ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4171 of 6020

7A4–36 UNIT REPAIR (AW30–40LE)

Diaassembly, Inspection and

Reassembly of minor Components

NOTE: The instructions here are organized so that you

work on only one component group at a time.

This will help avoid confusion from similar-looking parts

of different subassemblies being on your workbench at

the same time.

The component groups are inspected and repaired from

the converter housing side.

As much as possible, complete the inspection, repair

and reassembly before proceeding to the next

component group. If a component group cannot be

reassembled because parts are being ordered, be sure

to keep all parts of that group in separate container

while proceeding with disassembly, inspection, repair

and reassembly of other component groups.

Recommended ATF type DEXRON III.

General Cleaning Notes:

1. All disassembled parts should be washed clean and any fluid passages and holes should be blown

through with compressed air.

2. When using compressed air to dry parts, always aim away from yourself to prevent accidentally spraying

automatic transmission fluid in your face.

3. The recommended automatic transmission fluid should be used for cleaning.

Parts Arrangement:

1. After cleaning, the parts should be arranged inproper order to allow performing inspection, repairs,

and reassembly with efficiency.

2. When disassembling a valve body, be sure to keep each valve together with the corresponding spring.

3. New brakes and clutches that are to be used for replacement must be soaked in transmission fluid

for at least thirty minutes before assembly.

General Assembly:

1. All oil seal rings, clutch discs, clutch plates, rotating parts, and sliding surfaces should be coated with

transmission fluid prior to reassembly.

2. All gaskets and rubber O-ring should be replaced.

3. Make sure that the ends of a snap ring are not aligned with one of the cutouts and are installed in

the groove correctly.

4. If a worn bushing is to be replaced, the subassembly containing that bushing must be

replaced.

5. Check thrust bearings and races for wear or damage. Replace if necessary.

6. Use petroleum jelly or vaseline to keep parts in place.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4172 of 6020

UNIT REPAIR (AW30–40LE) 7A4–37

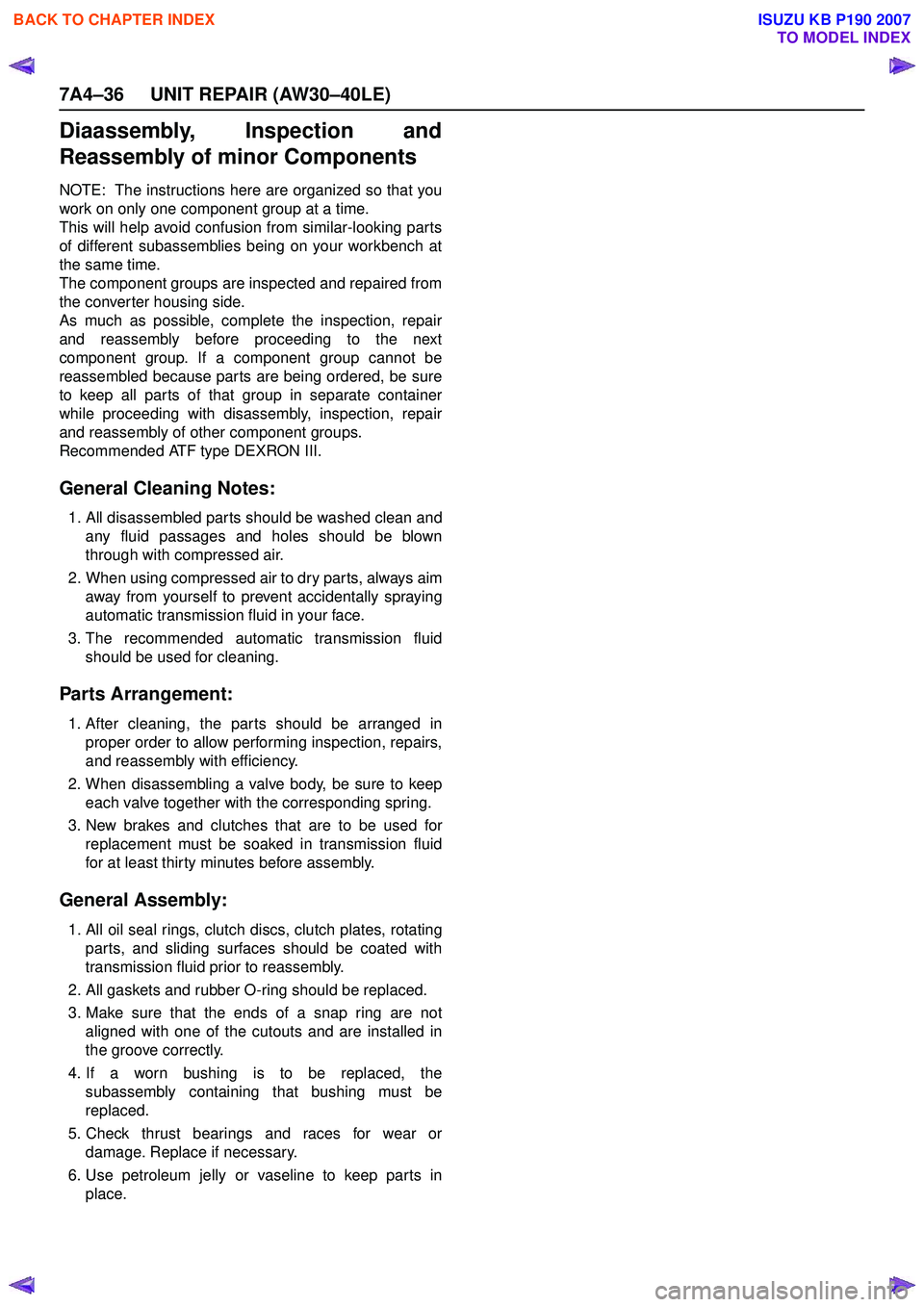

Oil Pump

Disassembly View

RTW77AMF000201

EndOFCallout

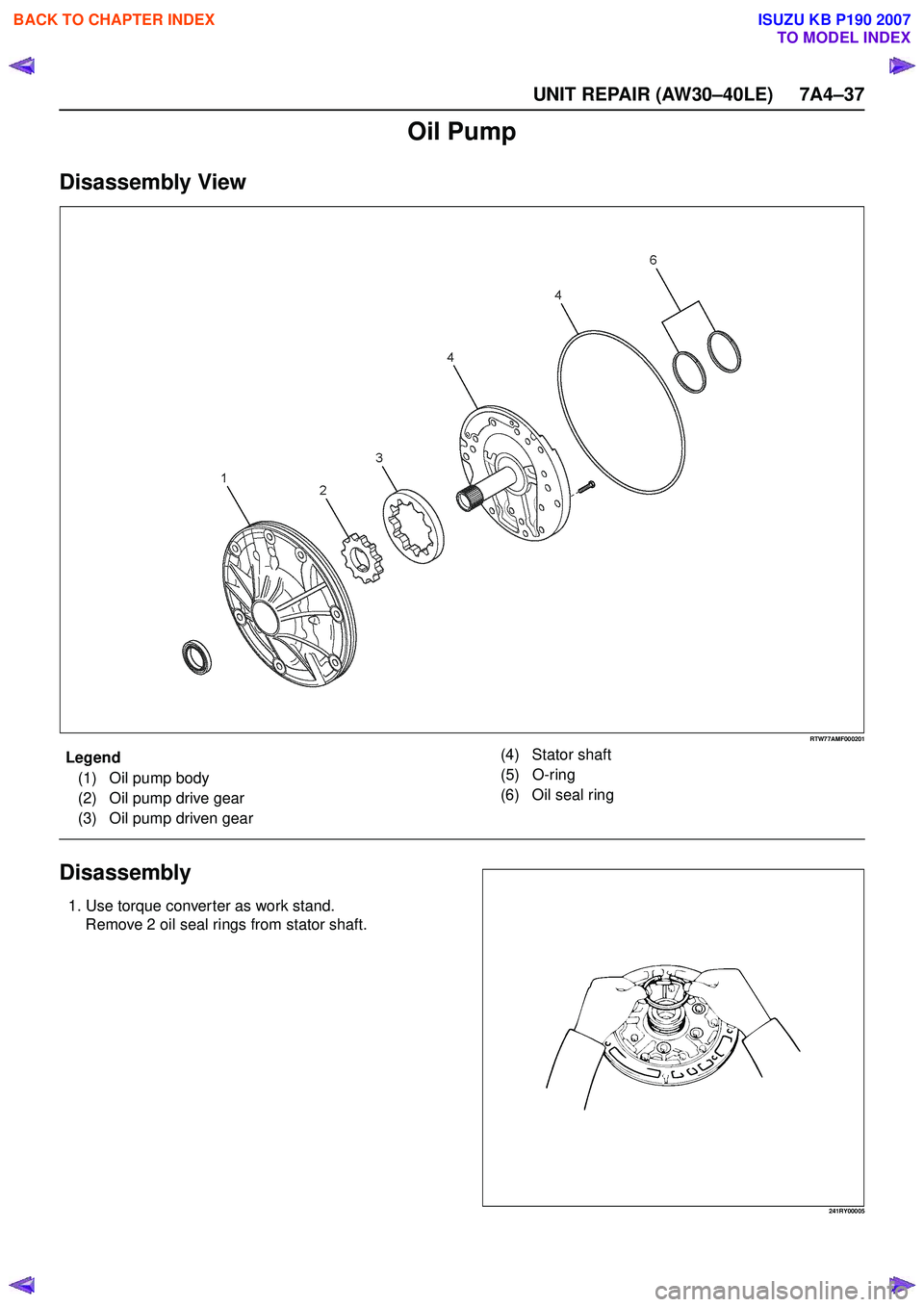

Disassembly

1. Use torque converter as work stand.Remove 2 oil seal rings from stator shaft.

241RY00005

Legend

(1) Oil pump body

(2) Oil pump drive gear

(3) Oil pump driven gear (4) Stator shaft

(5) O-ring

(6) Oil seal ring

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4173 of 6020

7A4–38 UNIT REPAIR (AW30–40LE)

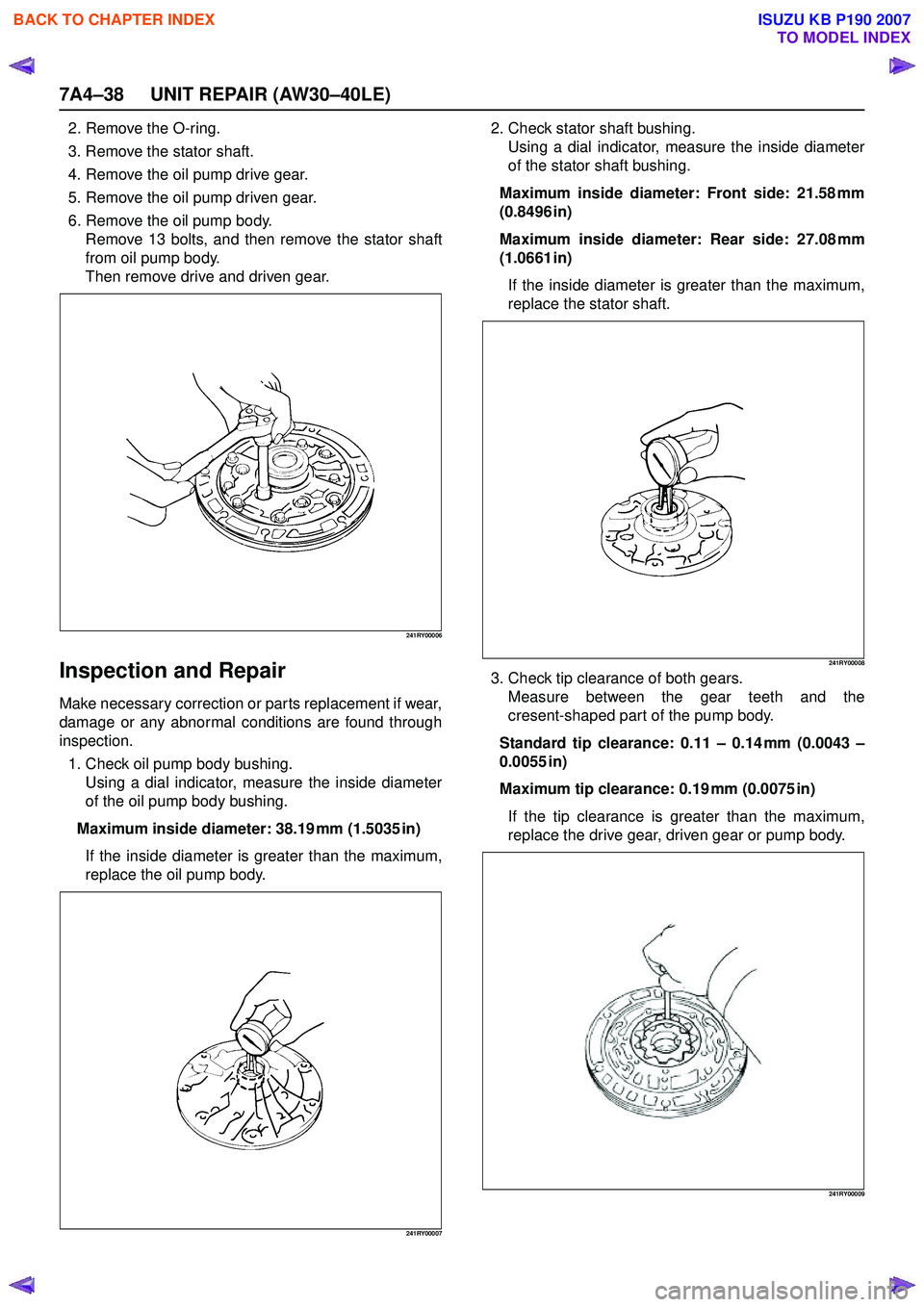

2. Remove the O-ring.

3. Remove the stator shaft.

4. Remove the oil pump drive gear.

5. Remove the oil pump driven gear.

6. Remove the oil pump body. Remove 13 bolts, and then remove the stator shaft

from oil pump body.

Then remove drive and driven gear.

241RY00006

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage or any abnormal conditions are found through

inspection.

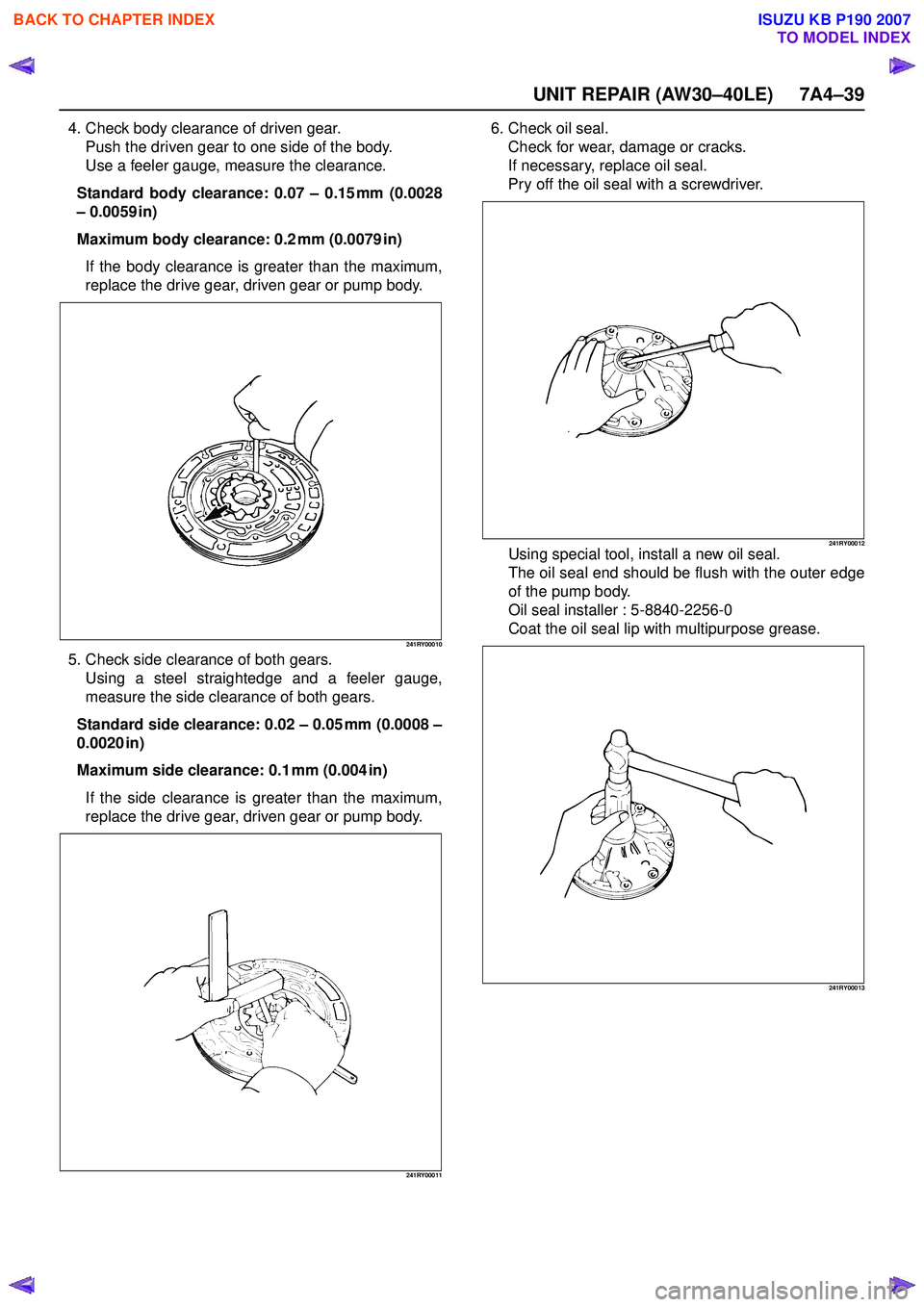

1. Check oil pump body bushing. Using a dial indicator, measure the inside diameter

of the oil pump body bushing.

Maximum inside diameter: 38.19 mm (1.5035 in) If the inside diameter is greater than the maximum,

replace the oil pump body.

241RY00007

2. Check stator shaft bushing. Using a dial indicator, measure the inside diameter

of the stator shaft bushing.

Maximum inside diameter: Front side: 21.58 mm

(0.8496 in)

Maximum inside diameter: Rear side: 27.08 mm

(1.0661 in)

If the inside diameter is greater than the maximum,

replace the stator shaft.

241RY00008

3. Check tip clearance of both gears. Measure between the gear teeth and the

cresent-shaped part of the pump body.

Standard tip clearance: 0.11 – 0.14 mm (0.0043 –

0.0055 in)

Maximum tip clearance: 0.19 mm (0.0075 in) If the tip clearance is greater than the maximum,

replace the drive gear, driven gear or pump body.

241RY00009

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4174 of 6020

UNIT REPAIR (AW30–40LE) 7A4–39

4. Check body clearance of driven gear.Push the driven gear to one side of the body.

Use a feeler gauge, measure the clearance.

Standard body clearance: 0.07 – 0.15 mm (0.0028

– 0.0059 in)

Maximum body clearance: 0.2 mm (0.0079 in) If the body clearance is greater than the maximum,

replace the drive gear, driven gear or pump body.

241RY00010

5. Check side clearance of both gears. Using a steel straightedge and a feeler gauge,

measure the side clearance of both gears.

Standard side clearance: 0.02 – 0.05 mm (0.0008 –

0.0020 in)

Maximum side clearance: 0.1 mm (0.004 in) If the side clearance is greater than the maximum,

replace the drive gear, driven gear or pump body.

241RY00011

6. Check oil seal. Check for wear, damage or cracks.

If necessary, replace oil seal.

Pry off the oil seal with a screwdriver.

241RY00012Using special tool, install a new oil seal.

The oil seal end should be flush with the outer edge

of the pump body.

Oil seal installer : 5-8840-2256-0

Coat the oil seal lip with multipurpose grease.

241RY00013

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4175 of 6020

7A4–40 UNIT REPAIR (AW30–40LE)

Reassembly

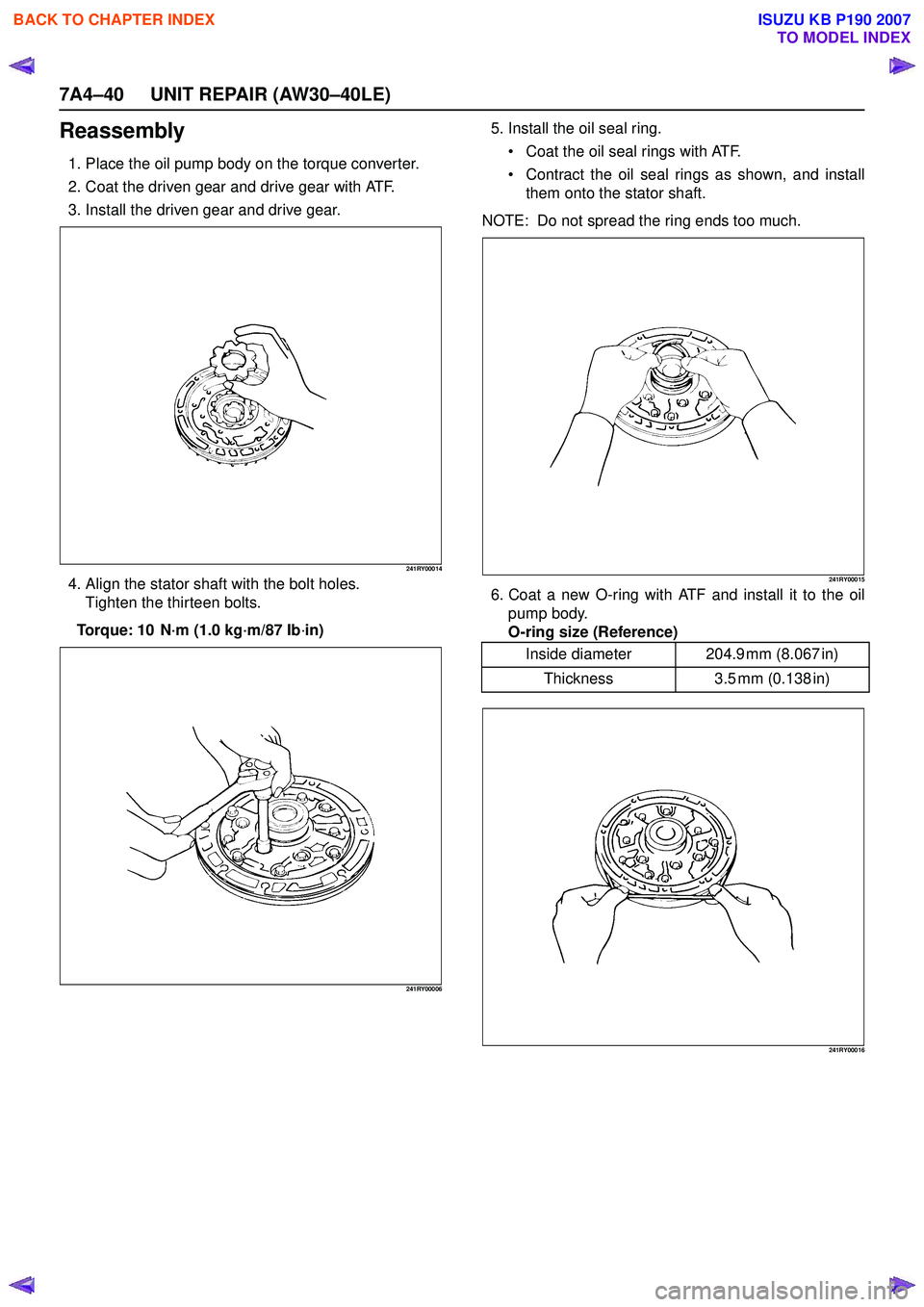

1. Place the oil pump body on the torque converter.

2. Coat the driven gear and drive gear with ATF.

3. Install the driven gear and drive gear.

241RY00014

4. Align the stator shaft with the bolt holes. Tighten the thirteen bolts.

Torque: 10 N ·m (1.0 kg ·m/87 Ib ·in)

241RY00006

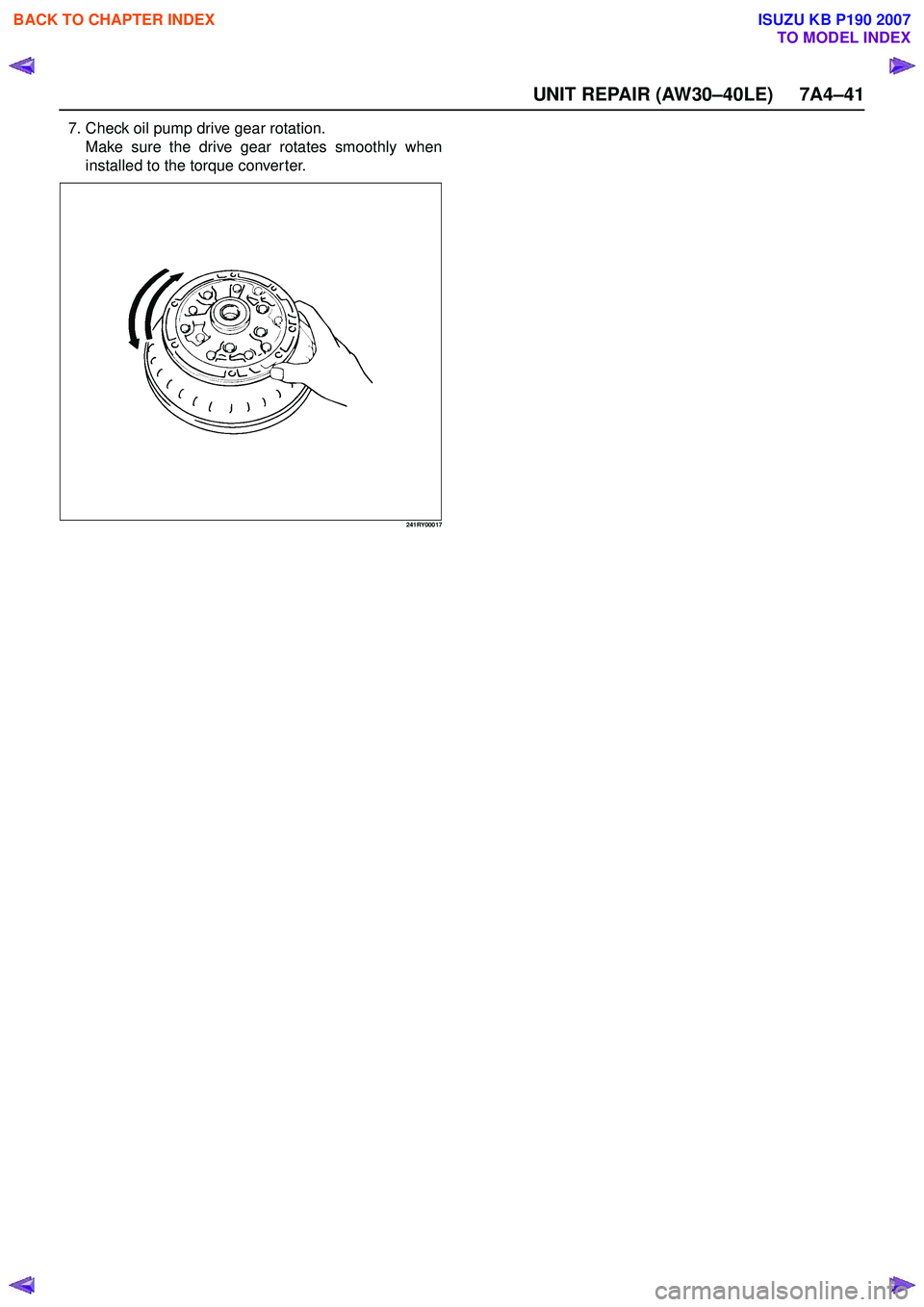

5. Install the oil seal ring.

Coat the oil seal rings with ATF.

Contract the oil seal rings as shown, and install

them onto the stator shaft.

NOTE: Do not spread the ring ends too much.

241RY00015

6. Coat a new O-ring with ATF and install it to the oil pump body.

O-ring size (Reference)

241RY00016

Inside diameter 204.9 mm (8.067 in)

Thickness 3.5 mm (0.138 in)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4176 of 6020

UNIT REPAIR (AW30–40LE) 7A4–41

7. Check oil pump drive gear rotation.Make sure the drive gear rotates smoothly when

installed to the torque converter.

241RY00017

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4177 of 6020

7A4–42 UNIT REPAIR (AW30–40LE)

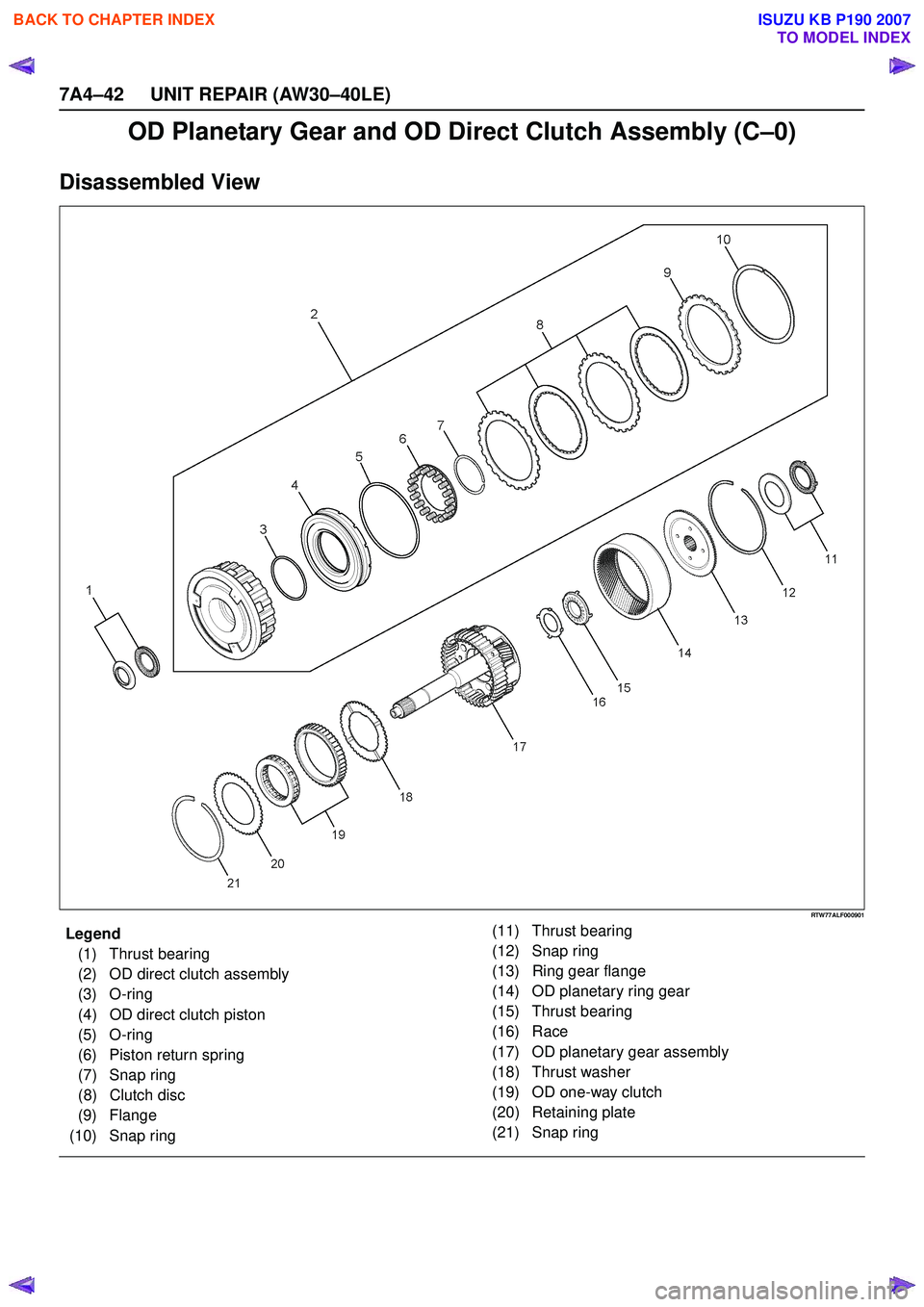

OD Planetary Gear and OD Direct Clutch Assembly (C–0)

Disassembled View

RTW77ALF000901

EndOFCallout

Legend(1) Thrust bearing

(2) OD direct clutch assembly

(3) O-ring

(4) OD direct clutch piston

(5) O-ring

(6) Piston return spring

(7) Snap ring

(8) Clutch disc

(9) Flange

(10) Snap ring (11) Thrust bearing

(12) Snap ring

(13) Ring gear flange

(14) OD planetary ring gear

(15) Thrust bearing

(16) Race

(17) OD planetary gear assembly

(18) Thrust washer

(19) OD one-way clutch

(20) Retaining plate

(21) Snap ring

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4178 of 6020

UNIT REPAIR (AW30–40LE) 7A4–43

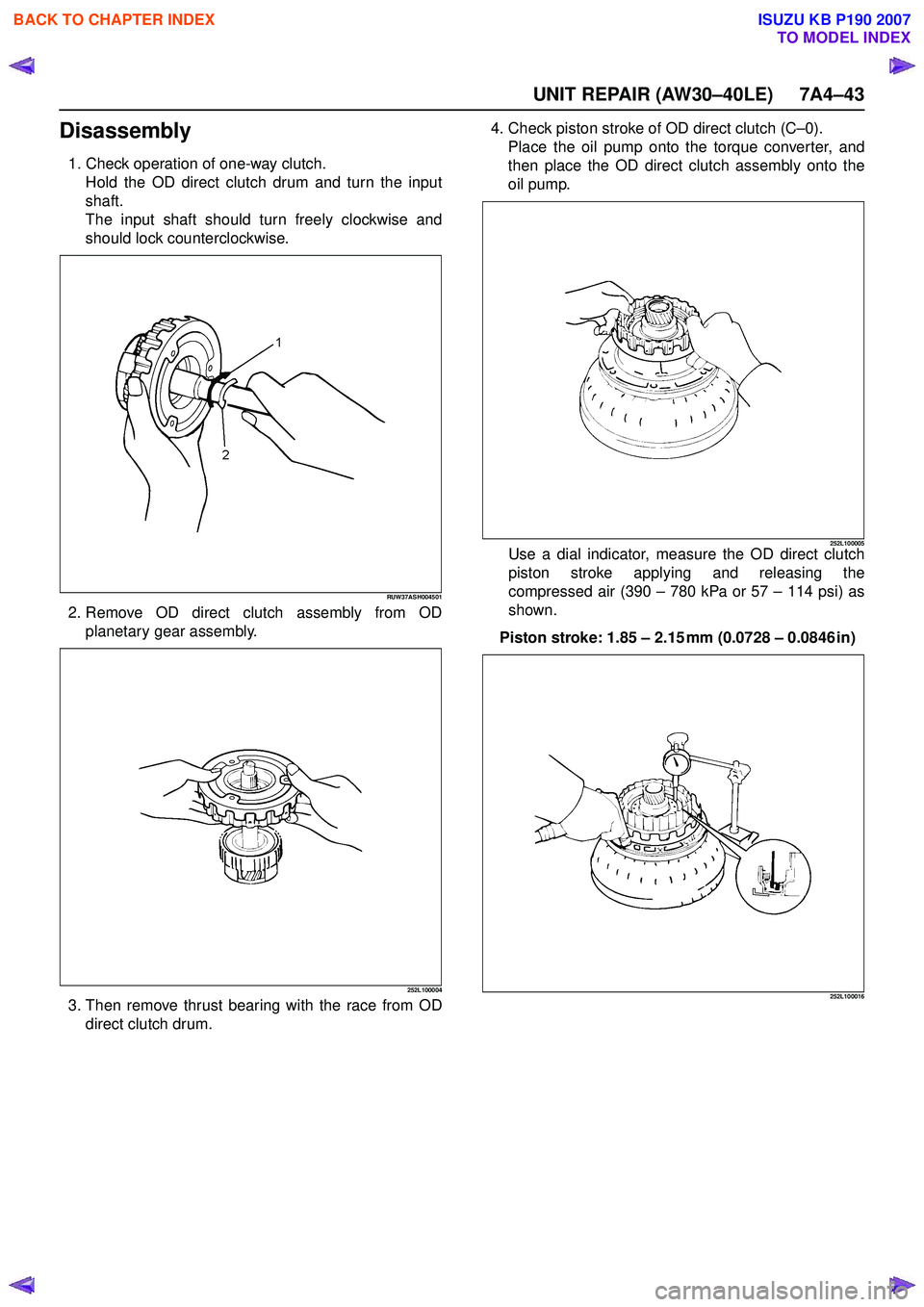

Disassembly

1. Check operation of one-way clutch.Hold the OD direct clutch drum and turn the input

shaft.

The input shaft should turn freely clockwise and

should lock counterclockwise.

RUW37ASH004501

2. Remove OD direct clutch assembly from OD planetary gear assembly.

252L100004

3. Then remove thrust bearing with the race from ODdirect clutch drum. 4. Check piston stroke of OD direct clutch (C

–0).

Place the oil pump onto the torque converter, and

then place the OD direct clutch assembly onto the

oil pump.

252L100005Use a dial indicator, measure the OD direct clutch

piston stroke applying and releasing the

compressed air (390 – 780 kPa or 57 – 114 psi) as

shown.

Piston stroke: 1.85 – 2.15 mm (0.0728 – 0.0846 in)

252L100016

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4179 of 6020

7A4–44 UNIT REPAIR (AW30–40LE)

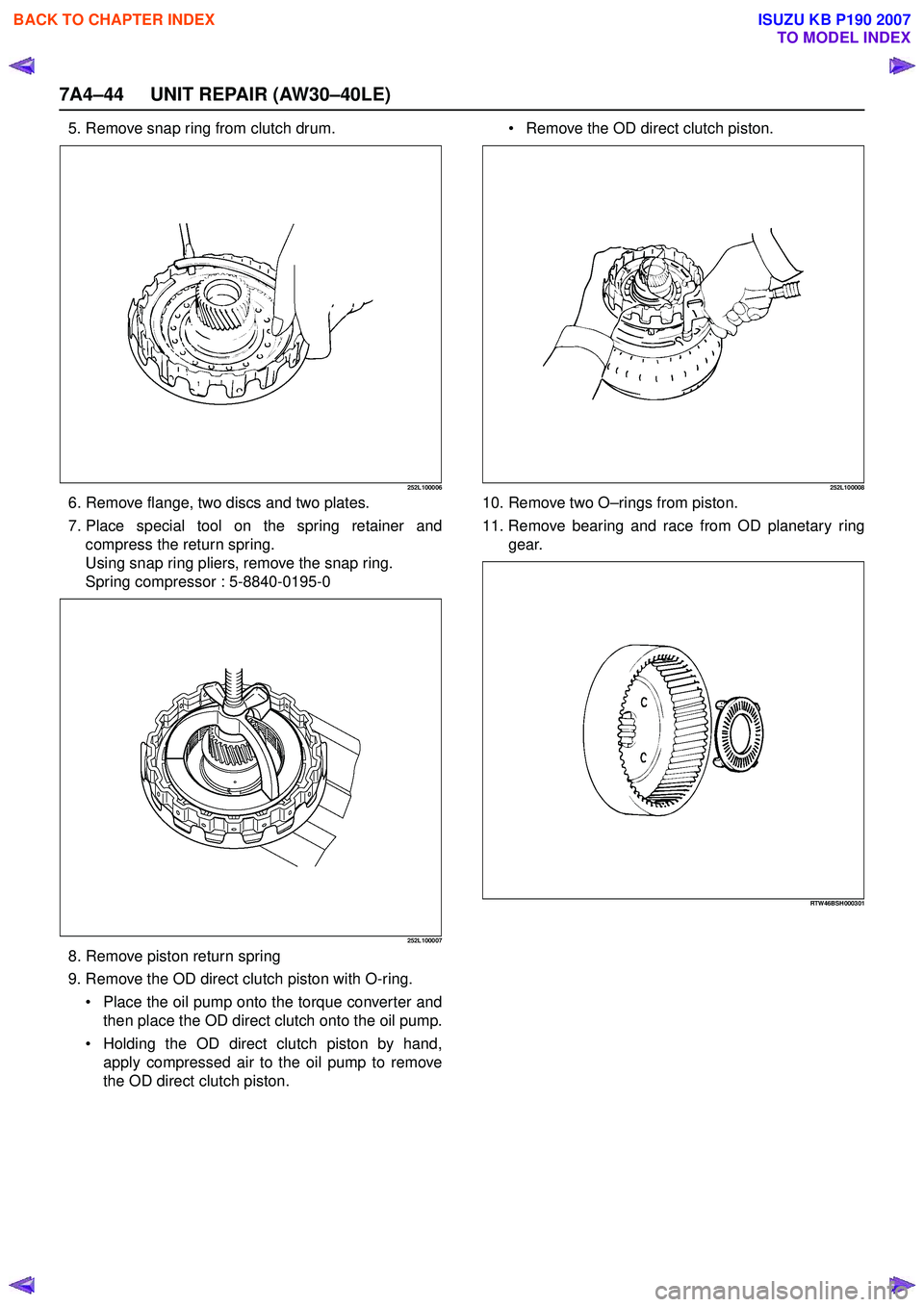

5. Remove snap ring from clutch drum.

252L100006

6. Remove flange, two discs and two plates.

7. Place special tool on the spring retainer and compress the return spring.

Using snap ring pliers, remove the snap ring.

Spring compressor : 5-8840-0195-0

252L100007

8. Remove piston return spring

9. Remove the OD direct clutch piston with O-ring.

Place the oil pump onto the torque converter and

then place the OD direct clutch onto the oil pump.

Holding the OD direct clutch piston by hand,

apply compressed air to the oil pump to remove

the OD direct clutch piston.

Remove the OD direct clutch piston.

252L100008

10. Remove two O –rings from piston.

11. Remove bearing and race from OD planetary ring gear.

RTW46BSH000301

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4180 of 6020

UNIT REPAIR (AW30–40LE) 7A4–45

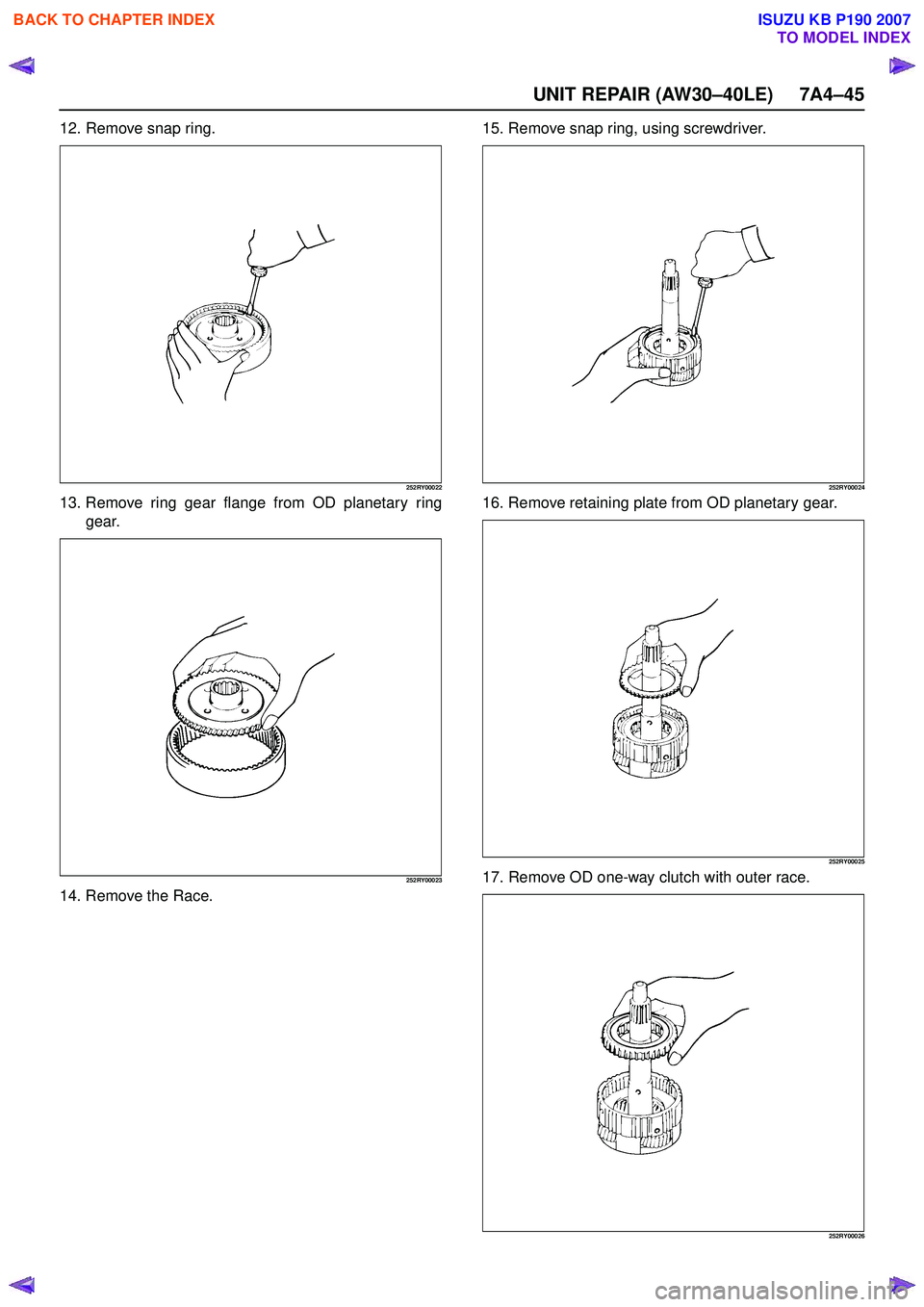

12. Remove snap ring.

252RY00022

13. Remove ring gear flange from OD planetary ringgear.

252RY00023

14. Remove the Race. 15. Remove snap ring, using screwdriver.

252RY00024

16. Remove retaining plate from OD planetary gear.

252RY00025

17. Remove OD one-way clutch with outer race.

252RY00026

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007