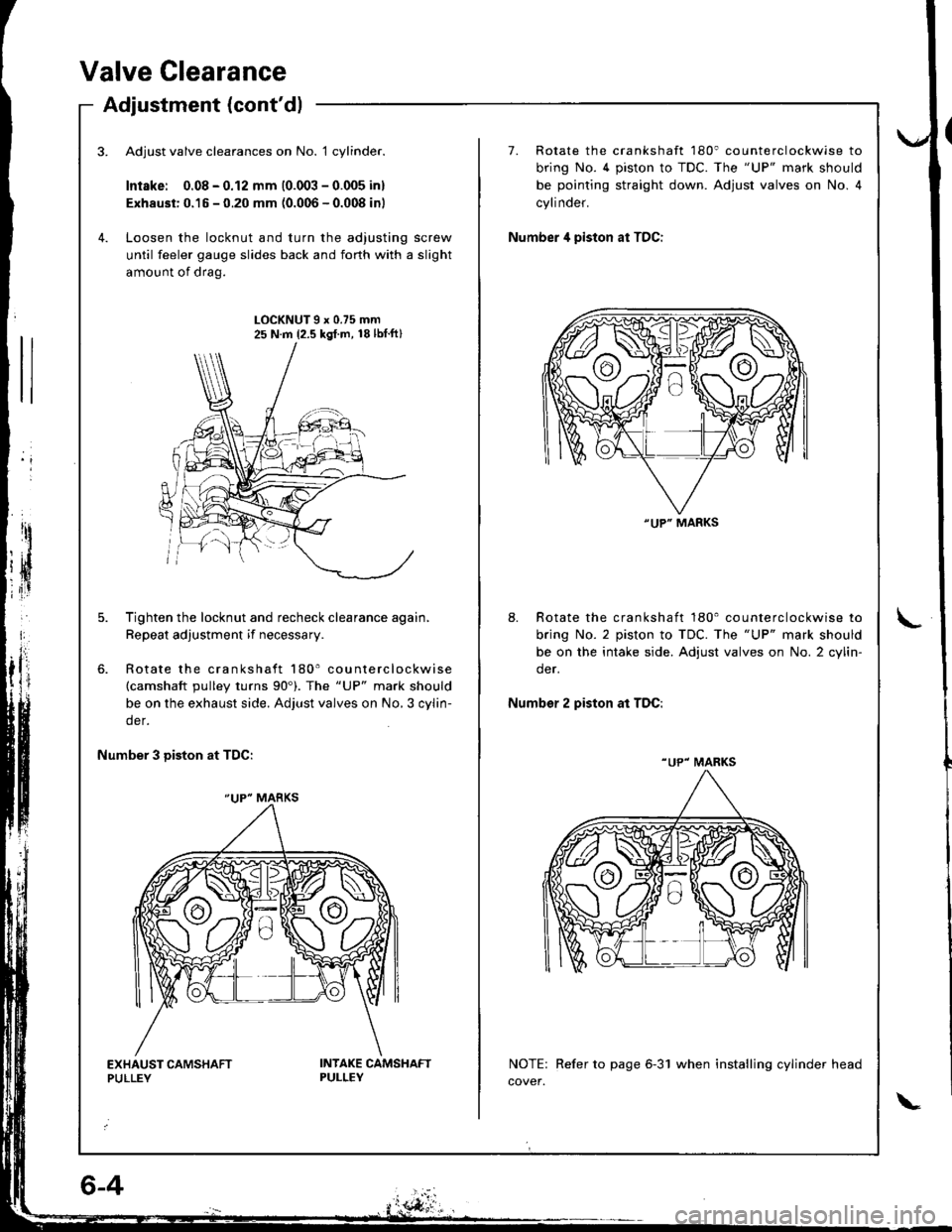

Adjust valve clearances on No. 1 cylinder.

Intske: 0.08 - 0.12 mm (0.003 - 0.005 inl

Exhaust: 0.15 - 0.20 mm (0.006 - 0.008 inl

Loosen the locknut and turn the adjusting screw

until feeler gauge slides back and forth with a slight

amount of drag.

7. Rotate the crankshaft 180' counterclockwise to

bring No. 4 piston to TDC. The "UP" mark should

be pointing straight down. Adjust valves on No. 4

cylinder.

Number 4 piston at TDC:

LOCKNUT9x0.75mm25 N.m {2.5 kgl.m, 18lbtft}

Tighten the locknut and recheck clearance again,

Repeat adjustment if necessary.

Rotate the crankshaft 180' counterclockwise(camshaft pulley turns 90'). The "UP" mark should

be on the exhaust side. Adjust valves on No,3 cylin-

der.

8. Rotate the crankshaft 180' counterclockwise to

bring No. 2 piston to TDC. The "UP" mark should

be on the intake side. Adjust valves on No. 2 cylin-

der.

Number 2 piston at TDC:

Number 3 Diston at TDC:

NOTE: Refer to page 6-31 when installing cylinder head

cover.

"UP" MARKS

"UP" MARKS

"UP" MARKS

Page 67 of 1681

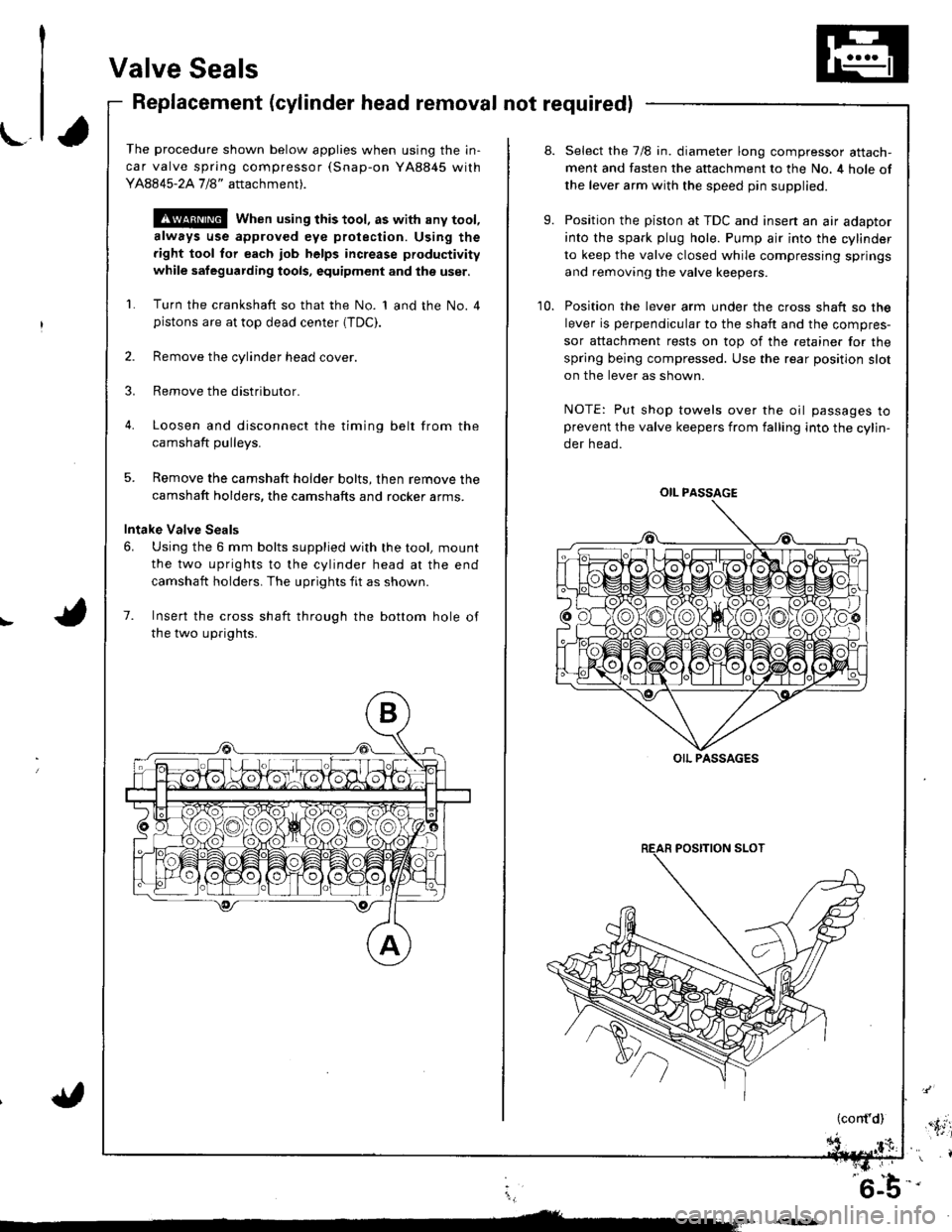

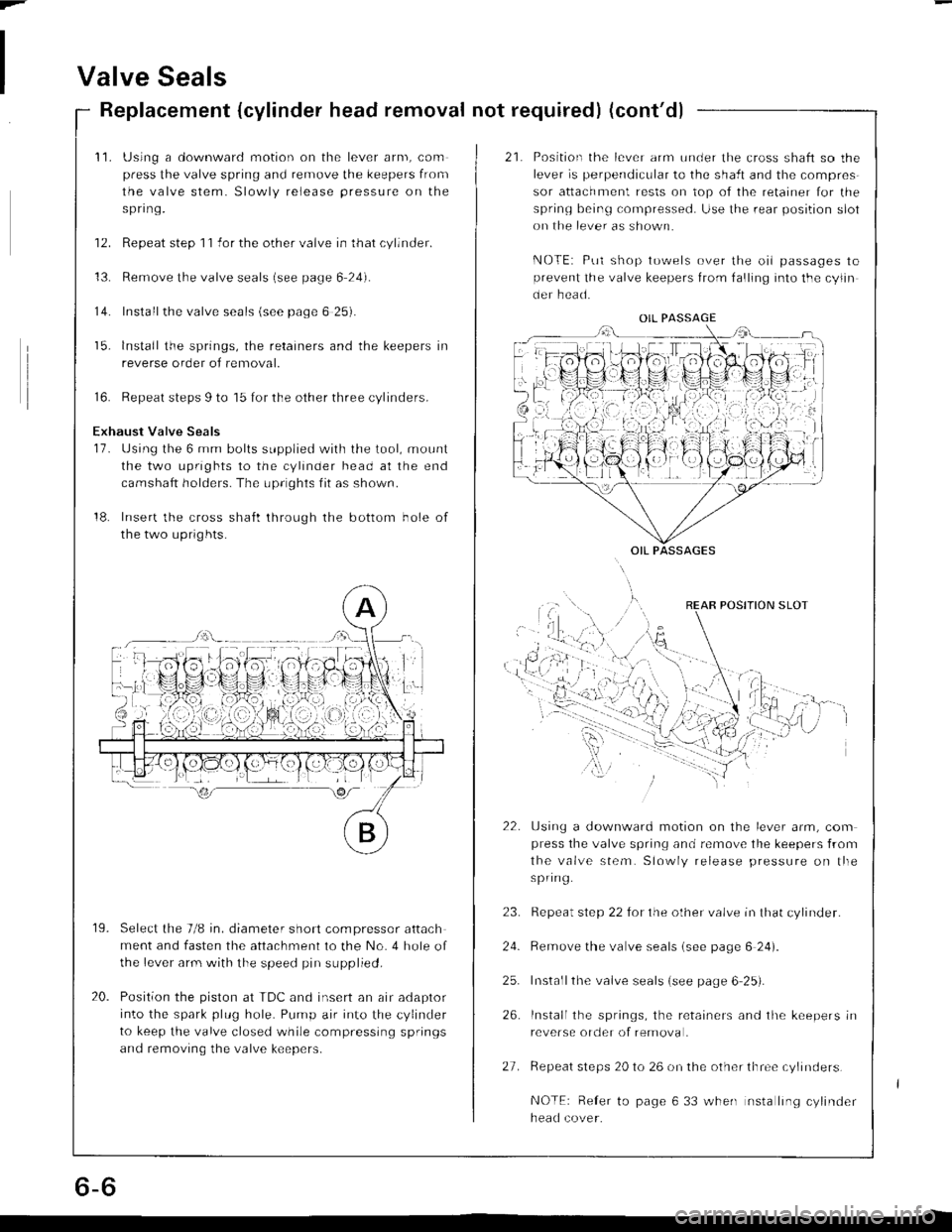

Valve Seals

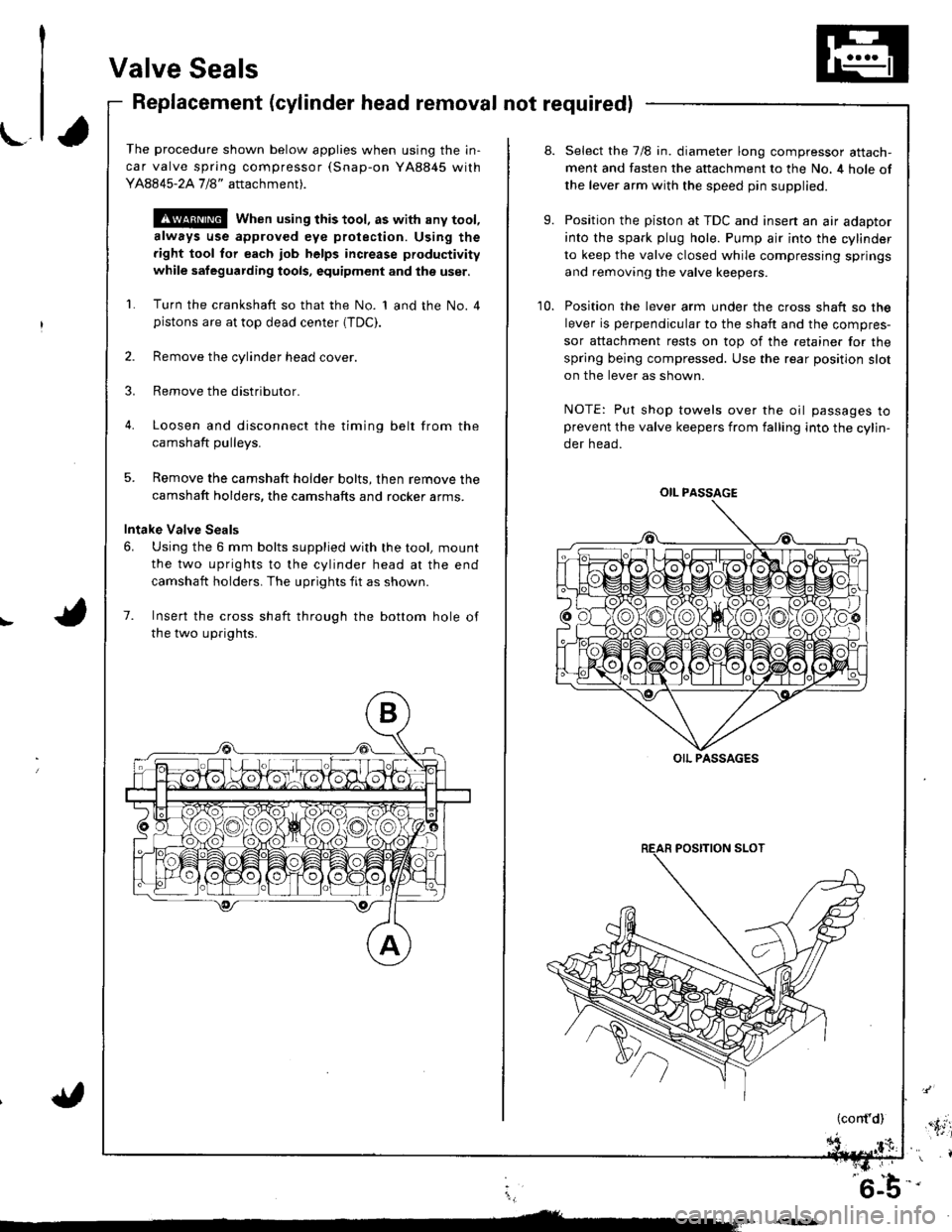

Replacement (cylinder head removal not required)

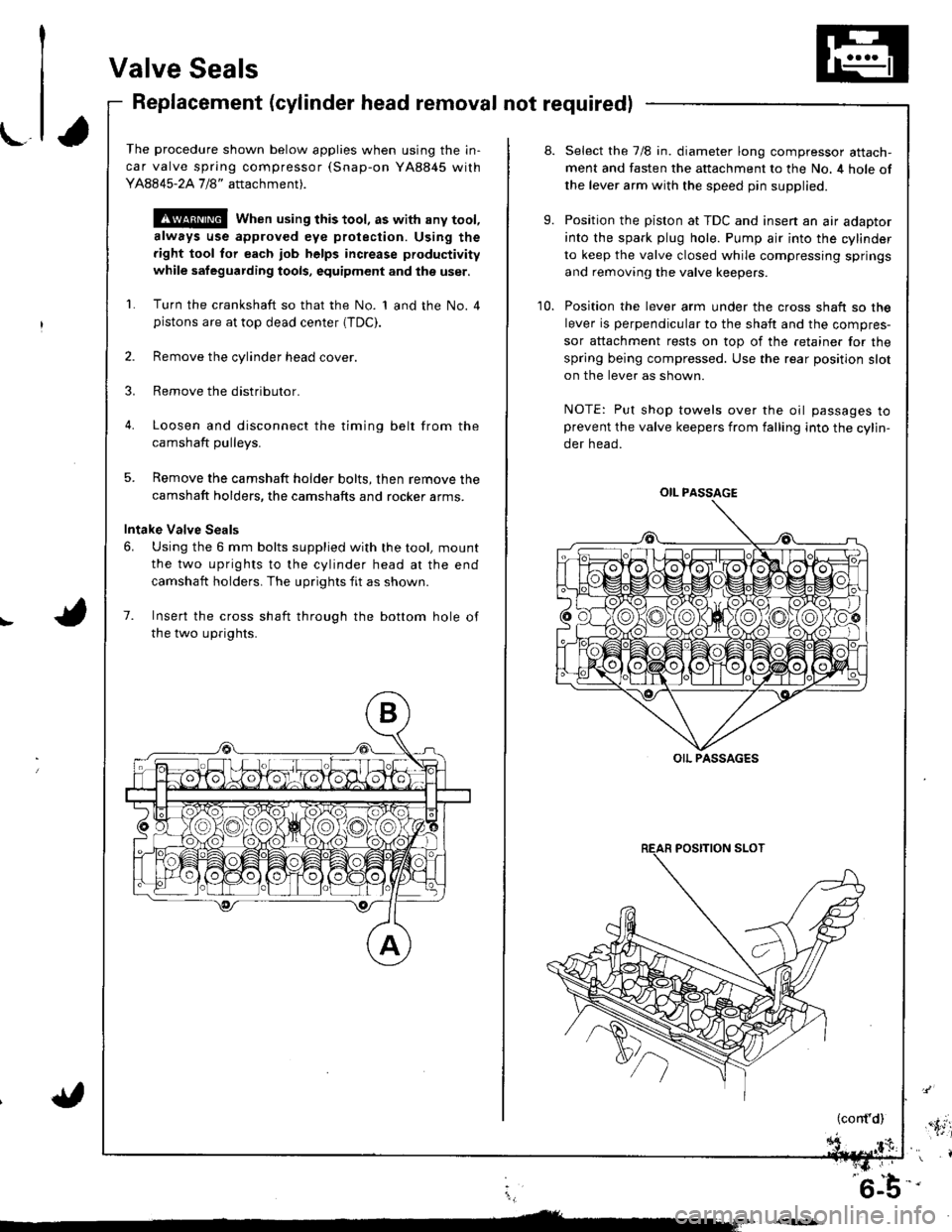

The procedure shown below applies when using the in-

car valve spring compressor (Snap-on YA8845 with

Y AAA45-2A 1 /8" attachment).

!@@ When using this tool, as with any tool,

always use approved eye protection. Using the

fight tool tor each job helps increase productivity

while safeguarding tools, equipment and ihe user.

Turn the crankshaft so that the No. 1 and the No. 4pistons are at top dead center (TDC).

Remove the cylinder head cover.

Remove the distributor.

Loosen and disconnect the timinq belt from the

camshaft oullevs.

5. Remove the camshaft holder bolts, then remove the

camshaft holders, the camshafts and rocker arms.

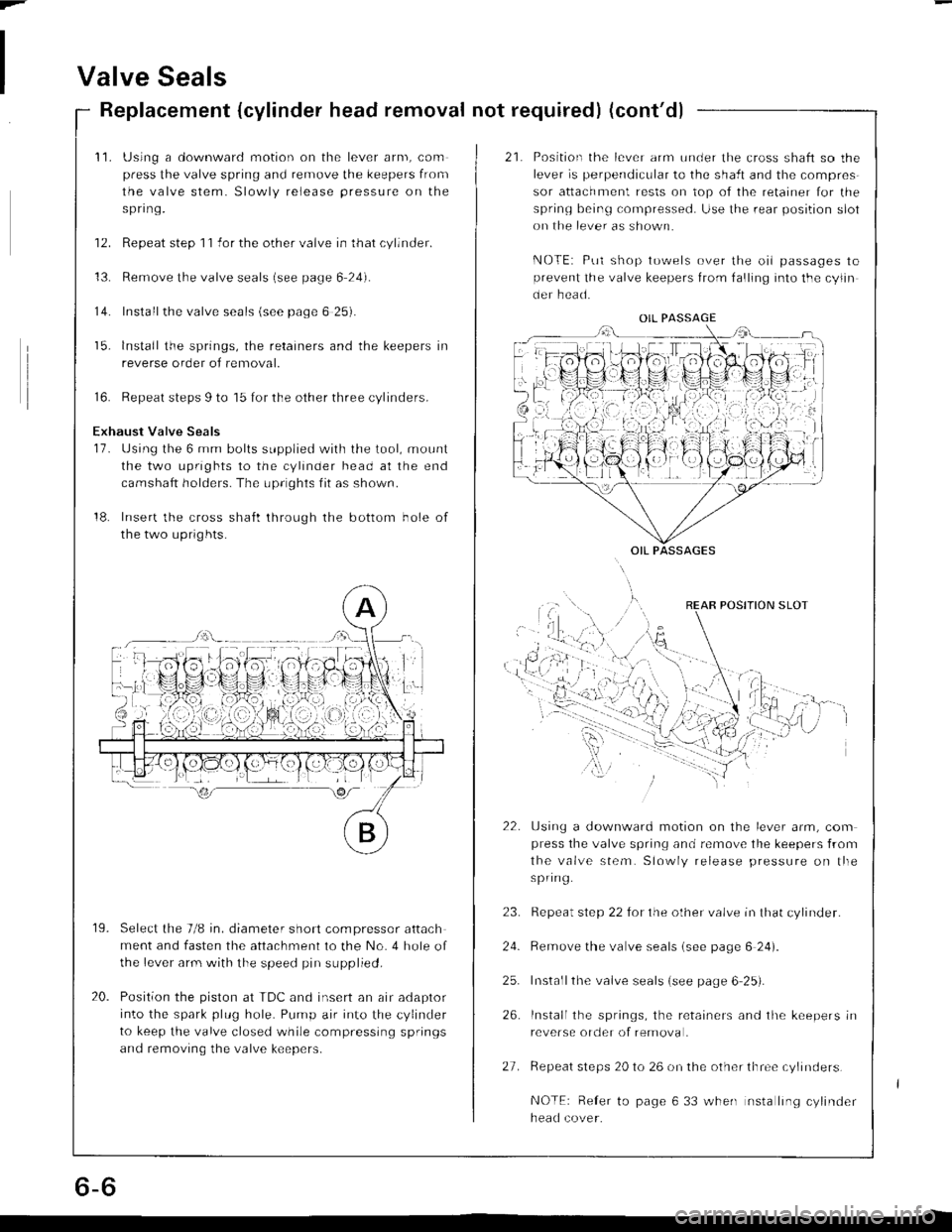

Intake Valve Seals

6. Using the 6 mm bolts supplied with the tool, mount

the two uprights to the cylinder head at the end

camshaft holders. The uprights fit as shown.

7. Insert the cross shaft through the bottom hole of

the two uprights.

8.

9.

10.

Select the 7/8 in. diameter long compressor attach-

ment and fasten the attachment to the No. 4 hole of

the lever arm with the speed pin supplied.

Position the piston at TDC and insen an air adaptor

into the spark plug hole. Pump air into the cylinder

to keep the valve closed while compressing springs

and removing the valve keepers.

Position the lever arm under the cross shaft so the

lever is perpendicular to the shaft and the compres-

sor attachment rests on top of the retainer for the

spring being compressed. Use the rear position slot

on the lever as shown.

NOTE: Put shop towels over the oil passages toprevent the valve keepers from falling into the cylin-

der head.

OIL PASSAGE

OIL PASSAGES

(cont'd),'.itil

i,

'6-b-'

Page 68 of 1681

Page 69 of 1681

-1,

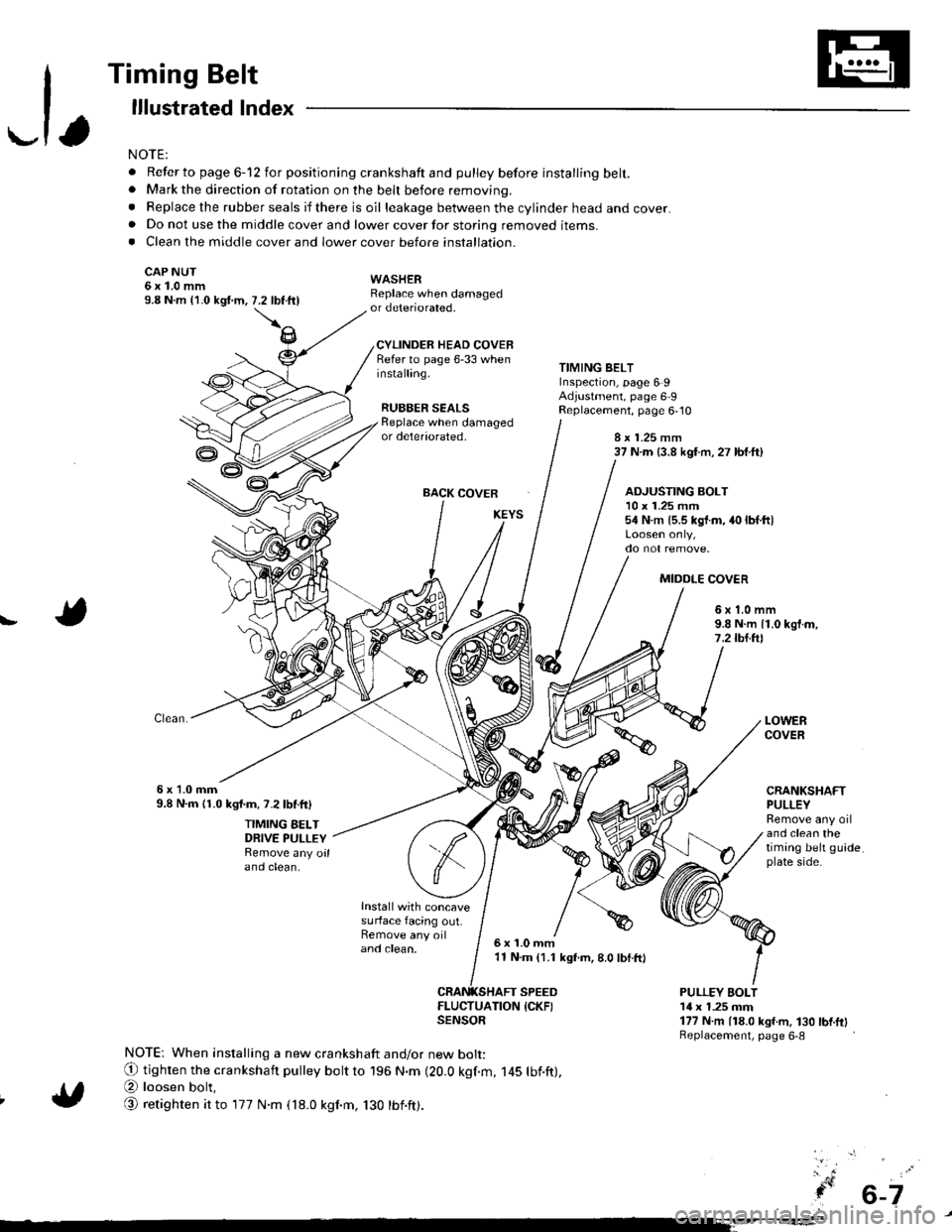

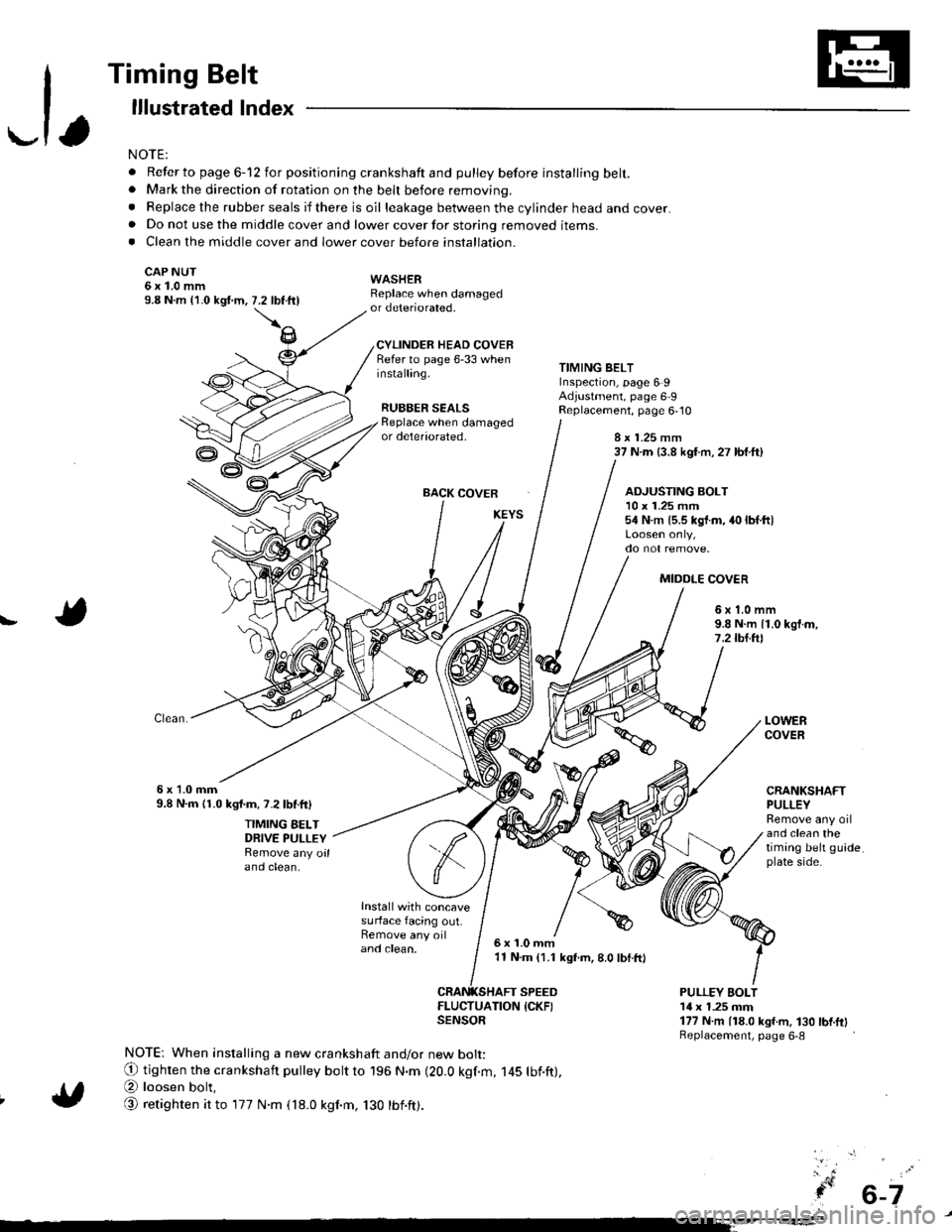

Timing Belt

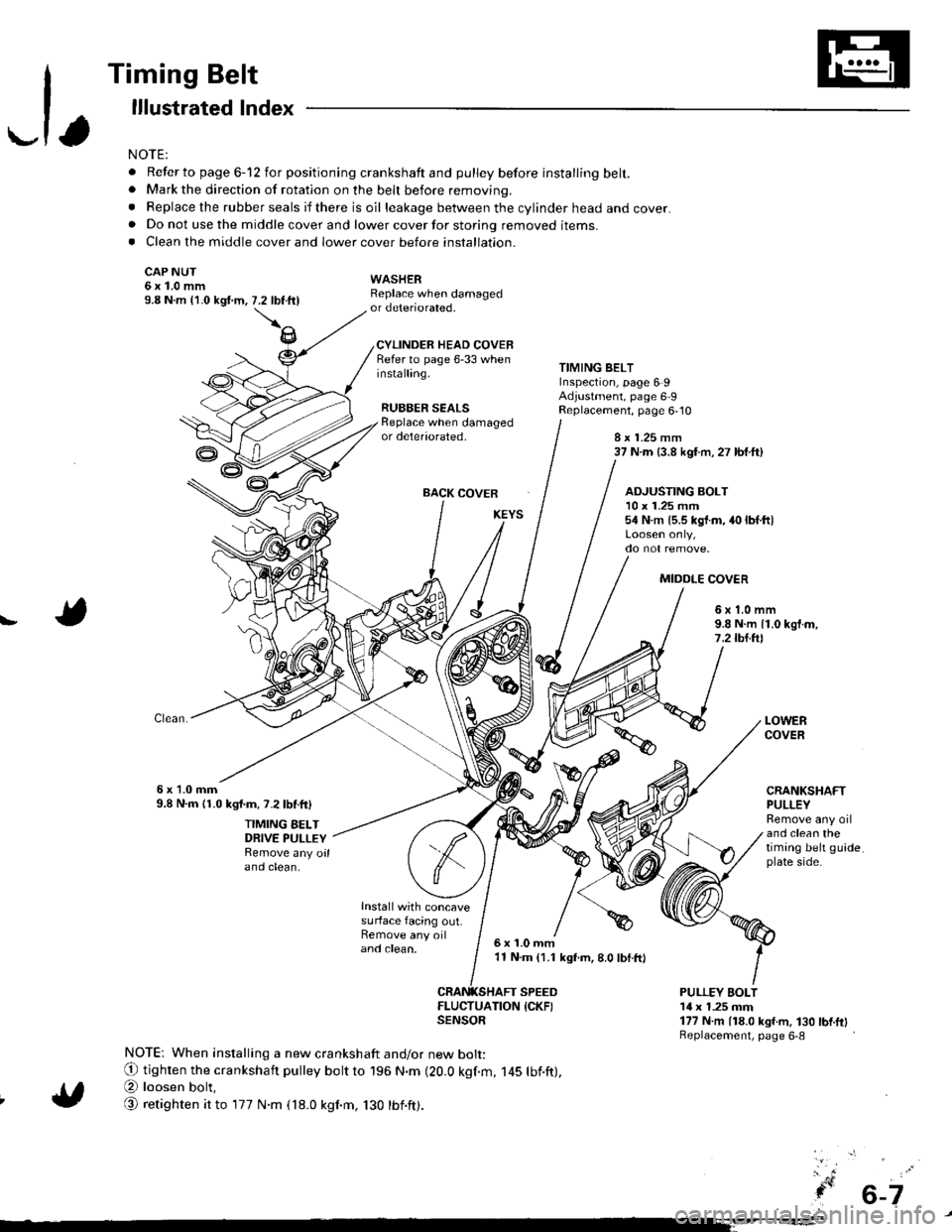

lllustrated lndex

NOTE:

. Refer to page 6-12 for positioning crankshaft and pulley before installing belt.. Mark the direction of rotation on the beh before removing.

. Replace the rubber seals if there is oil leakage between the cylinder head and cover.. Do not use the middle cover and lower cover for storing removed items.. Clean the middle cover and lower cover before installation.

CAP NUT6x1.0mm9.8 N.m {'1.0 kgi.m,

WASHERReplace when damagedor deteriorated.

CYLINDER HEAD COVERRefer to page 6-33 wheninstalling.

RUBBER SEALS

7.2 tbftll

TIMING BELTInspection, page 6 9Adjustment, page 6 9Replacement, page 6,10Beplace when damagedor deteriorated,8 x 1.25 mm37 N.m (3.8 kgf.m, 27 lbf.ft)

BACK COVER

Install with concavesurface facing out.Remove any oiland clean,

ADJUSTING BOLT10 x 1.25 mm54 N.m {5.5 kgt.m, 40 lbf.ltl

MIDDLE COV€R

!6x1.0mm9.8 N.m {1.0 kgf.m,7.2lbl.ftl

6x 1.0mm9.8 N.m 11.0 kgl.m, 7.2lbf.ftl

TIMING BELTDRIVE PULLEYRemove any oilano ctean.

LOWERCOVER

CRANKSHAFTPULLEYRemove any oiland clean thetiming belt guideplate side.

6x1.0mm'11 N.m (1.1 kgf.m, 8.0 lbI.ft)

SPEED

ItEi:lufrroN {cKF)

NOTE: When installing a new crankshaft and/or new bolt:

O tighten the crankshaft pulley bott to 196 N.m (20.0 kgf.m, 145 tbf.ft),

@ loosen bolt,

@ retighten it to 177 N.m (18.0 kgnm, 130 tbnft).

PULLEY EOLT14 x 1.25 mm177 N.m (18.0 kgf.m, 130 bnftlReplacement, page 6-8

6-7

Page 70 of 1681

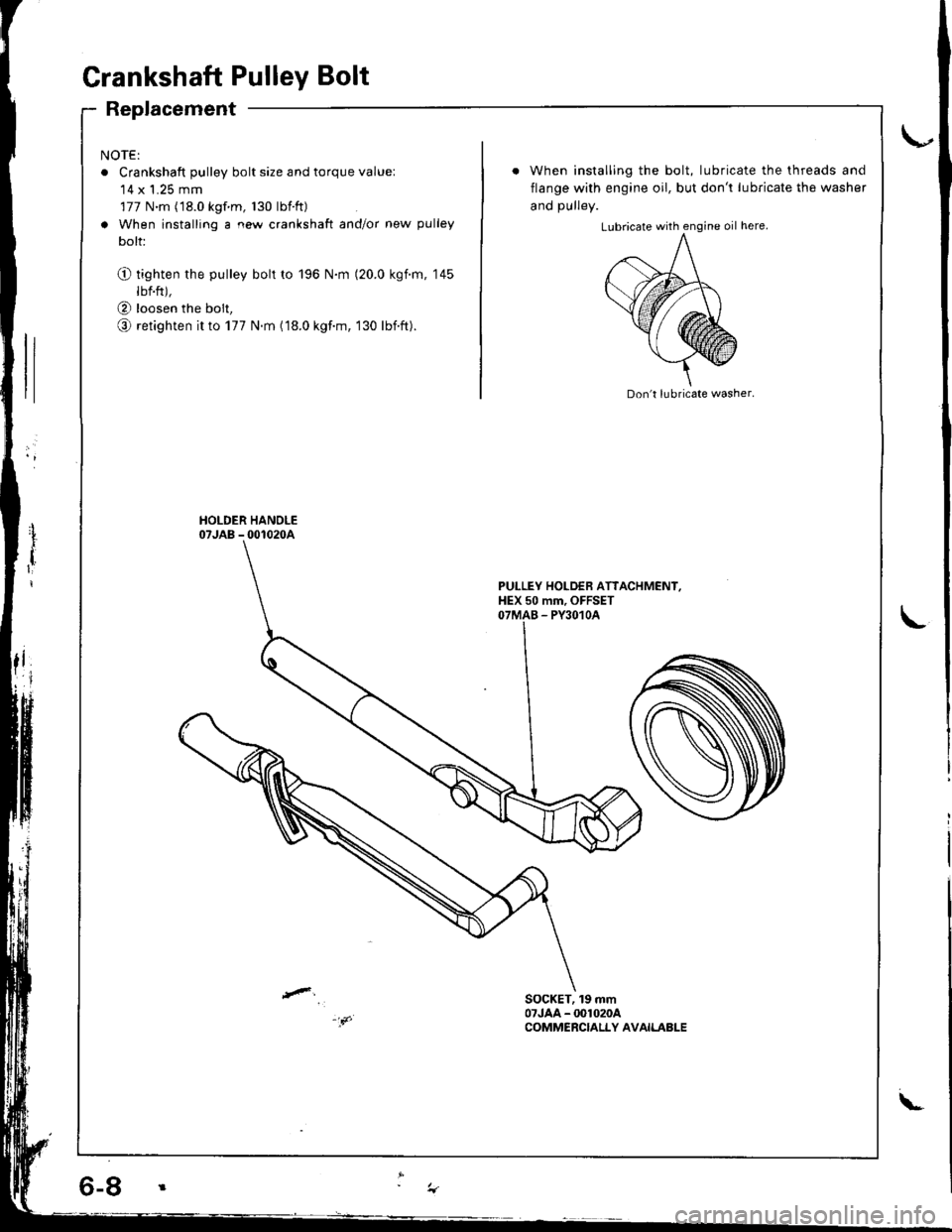

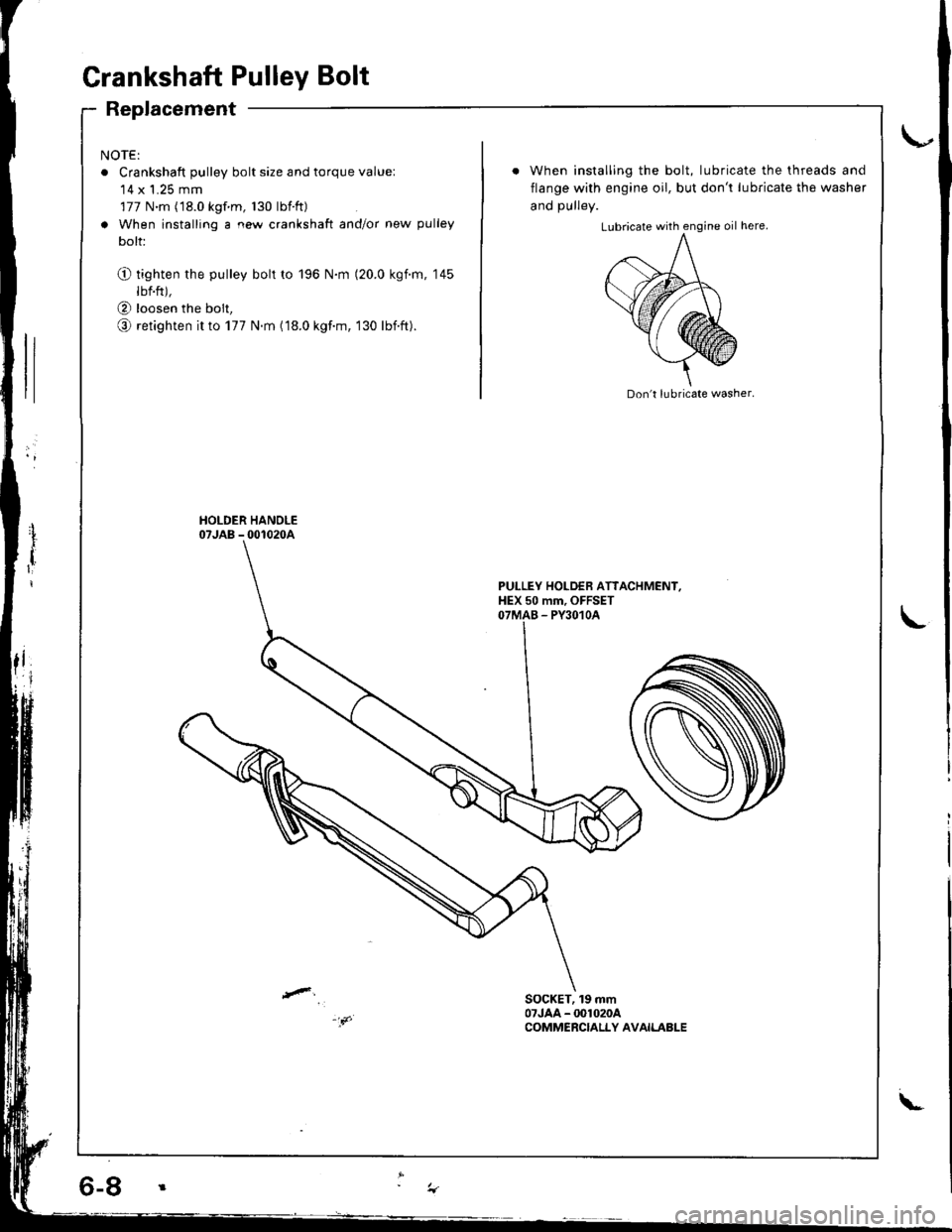

Grankshaft Pulley Bolt

Replacement

NOTE:

o Crankshaft pulley bolt size and torque value:'14 x 1.25 mm

177 N.m (18.0 kgf m, 130 lbtft)

a When installing a new crankshaft and/or new pulley

bolt:

O tighten the pulley bolt to 196 N.m (20.0 kgim, 145

lbf.ft),

@ loosen the bolt,

o retighten it to 177 N.m (18.0 kgf.m, 130 lbift).

When installing the bolt, lubricate the threads and

flange with engine oil, but don't lubricate the washer

and DUllev.

Don't lubricate washer.

PULLEY HOLDEB ATTACHMENI,HEX 50 mm, OFFSETOTMAB - PY3O1OA

SOCKET, 19 mm07JAA - @1020ACOMMERCIALLY AVAILABLE

\-

Trending: warranty, lock, check transmission fluid, hood open, C506, warning, fuse box diagram