IDX INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2184 of 2395

Special Service ToolsNBST0003The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

KV48100700

(J26364)

Torque adapter

NT169

Measuring pinion rotating torque

ST35300000

(Ð)

Drift

NT073

Installing power steering oil pump oil seal

a: 59 mm (2.32 in) dia.

b: 45 mm (1.77 in) dia.

ST27180001

(J25726-A)

Steering wheel puller

NT544

Removing steering wheel

ST29020001

(J24319-01)

Ball joint remover

NT694

Removing ball joint

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

KV48103500

(J26357 and J26357-10)

Pressure gauge

NT547

Measuring oil pressure

KV48102500

(Ð)

Pressure gauge adapter

NT542

Measuring oil pressure

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

PREPARATION

Special Service Tools

ST-3

Page 2186 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

(J-44183-A)

Spring gauge

LST025

Measuring rack sliding force

Commercial Service ToolsNBST0004

Tool name Description

Rear oil seal drift

NT063

Installing rear oil seal

a: 28 mm (1.10 in) dia.

Pinion oil seal drift

NT063

Installing pinion oil seal

a: 40 mm (1.57 in) dia.

Oil pump attachment

NT179

Disassembling and assembling oil pump

Unit: mm (in)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

PREPARATION

Special Service Tools (Cont'd)

ST-5

Page 2188 of 2395

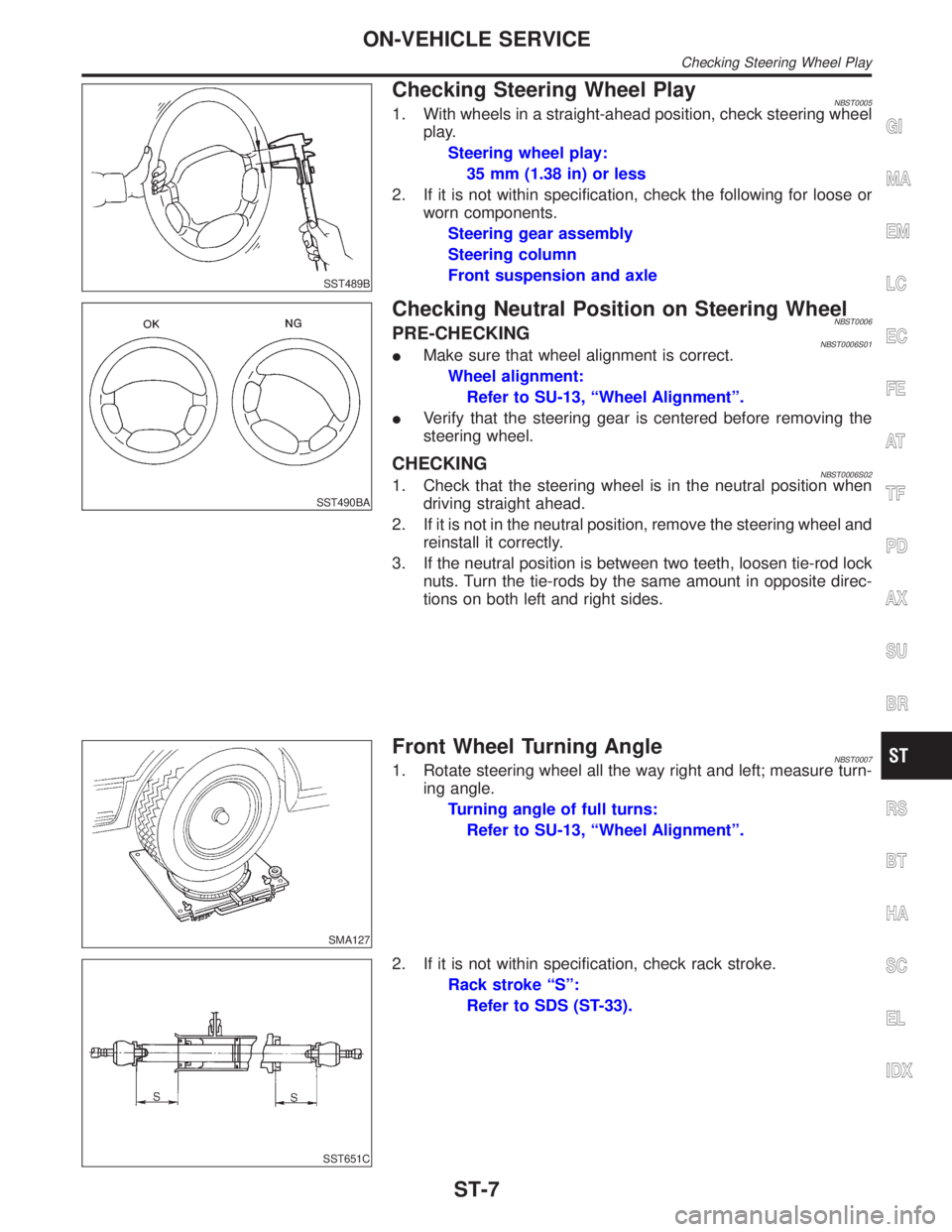

SST489B

Checking Steering Wheel PlayNBST00051. With wheels in a straight-ahead position, check steering wheel

play.

Steering wheel play:

35 mm (1.38 in) or less

2. If it is not within specification, check the following for loose or

worn components.

Steering gear assembly

Steering column

Front suspension and axle

SST490BA

Checking Neutral Position on Steering WheelNBST0006PRE-CHECKINGNBST0006S01IMake sure that wheel alignment is correct.

Wheel alignment:

Refer to SU-13, ªWheel Alignmentº.

IVerify that the steering gear is centered before removing the

steering wheel.

CHECKINGNBST0006S021. Check that the steering wheel is in the neutral position when

driving straight ahead.

2. If it is not in the neutral position, remove the steering wheel and

reinstall it correctly.

3. If the neutral position is between two teeth, loosen tie-rod lock

nuts. Turn the tie-rods by the same amount in opposite direc-

tions on both left and right sides.

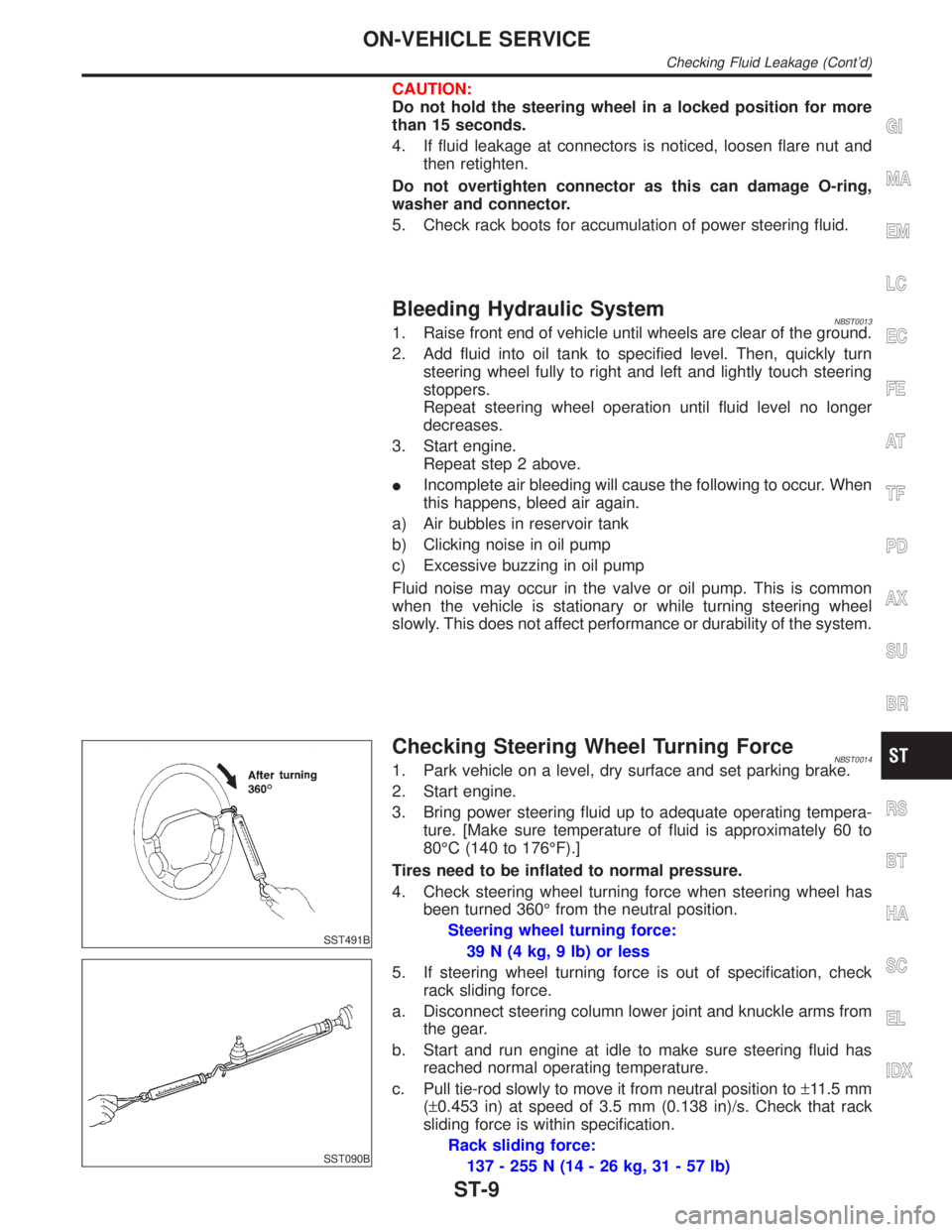

SMA127

Front Wheel Turning AngleNBST00071. Rotate steering wheel all the way right and left; measure turn-

ing angle.

Turning angle of full turns:

Refer to SU-13, ªWheel Alignmentº.

SST651C

2. If it is not within specification, check rack stroke.

Rack stroke ªSº:

Refer to SDS (ST-33).

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

ON-VEHICLE SERVICE

Checking Steering Wheel Play

ST-7

Page 2190 of 2395

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

4. If fluid leakage at connectors is noticed, loosen flare nut and

then retighten.

Do not overtighten connector as this can damage O-ring,

washer and connector.

5. Check rack boots for accumulation of power steering fluid.

Bleeding Hydraulic SystemNBST00131. Raise front end of vehicle until wheels are clear of the ground.

2. Add fluid into oil tank to specified level. Then, quickly turn

steering wheel fully to right and left and lightly touch steering

stoppers.

Repeat steering wheel operation until fluid level no longer

decreases.

3. Start engine.

Repeat step 2 above.

IIncomplete air bleeding will cause the following to occur. When

this happens, bleed air again.

a) Air bubbles in reservoir tank

b) Clicking noise in oil pump

c) Excessive buzzing in oil pump

Fluid noise may occur in the valve or oil pump. This is common

when the vehicle is stationary or while turning steering wheel

slowly. This does not affect performance or durability of the system.

SST491B

SST090B

Checking Steering Wheel Turning ForceNBST00141. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating tempera-

ture. [Make sure temperature of fluid is approximately 60 to

80ÉC (140 to 176ÉF).]

Tires need to be inflated to normal pressure.

4. Check steering wheel turning force when steering wheel has

been turned 360É from the neutral position.

Steering wheel turning force:

39 N (4 kg, 9 lb) or less

5. If steering wheel turning force is out of specification, check

rack sliding force.

a. Disconnect steering column lower joint and knuckle arms from

the gear.

b. Start and run engine at idle to make sure steering fluid has

reached normal operating temperature.

c. Pull tie-rod slowly to move it from neutral position to±11.5 mm

(±0.453 in) at speed of 3.5 mm (0.138 in)/s. Check that rack

sliding force is within specification.

Rack sliding force:

137 - 255 N (14 - 26 kg, 31 - 57 lb)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

ON-VEHICLE SERVICE

Checking Fluid Leakage (Cont'd)

ST-9

Page 2192 of 2395

ComponentsNBST0016

SST843C

1. Air bag module

2. Steering wheel3. Spiral cable

4. Combination switch5. Steering column assembly

6. Column cover

CAUTION:

IThe rotation of the spiral cable (SRS ªAIR BAGº compo-

nent part) is limited. If the steering gear must be removed,

set the front wheels in the straight-ahead direction. Do not

rotate the steering column while the steering gear is

removed.

IRemove the steering wheel before removing the steering

lower joint to avoid damaging the SRS spiral cable.

SBF812E

Removal and InstallationNBST0017STEERING WHEELNBST0017S011. Remove air bag module and spiral cable. Refer to RS-17,

ªRemoval Ð Air Bag Module and Spiral Cableº.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

STEERING WHEEL AND STEERING COLUMN

Components

ST-11

Page 2194 of 2395

Disassembly and AssemblyNBST0018

SST845C

1. Combination switch

2. Lock nut

3. Jacket tube assembly4. Tilt lever

5. Tilt spring

6. Steering column shaft assembly7. Band

8. Jacket tube bracket insulator

assembly

9. Hole cover

SST490C

IWhen disassembling and assembling, unlock steering lock

with key.

IInstall lock nut on steering column shaft and tighten the nut to

specification.

: 25 - 34 N´m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

SST742A

ISteering lock

a) Break self-shear type screws with a drill or other appropriate

tool.

b) Install new self-shear type screws and then cut off self-shear

type screw heads.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

STEERING WHEEL AND STEERING COLUMN

Disassembly and Assembly

ST-13

Page 2196 of 2395

RemovalNBST0021

SST846C

1. Power steering gear assembly

2. Steering column lower joint3. Transfer gear assembly 4. Steering column upper joint

SST609C

1. Set wheels in the straight-ahead position.

2. Straight-forward position is indicated by a protrusion on the

power steering gear rear cover cap and matching mark on the

rear housing.

SST610C

3. Remove steering column upper and lower joint from transfer

gear.

4. Remove transfer gear assembly.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

STEERING TRANSFER GEAR

Removal

ST-15

Page 2198 of 2395

ComponentsNBST0026

SST618CB

1. Rear cover cap

2. Rear housing assembly

3. Pinion seal ring

4. Pinion assembly

5. O-ring

6. Shim

7. Pinion oil seal

8. Lock nut

9. Adjusting screw

10. Spring11. Retainer

12. Gear housing assembly

13. Rack oil seal

14. Rack assembly

15. Rack seal ring

16. O-ring

17. O-ring

18. Rack bushing

19. Rack oil seal

20. Snap ring21. End cover assembly

22. Boot clamp

23. Dust boot

24. Boot clamp

25. Lock plate

26. Tie-rod inner socket

27. Tie-rod

28. Tie-rod outer socket

29. Cotter pin

30. Cylinder tube

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING GEAR AND LINKAGE

Components

ST-17

Page 2200 of 2395

in high-pressure connector. Take care to install the proper

O-ring.

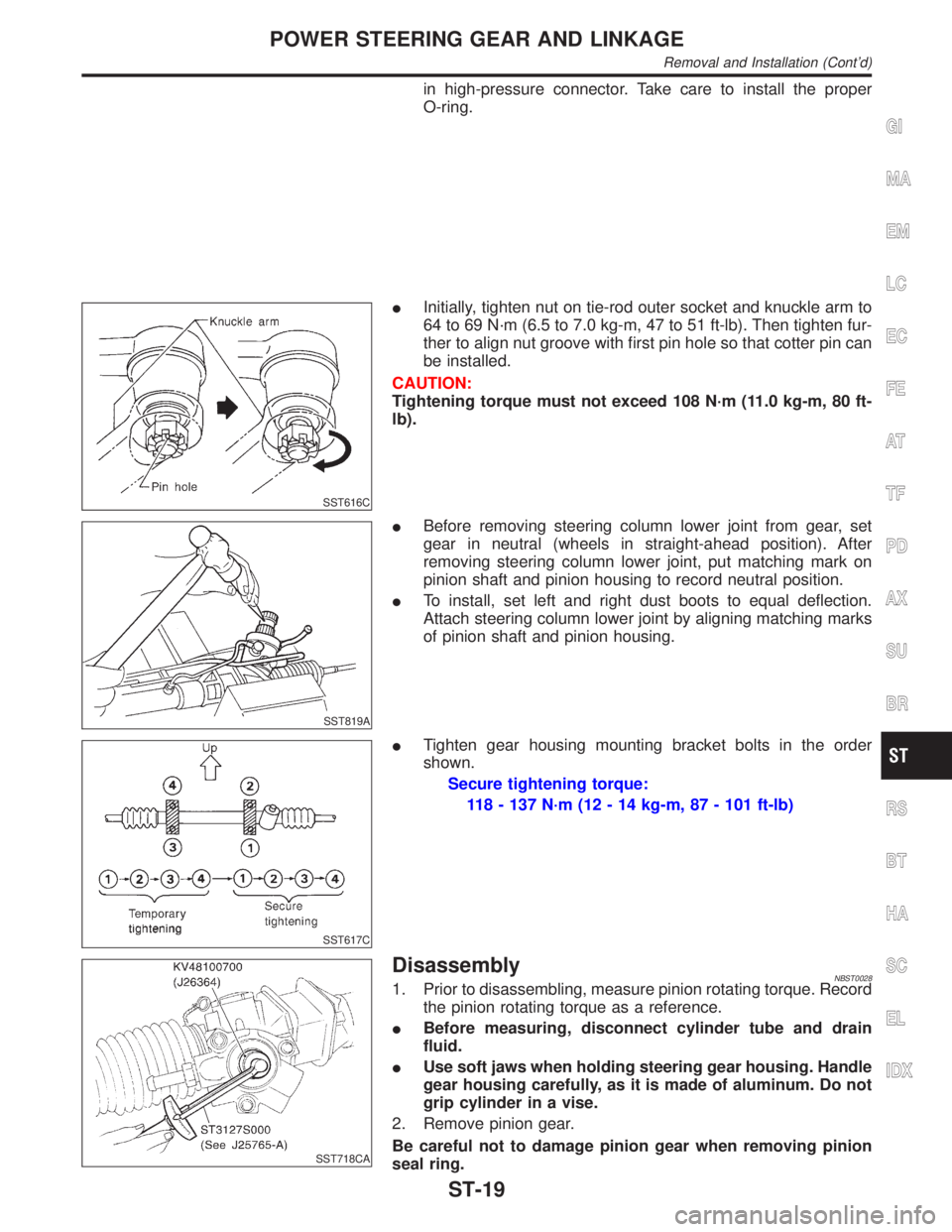

SST616C

IInitially, tighten nut on tie-rod outer socket and knuckle arm to

64 to 69 N´m (6.5 to 7.0 kg-m, 47 to 51 ft-lb). Then tighten fur-

ther to align nut groove with first pin hole so that cotter pin can

be installed.

CAUTION:

Tightening torque must not exceed 108 N´m (11.0 kg-m, 80 ft-

lb).

SST819A

IBefore removing steering column lower joint from gear, set

gear in neutral (wheels in straight-ahead position). After

removing steering column lower joint, put matching mark on

pinion shaft and pinion housing to record neutral position.

ITo install, set left and right dust boots to equal deflection.

Attach steering column lower joint by aligning matching marks

of pinion shaft and pinion housing.

SST617C

ITighten gear housing mounting bracket bolts in the order

shown.

Secure tightening torque:

118 - 137 N´m (12 - 14 kg-m, 87 - 101 ft-lb)

SST718CA

DisassemblyNBST00281. Prior to disassembling, measure pinion rotating torque. Record

the pinion rotating torque as a reference.

IBefore measuring, disconnect cylinder tube and drain

fluid.

IUse soft jaws when holding steering gear housing. Handle

gear housing carefully, as it is made of aluminum. Do not

grip cylinder in a vise.

2. Remove pinion gear.

Be careful not to damage pinion gear when removing pinion

seal ring.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING GEAR AND LINKAGE

Removal and Installation (Cont'd)

ST-19

Page 2202 of 2395

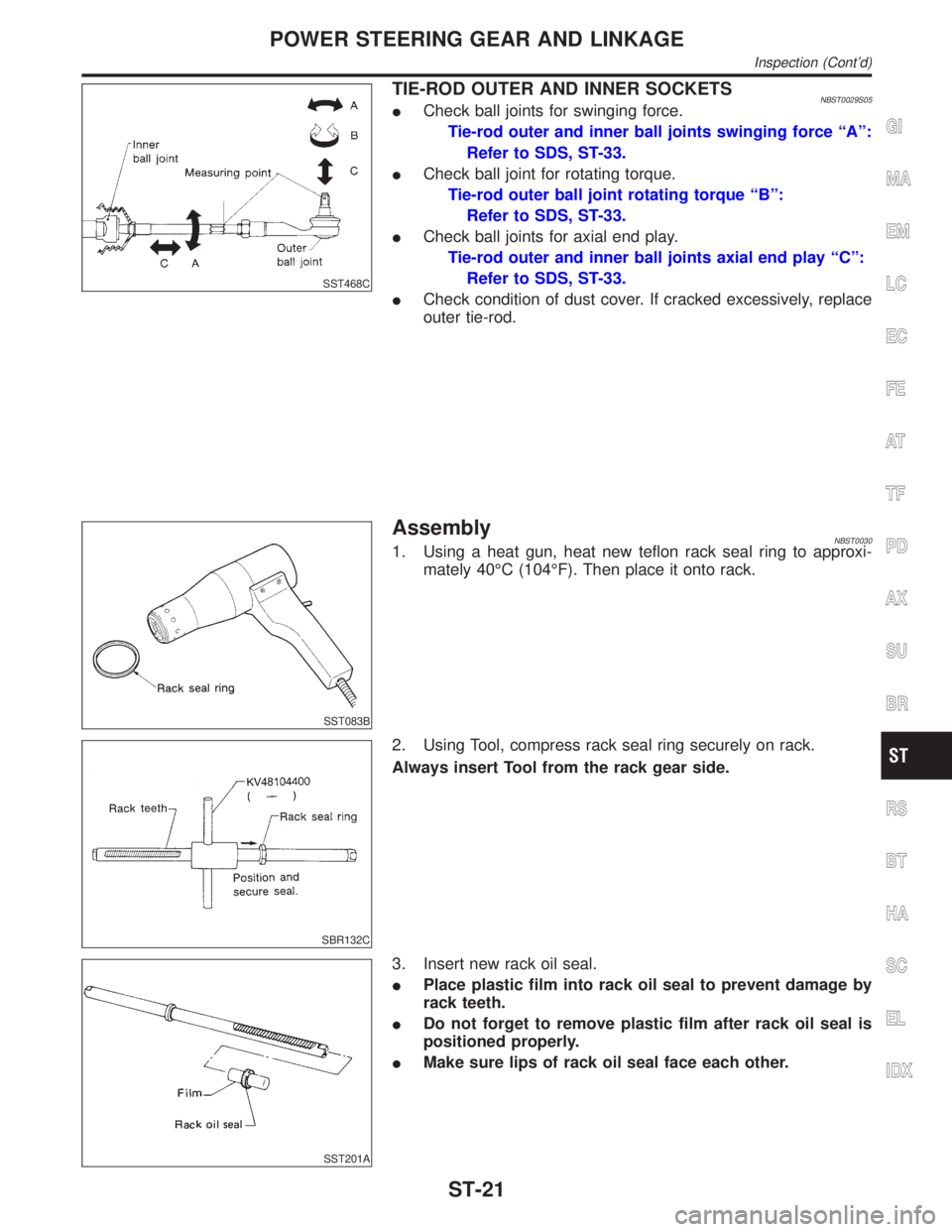

SST468C

TIE-ROD OUTER AND INNER SOCKETSNBST0029S05ICheck ball joints for swinging force.

Tie-rod outer and inner ball joints swinging force ªAº:

Refer to SDS, ST-33.

ICheck ball joint for rotating torque.

Tie-rod outer ball joint rotating torque ªBº:

Refer to SDS, ST-33.

ICheck ball joints for axial end play.

Tie-rod outer and inner ball joints axial end play ªCº:

Refer to SDS, ST-33.

ICheck condition of dust cover. If cracked excessively, replace

outer tie-rod.

SST083B

AssemblyNBST00301. Using a heat gun, heat new teflon rack seal ring to approxi-

mately 40ÉC (104ÉF). Then place it onto rack.

SBR132C

2. Using Tool, compress rack seal ring securely on rack.

Always insert Tool from the rack gear side.

SST201A

3. Insert new rack oil seal.

IPlace plastic film into rack oil seal to prevent damage by

rack teeth.

IDo not forget to remove plastic film after rack oil seal is

positioned properly.

IMake sure lips of rack oil seal face each other.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING GEAR AND LINKAGE

Inspection (Cont'd)

ST-21