body ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 5589 of 6020

Cruise Control – HFV6 Page 8C–11

Step Action Yes No

3 On Tech 2 select

Engine / V6 Engine / Diagnostic Trouble codes / Read DTCs’.

Are there any set DTC’s? Go to the

appropriate DTC table in 6C1-2 Engine

Management – V6 – Diagnostics Go to Step 4

4 Is the instrument cluster assembly functioning correctly? Go to 2.4

Cruise

Control Inoperative / Malfunctioning Refer to 8A

Electrical – Body

and Chassis.

When all diagnosis and repairs are completed, clear all DTCs and check the system for correct operation.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5593 of 6020

Cruise Control – HFV6 Page 8C–15

Step Action Yes No

3 Check the ignition supply circuits to the Stop Lamp Switch assembly

connector C – 44 pin 1 is serviceable using a multimeter set to

measure voltage, refer to 2.3 W iring Diagrams in this Section

Is there a +12 volt signal present at connector C – 44 pin 1?

Go to Step 4 Replace the faulty

fusible link Main,

IG2 or Stop Light fuse (refer to Note 1).

If either of the

fusible links or fuse blows again, repair

or replace the faulty circuit (refer to

Note 1)

4 1 Connect Tech 2 to the DLC.

2 On Tech 2 select: Body / Powertrain Interface Module / Diagnostic Data

Display.

3 Scroll to Cruise Main Switch.

4 W hile monitoring Tech 2, press the cruise control switch ON– OFF button.

Does Tech 2 display the following:

• Inactive and Active as the cruise control switch is pressed?

Go to Step 5 Go to Step 11

5 1 Scroll to Cruise Resume Switch.

2 While monitoring Tech 2, rotate the cruise control switch.

Does Tech 2 display the following:

• Inactive when the cruise control switch is in the neutral

position?

• Res / Acc when the cruise control switch is rotated to the RES–

ACC. Position? Go to Step 6 Go to Step 12

6

1 Scroll to Cruise Set Switch.

2 W hile monitoring Tech 2, press the cruise control switch.

Does Tech 2 display the following:

• Inactive when the cruise control switch is in the neutral

position?

• Set / Coast when the cruise control switch is pressed to the

SET–COAST position? Go to Step 7 Go to Step 13

7 1 Scroll to Cruise Cancel Switch.

2 While monitoring Tech 2, rotate the cruise control switch.

Does Tech 2 display the following:

• Inactive when the cruise control switch is in the neutral

position?

• Cancel when the cruise control switch is rotated to the CANCEL

position? Go to Step 8 Go to Step 14

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5628 of 6020

ACCESSORIES 9-23

No. Connector face No. Connector face

D-22

White

Tweeter -LH P-1

SilverBattery (+)

H-14

White

Rear body ∼ Rear door -LH P-2

SilverRelay & Fuse box

H-16

White

Rear body ∼ Rear door -RH P-5

SilverBattery (-)

H-18

White

Engine room ∼ INST P-6

SilverBody earth

H-36

White

INST ~ Front door-RH P-10

SilverEngine ground

H-37

White

INST ~ Front door-LH R-7

BlackRear speaker -LH

H-39

White

INST ~ Front door-LH R-8

BlackRear speaker -RH

H-42

White

INST ~ Front door-driver

H-43

INST ~ Body

H-43

White

INST ~ Body

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5636 of 6020

SUPPLEMENTAL RESTRAINT SYSTEM 9A-1

SECTION 9A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

TABLE OF CONTENTS

PAGE

Service Precaution ....................................................................................................... 9A- 4

General Description...................................................................................................... 9A- 4 Restraint Devices ..................................................................................................... 9A- 4

System Description .................................................................................................. 9A- 5

Circuit Diagram ............................................................................................................. 9A- 6

SRS Component And Wiring Location View .............................................................. 9A- 10

Component Description ............................................................................................... 9A- 14 SRS Control Unit ...................................................................................................... 9A- 14

"SRS" Warning Lamp .............................................................................................. 9A- 14

SRS Coil Assembly .................................................................................................. 9A- 15

Air Bag Assemblies.................................................................................................. 9A- 15

Steering Column ...................................................................................................... 9A- 16

Knee Bolster ............................................................................................................. 9A- 16

Definitions .................................................................................................................... . 9A- 16

Diagnosis...................................................................................................................... . 9A- 18

Diagnostic Trouble Codes ....................................................................................... 9A- 18

Scan Tool Diagnostics............................................................................................. 9A- 18

Use Of Special Tools ............................................................................................... 9A- 18

SRS Connec tor Body Face Vie ws ............................................................................. ..9 A- 19

Repairs And Inspec tions Required After A n A ccident ............................................ ..9 A- 20

Accident With Deployment-Component Replacement And Inspections ............. 9A- 20

Accident With or Without Deployment-Component Inspection ........................... 9A- 20

SRS Control Unit Replacement Guidelines ........................................................... 9A- 20

Wiring Damage ......................................................................................................... 9A- 20

SRS Connector (Plastic Body And Terminal Metal Pin) Damage ......................... 9A- 20

SRS Wire Pigtail Damage ........................................................................................ 9A- 20

PAGE 1 OF 3

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5652 of 6020

SUPPLEMENTAL RESTRAINT SYSTEM 9A-17

“Continuous Monitoring”

Tests are performed by the SRS control unit on the

SRS every 100 milliseconds while “Ignition 1” voltage

is in the normal operating voltage range at the SRS

control unit.

Data Link Connector (DLC)

Formerly “DLC”, a connector which allows

communication with an external computer, such as a

scan tool.

Datum Line

A base line parallel to the plane of the underbody or

frame from which all vertical measurements originate.

Deploy

To inflate the air bag.

Deployment Loops

The circuits which supply current to the air bag

assemblies to deploy the air bag.

Diagnostic Trouble Code (DTC)

Formerly “Code”, a numerical designator used by the

SRS control unit to indicate specific SRS malfunctions.

Driver Current Source

An output of the SRS control unit which applies current

into the driver air bag assembly circuit during the

“Initiator Assembly Resistance Test”.

Driver Air Bag Assembly

An assembly located in the steering wheel hub

consisting of an inflatable bag, an inflator and an

initiator.

EEPROM

Electrically Erasable Programmable Read Onl

y

Memory. Memory which retains its contents when

power is removed from the SRS control unit.

Ignition Cycle

The voltage at the SRS control unit “Ignition 1” input,

with ignition switch “ON”, is within the normal operating

voltage range for at least ten seconds before turning

the ignition switch “OFF”.

Ignition 1

A battery voltage (B+) circuit which is only powered

when the ignition switch is in the ON, or START

position.

Initiator

The electrical component inside the air bag assembl

y

which, when sufficient current flows, sets off the

chemical reaction that inflates the air bag.

“Initiator Assembly Resistance Test”

Tests are performed once for each ignition cycle when

no malfunctions are detected during “Turn–ON” o

r

“Continuous Monitoring”. This test checks for the

correct SRS control unit configuration for the vehicle,

shorts to “Ignition 1” in the deployment loops, high

resistance or opens in the “Driver Side” and

“Passenger Side” circuits and measures the resistance

of the inflator assembly consisting of 1) Initiators, 2)

SRS coil assembly (driver side only), 3) Connectors

and associated wiring.

Normal Operating Voltage Range

The voltage measured between the SRS control unit

“Ignition 1” terminals and “Ground” terminals is

between 9 and 16 volts.

Passenger Current Source

An output of the SRS control unit which applies current

into the passenger air bag assembly circuit during the

“Initiator Assembly Resistance Test”.

Passenger Air Bag Assembly

An assembly located in the front of the passenger side

of the instrument panel consisting of an inflatable bag,

an inflator and an initiator.

Scan Tool

An external computer used to read diagnostic

information from on–board computers via the data link

connector.

SRS control unit

SRS control unit which provides reserve energy to the

deployment loops, deploys the air bags when required

and performs diagnostic monitoring of all SRS

components.

Serial Data

Information representing the status of the SRS.

SRS

Supplemental Restraint System.

SRS Coil Assembly

An assembly of two current–carrying coils in the drive

r

deployment loop that allows the rotation of the steering

wheel while maintaining the continuous contact of the

driver deployment loop to the driver air bag assembly.

SRS Wiring Harness

The wires and connectors that electrically connect the

components in the SRS.

“Turn–ON”

Test which the SRS control unit performs on the SRS

once during each ignition cycle immediately afte

r

“Ignition 1” voltage is applied to the SRS control unit

and before “Continuous Monitoring”.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5654 of 6020

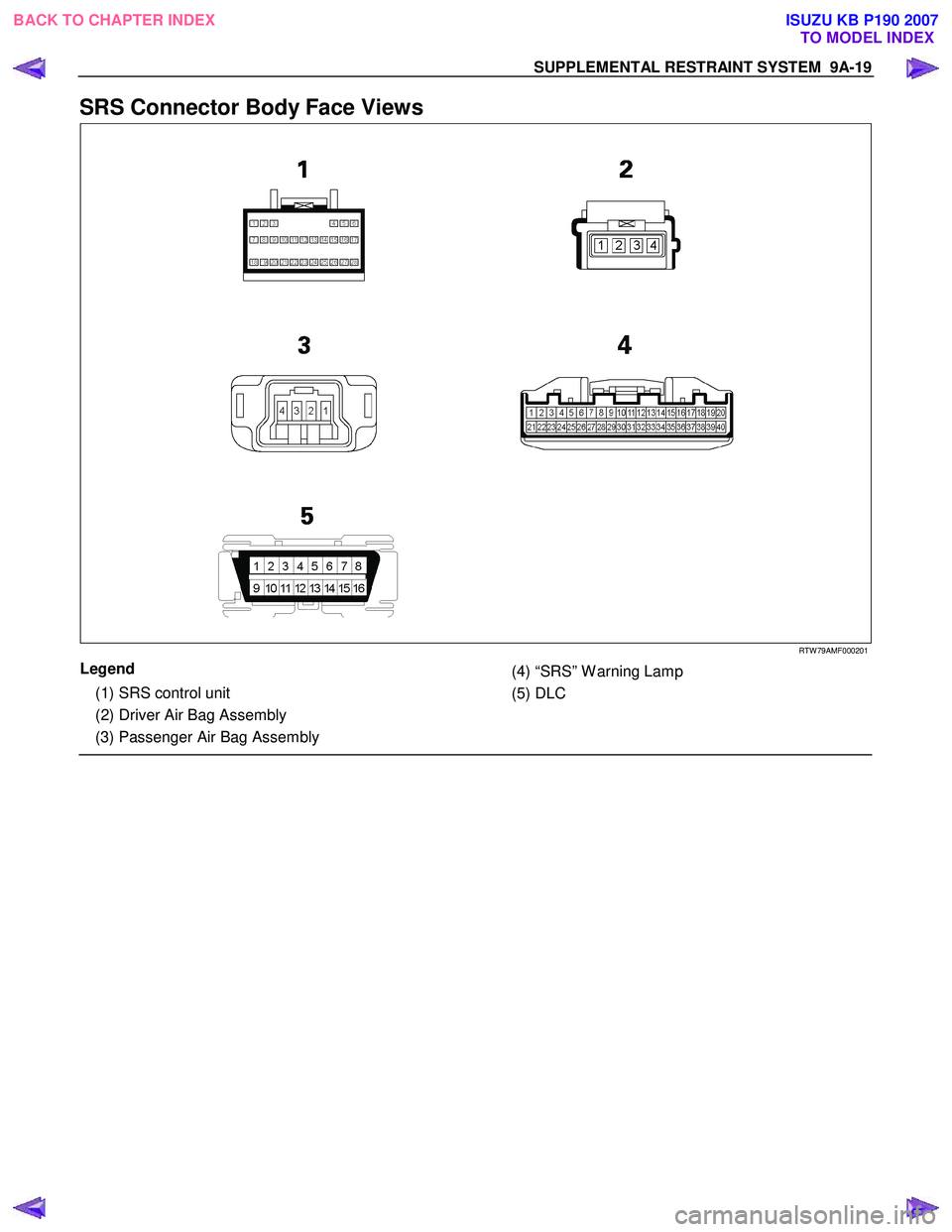

SUPPLEMENTAL RESTRAINT SYSTEM 9A-19

SRS Connector Body Face Views

RTW 79AMF000201

Legend

(1) SRS control unit

(2) Driver Air Bag Assembly

(3) Passenger Air Bag Assembly

(4) “SRS” W arning Lamp

(5) DLC

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5655 of 6020

9A-20 SUPPLEMENTAL RESTRAINT SYSTEM

Repairs And Inspections Required

After An Accident

If any SRS components are damaged, they must be

replaced. If SRS component mounting points are

damaged, they must be replaced.

• Never use SRS parts from another vehicle. This does not include remanufactured parts purchased

from an authorized dealer; they may be used fo

r

SRS repairs.

• Do not attempt to service the SRS control unit, the SRS coil assembly, or the air bag assembly.

Service of these items is by replacement only.

• Verify the part number of the replacement air bag assembly.

CAUTION: Never use the air bag assembly from

another vehicle or different model year air bag

assembly.

Use only a new air bag assembly matched to the

TFR/S which is being repaired.

CAUTION: Proper operation of the sensors and

supplemental restraint system (SRS) requires that

any repairs to the vehicle structure return it to the

original production configuration. Deployment

requires, at a minimum, replacement of the SRS

control unit, air bag assembly and dimensional

inspection of the steering column. Any visible

damage to the SRS control unit mounting bracket

(s) requires replacement, and the steering column

must be dimensionally inspected, whethe

r

deployment occurred or not.

Accident With Deployment – Component

Replacement And Inspections

Certain SRS components must be replaced or

inspected for damage after a frontal crash involving air

bag deployment. Those components are:

• Air bag assembly

• SRS control unit

CAUTION: Refer to “SRS control unit Replacement

Guidelines” below for important information on

SRS control unit replacement in both deployment

and non-deployment crashes.

• SRS coil assembly — Inspect wiring and connecto

r

for any signs of scorching, melting, or damage due

to excessive heat. Replace if damaged. Refer to

section “SRS Coil Assembly” in this manual.

Accident With or Without Deployment –

Component Inspection

Certain SRS system components and rotation parts

must be inspected after any crash, whether the air bag

has been deployed or not. Those components are:

• Steering column — Refer to Inspection Required “After an Accident” in this manual.

• Knee bolsters and mounting points — Inspect fo

r

any distortion, bending, cracking, or other damage.

• I/P steering column reinforcement plate — Inspect for any distortion, bending, cracking, or othe

r

damage.

• I/P braces — Inspect for any distortion, bending, cracking, or other damage.

• Seat belts and mounting points — Refer to “Seat Belts” in Section “Seat Belt” of this workshop

manual.

SRS Control Unit Replacement Guidelines

SRS control unit replacement policy requires

replacement of the SRS control unit after a crash

involving air bag deployment when the “SRS W arning

Lamp” turned “ON”, the “SRS Diagnosis” should be

done according to Section “Restraint Control System.”

Wiring Damage

If any SRS wire harness is damaged, it should be

replaced. Don't repair the SRS harness. It is

replacement only.

SRS Connector (Plastic Body And

Terminal Metal Pin) Damage

If any connector or terminal in the SRS wire harness

(except pigtails) is damaged, it should be replaced.

SRS Wire Pigtail Damage

If the wiring pigtail (a wire or wires attached directly to

the device, not by a connector) is damaged, the entire

component (with pigtail) must be replaced. Examples

of “pigtail” components are the driver air bag

assembly, the passenger air bag assembly, and the

SRS coil assembly.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5761 of 6020

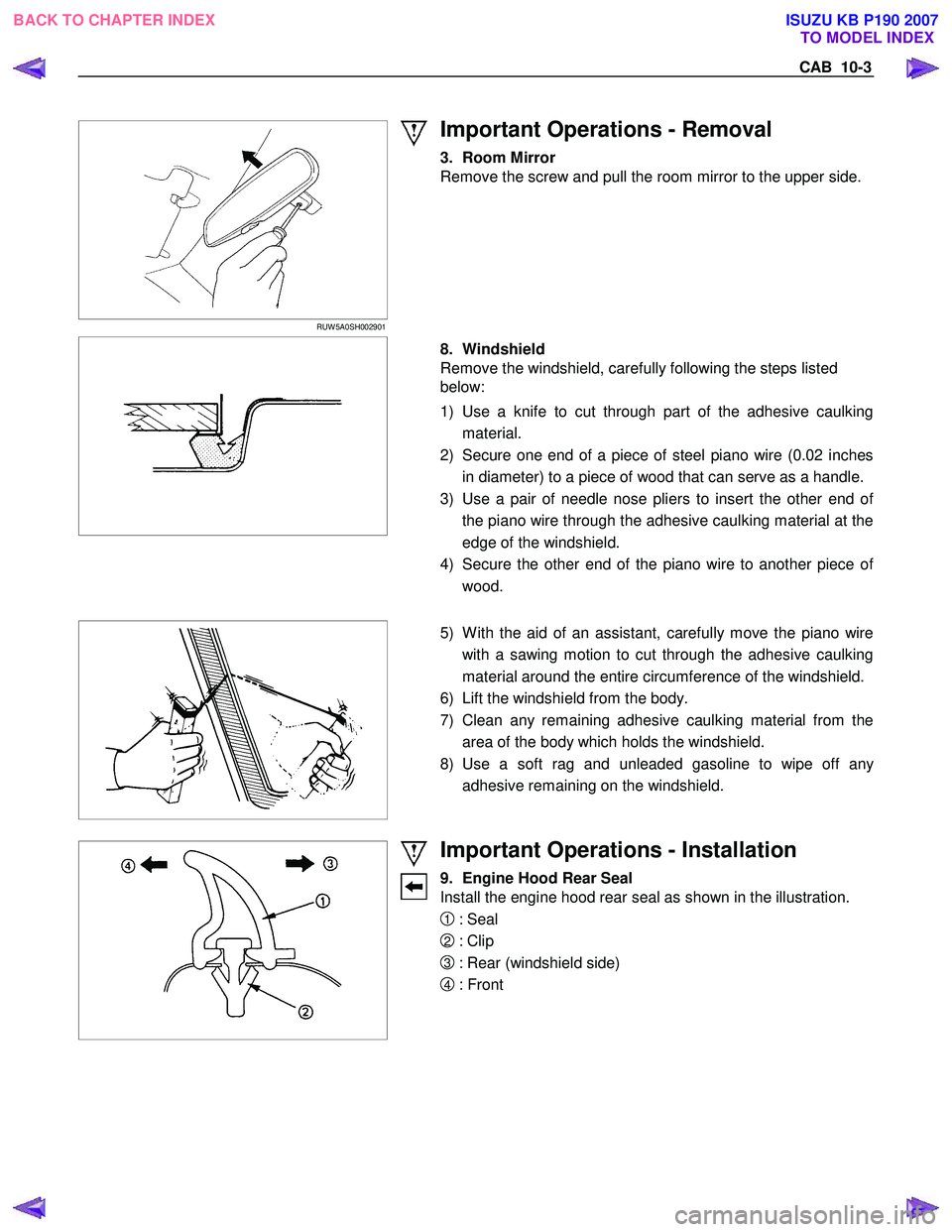

CAB 10-3

RUW 5A0SH002901

Important Operations - Removal

3. Room Mirror

Remove the screw and pull the room mirror to the upper side.

8. Windshield

Remove the windshield, carefully following the steps listed

below:

1) Use a knife to cut through part of the adhesive caulking material.

2) Secure one end of a piece of steel piano wire (0.02 inches in diameter) to a piece of wood that can serve as a handle.

3) Use a pair of needle nose pliers to insert the other end o

f

the piano wire through the adhesive caulking material at the

edge of the windshield.

4) Secure the other end of the piano wire to another piece o

f

wood.

5) W ith the aid of an assistant, carefully move the piano wire

with a sawing motion to cut through the adhesive caulking

material around the entire circumference of the windshield.

6) Lift the windshield from the body.

7) Clean any remaining adhesive caulking material from the area of the body which holds the windshield.

8) Use a soft rag and unleaded gasoline to wipe off an

y

adhesive remaining on the windshield.

Important Operations - Installation

9. Engine Hood Rear Seal

Install the engine hood rear seal as shown in the illustration.

1 : Seal

2 : Clip

3 : Rear (windshield side)

4 : Front

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5762 of 6020

10-4 CAB

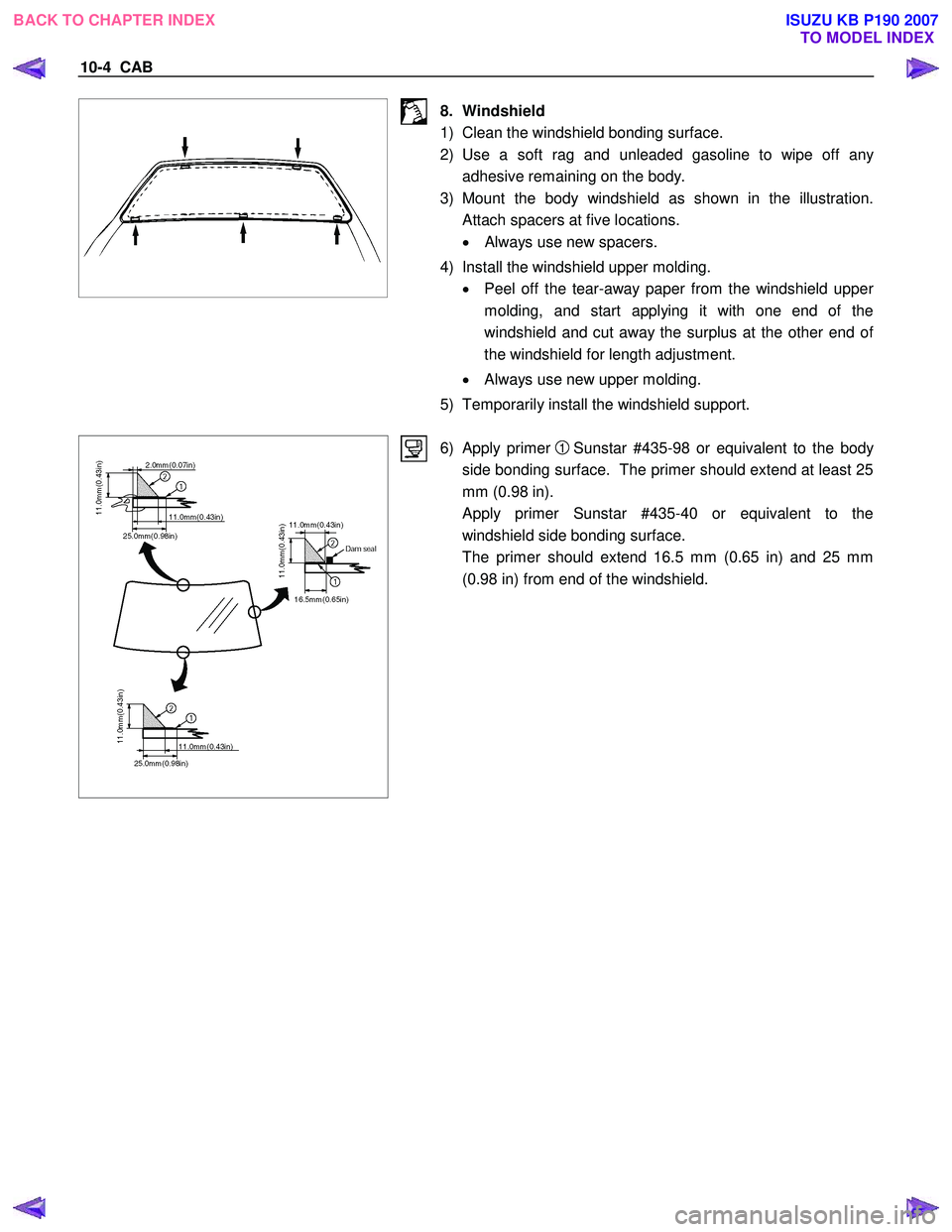

8. Windshield

1) Clean the windshield bonding surface.

2) Use a soft rag and unleaded gasoline to wipe off an

y

adhesive remaining on the body.

3) Mount the body windshield as shown in the illustration. Attach spacers at five locations.

• Always use new spacers.

4) Install the windshield upper molding. • Peel off the tear-away paper from the windshield uppe

r

molding, and start applying it with one end of the

windshield and cut away the surplus at the other end o

f

the windshield for length adjustment.

• Always use new upper molding.

5) Temporarily install the windshield support.

6) Apply primer

1 Sunstar #435-98 or equivalent to the body

side bonding surface. The primer should extend at least 25

mm (0.98 in).

Apply primer Sunstar #435-40 or equivalent to the windshield side bonding surface.

The primer should extend 16.5 mm (0.65 in) and 25 mm (0.98 in) from end of the windshield.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5763 of 6020

CAB 10-5

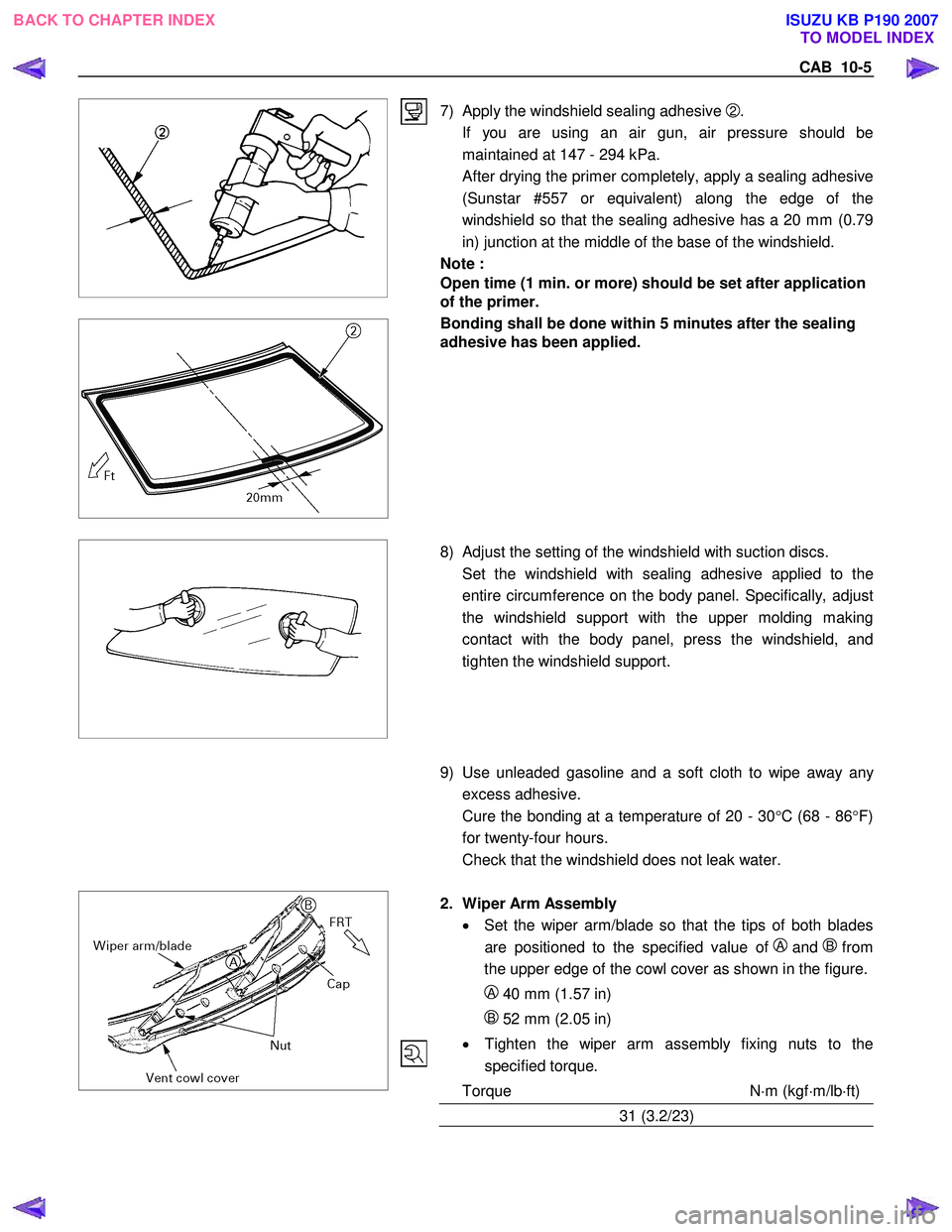

7) Apply the windshield sealing adhesive

2.

If you are using an air gun, air pressure should be maintained at 147 - 294 kPa.

After drying the primer completely, apply a sealing adhesive (Sunstar #557 or equivalent) along the edge of the

windshield so that the sealing adhesive has a 20 mm (0.79

in) junction at the middle of the base of the windshield.

Note :

Open time (1 min. or more) should be set after application

of the primer.

Bonding shall be done within 5 minutes after the sealing

adhesive has been applied.

8) Adjust the setting of the windshield with suction discs.

Set the windshield with sealing adhesive applied to the entire circumference on the body panel. Specifically, adjust

the windshield support with the upper molding making

contact with the body panel, press the windshield, and

tighten the windshield support.

9) Use unleaded gasoline and a soft cloth to wipe away any

excess adhesive.

Cure the bonding at a temperature of 20 - 30 °C (68 - 86 °F)

for twenty-four hours.

Check that the windshield does not leak water.

2. Wiper Arm Assembly

• Set the wiper arm/blade so that the tips of both blades

are positioned to the specified value of

A and Bfrom

the upper edge of the cowl cover as shown in the figure.

A 40 mm (1.57 in)

B 52 mm (2.05 in)

• Tighten the wiper arm assembly fixing nuts to the

specified torque.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

31 (3.2/23)

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007