INFINITI QX56 2011 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 5571 of 5598

WW-52

< SYMPTOM DIAGNOSIS >

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006300483

FRONT WIPER MOTOR PROTECTION FUNCTION

IPDM E/R may stop the front wiper to protect the front wiper motor if any obstruction (operation resistance)

such as a large amount of snow is detected during the front wiper operation.

At that time turn OFF the front wiper and remove t he foreign object. Then wait for approximately 20 seconds

or more and reactivate the front wiper. The wiper will operate normally.

REAR WIPER MOTOR PROTECTION FUNCTION

BCM may stop rear wiper to protect the rear wiper motor when the rear wiper is stopped for 5 seconds or

more due to a snowfall.

Rear wiper operates normally one minute after t he obstacles are removed with rear wiper OFF.

Revision: 2010 May2011 QX56

Page 5572 of 5598

FRONT WIPER DOES NOT OPERATEWW-53

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

FRONT WIPER DO ES NOT OPERATE

DescriptionINFOID:0000000006300484

The front wiper does not operate under any operation conditions.

Diagnosis ProcedureINFOID:0000000006300485

1.CHECK WIPER RELAY OPERATION

CONSULT-III ACTIVE TEST

1. Select “FRONT WIPER” of IPDM E/R active test item.

2. With operating the test item, check front wiper operation.

Is front wiper operation normally?

YES >> GO TO 5.

NO >> GO TO 2.

2.CHECK FRONT WIPER MOTOR FUSE

Check front wiper motor fuse. Refer to WW-35, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace the fuse after repairing the applicable circuit.

3.CHECK FRONT WIPER MOTOR GROUND CIRCUIT

Check front wiper motor ground circuit. Refer to WW-39, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK FRONT WIPER MOTOR INPUT VOLTAGE

CONSULT-III ACTIVE TEST

1. Turn ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Turn ignition switch ON.

4. Select “FRONT WIPER” of IPDM E/R active test item.

5. With operating the test item, check voltage between front wiper motor harness connector and ground.

Is the inspection result normal?

YES >> Replace front wiper motor.

NO >> Replace IPDM E/R.

5.CHECK FRONT WIPER REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select “FR WIP REQ” of IPDM E/R data monitor item.

2. Switch the front wiper switch to HI and LO. Lo : Front wiper LO operation

Hi : Front wiper HI operation

Off : Stop the front wiper.

(+)

(− ) Condition Voltage (Approx.)

Front wiper motor

Connector Terminal

E42 1

Ground FRONT WIPER Lo Battery voltage

Off 0 V

4 Hi Battery voltage

Off 0 V

Revision: 2010 May2011 QX56

Page 5573 of 5598

WW-54

< SYMPTOM DIAGNOSIS >

FRONT WIPER DOES NOT OPERATE

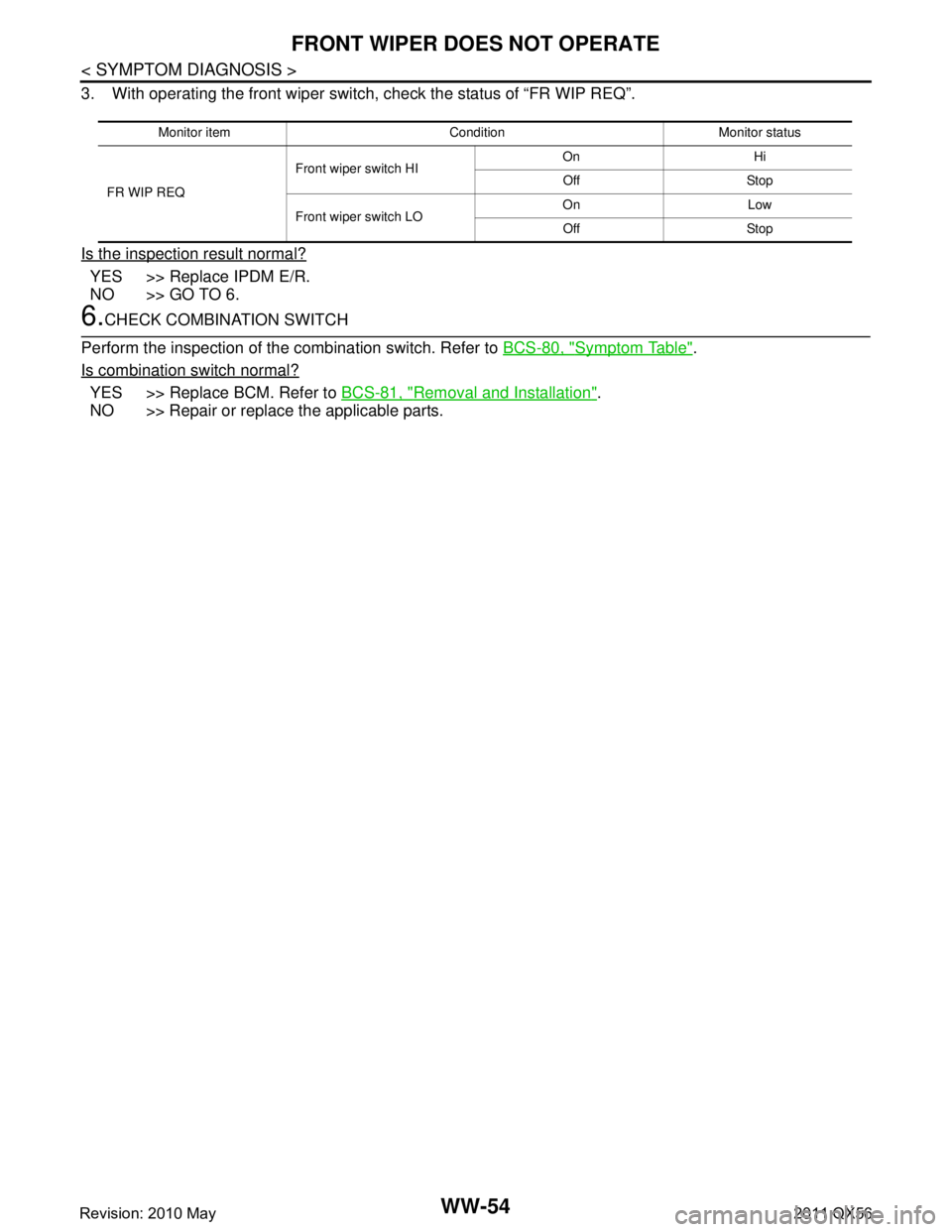

3. With operating the front wiper switch, check the status of “FR WIP REQ”.

Is the inspection result normal?

YES >> Replace IPDM E/R.

NO >> GO TO 6.

6.CHECK COMBINATION SWITCH

Perform the inspection of the combination switch. Refer to BCS-80, "

Symptom Table".

Is combination switch normal?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation".

NO >> Repair or replace the applicable parts.

Monitor item Condition Monitor status

FR WIP REQ Front wiper switch HI

On Hi

Off Stop

Front wiper switch LO On Low

Off Stop

Revision: 2010 May2011 QX56

Page 5574 of 5598

HEADLAMP WASHER NOZZLE AND TUBEWW-55

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

REMOVAL AND INSTALLATION

HEADLAMP WASHER NOZZLE AND TUBE

Exploded ViewINFOID:0000000006220393

Hydraulic LayoutINFOID:0000000006220394

1. Headlamp washer nozzle cover 2. Headlamp washer nozzle assembly 3. Headlamp washer nozzle retainer

4. Headlamp washer nozzle bracket 5. Front bumper fascia : Pawl

JMLIA1096ZZ

1. Headlamp washer nozzle assembly LH 2. Headlamp washer tube 3. Headlamp washer tube (tank side)

4. Headlamp washer nozzle assembly RH 5. Front bumper fascia

A. Metal clip

JMLIA1097ZZ

Revision: 2010 May2011 QX56

Page 5575 of 5598

WW-56

< REMOVAL AND INSTALLATION >

HEADLAMP WASHER NOZZLE AND TUBE

Removal and Installation

INFOID:0000000006220395

REMOVAL

1. Pull out headlamp washer nozzle from bumper fascia, disen- gage pawl (A), and then remove headlamp washer nozzle cover

(1).

2. Remove front bumper fascia. Refer to EXT-13, "

Removal and Installation".

3. Disconnect headlamp washer tube joint.

4. Remove headlamp washer nozzle retainer.

5. Remove headlamp washer nozzle bracket.

6. Remove headlamp washer nozzle from the front bumper fascia.

INSTALLATION

Install in the reverse order of removal.

InspectionINFOID:0000000006220396

HEADLAMP WASHER NOZZLE SPRAY POSITION INSPECTION

CAUTION:

Replace headlamp washer nozzle assembly with a new pa rt if headlamp washer jet position is outside

the headlamp illumination area shown in the figure.

Check that headlamp washer injection is certainly on headlamp

illumination area.

Check the headlamp washer injection range as shown in the fig- ure.

JPLIA1030ZZ

JMLIA1098ZZ

a : 67.8 mm (2.31 in)

B : 83.2 mm (3.04 in)

C : 316.2 mm (12.13 in)

JMLIA1099ZZ

Revision: 2010 May2011 QX56

Page 5576 of 5598

HEADLAMP WASHER NOZZLE AND TUBEWW-57

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

Check the headlamp washer nozzle spray angle.

Outside (A)

Inside (B)

NOTE:

This drawing shows the parts of the headlamp washer nozzle (LH). The headlamp washer nozzle (RH) is

symmetrical of this drawing.

1. Headlamp washer nozzle (outside) 2. Headlamp washer nozzle (inside)

JPLIA1033ZZ

a: 30 °± 3°

b: 70 °± 3°

c: 55 °± 3°

d: 45 °± 3°

Revision: 2010 May2011 QX56

Page 5577 of 5598

WW-58

< REMOVAL AND INSTALLATION >

WASHER TANK

WASHER TANK

Exploded ViewINFOID:0000000006220397

Removal and InstallationINFOID:0000000006220398

REMOVAL

1. Fully open hood.

2. Remove washer tank inlet fixing clip (A).

3. Pull out washer tank inlet (1) from washer tank.

4. Remove fender protector RH (front). Refer to EXT-23, "

FENDER PROTECTOR : Removal and Installa-

tion".

5. Disconnect washer pump connector.

6. Disconnect headlamp washer pump connector.

7. Disconnect washer level switch connector.

8. Disconnect front washer tube and rear washer tube.

9. Disconnect headlamp washer tube joint.

10. Remove washer tank mounting bolts.

1. Washer tank 2. Washer tank inlet

: Vehicle front

Refer to GI-4, "

Components" for the symbols in the figure.

JMLIA0932GB

: Vehicle front

JMLIA0933ZZ

Revision: 2010 May2011 QX56

Page 5578 of 5598

WASHER TANKWW-59

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

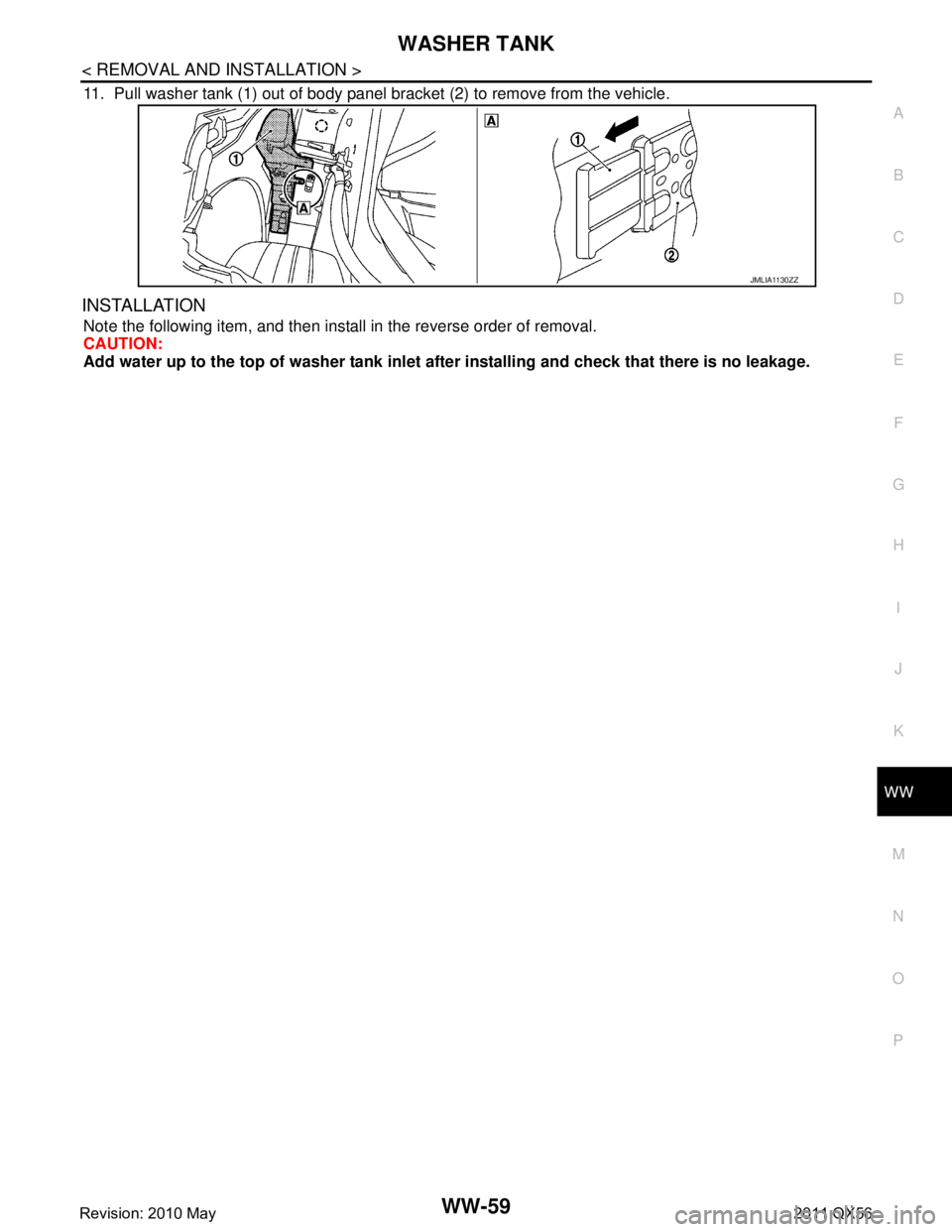

11. Pull washer tank (1) out of body panel bracket (2) to remove from the vehicle.

INSTALLATION

Note the following item, and then install in the reverse order of removal.

CAUTION:

Add water up to the top of washer tank inlet af ter installing and check that there is no leakage.

JMLIA1130ZZ

Revision: 2010 May2011 QX56

Page 5579 of 5598

WW-60

< REMOVAL AND INSTALLATION >

WASHER PUMP

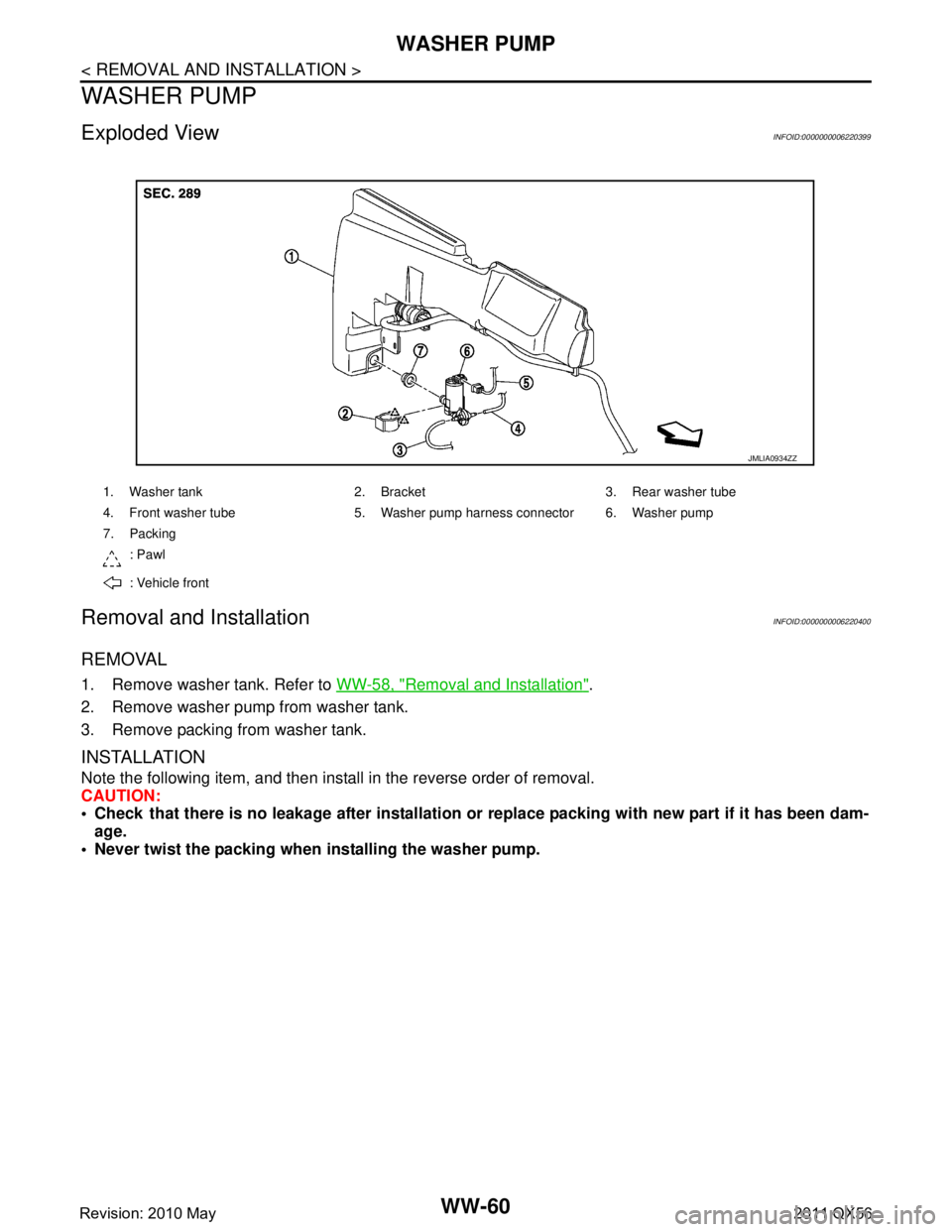

WASHER PUMP

Exploded ViewINFOID:0000000006220399

Removal and InstallationINFOID:0000000006220400

REMOVAL

1. Remove washer tank. Refer to WW-58, "Removal and Installation".

2. Remove washer pump from washer tank.

3. Remove packing from washer tank.

INSTALLATION

Note the following item, and then install in the reverse order of removal.

CAUTION:

Check that there is no leakage after installation or replace packing with new part if it has been dam-

age.

Never twist the packing when installing the washer pump.

1. Washer tank 2. Bracket 3. Rear washer tube

4. Front washer tube 5. Washer pump harness connector 6. Washer pump

7. Packing

: Pawl

: Vehicle front

JMLIA0934ZZ

Revision: 2010 May2011 QX56

Page 5580 of 5598

HEADLAMP WASHER PUMPWW-61

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

HEADLAMP WASHER PUMP

Exploded ViewINFOID:0000000006220401

Removal and InstallationINFOID:0000000006220402

REMOVAL

1. Remove washer tank. Refer to WW-58, "Removal and Installation".

2. Remove the mounting bolt, and then remove headlamp washer pump from the washer tank.

3. Remove the packing from the washer tank.

INSTALLATION

Note the following item, and then install in the reverse order of removal.

CAUTION:

Check that there is no leakage after installation or replace packing with new part if it has been dam-

age.

Never twist the packing when inst alling the headlamp washer pump.

1. Washer tank 2. Headlamp washer tube 3. Headlamp washer pump harness

connector

4. Headlamp washer pump 5. Packing : Vehicle front

JMLIA0935ZZ

Revision: 2010 May2011 QX56