INFINITI FX35 2008 Service Manual

FX35 2008

INFINITI

INFINITI

https://www.carmanualsonline.info/img/42/57017/w960_57017-0.png

INFINITI FX35 2008 Service Manual

Trending: lights, gas mileage, radiator, engine oil capacity, buttons, turn signal bulb, towing

Page 341 of 3924

AT-268

< SERVICE INFORMATION >

DISASSEMBLY

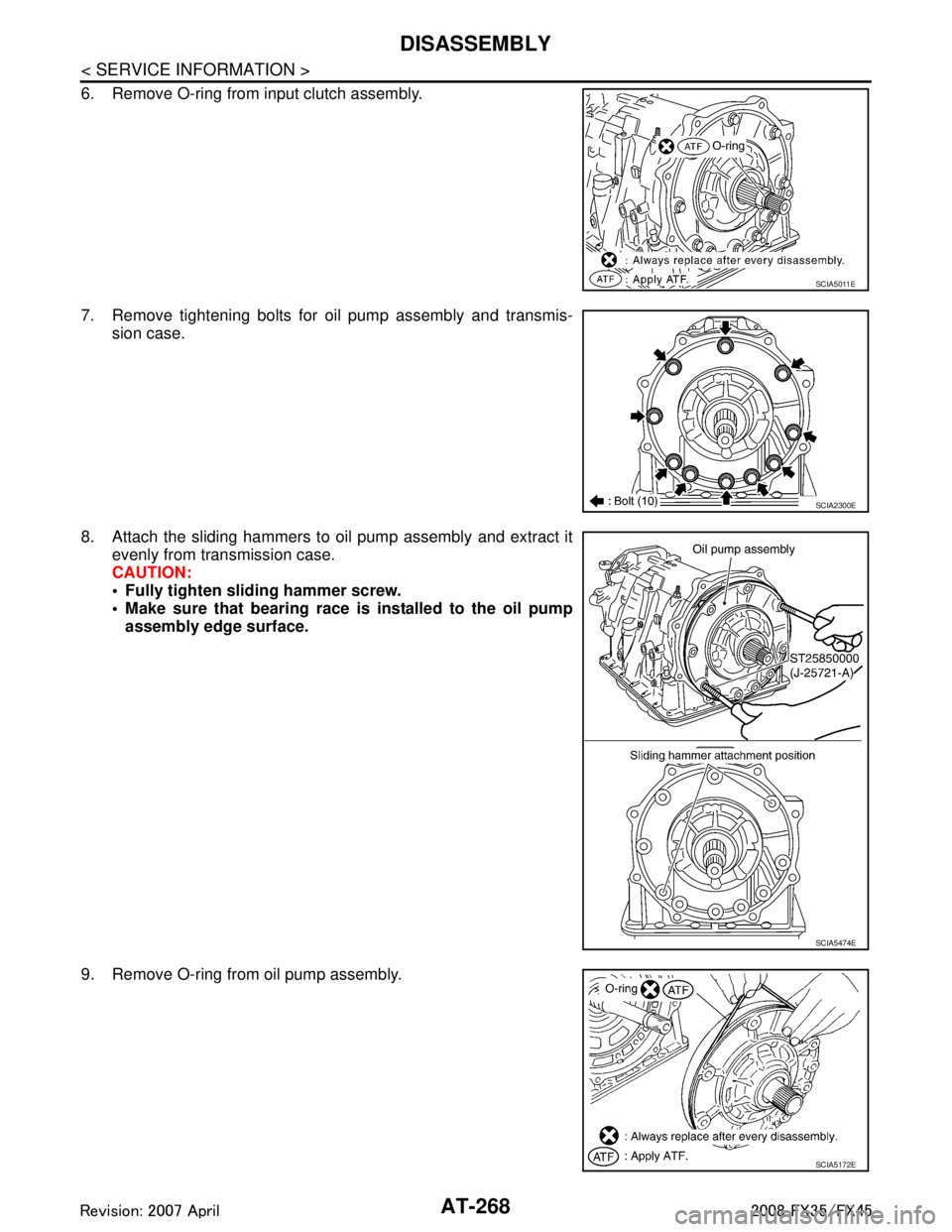

6. Remove O-ring from input clutch assembly.

7. Remove tightening bolts for oil pump assembly and transmis-sion case.

8. Attach the sliding hammers to oil pump assembly and extract it evenly from transmission case.

CAUTION:

Fully tighten sliding hammer screw.

Make sure that bearing race is installed to the oil pumpassembly edge surface.

9. Remove O-ring from oil pump assembly.

SCIA5011E

SCIA2300E

SCIA5474E

SCIA5172E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 342 of 3924

DISASSEMBLYAT-269

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

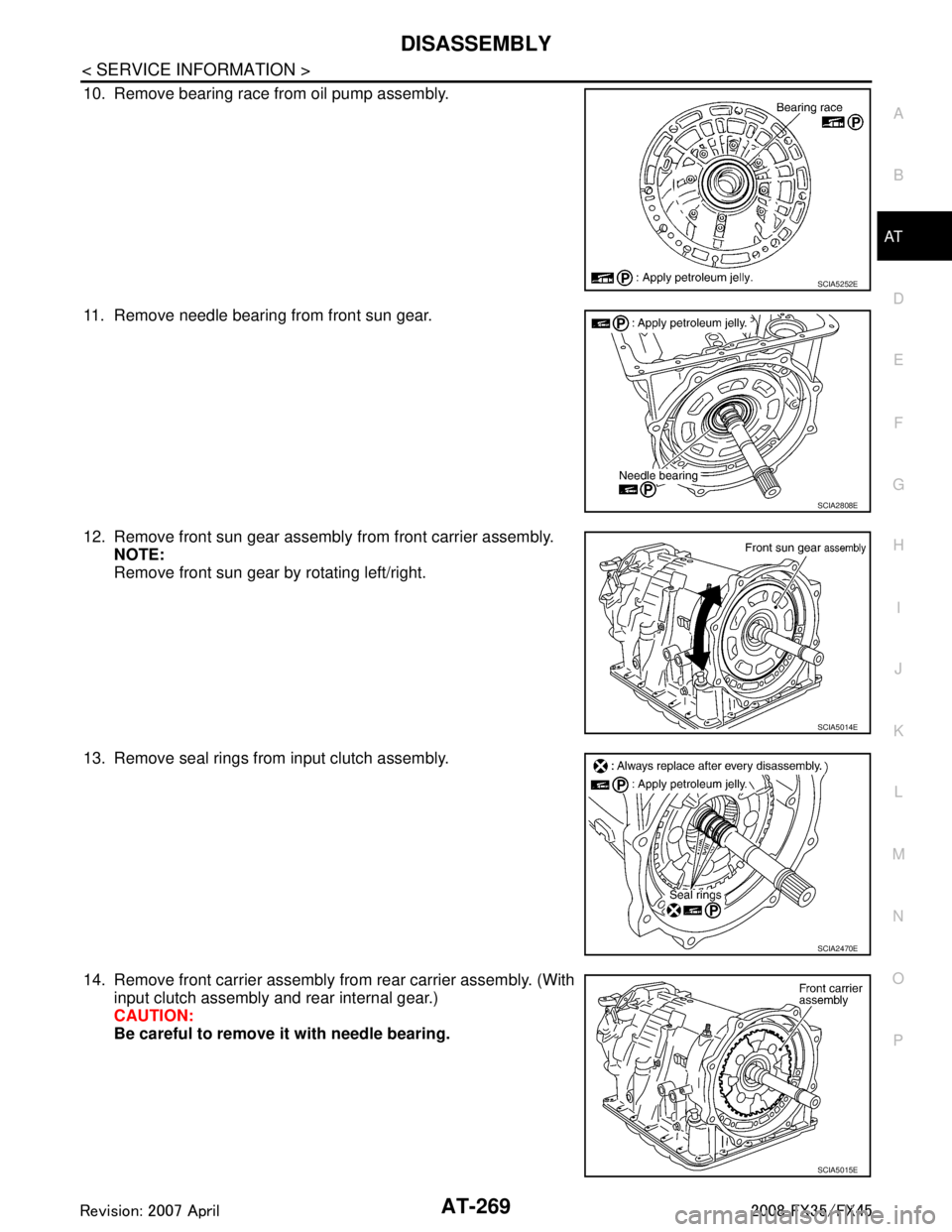

10. Remove bearing race from oil pump assembly.

11. Remove needle bearing from front sun gear.

12. Remove front sun gear assembly from front carrier assembly. NOTE:

Remove front sun gear by rotating left/right.

13. Remove seal rings from input clutch assembly.

14. Remove front carrier assembly from rear carrier assembly. (With input clutch assembly and rear internal gear.)

CAUTION:

Be careful to remove it with needle bearing.

SCIA5252E

SCIA2808E

SCIA5014E

SCIA2470E

SCIA5015E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 343 of 3924

AT-270

< SERVICE INFORMATION >

DISASSEMBLY

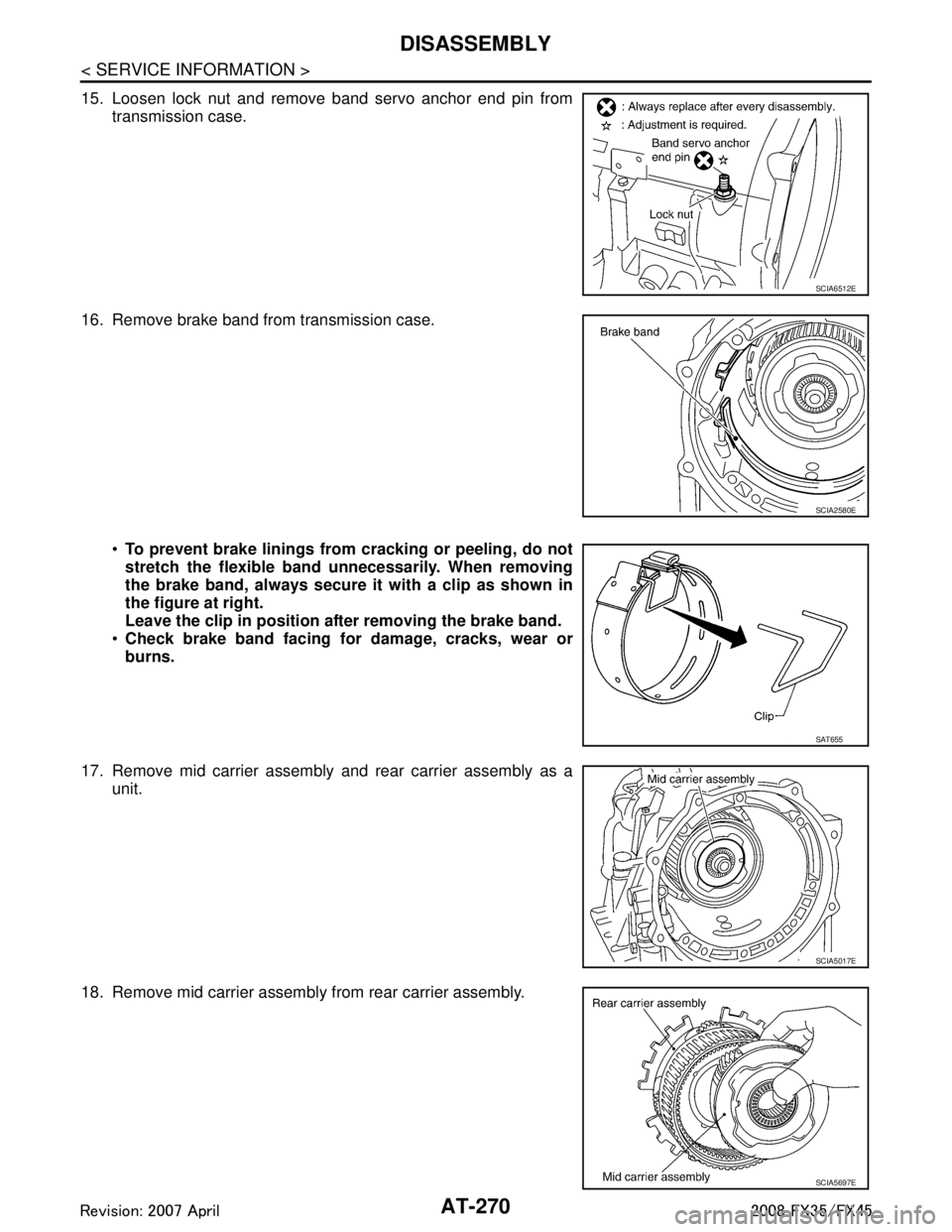

15. Loosen lock nut and remove band servo anchor end pin fromtransmission case.

16. Remove brake band from transmission case.

To prevent brake linings from cr acking or peeling, do not

stretch the flexible band unnecessarily. When removing

the brake band, always secure it with a clip as shown in

the figure at right.

Leave the clip in position after removing the brake band.

Check brake band facing for damage, cracks, wear or

burns.

17. Remove mid carrier assembly and rear carrier assembly as a unit.

18. Remove mid carrier assembly from rear carrier assembly.

SCIA6512E

SCIA2580E

SAT655

SCIA5017E

SCIA5697E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 344 of 3924

DISASSEMBLYAT-271

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

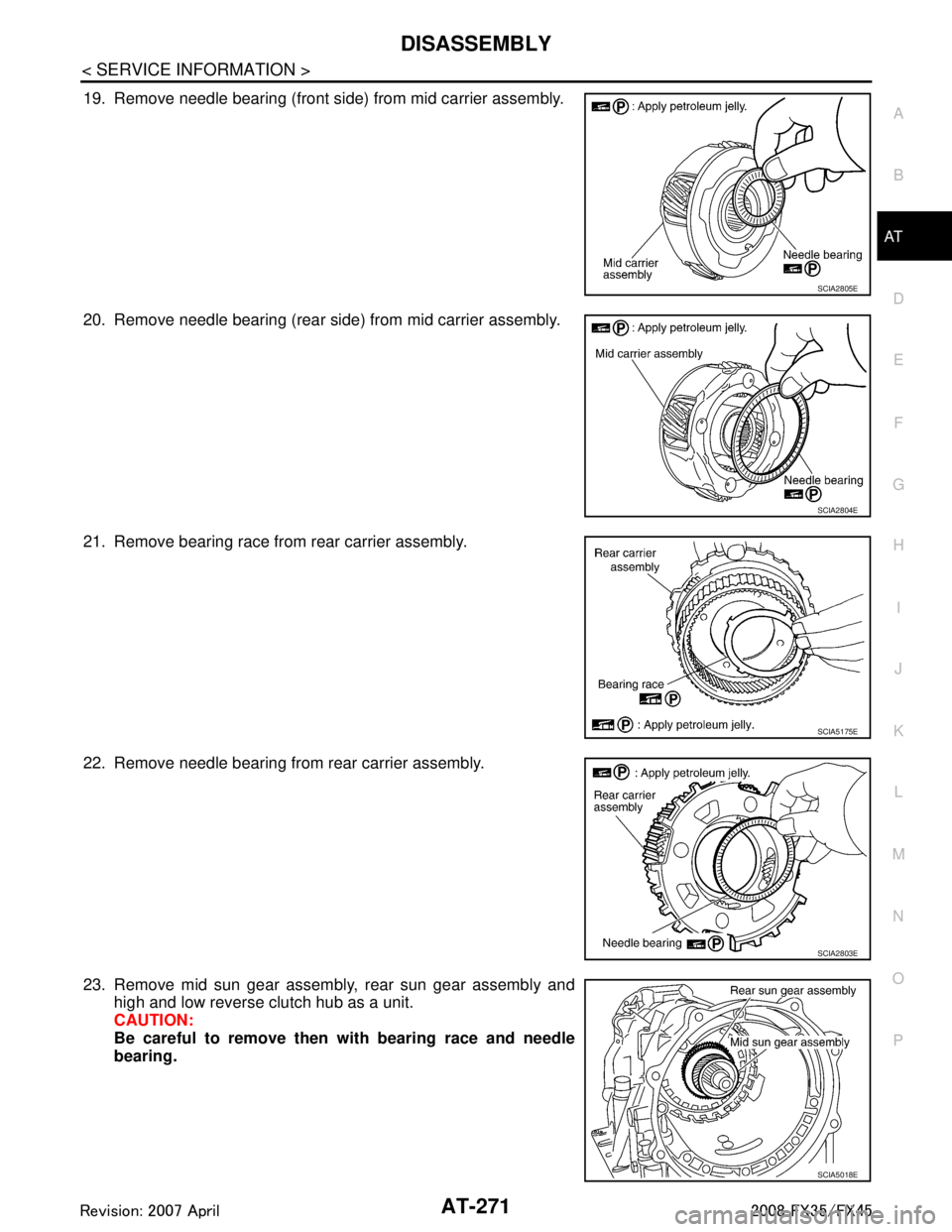

19. Remove needle bearing (front side) from mid carrier assembly.

20. Remove needle bearing (rear side) from mid carrier assembly.

21. Remove bearing race from rear carrier assembly.

22. Remove needle bearing from rear carrier assembly.

23. Remove mid sun gear assembly , rear sun gear assembly and

high and low reverse clutch hub as a unit.

CAUTION:

Be careful to remove then with bearing race and needle

bearing.

SCIA2805E

SCIA2804E

SCIA5175E

SCIA2803E

SCIA5018E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 345 of 3924

AT-272

< SERVICE INFORMATION >

DISASSEMBLY

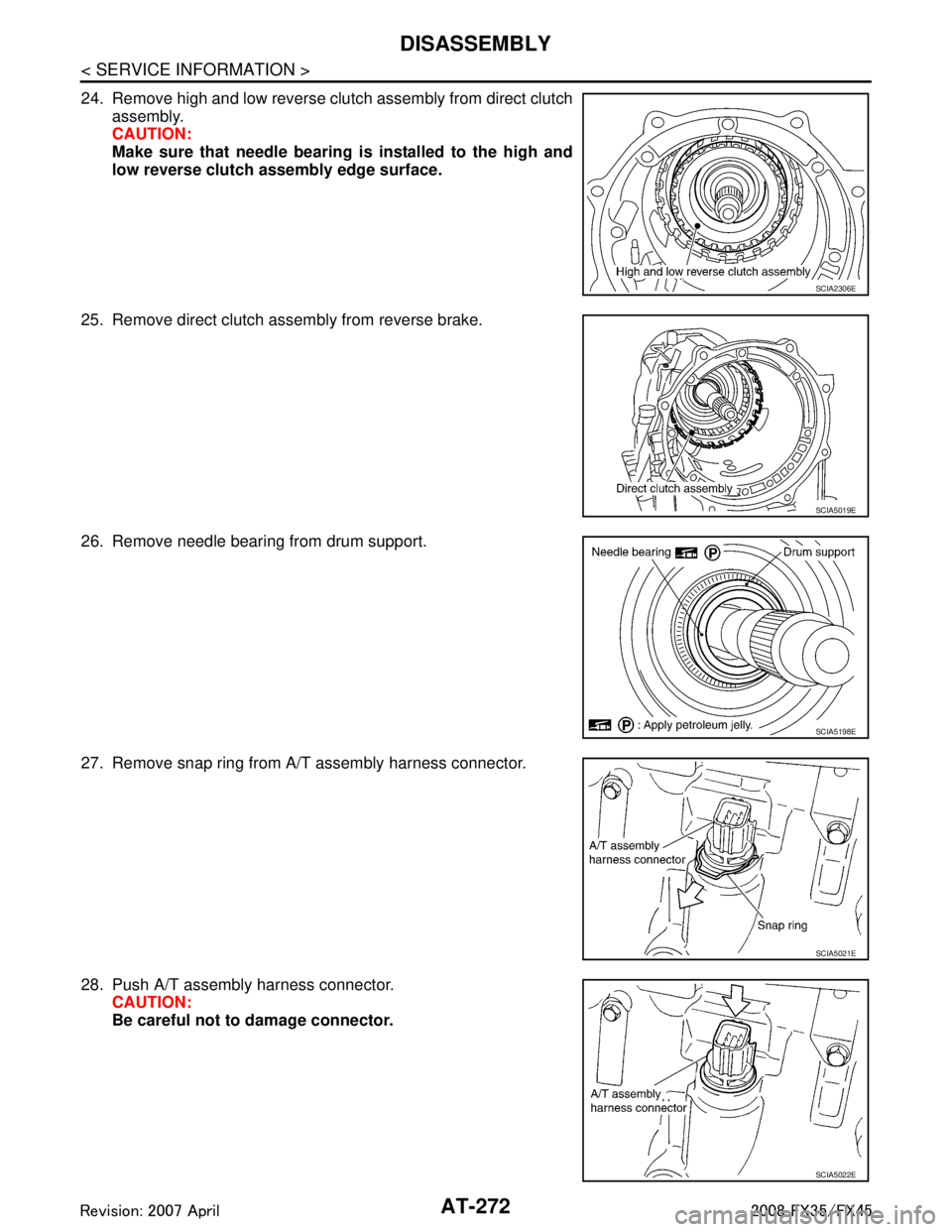

24. Remove high and low reverse clutch assembly from direct clutchassembly.

CAUTION:

Make sure that needle bearing is installed to the high and

low reverse clutch assembly edge surface.

25. Remove direct clutch assembly from reverse brake.

26. Remove needle bearing from drum support.

27. Remove snap ring from A/T assembly harness connector.

28. Push A/T assembly harness connector. CAUTION:

Be careful not to damage connector.

SCIA2306E

SCIA5019E

SCIA5198E

SCIA5021E

SCIA5022E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 346 of 3924

DISASSEMBLYAT-273

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

29. Remove bracket (1) (VK45DE), clips (2), oil pan (3) and oil pan gasket.

: Vehicle front

: Bolt (22)

Drain plug (4)

30. Check foreign materials in oil pan to help determine causes of malfunction. If the ATF is very dark, smells burned, or contains

foreign particles, the frictional material (clutches, band) may

need replacement. A tacky film that will not wipe clean indicates

varnish build up. Varnish can c ause valves, servo, and clutches

to stick and can inhibit pump pressure.

If frictional material is detected, perform A/T fluid cooler

cleaning. Refer to AT-13, "

A/T Fluid Cooler Cleaning".

31. Remove magnets from oil pan.

32. Disconnect A/T fluid temperature sensor 2 connector (1). CAUTION:

Be careful not to damage connector.

33. Straighten terminal clips ( ) to free terminal cord assembly and A/T fluid temperature sensor 2 harness.

34. Disconnect revolution sensor connector. CAUTION:

Be careful not to damage connector.

SCIA8128E

SCIA5199E

SCIA5200E

SCIA8069E

SCIA7524E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 347 of 3924

AT-274

< SERVICE INFORMATION >

DISASSEMBLY

35. Straighten terminal clip to free revolution sensor harness.

36. Remove bolts A, B and C from control valve with TCM. : Front

37. Remove control valve with TCM from transmission case. CAUTION:

When removing, be careful with the manual valve notch and

manual plate height. Remove it vertically.

38. Remove A/T fluid temperature sensor 2 with bracket from con- trol valve with TCM.

39. Remove bracket from A/T fluid temperature sensor 2.

SCIA7526E

Bolt symbol Length mm (in) Number of bolts A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA8077E

SCIA5260E

SCIA5301E

SCIA5264E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 348 of 3924

DISASSEMBLYAT-275

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

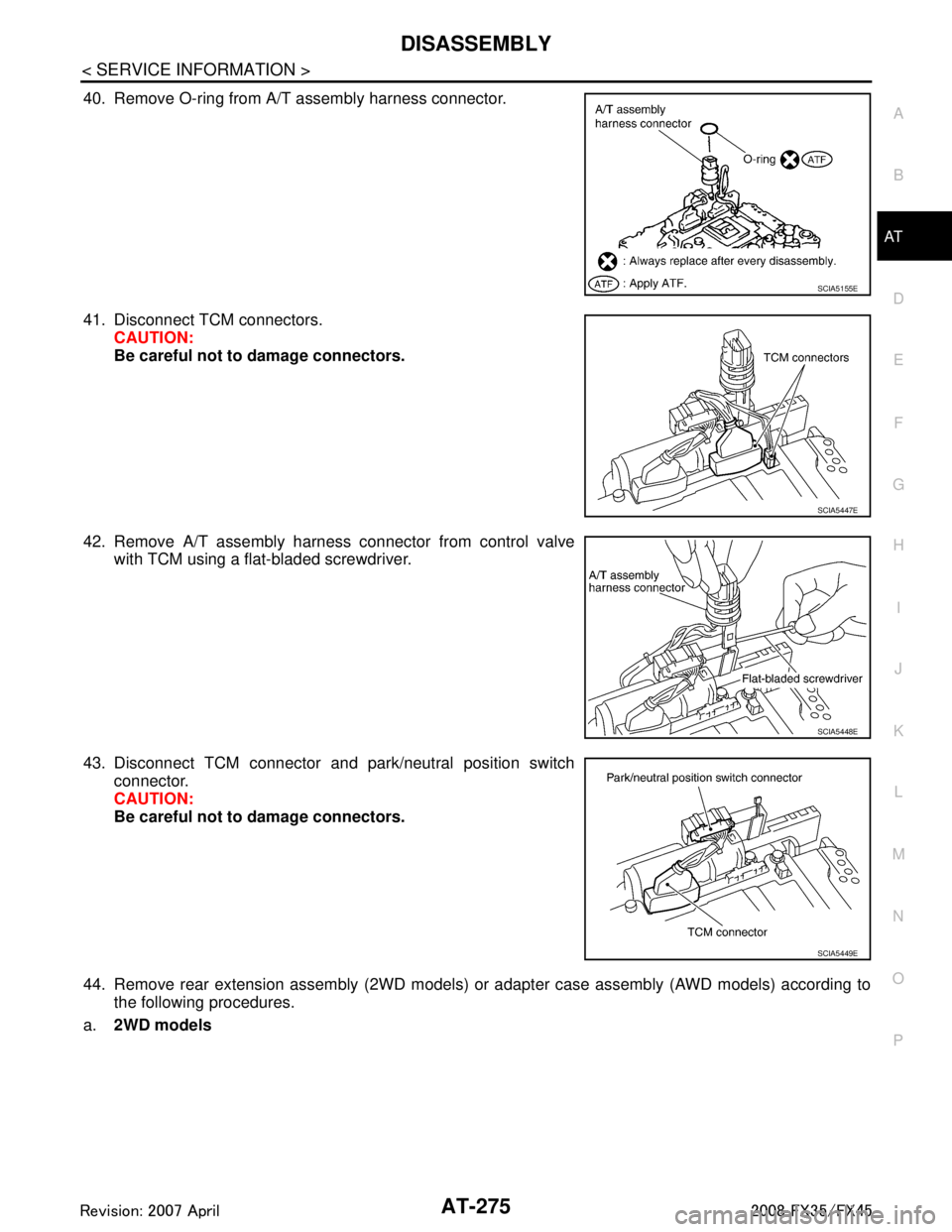

40. Remove O-ring from A/T assembly harness connector.

41. Disconnect TCM connectors. CAUTION:

Be careful not to damage connectors.

42. Remove A/T assembly harness connector from control valve with TCM using a flat-bladed screwdriver.

43. Disconnect TCM connector and park/neutral position switch connector.

CAUTION:

Be careful not to damage connectors.

44. Remove rear extension assembly (2WD models) or adapter case assembly (AWD models) according to the following procedures.

a. 2WD models

SCIA5155E

SCIA5447E

SCIA5448E

SCIA5449E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 349 of 3924

AT-276

< SERVICE INFORMATION >

DISASSEMBLY

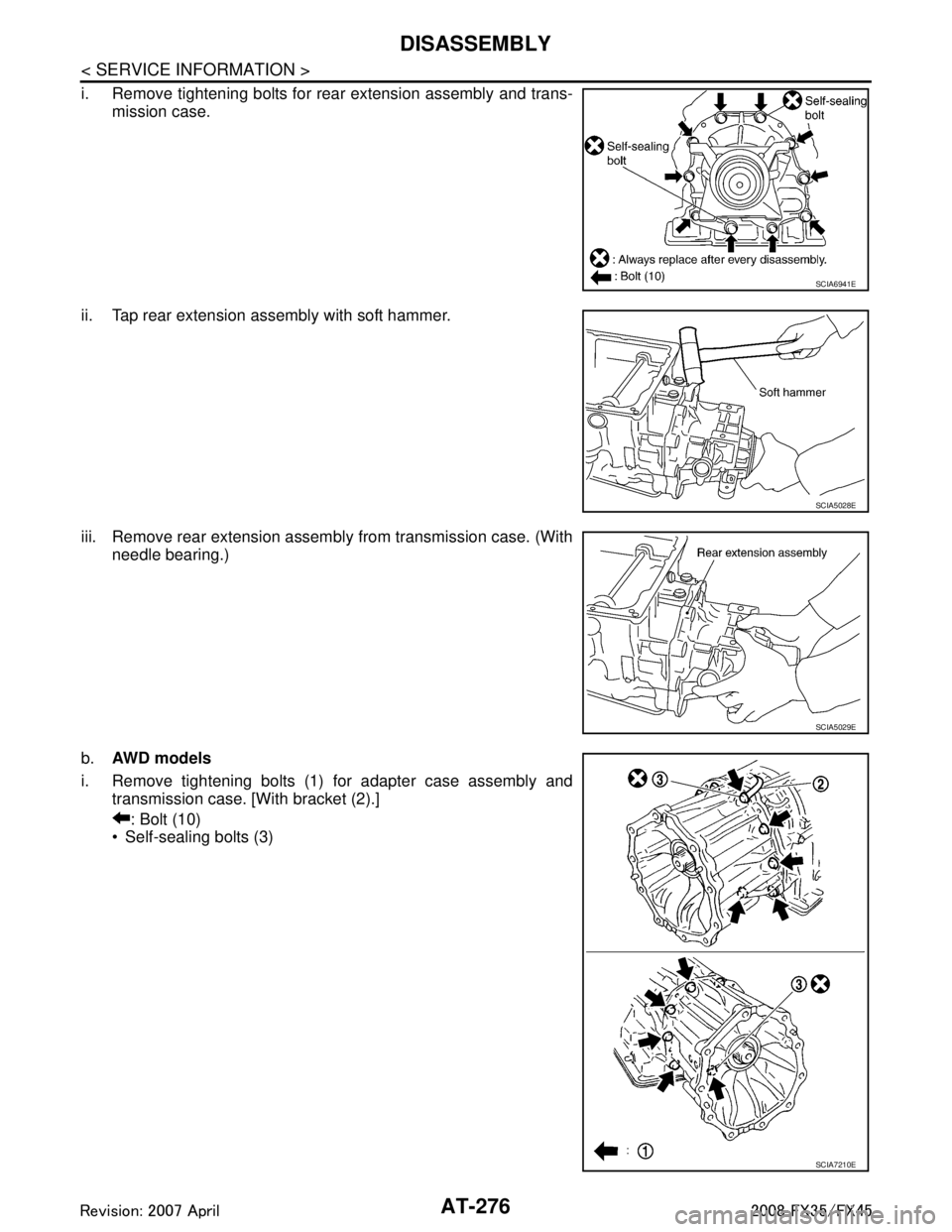

i. Remove tightening bolts for rear extension assembly and trans-mission case.

ii. Tap rear extension assembly with soft hammer.

iii. Remove rear extension assembly from transmission case. (With needle bearing.)

b. AWD models

i. Remove tightening bolts (1) for adapter case assembly and transmission case. [With bracket (2).]

: Bolt (10)

Self-sealing bolts (3)

SCIA6941E

SCIA5028E

SCIA5029E

SCIA7210E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 350 of 3924

DISASSEMBLYAT-277

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

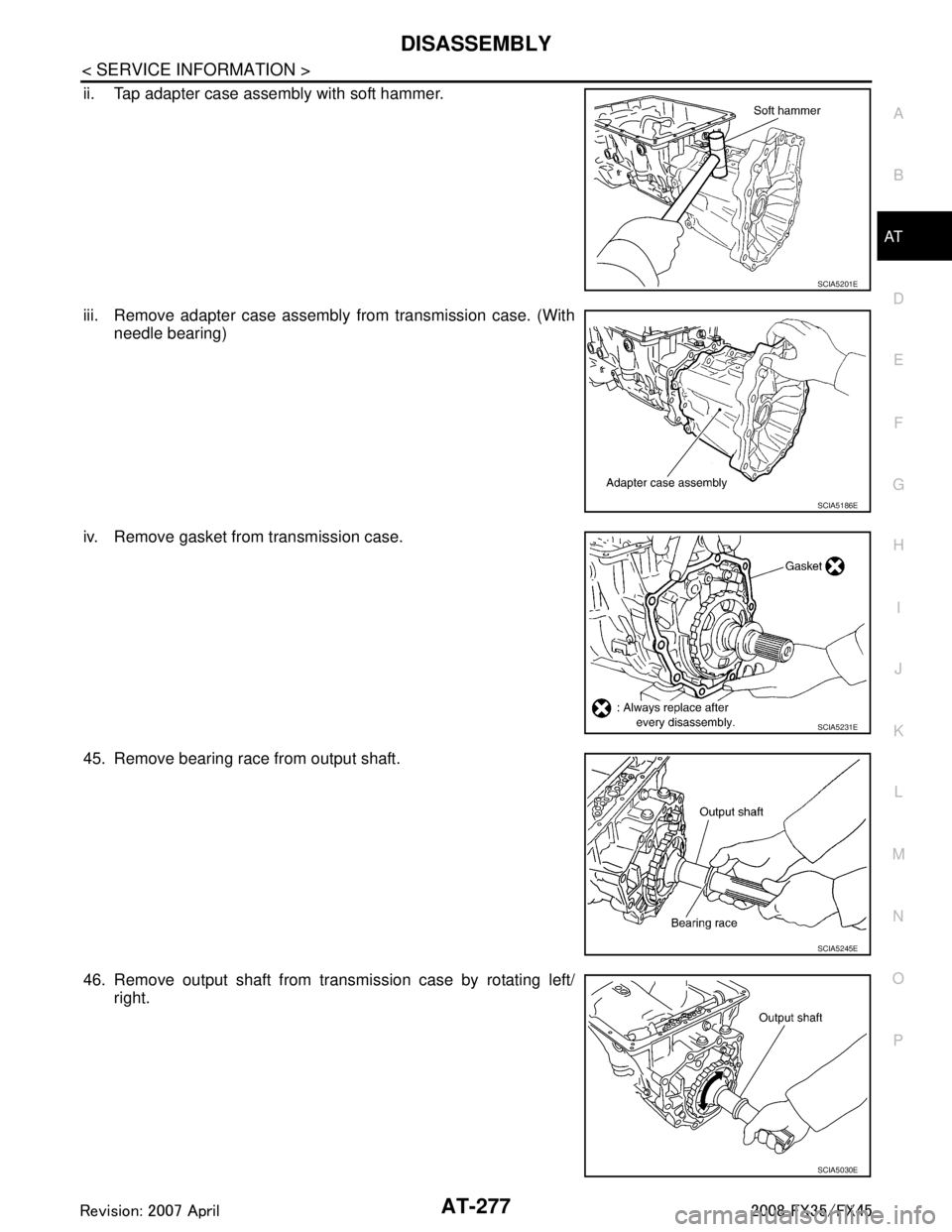

ii. Tap adapter case assembly with soft hammer.

iii. Remove adapter case assembly from transmission case. (With needle bearing)

iv. Remove gasket from transmission case.

45. Remove bearing race from output shaft.

46. Remove output shaft from transmission case by rotating left/ right.

SCIA5201E

SCIA5186E

SCIA5231E

SCIA5245E

SCIA5030E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Trending: engine coolant, warning lights, instrument, instrument cluster, Timing chain, reset, check engine