HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 661 of 1681

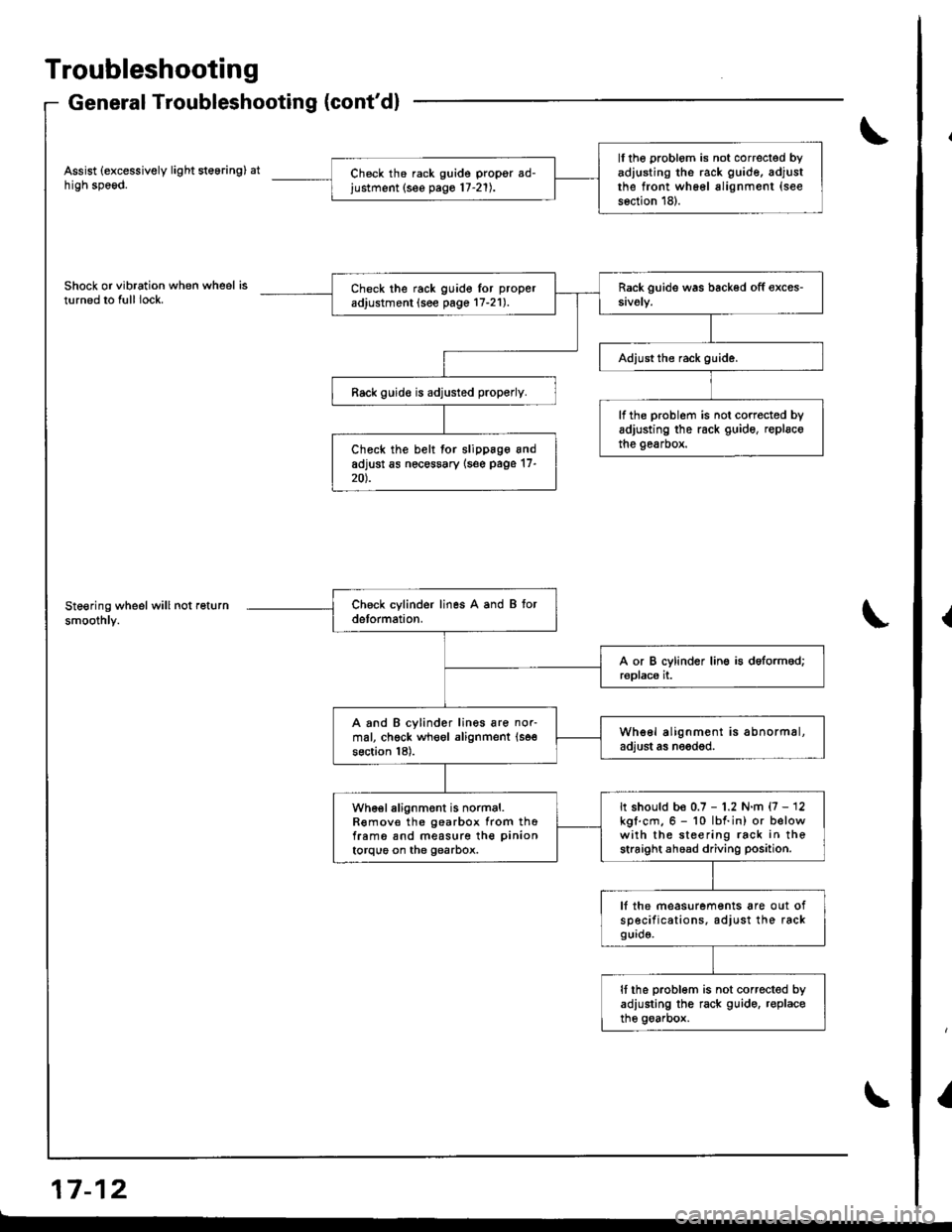

Troubleshooting

General Troubleshooting (cont'dl

Assist (excessively light steering) athigh speod.

Shock or vibration when wheel isturned to full lock.

Steering wheel will not return

smoothly.

a-, aa GrI r- tz

ll the problom is not correcled byadiusting the rack guide, adjustthe front wh66l alignment (see

s6ction 18).

Ch6ck th6 rack guide propgr ad-justment (see pago 17-21).

Check the rack guido lor proper

adjustment (see page 17-21).

Rack guid€ is adjusted properly.

lf the problem is not corrected byadjusting the rack guide, replscothe gearbox.Check the belt for slippage andadjust as nec€ssary {s6e page 17-20).

A and B cylinder lines are nor-mal, chgck wheol alignment (se€

section 18).

Whe6l alignment is abnormal,adjust as needod.

It should be 0.7 - 1.2 N.m {7 - 12kgl.cm.6 - 10 lbf.in) or belowwith the steering rack in thestraight ahoad driving position.

wh€el alignment is normal.R€mov€ the gearbox from thofram6 snd measure the pinion

torque on the gearbox.

lf the measurements are out ofsp€cifications. adjust the rackgurd9.

It the problom is not corrected byadiusting the rack guido. r€placethe goarbox.

{

I

Page 662 of 1681

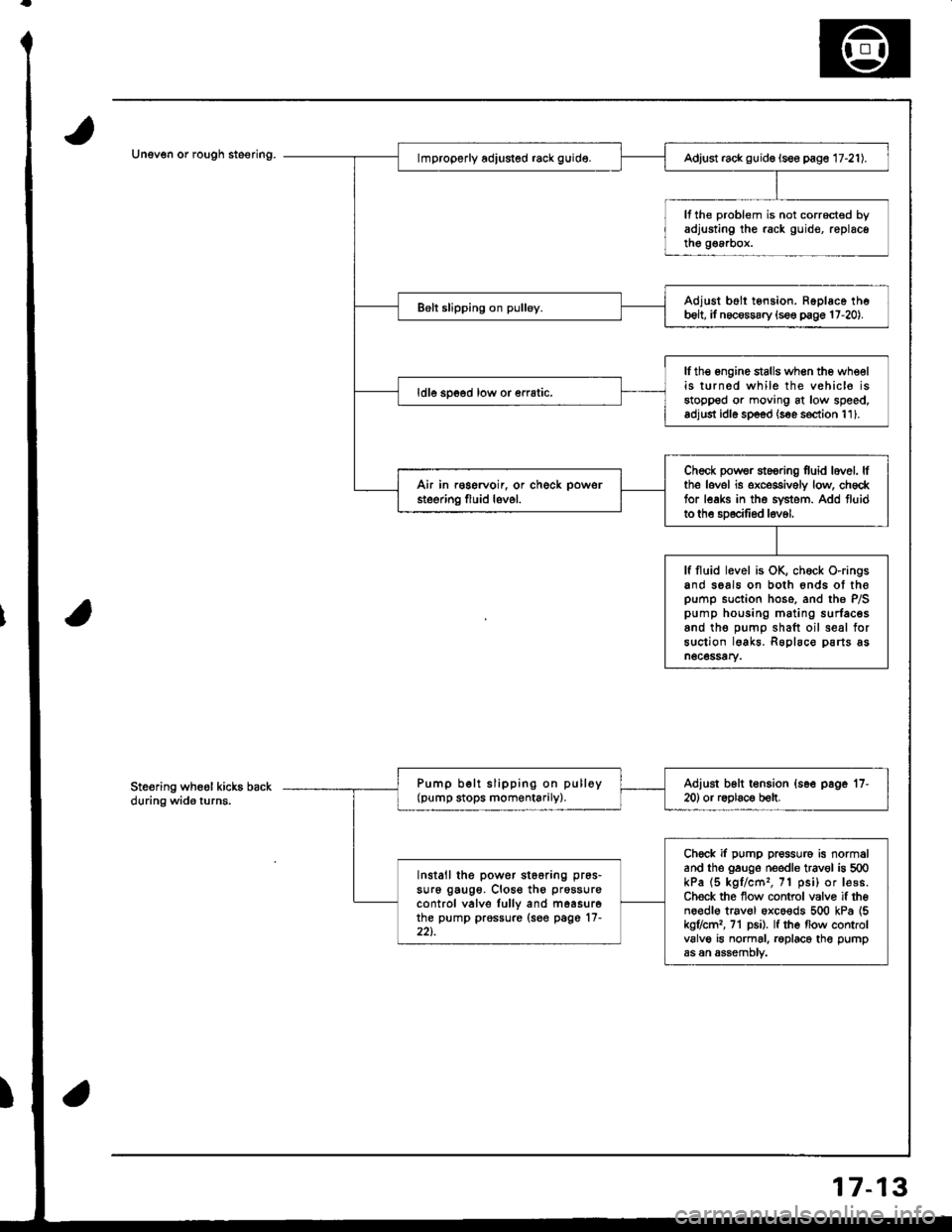

Unev€n or rough steering.Adjust rack guid€ (see page 17-21).

It the problem is not corrocted byadjusting the rack guid€, replacethe g€a.box.

Adjust b6ll tension. Ropl6ce theb6lt, it necossary {s€e p€ge 17-20).

lfth€ engine stalls when the wheelis turned while the vehic16 isstopped or moving at low speed.adjust idl6 sp6od (s€e s€ction 111.

ldle spoed low or €rratic.

Check powsr st6oring fuid lovel. lfthe lovel is exceggively low, ch6cktor leaks in the svstem. Add fluidto the sD6cilied l6v6l,

Air in r€gervoir, or check powsr

steering fluid lovel.

lf fluid level is OK, chock O-ringsand seals on both 6nds ot thepump suction hose. and the P/Spump housing mating surfacesand tho oumo shaft oil seal forsuction lgakr. Roplaco parts asn6c6ssary.

Pump b€lt slipping on pulloy(pump stops momentarily).Adiust b6lt t€nsion {s6e page '17-

20) or r6olac€ b€lt.

Chock if pump pressure is normaland the gauge needle trav€l is 500kPa (5 kgl/cm'�, 71 psi) or lesB.Ch€ck the flow control valvo if theno€dl€ trav€l oxco€ds 500 kPa {5kg7cml, 71 p6i). lf the flow controlvalve is normal. roplace the pumpas an assemDtv.

Install the power st66ring pr6s-

su16 gaug6. Close th6 prossure

control valve lully and m6asurethe pump prossure (see page'17-22t.

Ste€ring wheol kicks backduring wide turns.

7-13

Page 663 of 1681

I

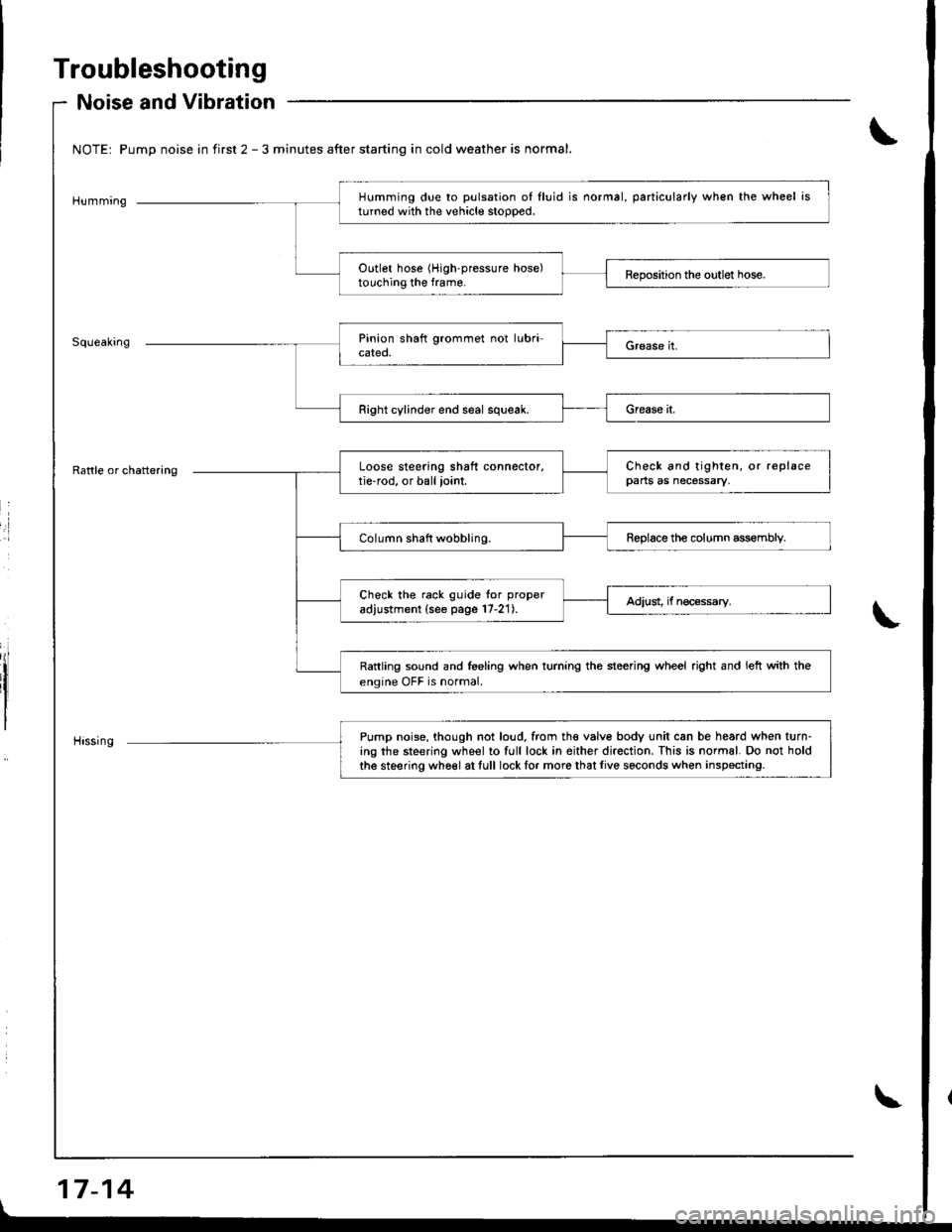

Troubleshooting

17-14

Noise and Vibration

NOTEr Pump noise in first 2 - 3 minutes after starting in cold weather is normal.

Humming

Rattle or chattering

Humming due to pulsation oI lluid is normal, particularly when the wheel isturned with the vehicle stoooed.

Outlet hose (High-pressure hose)touching the frame.

Right cylinder end seal squeak.

Pump noise, though not loud, from tho valv6 body unit can be heard when turn-ing the steering wheel to full lock in either direction. This is normal. Do not hold

the steering wh6el at tull lock tor more that live seconds wh€n inspecting.

Loose steering shaft connector,tie-rod, or ball ioint.

Check and tighten, or replacepans as necessary,

Column shaft wobbling.Reolace the column assemblv.

Check ihe rack guide tor proper

adjustment (see page 17-21).Adiust, if nec€ssary.

Rattling sound and feeling when turning the steering wheel right and left with the

engine OFF is normal.

Page 664 of 1681

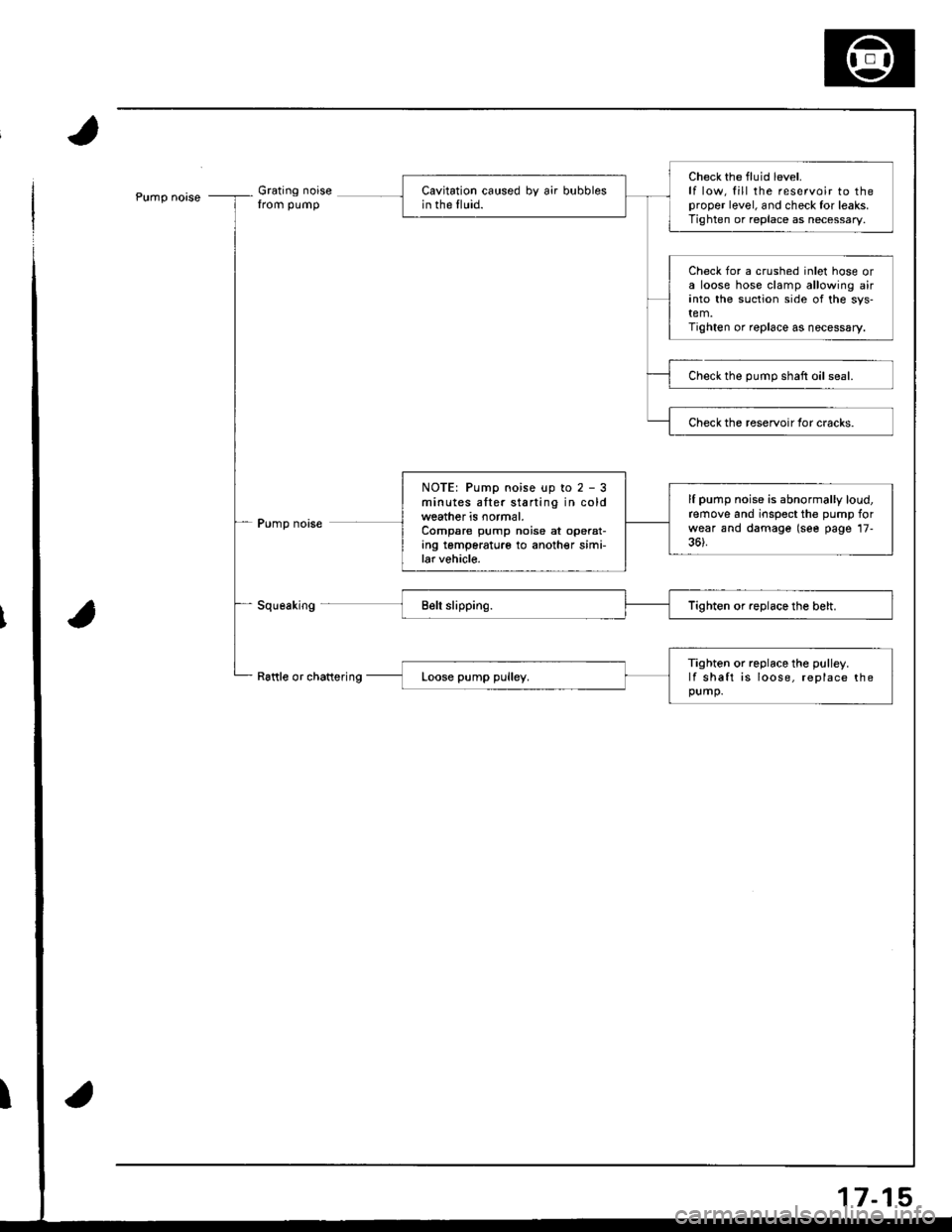

Pump noiseGrating noisefrom pump

Pump noise

I

aou""*,nn

Rattle or chattering

Check the flu id level.lf low, fill the reservoir to theproper level, and check for leaks.Tighten or replace as necessary.

Cavitation caused by air bubblesin the fluid.

Check for a crushed inlet hose ora loose hose clamp allowing airinto the suction side of the sys-tem.Tighten or replace as oecessary.

Check the oumo shaft oil seal.

Check the reservoir for cracks.

NOTE: Pump noise up to 2 - 3minutes alter starting in coldweather is normal.Compare pump noise at operat-ing tomperature to another simi-lar vehicle.

lf pump noise is abnormally loud,remove and inspect the pump forwear and damage (see page 17-36).

Tighten or replace the pulley.lf shaft is loose, replace thepump.

17-15

Page 665 of 1681

Troubleshooting

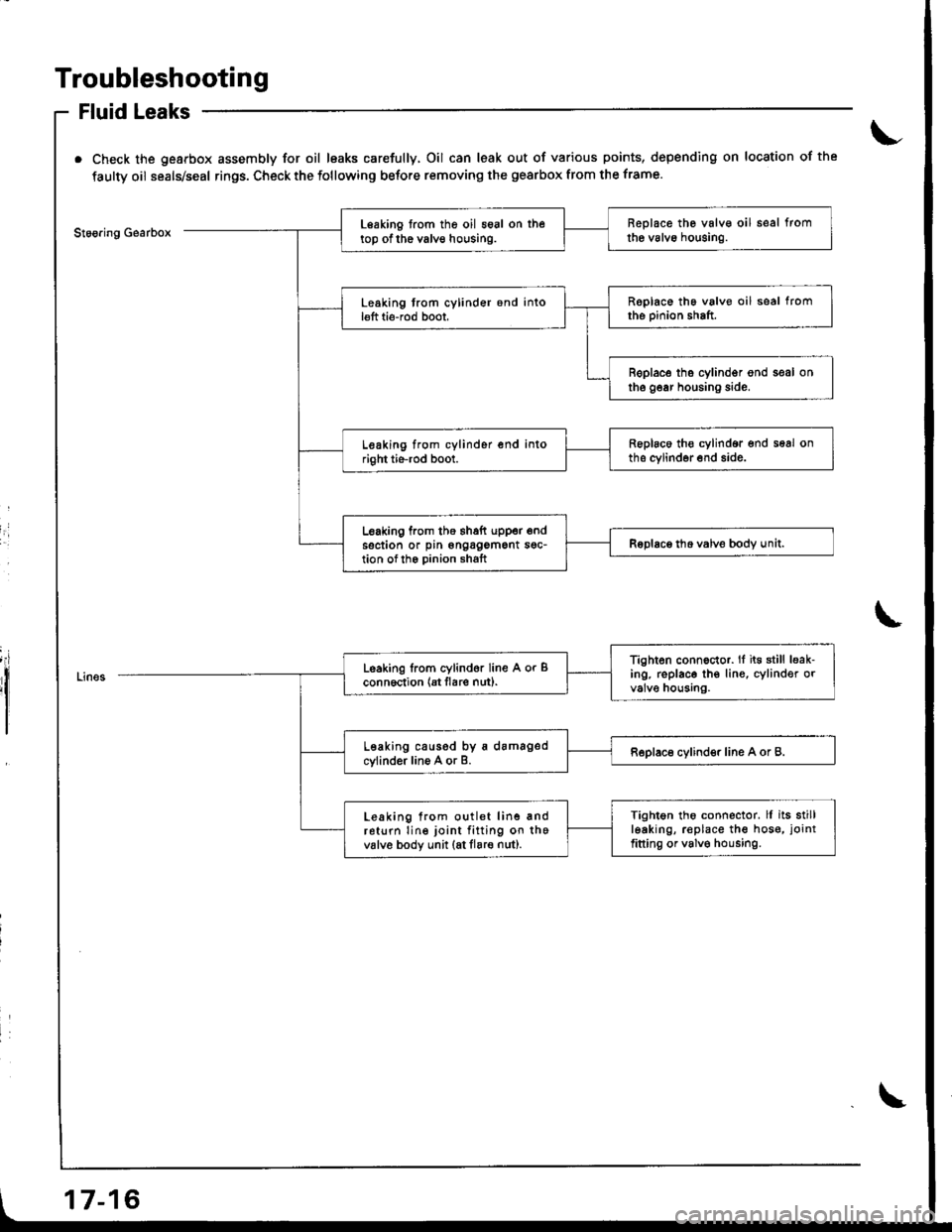

Fluid Leaks

Check the gearbox assembly for oil leaks carefully, Oil can leak out of various points, depending on location of the

faulty oil seals/seal rings. Check the following before removing the gearbox from the frame.

Stoo.ing GearboxReplace the valv€ oil seal fromthe valvo houging.Leaking from the oil seal on thetop of the valve housing.

Roplace the valve oil seal fromthe pinion shaft.Leaking trom cylinder 6nd intol€ft ti6-rod boot,

B€place tho cylindgr ond seal onthe gear housing side.

Replaco th€ cylindor end seal onths cylinder end side.Leaking from cylinder end intoright tie-rod boot.

Leaking from the thaft upper endsection or pin ongagement sgc-tion ofth6 Dinion shaftRoDlace tho valve bodv unit.I

I

Tighten connector. lf it€ still leak-ing. replace th€ lin€, cylinder orvalve housing.

Leaking lrom cylind6r line A or Bconn6ction {Et flare nut).

Leaking caused by a damagedcylinder line A or B.Replace cylinder line A or B.

Tightgn tho connector. ll its stillleaking, r€place the hos€, joint

fitting or valv€ housing.

Leaking from outlet line andreturn line joint fitting on thevalv6 body unit (at flare nut).

17-16

Page 666 of 1681

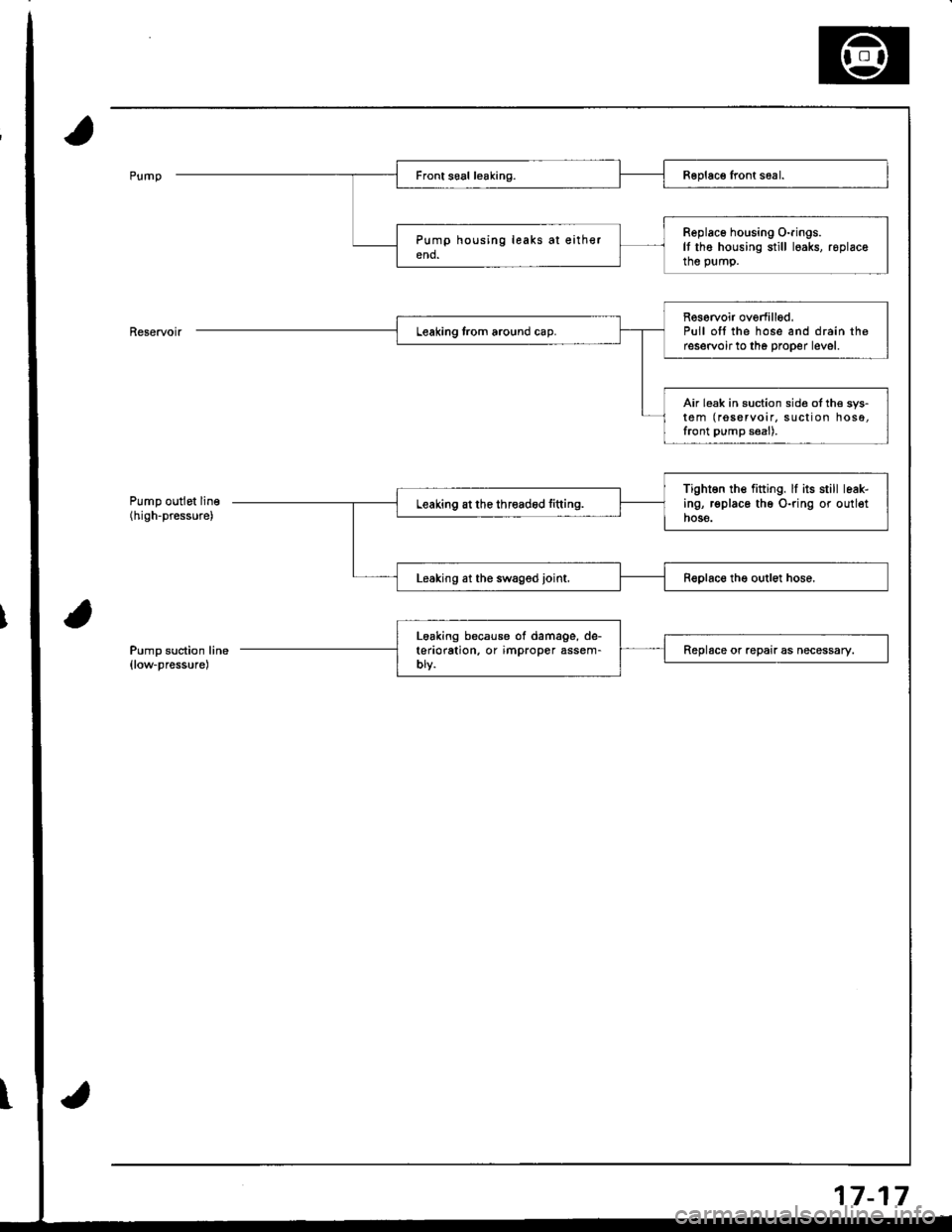

Replace housing O-rings.It the housing still loaks. roplacethe pump.

Reservoir overfill6d,Pull oft the hose and drain th€reservoir to the proper level.

Air l6ak in suction sid€ ot th€ sys-tem (rgservoir, suction hose,front pump s€al).

Tighton the fitting, lI its still leak-ing, replace the O-ring or outlethose.Leaking at the threaded fitting.

Leaking at the swaged,oint.

Loaking because of damage, de-terioration. or improper assem-Replace or repair as necessary.

Pump outlot line(high-pressure)

Pump suction line{low-pressure)

17-17

Page 667 of 1681

Inspection and Adjustment

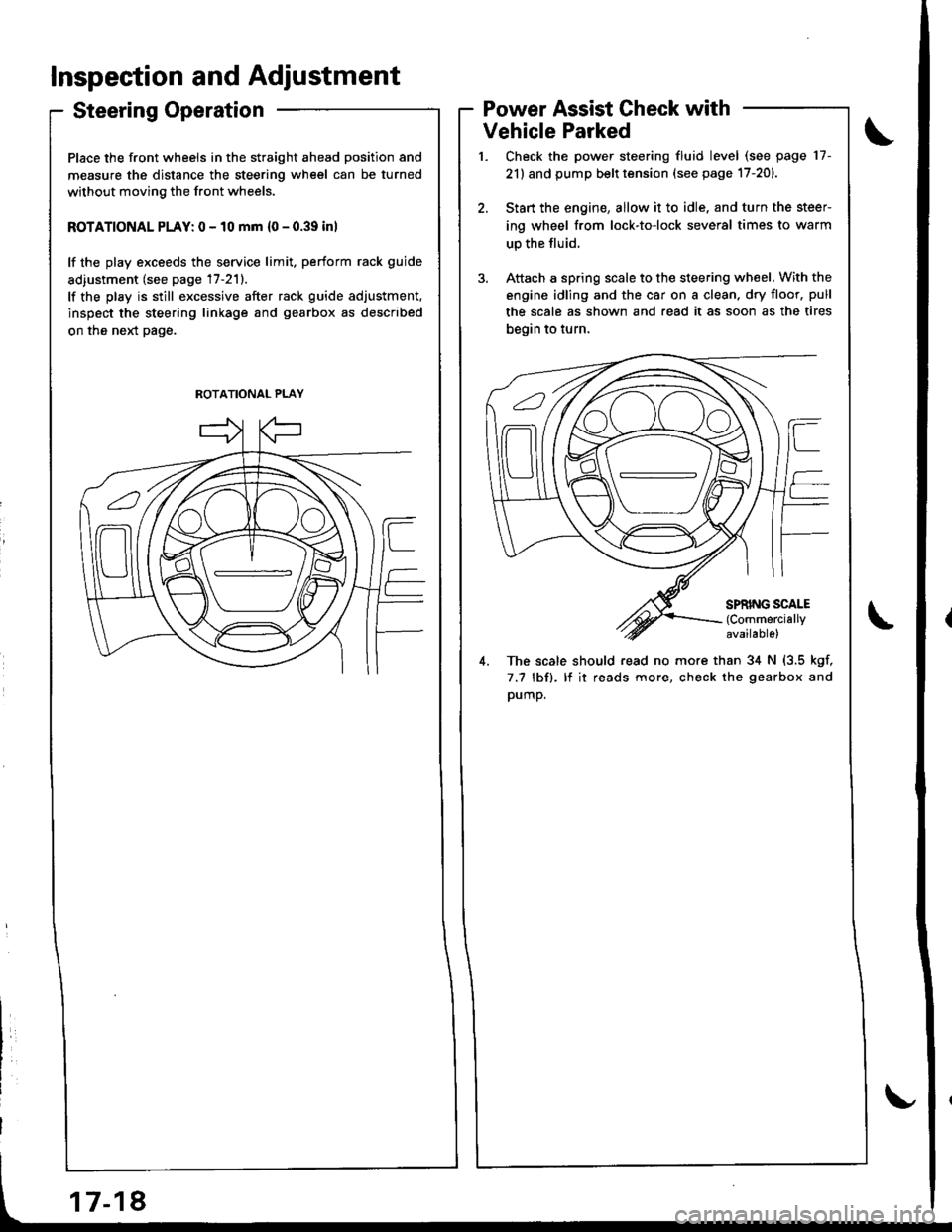

Steering Operation

Place the front wheels in the straight ahead position and

measure the distance the steering wheel can be turned

without moving the front wheels.

ROTATIONAL PLAY: 0 - 10 mm {0 - 0.39 inl

lf the play exceeds the service limit. perform rack guide

adiustment (see page 17-211.

lf the play is still excessive after rack guide adjustment.

inspect the steering linkage and gearbox as described

on the neld page.

Power Assist Check with

Vehicle Parked

Check the power steering fluid level (see page 17-

21) and pump belt tension (see page 17-201.

Start the engine, allow it to idle. and turn the steer

ing wheel from lock-to-lock several times to warm

up the fluid.

Attach a spring scale to the steering wheel. With the

engine idling and the car on a clean. dry floor. pull

the scale as shown and read it as soon as the tires

begin to turn,

4. The scale should read no more than 34 N (3.5 kgf,

7.7 lbf). lf it reads more, check the gearbox and

pump.

ROTATIONAL PLAY

Page 668 of 1681

I

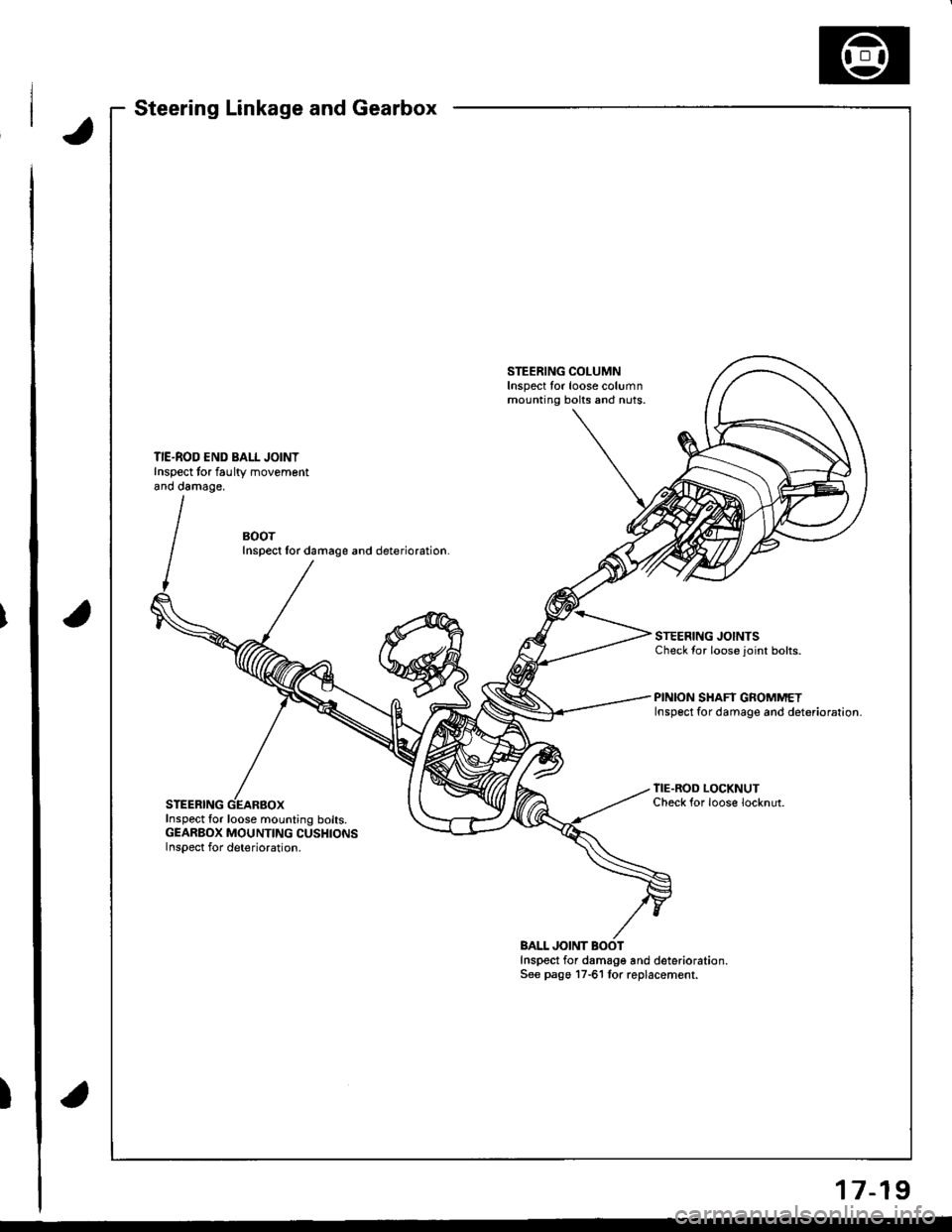

Steering Linkage and Gearbox

STEERING COLUMNInspect tor loose columnmounting bolts and nuts.

TIE.ROD END BALL JOINTInspect tor faultv movementano oamage,

BOOTInspect lor damage and deterioration.

STEERING JOINTSCheck {or loose joint bolts.

PINION SHAFT GROMMETInsp6ct for damage and deterioration.

STEERING

TIE.ROD LOCKNUTCheck {or loose locknut.

Inspect for loose mounting bolts.GEARBOX MOUNTING CUSHIONSInspect for deterioration.

BALL JOINTInspect for damage and deterioration.See pago 17-61 lor replacement.

17-19

Page 669 of 1681

Inspection and Adjustment

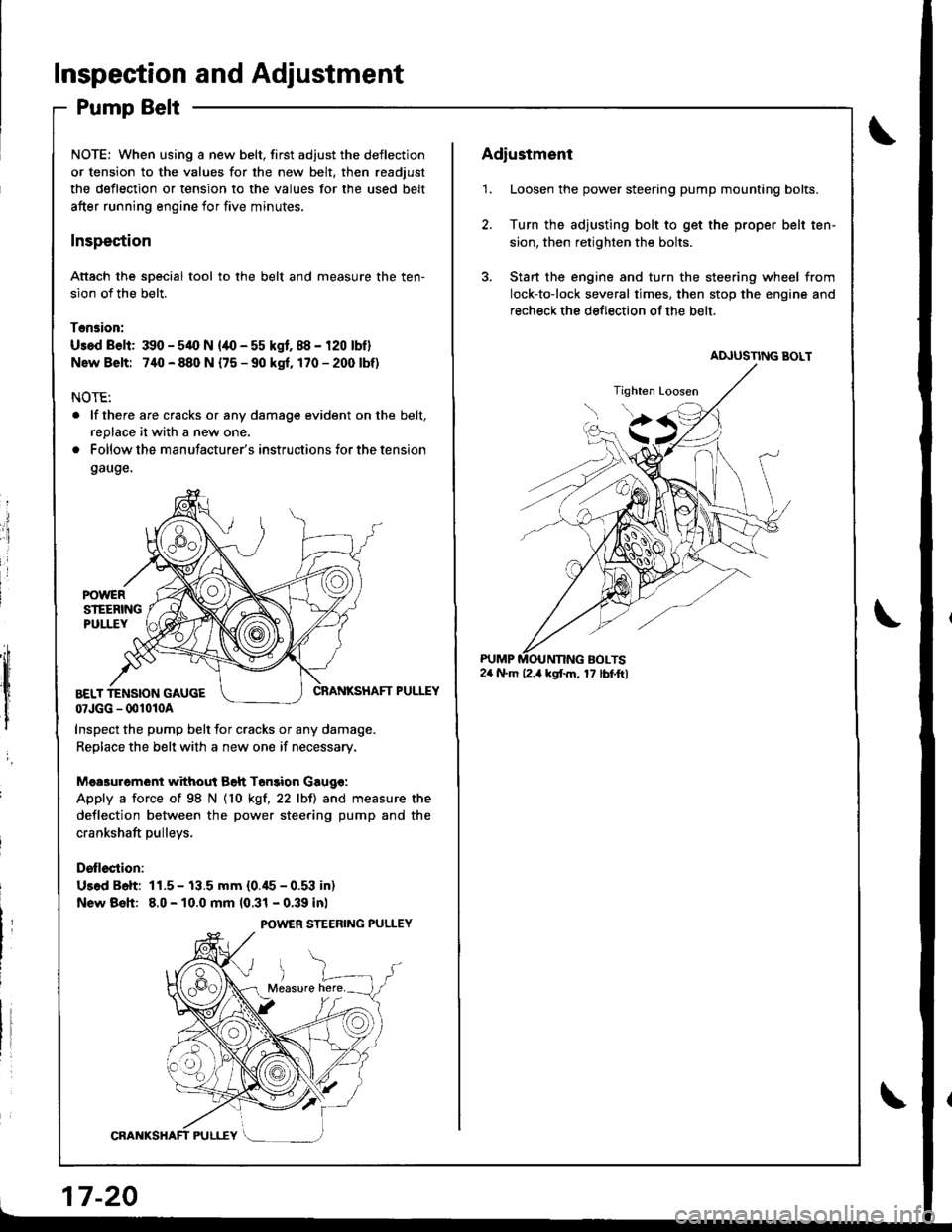

Pump Belt

NOTE: When using a new belt, first adjust the deflection

or tension to the values for the new belt, then readjust

the deflection or tension to the values for the used belt

after running engine for five minutes,

Inspection

Attach the soecial tool to the belt and measure the ten-

sion of the belt.

Tension:

Usad Belt: 390 - 54O N {/10 - 55 kgf. 88 - 120 lbf}

Nsw Belt: 740 - 880 N {75 - 90 kgf. 170-2(X)lbf)

NOTE:

. lf there are cracks or any damage evident on the belt,

replace it with a new one.

. Follow the manufacturer's instructions for the tension

gauge.

ii

:i

i

I

,;h

,lt l

I

i

CRANKSHAFT PULEYBELT TENSION GAUGE07JGG - 001010A

Inspect the pump belt for cracks or any damage.

Replace the belt with a new one if necessary.

Mea3urement without Bah Tonsion Gaugo:

Apply a force of 98 N {10 kgt,22 lbll and measure the

deflection between the power steering pump and the

crankshaft pulleys,

Drllection:

Us.d B6h: 11.5 - 13.5 mm (0.45 - 0.53 in)

New Bsh: 8.0 - 10.0 mm 10.31 - 0.39 inl

POWER STEERING PULLEY

17-20

Adiustment

1. Loosen the power steering pump mounting bolts.

2. Turn the adjusting bolt to get the proper belt ten-

sion, then retighten the bolts.

3. Stan the engine and turn the steering wheel from

lock-to-lock several times. then stop the engine and

recheck the deflection of the belt.

24 N.m l2.a kgf.m, 17 lbf.ftl

Page 670 of 1681

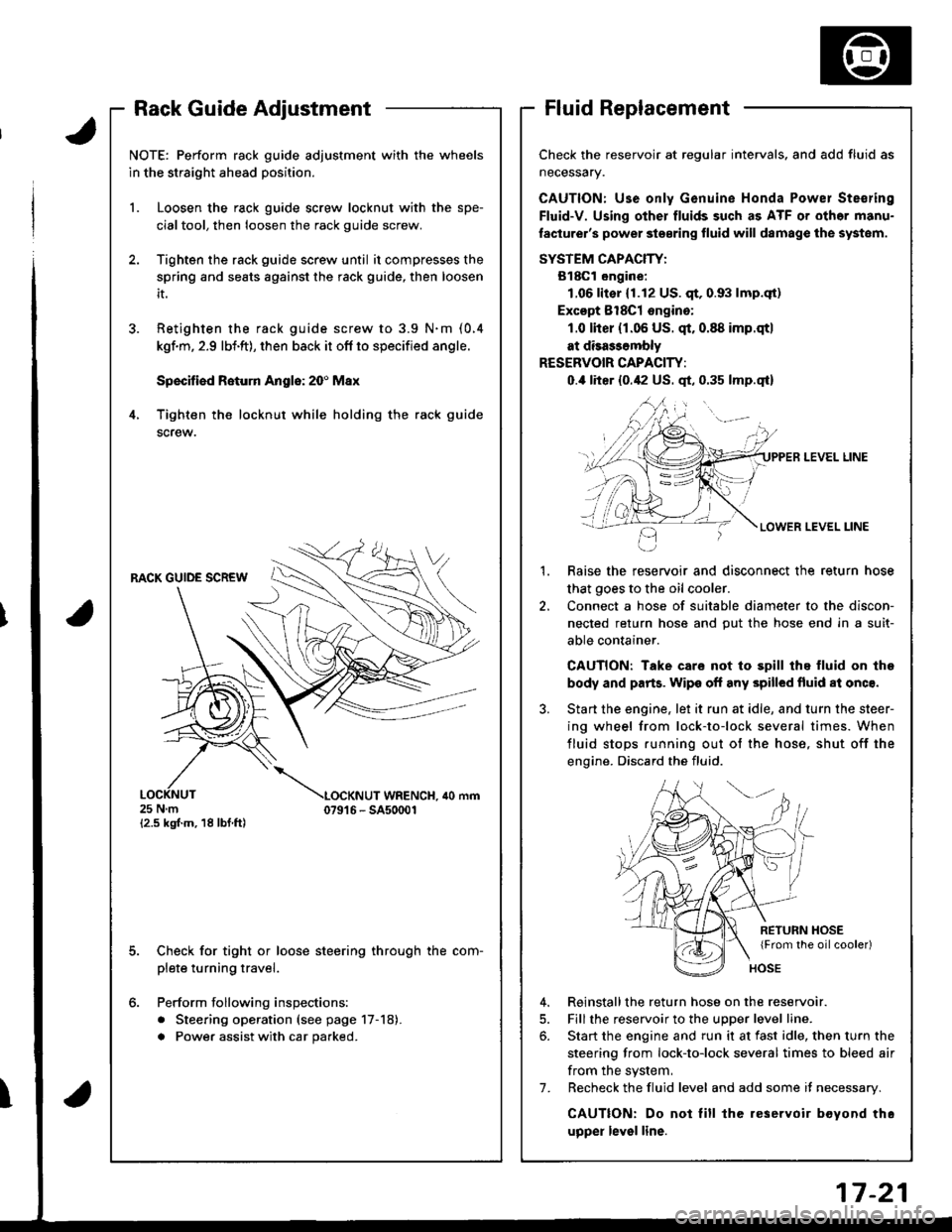

Rack Guide AdjustmentFluid Replacement

Check the reservoir at regular intervals, and add fluid as

neceSsary.

CAUTION: Use only Genuine Honda Powel Ste€ring

Fluid-V. Using other fluids such as ATF or othor manu-

laclurer's power ste€ring fluid will damag€ the systom.

SYSTEM CAPACIW:

B18Gl ongine:

1.06lit€r (1.12 US. qt,0.93 lmp.qt)

Excopt 8l8Cl ongino:

1.0 lher (r.06 US. qt.0.88 imp.qtl

at disa$ombly

RESERVOIR CAPACITY:

0.,0 liter {0.42 US. qt, 0.35 lmp.qt}

LEVEL LINE

LEVEL LINE

Raise the reservoir and disconnect the return hose

that goes to the oil cooler.

Connect a hose of suitable diameter to the discon-

nected return hose and put the hose end in a suit-

able container.

CAUTION: Take care not to spill thq fluid on lhe

body and parts. Wipe off any spilled fluid al onc€.

Start the engine. let it run at idle, and turn the steer-

ing wheel from lock-to-lock several times. When

fluid stops running out of the hose, shut off the

engine. Discard the fluid.

2.

RETURN HOSE{From the oilcooler)

4. Reinstallthe return hose on the reservoir.

5. Fill the reservoir to the uDDer level line.

6. Start the engine and run it at fast idle, then turn the

steering from lock-to-lock several times to bleed air

from the system,

7. Recheck the fluid level and add some it necessary.

CAUTION: Do not lill the reservoir boyond thc

upper level line.

J.

4.

NOTE: Perform rack guide adjustment with the wheels

in the straight ahead position.

1. Loosen the rack guide screw locknut with the spe-

cialtool, then loosen the rack guide screw.

Tighten the rack guide screw until it compresses the

spring and seats against the rack guide, then loosen

it.

Retighten ihe rack guide screw to 3.9 N.m (0.4

kgf.m, 2.9 lbi.ft), then back it ofl to specified angle.

Speciliad Roturn Anglo: 20' Max

Tighten th€ locknut while holding the rack guide

screw.

RACK GUIDE SCREW

25Nm{2.5 kgf.m, 18 lbf ft)

LOCKNUT WRENCH. ilo mm079't 6 - SA50001

E

6.

Check for tight or loose steering through the com-

plete turning travel.

Perform following inspections:

. Steering operation (see page 17-18).

a Power assist with car parked.

I