INFINITI QX4 2001 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2381 of 2395

SMT955C

4. Align dowel pin hole and mounting bolt hole of sub-oil pump

assembly with center case. Then tighten bolts.

:7-9N´m(0.7 - 0.9 kg-m, 61 - 78 in-lb)

SMT956C

5. Apply ATF or petroleum jelly to new O-ring and install it to

transfer motor.

6. Fit double-flat end of transfer motor shaft into slot of sub-oil

pump assembly. Then tighten bolts.

: 41 - 48 N´m (4.2 - 4.9 kg-m, 30 - 35 ft-lb)

SMT957C

Main Oil PumpNBTF0083S031. Install inner gear and outer gear in the main oil pump housing

with their identification marks facing toward center case

mounting surface side. Then, measure the side clearance.

Refer to ªMain Oil Pumpº, ªCenter Caseº, TF-138.

SMT930C

2. Install main oil pump assembly to center case assembly, and

tighten bolts.

:7-9N´m(0.7 - 0.9 kg-m, 61 - 78 in-lb)

3. Install oil pump shaft to main oil pump, then install rear case

assembly to center case.

Refer to ªFinal Assemblyº, TF-153.

ASSEMBLY

Center Case (Cont'd)

TF-146

Page 2382 of 2395

SMT928C

SMT926C

Control ValveNBTF0083S041. Clean upper body, control valves and springs with cleaning

agent, and apply air blow.

2. Dip control valves in ATF, and apply ATF to the valve-mount-

ing area of upper body.

3. Install each control valve, spring, and plug to upper body, and

fix it with retainer plates.

CAUTION:

ITo insert control valves into upper body, place upper body

on a level surface in order to prevent flaw or damage.

IMake sure each control valve is smoothly inserted.

4. Install reverse balls, relief balls and relief springs, accumula-

tor pistons, valve springs and two filters to upper body.

SMT925C

5. Install lower body and separator plate to upper body.

IDo not reuse separator plates.

SMT962CA

6. With lower body down, tighten two bolts in the position shown

in the figure.

7. Apply ATF or petroleum jelly to new O-ring, and install it to

2-4WD shift solenoid valve, terminal body, line pressure switch

and 4WD solenoid valve. Install them to control valve assem-

bly.

IDo not reuse O-rings.

SMT922CA

8. Apply ATF or petroleum jelly to lip seals, and install them to

center case.

IDo not reuse lip seals.

IThere are 2 kinds of lip seals (lip seal of large inner diam-

eter: 5 pieces, lip seal of small inner diameter: 2 pieces).

Confirm the position before installation.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ASSEMBLY

Center Case (Cont'd)

TF-147

Page 2383 of 2395

SMT911D

9. Install bolts as shown in the figure, and tighten them to speci-

fied torque.

Bolt symbol a b *c d e f

Length under head

mm (in)38

(1.50)43.5

(1.713)62

(2.44)19

(0.75)52

(2.05)47

(1.85)

Q'ty 1732111

Tightening torque

N´m (kg-m, in-lb)6.9 - 8.8 (0.70 - 0.90, 61.1 - 77.9)

*: Tighten with oil strainer.

SMT920C

10. Install control valve assembly to center case, and tighten bolts.

: 6.9 - 8.8 N´m (0.70 - 0.90 kg-m, 61.1 - 77.9 in-lb)

SMT921C

11. Secure terminal body with snap ring.

SMT919C

12. Apply ATF or petroleum jelly to O-rings, and install them to oil

strainer.

CAUTION:

Do not reuse snap ring.

13. Install oil strainer to control valve assembly.

14. Install mainshaft and clutch drum to center case. Refer to

ªMainshaft and Clutch Drumº, TF-149.

15. Install front case assembly and rear case assembly. Refer to

ªFinal Assemblyº, TF-153.

SMT917C

Clutch PistonNBTF0083S051. Apply ATF to D-ring and lip seal, and install them to clutch pis-

ton.

ASSEMBLY

Center Case (Cont'd)

TF-148

Page 2384 of 2395

SMT969C

2. Set clutch piston to a clutch piston attachment (KV31103400).

SMT970C

3. Set the clutch piston attachment to center case, and install

clutch piston, tap it lightly.

4. Install slide needle bearing race to clutch piston.

SMT915C

5. Remove all the liquid gasket from oil pressure check port and

inside center case. With oil pressure check plug threaded in 1

or 2 pitches, apply gasket fluid 1215 (Three Bond) to the thread

of plug, and tighten.

: 10 - 17 N´m (1.0 - 1.7 kg-m, 87 - 148 in-lb)

6. Install mainshaft and clutch drum. Refer to ªMainshaft and

Clutch Drumº, TF-149.

SMT972C

Mainshaft and Clutch DrumNBTF0083S061. Install drive plates, driven plates and press flange to clutch

hub.

2. Place clutch hub on a surface plate and measure dimension

ªAº between snap ring mounting surface of press flange and

clutch drum sliding face of clutch hub.

CAUTION:

Measure at least 2 points, and take an average.

SMT973C

3. Measure dimension ªBº between the gear end of mainshaft

and the snap ring mounting portion.

4. Calculate end play using dimension ªAº and dimension ªBº

(obtained in steps 2 and 3), and select proper retaining plate

so that the end play is within specifications.

Calculation formula:

End play = B þ A þ Retaining plate thickness

Standard end play:

0.2 - 0.5 mm (0.008 - 0.020 in)

Retaining plate:

Refer to SDS, TF-158.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ASSEMBLY

Center Case (Cont'd)

TF-149

Page 2385 of 2395

SMT974C

5. Install clutch drum, needle bearing and clutch hub to

mainshaft, and secure them with snap ring.

IDo not reuse snap ring.

SMT975C

6. Install each clutch to clutch drum.

SMT911C

7. Align the notch of return spring assembly with the pin of clutch

hub, and install it.

SMT977C

8. Install press flange (with the holes indicated by arrows aligned

with pins of clutch hub).

SMT909C

9. Install washer.

ASSEMBLY

Center Case (Cont'd)

TF-150

Page 2386 of 2395

SMT907C

10. Pass mainshaft through snap ring. Set a drift (KV31103300),

a support ring (KV40104710), a support ring (ST27863000)

and a drift (ST35271000) to press flange at the position shown

in the figure, and press snap ring until it fits into snap ring

groove on mainshaft.

IDo not reuse snap ring.

SMT908C

11. Fix snap ring to mainshaft.

SMT905C

12. Install thrust needle bearing to press flange.

SMT982C

13. Apply petroleum jelly to new seal rings, and install them to

mainshaft. Measure clearance between seal ring and groove

using feeler gauge.

Standard clearance:

0.05 - 0.30 mm (0.0020 - 0.0118 in)

Limit clearance:

0.30 mm (0.0118 in)

IPass seal ring from mainshaft rear end to install it.

Seal ring dimension:

Refer to SDS, TF-159.

SMT983C

14. Install mainshaft rear bearing to center case.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ASSEMBLY

Center Case (Cont'd)

TF-151

Page 2387 of 2395

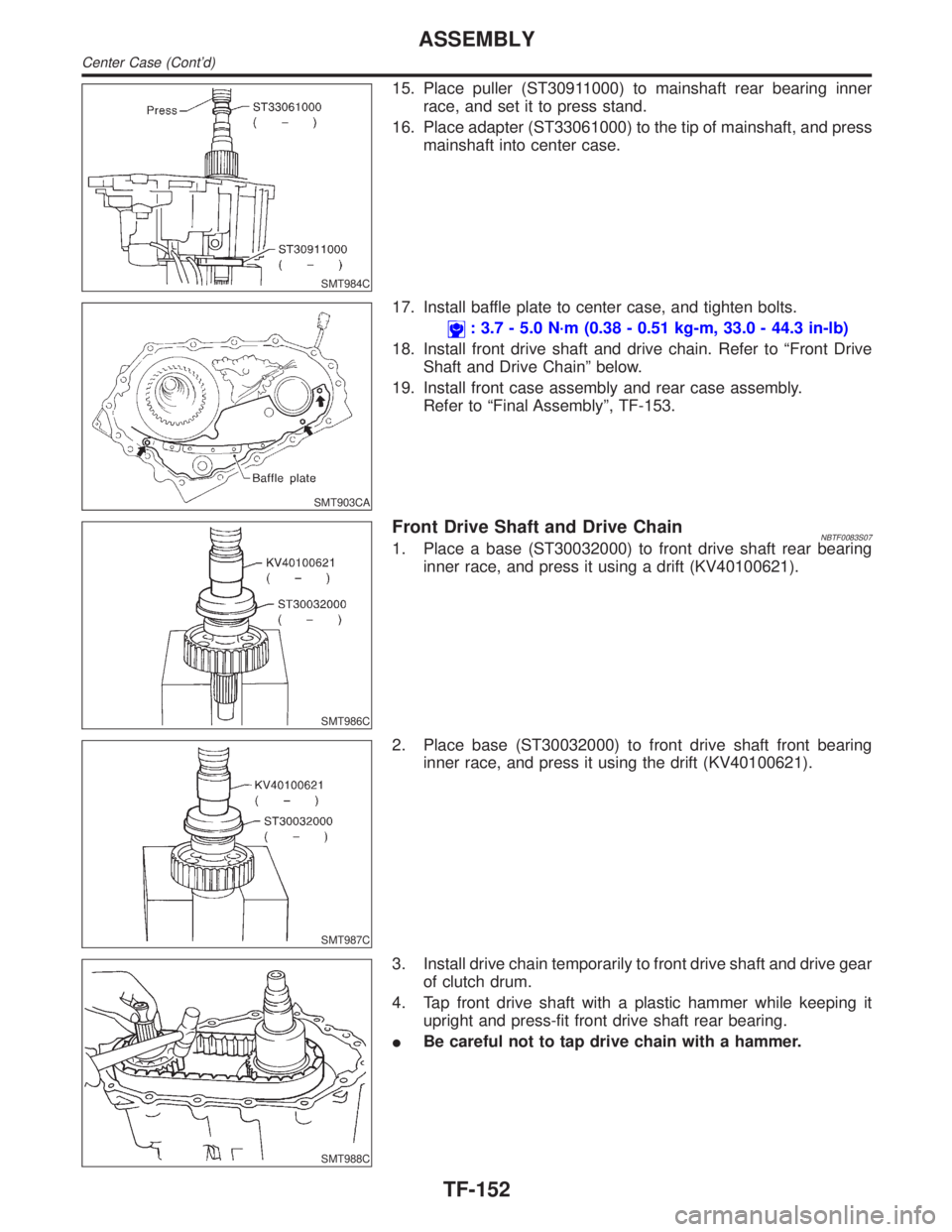

SMT984C

15. Place puller (ST30911000) to mainshaft rear bearing inner

race, and set it to press stand.

16. Place adapter (ST33061000) to the tip of mainshaft, and press

mainshaft into center case.

SMT903CA

17. Install baffle plate to center case, and tighten bolts.

: 3.7 - 5.0 N´m (0.38 - 0.51 kg-m, 33.0 - 44.3 in-lb)

18. Install front drive shaft and drive chain. Refer to ªFront Drive

Shaft and Drive Chainº below.

19. Install front case assembly and rear case assembly.

Refer to ªFinal Assemblyº, TF-153.

SMT986C

Front Drive Shaft and Drive ChainNBTF0083S071. Place a base (ST30032000) to front drive shaft rear bearing

inner race, and press it using a drift (KV40100621).

SMT987C

2. Place base (ST30032000) to front drive shaft front bearing

inner race, and press it using the drift (KV40100621).

SMT988C

3. Install drive chain temporarily to front drive shaft and drive gear

of clutch drum.

4. Tap front drive shaft with a plastic hammer while keeping it

upright and press-fit front drive shaft rear bearing.

IBe careful not to tap drive chain with a hammer.

ASSEMBLY

Center Case (Cont'd)

TF-152

Page 2388 of 2395

SMT989C

5. Align claw of oil gutter with center case, and install it.

6. Install front case assembly and rear case assembly.

Refer to ªFinal Assemblyº, TF-153.

SMT891C

Final AssemblyNBTF00841. Install C-rings to mainshaft rear bearing.

SMT889C

2. Check speedometer drive gear teeth for abnormal wear. Set

speedometer drive gear properly on mainshaft, and secure it

with snap ring.

IDo not reuse snap ring.

SMT893C

3. Apply sealing fluid 518 (Locktite) to the entire center case

mounting surface of front case as shown in the figure.

CAUTION:

Remove all foreign materials such as water, oil and grease

from center case and front case mating surfaces.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ASSEMBLY

Center Case (Cont'd)

TF-153

Page 2389 of 2395

SMT894C

4. Make sure the two claws of oil gutter are securely attached to

slots in center case.

SMT895C

5. With the claws of oil gutter held by a finger, install center case

assembly to front case assembly.

CAUTION:

Pay careful attention so that mainshaft end does not damage

radial needle bearing in sun gear assembly.

6. Tap center case lightly with a rubber hammer or the like and

press-fit front drive shaft bearing into front case.

SMT896C

7. Make sure oil gutter rear end protrudes from point ªAº in the

figure.

8. Tighten bolts to specified torque.

: 41 - 48 N´m (4.2 - 4.9 kg-m, 30 - 35 ft-lb)

IBe sure to install air breather hose clamp, connector

bracket and harness clip.

SMT883C

9. Fit double-flat end of oil pump shaft into slot of main oil pump

and install it.

NOTE:

When oil pump shaft is rotated slightly, it drops into position where

both parts fit.

SMT884C

10. Install stem bleeder to center case.

ASSEMBLY

Final Assembly (Cont'd)

TF-154

Page 2390 of 2395

SMT881C

11. Remove rear oil seal.

IDo not reuse oil seal.

SMT882C

12. Apply ATF to the circumference of new rear oil seal, and tap it

using a drift as shown in the figure so that it is aligned with

case tip face.

IApply multi-purpose grease to oil seal lip.

SMT879C

13. Apply sealing fluid 518 (Locktite) to entire rear case mounting

surface of center case as shown in the figure.

CAUTION:

IRemove all foreign materials such as water, oil, and

grease from center case and rear case mating surfaces.

IBe careful not to allow sealing fluid to clog bleeder hole.

14. Install rear case to center case, and tighten bolts to specified

torque.

: 41 - 48 N´m (4.2 - 4.9 kg-m, 30 - 35 ft-lb)

IBe sure to attach harness clips.

SMT880C

15. Remove all the gasket fluid 1215 (Three Bond) from switch

mounting area and inside rear case, with ATP switch and neu-

tral-4LO switch threaded in 1 to 2 pitches, apply gasket fluid

1215 (Three Bond) to the thread of the switches and tighten it

to specified torque.

: 15 - 20 N´m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

16. Install rear case assembly to center case assembly.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ASSEMBLY

Final Assembly (Cont'd)

TF-155