INFINITI QX4 2001 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2371 of 2395

SMT002DA

8. Set an adapter to sun gear as shown in the figure. Remove sun

gear from planetary carrier. Remove main gear bearing, bear-

ing race and thrust needle bearing (front and rear of planetary

carrier) from sun gear.

SMT003D

9. Remove plug bolt, then remove resist spring and pin.

SMT004D

10. Remove snap ring, and remove internal gear.

IDo not reuse snap ring.

SMT005D

11. Remove front oil seal.

IDo not reuse oil seal.

12. Loosen nut of outer lever assembly to pull out cotter pin, and

remove outer lever.

13. Remove inner lever assembly.

DISASSEMBLY

Front Case (Cont'd)

TF-136

Page 2372 of 2395

SMT006D

Front Case

INSPECTIONNBTF0080Planetary CarrierNBTF0080S01IMeasure end play of each pinion gear, and make sure the

measurement is within specification shown below. If out of

specification, replace planetary carrier with new one.

Pinion gear end play:

0.1 - 0.7 mm (0.004 - 0.028 in)

ICheck working face of each gear, bearing and others for

damage, burrs, partial wear, dents and other abnormality. If

any is found, replace planetary carrier with new one.

SMT007D

Sun GearNBTF0080S02ICheck if oil passage of sun gear is clogged. For this, try to pass

a 3.6 mm (0.142 in) dia. wire through oil passage as shown in

the figure.

ICheck sliding/contact surface of each gear, bearing and others

for damage, burrs, partial wear, dents, and other abnormality.

If any is found, replace sun gear with new one.

SMT008D

Internal GearNBTF0080S03ICheck internal gear teeth for damage, partial wear, dents and

other abnormality. If any is found, replace internal gear with

new one.

SMT009D

Shift Rod ComponentsNBTF0080S04ICheck working face of shift rod and fork for wear, partial wear,

bending and other abnormality. If any is found, replace with

new one.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Front Case

TF-137

Page 2373 of 2395

SMT010D

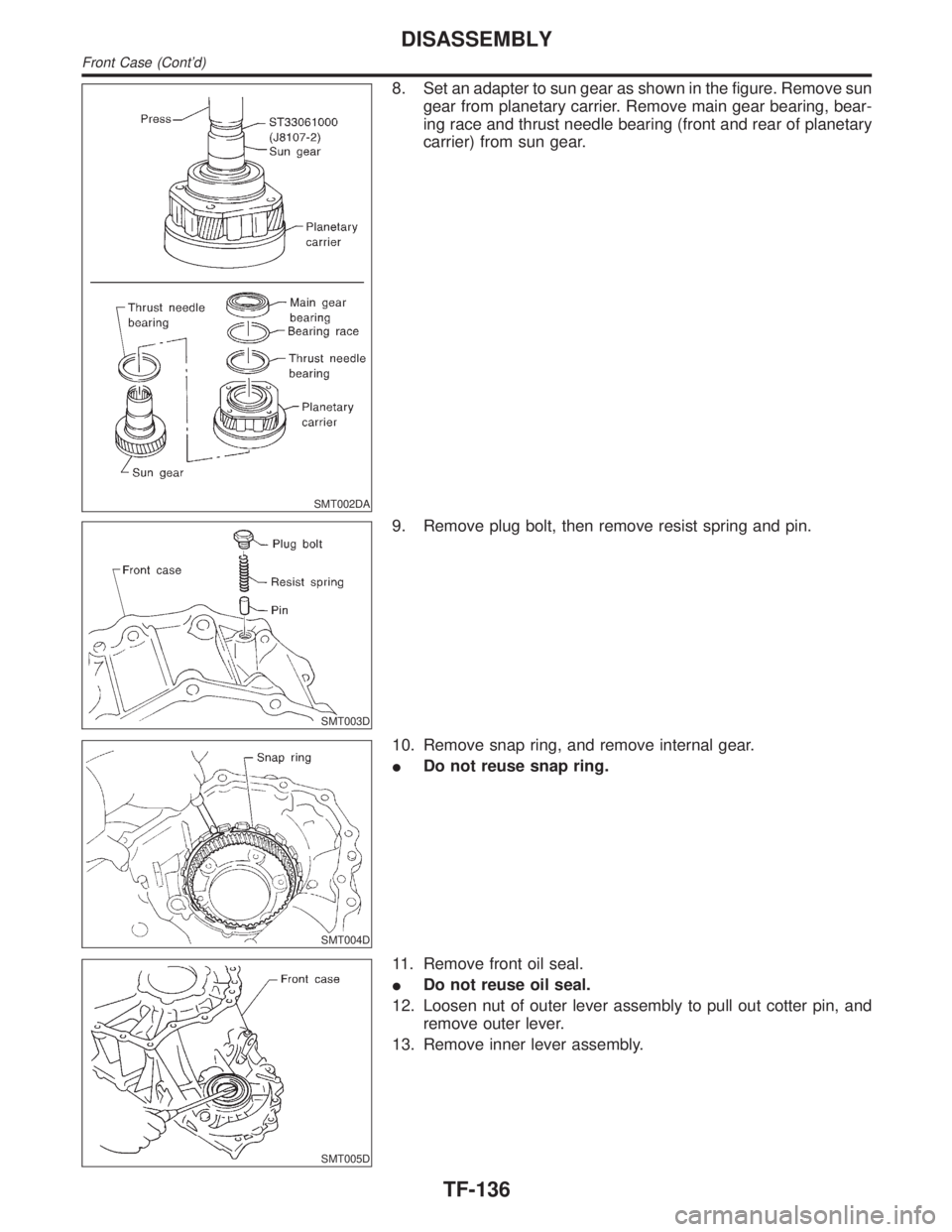

IMeasure clearance between shift fork and sleeve. If it is out of

specification, replace it with new one.

Standard value:

Less than 0.36 mm (0.0142 in)

SMT942C

Center Case

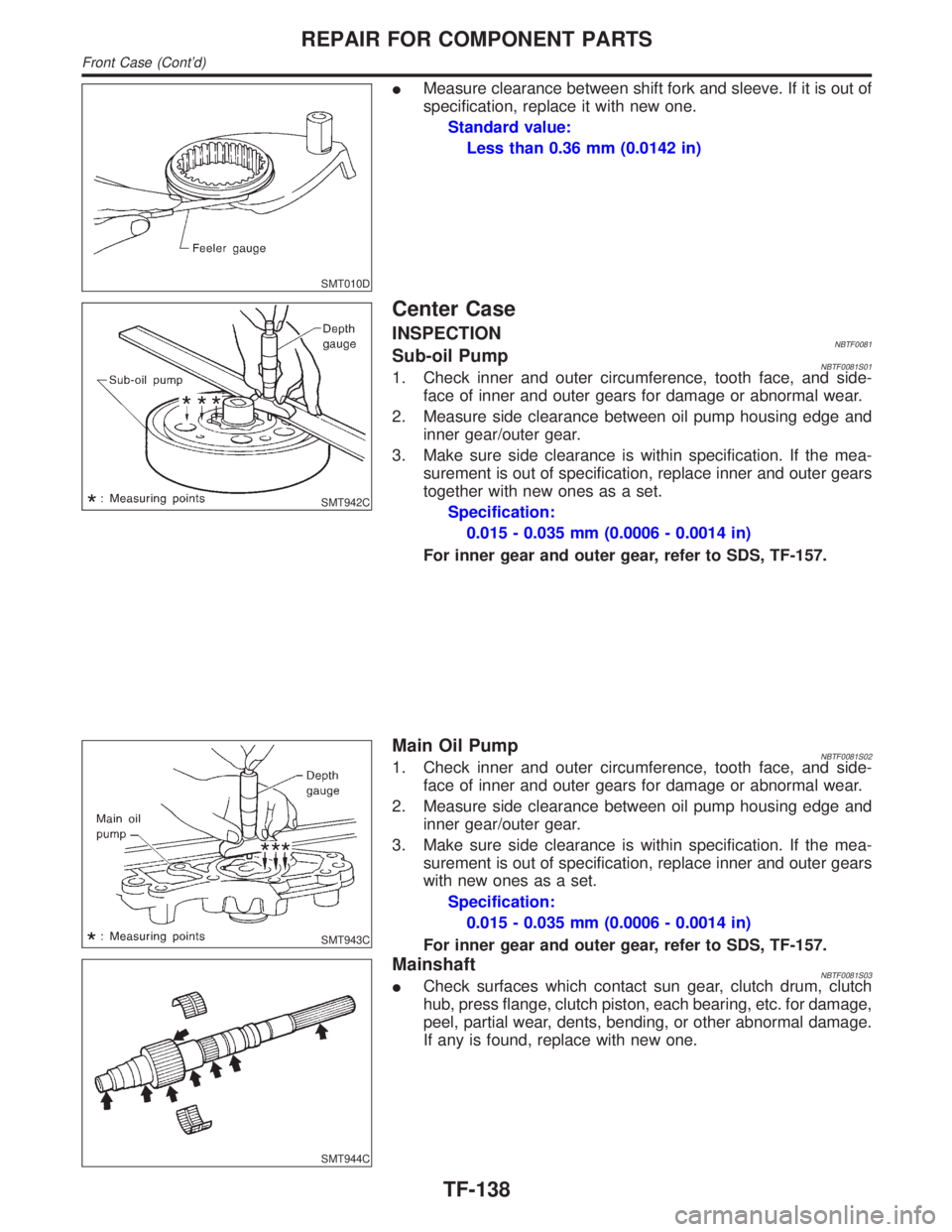

INSPECTIONNBTF0081Sub-oil PumpNBTF0081S011. Check inner and outer circumference, tooth face, and side-

face of inner and outer gears for damage or abnormal wear.

2. Measure side clearance between oil pump housing edge and

inner gear/outer gear.

3. Make sure side clearance is within specification. If the mea-

surement is out of specification, replace inner and outer gears

together with new ones as a set.

Specification:

0.015 - 0.035 mm (0.0006 - 0.0014 in)

For inner gear and outer gear, refer to SDS, TF-157.

SMT943C

Main Oil PumpNBTF0081S021. Check inner and outer circumference, tooth face, and side-

face of inner and outer gears for damage or abnormal wear.

2. Measure side clearance between oil pump housing edge and

inner gear/outer gear.

3. Make sure side clearance is within specification. If the mea-

surement is out of specification, replace inner and outer gears

with new ones as a set.

Specification:

0.015 - 0.035 mm (0.0006 - 0.0014 in)

For inner gear and outer gear, refer to SDS, TF-157.

SMT944C

MainshaftNBTF0081S03ICheck surfaces which contact sun gear, clutch drum, clutch

hub, press flange, clutch piston, each bearing, etc. for damage,

peel, partial wear, dents, bending, or other abnormal damage.

If any is found, replace with new one.

REPAIR FOR COMPONENT PARTS

Front Case (Cont'd)

TF-138

Page 2374 of 2395

SMT945C

Control ValveNBTF0081S04ICheck oil filter screen for damage. If any is found, replace with

new one.

SMT946CA

ICheck resistance between terminals of 4WD solenoid valve,

2-4WD shift solenoid valve and transfer fluid temperature sen-

sor.

Resistance:

Refer to ªCOMPONENT INSPECTIONº, TF-111.

SMT947C

ICheck sliding faces of control valves and plugs for abnormal-

ity. If any is found, replace the control valve assembly with new

one.

CAUTION:

Replace control valve body together with clutch return spring

as a set.

Control valve:

Refer to SDS, TF-157.

SMT948C

ICheck each control valve spring for damage or distortion, and

also check its free length, outer diameter and wire diameter. If

any damage or fatigue is found, replace control valve body with

new one.

IReplace control valve body together with clutch return

spring as a set.

Inspection standard:

Refer to SDS, TF-157.

SMT949C

ClutchNBTF0081S05ICheck drive plate and driven plate facings for damage, cracks

or other abnormality. If any, replace with new one.

ICheck the thickness of drive plate and driven plate facings.

Inspection standard:

Refer to SDS, TF-158.

CAUTION:

IMeasure facing thickness at 3 points to take an average.

ICheck all the drive and driven plates.

ICheck return spring for damage or deformation.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Center Case (Cont'd)

TF-139

Page 2375 of 2395

SMT950C

ICheck stamped mark shown in the figure. Then, check that

free length, outer diameter and wire diameter are within speci-

fications. If any abnormality is found, replace with new return

spring assembly of the same stamped number.

Inspection standard:

Refer to SDS, TF-158.

REPAIR FOR COMPONENT PARTS

Center Case (Cont'd)

TF-140

Page 2376 of 2395

SMT011D

Front Case

ASSEMBLYNBTF0082Planetary Carrier, Sun Gear and Internal GearNBTF0082S011. Apply ATF to oil seal periphery, and install oil seal so that it is

flush with the end face of front case.

IDo not reuse oil seal.

SMT012D

2. Install internal gear with its groove facing snap ring into front

case. Then secure it with snap ring.

IDo not reuse snap ring.

SMT108D

3. Remove all the liquid gasket on plug bolt and front case. Apply

locking sealant to plug bolt, install it to front case and tighten

it to specified torque.

IWith one crest of plug bolt inserted in the hole, apply liquid

gasket 1215 to the thread.

: 19 - 25 N´m (1.9 - 2.5 kg-m, 14 - 18 ft-lb)

SMT014D

4. Install snap ring to main gear bearing.

IDo not reuse snap rings.

SMT015D

5. Set main gear bearing to front case, then press it.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ASSEMBLY

Front Case

TF-141

Page 2377 of 2395

SMT016D

6. Install thrust needle bearing to sun gear.

7. Install sun gear to planetary carrier.

SMT017D

8. Set a support (KV40105500) to bushing replacer puller

(ST30911000) as shown in the figure, and place planetary

carrier on it.

9. Install thrust needle bearing to planetary carrier with its roller

facing front case.

10. Measure ªCº from the end of sun gear to the roller surface of

thrust needle bearing.

SMT018D

11. Measure ªDº from the end of sun gear to the main gear bear-

ing contact surface.

12. Calculate end play ªEº using ªCº and ªDº obtained in steps 10

and 11. Select bearing race so that the end play becomes the

standard value.

Calculation formula:

End play ªEº = ªCº þ ªDº

Standard end play:

0.1 - 0.25 mm (0.0039 - 0.0098 in)

Bearing race:

Refer to SDS, TF-159.

SMT019D

13. Set planetary carrier to press in the status described in step 8.

Then install the selected bearing race to planetary carrier.

SMT020D

14. Install front case to planetary carrier. Set a support ring

(KV40105310) and an adapter B (KV40105230) to main gear

bearing inner race, then press it.

ASSEMBLY

Front Case (Cont'd)

TF-142

Page 2378 of 2395

SMT021D

15. Install washer to sun gear assembly, and select proper snap

ring so that end play ªFº of sun gear is within specifications.

Standard end play ªFº:

0 - 0.15 mm (0 - 0.0059 in)

Snap ring: Refer to SDS, TF-159.

SMT022D

16. Install the selected snap ring.

IDo not reuse snap rings.

17. Apply ATF to the periphery of new transfer cover oil seal, and

attach it at 1.5 mm (0.059 in) from the transfer cover and face.

IDo not reuse oil seal.

SMT023D

18. Apply sealing fluid (Locktite 518´C1335 x 25) to transfer cover

mounting surface of front case as shown in the figure.

CAUTION:

IRemove all foreign materials such as water, oil, and

grease from mating surfaces of front case and transfer

cover.

IPrevent sealing fluid from entering into oil holes of front

case.

SMT024D

19. Align oil hole of front case with notch of transfer cover, and

tighten bolts.

: 49 - 58 N´m (5.0 - 5.9 kg-m, 36 - 43 ft-lb)

IDo not reuse bolts.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ASSEMBLY

Front Case (Cont'd)

TF-143

Page 2379 of 2395

SMT995C

20. Apply petroleum jelly to radial needle bearing, and install it

inside sun gear.

21. Install shift rod assembly to front case assembly. Refer to ªShift

Rod Assemblyº, TF-144.

22. Install center case assembly to front case assembly. Refer to

ªFinal Assemblyº, TF-153.

23. Install rear case assembly to center case. Refer to ªFinal

Assemblyº, TF-153.

SMT994C

Shift Rod AssemblyNBTF0082S021. Install fork guide, shift fork spring, 2-4 fork, and L-H fork to shift

rod, and secure them with roll pins.

IDo not reuse roll pins.

SMT992C

2. Install 2-4 sleeve and L-H sleeve to each fork.

SMT991C

3. While aligning L-H sleeve with planetary carrier, install shift rod

assembly to front case.

SMT990C

4. Remove all the liquid gasket on check plug and front case, and

install check ball and check spring to front case. Apply gasket

fluid 1215 (Three Bond) to check plug, install it to front case,

and tighten it to specified torque.

IWith plug bolt threaded one pitch into the hole, apply gasket

fluid 1215 (Three Bond) to the thread.

: 19 - 25 N´m (1.9 - 2.5 kg-m, 14 - 18 ft-lb)

5. Remove all the liquid gasket on the switch fitting and inner side

of front case, and with wait detection switch threaded one pitch

into the hole, apply gasket fluid 1215 (Three Bond) to the

thread, install it, and tighten it to specified torque.

ASSEMBLY

Front Case (Cont'd)

TF-144

Page 2380 of 2395

: 15 - 20 N´m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

IWait detection switch harness connector is black.

6. Install center case assembly to front case assembly. Refer to

ªFinal Assemblyº, TF-153.

7. Install rear case assembly to center case. Refer to ªFinal

Assemblyº, TF-153.

SMT951C

Center Case

ASSEMBLYNBTF0083Oil FilterNBTF0083S011. Apply ATF or petroleum jelly to new O-ring, and install it to oil

filter stud.

IDo not reuse O-rings.

2. Install oil filter stud to center case, and tighten it.

: 25 - 35 N´m (2.6 - 3.6 kg-m, 19 - 26 ft-lb)

SMT939C

3. Apply ATF or petroleum jelly to two new O-rings, and install

them to oil filter.

IDo not reuse O-rings.

4. Install oil filter to center case and tighten bolts.

:7-9N´m(0.7 - 0.9 kg-m, 61 - 78 in-lb)

IDo not knock oil filter with a tool such as a hammer.

SMT935C

Sub-oil PumpNBTF0083S021. Install new oil pump gasket to center case by aligning it with

dowel pin inside the center case.

IDo not reuse gaskets.

SMT936C

2. Install outer gear* and inner gear to sub-oil pump housing, and

measure side clearance. Refer to ªSub-oil Pumpº,

ªINSPECTIONº, TF-138.

3. Set new O-ring to sub-oil pump housing, and install sub-oil

pump cover.

IDo not reuse O-rings.

* Identification mark ªHº is placed on the side of sub-oil pump

cover.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ASSEMBLY

Front Case (Cont'd)

TF-145