INFINITI QX56 2011 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 5531 of 5598

WW-12

< SYSTEM DESCRIPTION >

SYSTEM

- Rear washer switch ON (0.4 second or more)

The washer pump is grounded through the combination switch with the rear washer switch ON.

REAR WIPER OPERATION LINKED WITH REVERSE (WITH RAIN SENSOR)

BCM controls rear wiper to operate once according to the conditions of rear wiper operation linked with

reverse.

Condition of rear wiper operation linked with reverse - Ignition switch ON

- Front wiper switch: LO, HI or AUTO, and the front wiper auto operation ON judgement.

- Rear wiper switch OFF

- Selector lever “R”

TCM transmits the shift position signal to BCM thr ough the CAN communication line when the selector lever

is shifted to "R".

BCM supplies power to the rear wiper motor when receiving the shift position signal.

REAR WIPER OPERATION LINKED WITH REVERSE (WITHOUT RAIN SENSOR)

BCM controls rear wiper to operate once according to the conditions of rear wiper operation linked with

reverse.

Condition of rear wiper operation linked with reverse

- Ignition switch ON

- Front wiper switch: LO, HI or INT.

- Rear wiper switch OFF

- Selector lever “R”

TCM transmits the shift position signal to BCM thr ough the CAN communication line when the selector lever

is shifted to "R".

BCM supplies power to the rear wiper motor when receiving the shift position signal.

REAR WIPER DROP WIPE OPERATION

BCM controls the rear wiper to operate once acco rding to the rear wiper drop wipe operating condition.

Rear wiper drop wipe operating condition- Ignition switch ON

- Rear wiper switch OFF

- Rear washer switch OFF

BCM controls the rear wiper so that it operates once approximately three seconds later after the washer

interlocking operation of the rear wiper.

REAR WIPER AND WASHER SYSTEM : Fail SafeINFOID:0000000006300459

REAR WIPER MOTOR PROTECTION

BCM detects the rear wiper stopping position ac cording to the rear wiper auto stop signal.

When the rear wiper auto stop signal does not change more than 5 seconds while driving the rear wiper, BCM

stops power supply to protect the rear wiper motor.

Condition of cancellation

1. Pass more than 1 minute after the rear wiper stop.

2. Operate the rear wiper switch.

HEADLAMP WASHER SYSTEM

Revision: 2010 May2011 QX56

Page 5532 of 5598

SYSTEMWW-13

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

HEADLAMP WASHER SYSTEM : System DiagramINFOID:0000000006372942

HEADLAMP WASHER SYSTEM : System DescriptionINFOID:0000000006372943

OUTLINE

Headlamp washer is controlled by each function of BCM and IPDM E/R.

Control by BCM Combination switch reading function

Headlamp washer control function

Control by IPDM E/R Headlamp washer relay control function

HEADLAMP WASHER BASIC OPERATION

BCM detects the combination switch conditi on by the combination switch reading function.

BCM transmits the headlamp washer request signal to IPDM E/R with CAN communication depending on

each operating condition of the headlamp washer.

Operation by front washer switch (The first time)

- Ignition switch ON

- Headlamps ON

- Front washer switch ON at first time

Operation by front washer switch (From the second time)- Ignition switch ON

- Headlamps ON

- Front washer switch ON at fifth time after the first time

IPDM E/R turns ON/OFF the headlamp washer relay by receiving the headlamp washer request signal, and

controls the headlamp washer.

JPLIA1329GB

JPLIA1391GB

Revision: 2010 May2011 QX56

Page 5533 of 5598

WW-14

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000006349813

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate ea ch device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 5534 of 5598

DIAGNOSIS SYSTEM (BCM)WW-15

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

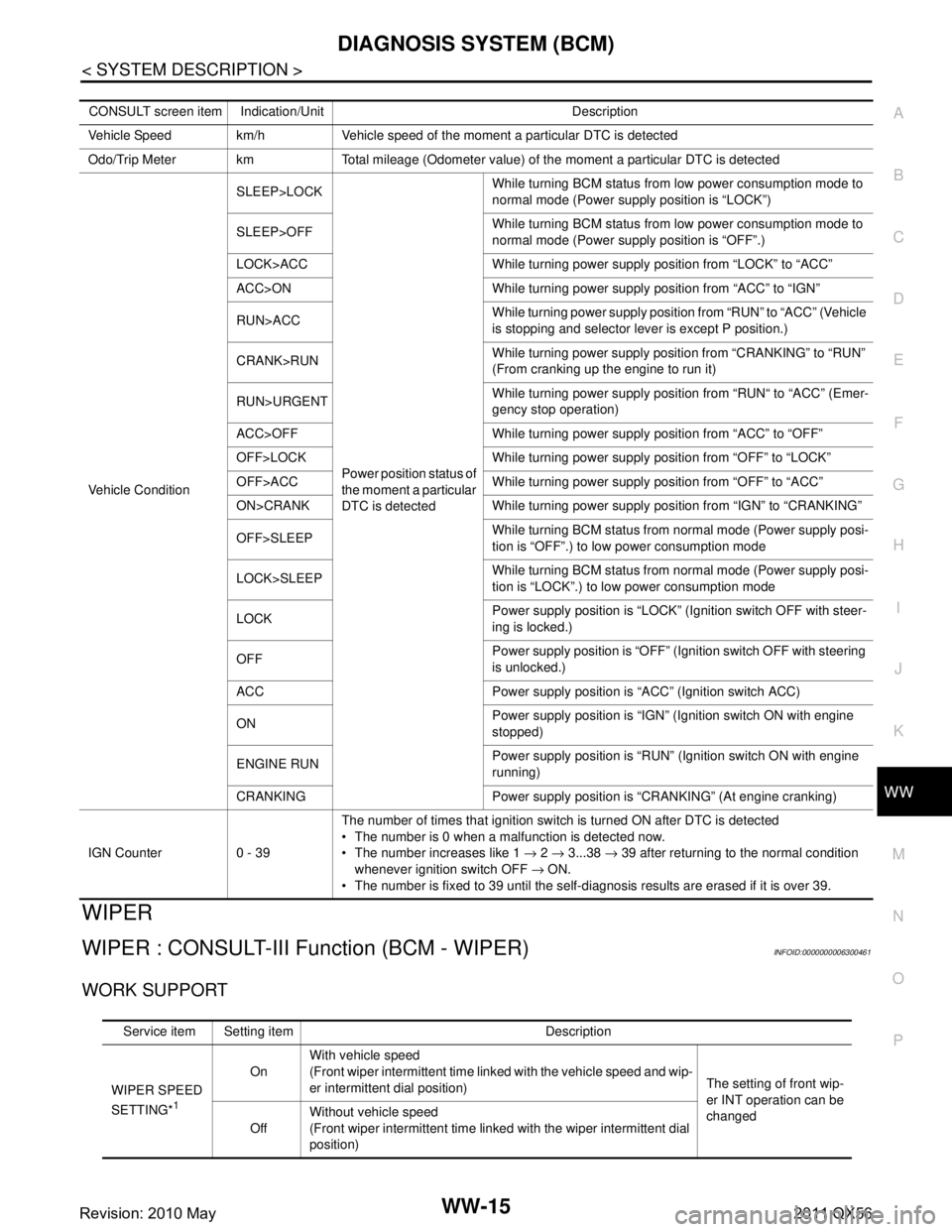

WIPER

WIPER : CONSULT-III Function (BCM - WIPER)INFOID:0000000006300461

WORK SUPPORT

CONSULT screen item Indication/Unit Description

Vehicle Speed km/h Vehicle speed of the moment a particular DTC is detected

Odo/Trip Meter km Total mileage (Odometer value) of the moment a particular DTC is detected

Vehicle Condition SLEEP>LOCK

Power position status of

the moment a particular

DTC is detected While turning BCM status from low power consumption mode to

normal mode (Power supply position is “LOCK”)

SLEEP>OFF While turning BCM status from low power consumption mode to

normal mode (Power supply position is “OFF”.)

LOCK>ACC While turning power supply position from “LOCK” to “ACC”

ACC>ON While turning power supply position from “ACC” to “IGN”

RUN>ACC While turning power supply position

from “RUN” to “ACC” (Vehicle

is stopping and selector lever is except P position.)

CRANK>RUN While turning power su

pply position from “CRANKING” to “RUN”

(From cranking up the engine to run it)

RUN>URGENT While turning power su

pply position from “RUN“ to “ACC” (Emer-

gency stop operation)

ACC>OFF While turning power supply position from “ACC” to “OFF”

OFF>LOCK While turning power supply position from “OFF” to “LOCK”

OFF>ACC While turning power supply position from “OFF” to “ACC”

ON>CRANK While turning po wer supply position from “IGN” to “CRANKING”

OFF>SLEEP While turning BCM status from normal mode (Power supply posi-

tion is “OFF”.) to low power consumption mode

LOCK>SLEEP While turning BCM status from normal mode (Power supply posi-

tion is “LOCK”.) to low power consumption mode

LOCK Power supply position is “LOCK” (Ignition switch OFF with steer-

ing is locked.)

OFF Power supply position

is “OFF” (Ignition switch OFF with steering

is unlocked.)

ACC Power supply position is “ACC” (Ignition switch ACC)

ON Power supply position is “IGN” (Ignition switch ON with engine

stopped)

ENGINE RUN Power supply posi

tion is “RUN” (Ignition switch ON with engine

running)

CRANKING Power supply position is “CRANKING” (At engine cranking)

IGN Counter 0 - 39 The number of times that ignition switch is turned ON after DTC is detected

The number is 0 when a malfunction is detected now.

The number increases like 1

→ 2 → 3...38 → 39 after returning to the normal condition

whenever ignition switch OFF → ON.

The number is fixed to 39 until the self-diagnosis results are erased if it is over 39.

Service item Setting item Description

WIPER SPEED

SETTING*

1

On With vehicle speed

(Front wiper intermittent time linked with the vehicle speed and wip-

er intermittent dial position)

The setting of front wip-

er INT operation can be

changed

Off Without vehicle speed

(Front wiper intermittent time linked with the wiper intermittent dial

position)

Revision: 2010 May2011 QX56

Page 5535 of 5598

WW-16

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

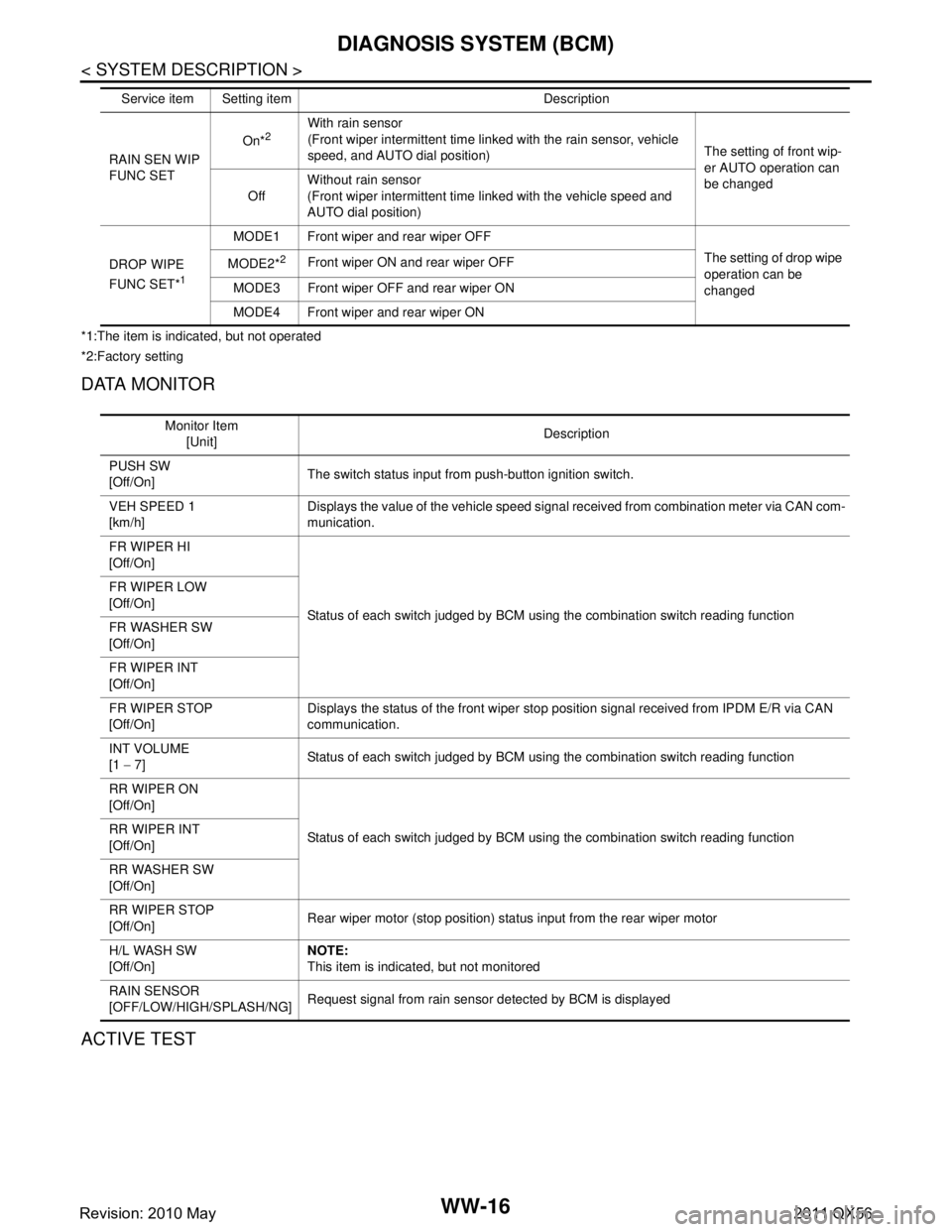

*1:The item is indicated, but not operated

*2:Factory setting

DATA MONITOR

ACTIVE TEST

RAIN SEN WIP

FUNC SETOn*

2With rain sensor

(Front wiper intermittent time linked with the rain sensor, vehicle

speed, and AUTO dial position)

The setting of front wip-

er AUTO operation can

be changed

Off Without rain sensor

(Front wiper intermittent time linked with the vehicle speed and

AUTO dial position)

DROP WIPE

FUNC SET*

1

MODE1 Front wiper and rear wiper OFF The setting of drop wipe

operation can be

changed

MODE2*

2Front wiper ON and rear wiper OFF

MODE3 Front wiper OFF and rear wiper ON

MODE4 Front wiper and rear wiper ON

Service item Setting item Description

Monitor Item

[Unit] Description

PUSH SW

[Off/On] The switch status input from push-button ignition switch.

VEH SPEED 1

[km/h] Displays the value of the vehicle speed signal received from combination meter via CAN com-

munication.

FR WIPER HI

[Off/On]

Status of each switch judged by BCM using the combination switch reading function

FR WIPER LOW

[Off/On]

FR WASHER SW

[Off/On]

FR WIPER INT

[Off/On]

FR WIPER STOP

[Off/On]

Displays the status of the front wiper stop position signal received from IPDM E/R via CAN

communication.

INT VOLUME

[1 − 7] Status of each switch judged by BCM using the combination switch reading function

RR WIPER ON

[Off/On] Status of each switch judged by BCM using the combination switch reading function

RR WIPER INT

[Off/On]

RR WASHER SW

[Off/On]

RR WIPER STOP

[Off/On] Rear wiper motor (stop position) status input from the rear wiper motor

H/L WASH SW

[Off/On] NOTE:

This item is indicated, but not monitored

RAIN SENSOR

[OFF/LOW/HIGH/SPLASH/NG] Request signal from rain sensor detected by BCM is displayed

Revision: 2010 May2011 QX56

Page 5536 of 5598

DIAGNOSIS SYSTEM (BCM)WW-17

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

Test item Operation Description

FR WIPER Hi

Transmits the front wiper request signal (HI) to IPDM E/R via CAN communication to op-

erate the front wiper HI operation.

Lo Transmits the front wiper request signal (LO) to IPDM E/R via CAN communication to

operate the front wiper LO operation.

INT Transmits the front wiper request signal (INT) to IPDM E/R via CAN communication to

operate the front wiper INT operation.

Off Stops transmitting the front wiper request signal to stop the front wiper operation.

RR WIPER On Output the voltage to operate the rear wiper motor.

Off Stops the voltage to stop the rear wiper motor.

HEADLAMP WASH-

ER On

Transmits the headlamp washer request signal to IPDM E/R via CAN communication to

operate the headlamp washer operation.

Revision: 2010 May2011 QX56

Page 5537 of 5598

WW-18

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (IPDM E/R)

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000006349814

AUTO ACTIVE TEST

Description

In auto active test, the IPDM E/R sends a drive signal to the following systems to check their operation.

Oil pressure warning lamp

Rear window defogger

Front wiper (LO, HI)

Parking lamp

License plate lamp

Tail lamp

Side marker lamp

Front fog lamp

Headlamp (LO, HI)

A/C compressor (magnet clutch)

Operation Procedure

CAUTION:

Never perform auto active test in the following conditions.

Engine is running.

CONSULT-III is connected.

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn the ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, pr ess the driver door switch 10 times. Then turn the

ignition switch OFF.

CAUTION:

Close passenger door.

4. Turn the ignition switch ON within 10 seconds. Af ter that the horn sounds once and the auto active test

starts.

CAUTION:

Engine starts when igniti on switch is turned ON while brake pedal is depressed.

5. The oil pressure warning lamp starts blinking when the auto active test starts.

6. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

When auto active test has to be cancelled halfway through test, turn the ignition switch OFF.

When auto active test is not activated, door swit ch may be the cause. Check door switch. Refer to DLK-117,

"ComponentFunctionCheck".

Inspection in Auto Active Test

When auto active test is actuated, the following operation sequence is repeated 3 times.

Operation

sequence Inspection location Operation

1 Oil pressure warning lamp Blinks continuously during operation of auto active test

2 Rear window defogger 10 seconds

3 Front wiper LO for 5 seconds → HI for 5 seconds

4 Parking lamp

License plate lamp

Tail lamp

Side marker lamp

Front fog lamp 10 seconds

Revision: 2010 May2011 QX56

Page 5538 of 5598

DIAGNOSIS SYSTEM (IPDM E/R)WW-19

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

Concept of auto active test

IPDM E/R starts the auto active test with the door

switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto

active test starts successfully.

The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

Diagnosis chart in auto active test

5 Headlamp LO for 10 seconds →HI ON ⇔ OFF 5 times

6 A/C compressor (magnet clutch) ON ⇔ OFF 5 times

Operation

sequence Inspection location Operation

JMMIA0492GB

Symptom Inspection contents Possible cause

Rear window defogger does not operate Perform auto active test.

Does the rear window defog-

ger operate?YES BCM signal input circuit

NO Rear window defogger

Rear window defogger

ground circuit

Harness or connector be- tween IPDM E/R and rear

window defogger

IPDM E/R

Any of the following components do not operate

Parking lamp

License plate lamp

Tail lamp

Side marker lamp

Front fog lamp

Headlamp (HI, LO)

Front wiper (HI, LO) Perform auto active test.

Does the applicable system

operate?YES BCM signal input circuit

NO Lamp or motor

Lamp or motor ground cir-

cuit

Harness or connector be- tween IPDM E/R and appli-

cable system

IPDM E/R

A/C compressor does not operate Perform auto active test.

Does the magnet clutch oper-

ate?YES

A/C auto amp. signal input

circuit

CAN communication signal

between A/C auto amp. and

ECM

CAN communication signal

between ECM and IPDM E/

R

NO Magnet clutch

Harness or connector be-

tween IPDM E/R and mag-

net clutch

IPDM E/R

Revision: 2010 May2011 QX56

Page 5539 of 5598

WW-20

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (IPDM E/R)

CONSULT-III Function (IPDM E/R)

INFOID:0000000006349815

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with IPDM E/R.

SELF DIAGNOSTIC RESULT

Refer to PCS-22, "DTCIndex".

DATA MONITOR

Monitor item

Oil pressure warning lamp does not operate Perform auto active test.

Does the oil pressure warning

lamp blink?YES

Harness or connector be-

tween IPDM E/R and oil

pressure switch

Oil pressure switch

IPDM E/R

NO CAN communication signal

between IPDM E/R and

BCM

CAN communication signal

between BCM and combi-

nation meter

Combination meter

Symptom Inspection contents Possible cause

Diagnosis mode Description

Ecu Identification Allows confirmation of IPDM E/R part number.

Self Diagnostic Result Displays the diagnosis results judged by IPDM E/R.

Data Monitor Displays the real-time input/output data from IPDM E/R input/output data.

Active Test IPDM E/R can provide a drive signal to electronic components to check their operations.

CAN Diag Support Monitor The results of transmit/receive diagnosis of CAN communication can be read.

Monitor Item [Unit] MAIN SIG-

NALS Description

RAD FAN REQ

[1/2/3/4] ×Displays the value of the cooling fan speed request signal received from ECM via

CAN communication.

AC COMP REQ

[Off/On] ×Displays the status of the A/C compressor request signal received from ECM via

CAN communication.

TA I L & C L R R E Q

[Off/On] ×

Displays the status of the position light request signal received from BCM via CAN

communication.

HL LO REQ

[Off/On] ×Displays the status of the low beam request signal received from BCM via CAN

communication.

HL HI REQ

[Off/On] ×Displays the status of the high beam request signal received from BCM via CAN

communication.

FR FOG REQ

[Off/On] ×Displays the status of the front fog light request signal received from BCM via

CAN communication.

FR WIP REQ

[Stop/1LOW/Low/Hi] ×

Displays the status of the front wiper request signal received from BCM via CAN

communication.

WIP AUTO STOP

[STOP P/ACT P] ×

Displays the status of the front wiper auto stop signal judged by IPDM E/R.

WIP PROT

[Off/BLOCK] ×

Displays the status of the front wiper fail-safe operation judged by IPDM E/R.

IGN RLY1 -REQ

[Off/On] Displays the status of the ignition switch ON signal received from BCM via CAN

communication.

IGN RLY

[Off/On] ×

Displays the status of the ignition relay judged by IPDM E/R.

Revision: 2010 May2011 QX56

Page 5540 of 5598

![INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (IPDM E/R)WW-21

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

ACTIVE TEST

Te s t i t e m

PUSH SW

[Off/On] Displays the status of the push-button ignition switch judged by I INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (IPDM E/R)WW-21

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

ACTIVE TEST

Te s t i t e m

PUSH SW

[Off/On] Displays the status of the push-button ignition switch judged by I](/img/42/57033/w960_57033-5539.png)

DIAGNOSIS SYSTEM (IPDM E/R)WW-21

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

ACTIVE TEST

Te s t i t e m

PUSH SW

[Off/On] Displays the status of the push-button ignition switch judged by IPDM E/R.

INTER/NP SW

[Off/On] Displays the status of the shift position judged by IPDM E/R.

ST RLY CONT

[Off/On] Displays the status of the starter relay status signal received from BCM via CAN

communication.

IHBT RLY -REQ

[Off/On] Displays the status of the starter control relay signal received from BCM via CAN

communication.

ST/INHI RLY

[Off/ ST ON/INHI ON/UNKWN] Displays the status of the starter relay and starter control relay judged by IPDM

E/R.

DETENT SW

[Off/On] Displays the status of the A/T shift selector (detention switch) judged by IPDM E/

R.

S/L RLY -REQ

[Off/On] Displays the status of the steering lock relay signal received from BCM via CAN

communication.

S/L STATE

[LOCK/UNLK/UNKWN] Displays the status of the steering lock judged by IPDM E/R.

OIL P SW

[Open/Close] Displays the status of the oil pressure switch judged by IPDM E/R.

HOOD SW

[Off/On] Displays the status of the hood switch judged by IPDM E/R.

HL WASHER REQ

[Off/On] Displays the status of the headlamp washer request signal received from BCM via

CAN communication.

THFT HRN REQ

[Off/On] Displays the status of the theft warning horn request signal received from BCM

via CAN communication.

HORN CHIRP

[Off/On] Displays the status of the horn reminder signal received from BCM via CAN com-

munication.

Monitor Item

[Unit] MAIN SIG-

NALS Description

Test item Operation Description

CORNERING LAMP LH

NOTE:

This item is indicated, but cannot be tested.

RH

HORN On Operates horn relay for 20 ms.

REAR DEFOGGER Off OFF

On Operates the rear window defogger relay.

FRONT WIPER Off OFF

Lo Operates the front wiper relay.

Hi Operates the front wiper relay and front wiper high relay.

MOTOR FAN* 1OFF

2 Transmits 50% pulse duty signal (PWM signal) to the cooling fan control module.

3 Transmits 75% pulse duty signal (PWM signal) to the cooling fan control module.

4

Transmits 100% pulse duty signal (PWM signal) to the cooling fan control mod-

ule.

HEAD LAMP WASHER On Operates the headlamp washer relay for 1 second.

Revision: 2010 May2011 QX56