ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4131 of 6020

7A3-46 ON-VEHICLE SERVICE (AW30–40LE)

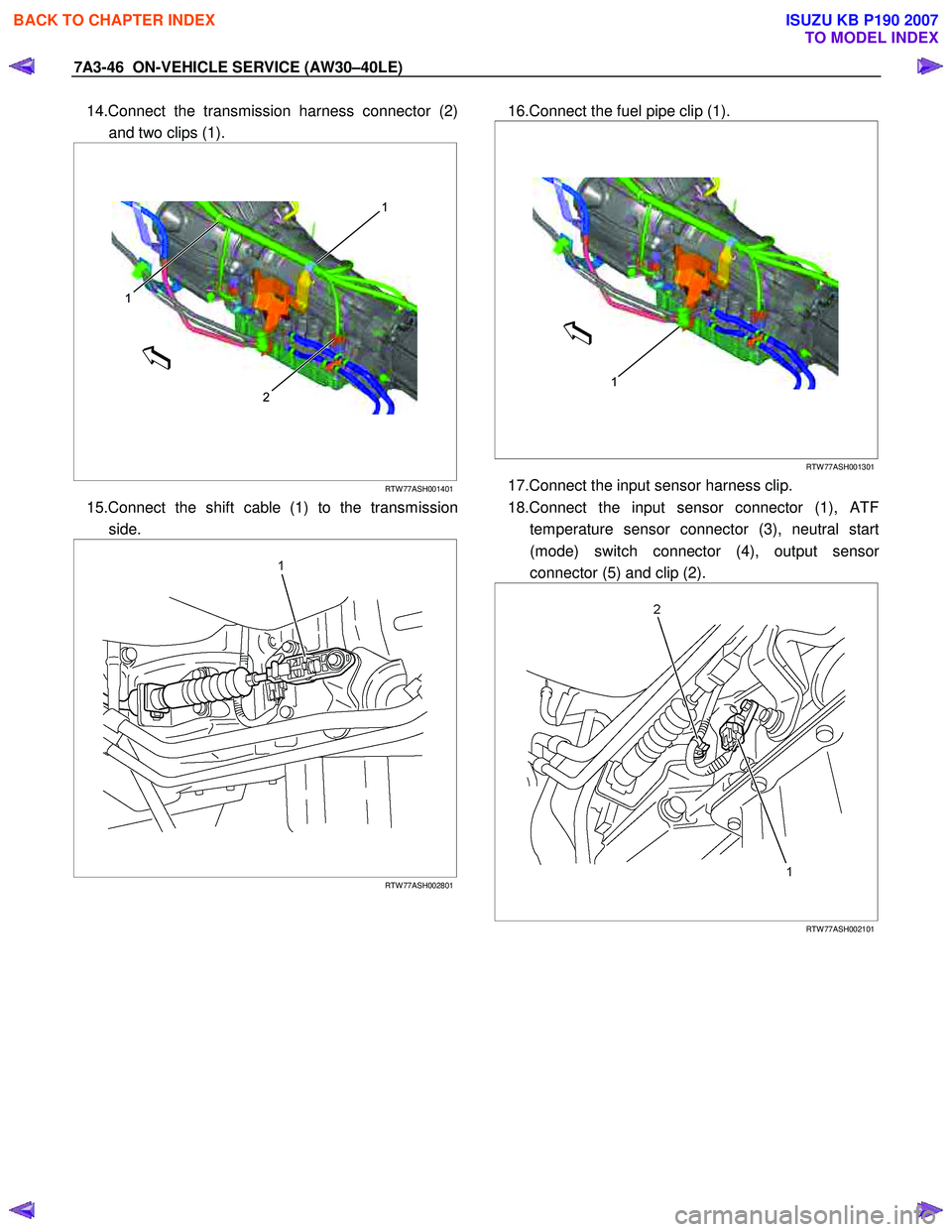

14.Connect the transmission harness connector (2)

and two clips (1).

2

1

1

RTW 77ASH001401

15.Connect the shift cable (1) to the transmission

side.

RTW 77ASH002801

16.Connect the fuel pipe clip (1).

1

RTW 77ASH001301

17.Connect the input sensor harness clip.

18.Connect the input sensor connector (1), ATF temperature sensor connector (3), neutral start

(mode) switch connector (4), output senso

r

connector (5) and clip (2).

RTW 77ASH002101

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4132 of 6020

ON-VEHICLE SERVICE (AW30–40LE) 7A3-47

RTW 77ASH002201

RTW 77ASH002301

19.Install the transfer assembly.(4 ×4 only)

•

Apply a thin coat of molybdenum disulfide

grease to the input shaft spline.

Torque: 41 N ⋅

⋅⋅

⋅

m(4.2 kgf ⋅m/30 lb ⋅ft)

RTW 77ASH001701

20.Connect two harness clips (1) of the tansfer upper

side.

1

1

RTW 77ASH001601

21.Connect the speed sensor connector.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4133 of 6020

7A3-48 ON-VEHICLE SERVICE (AW30–40LE)

22.Connect the 2W D-4W D switch connector (1),

neutral switch connector (2), actuator connecto

r

(3) and speed sensor connector (4).

RTW 77ASH001801

RTW 77ASH001901

RTW 77ASH002001

23.Install the rear propeller shaft.

NOTE: Align alignment marks on the flange.

Torque: 59 N ⋅

⋅⋅

⋅

m (6.0 kgf ⋅m/43 lb ⋅ft)

RTW 77BSH000201

24.Install the center bearing on the crossmember.

Torque: 69 N ⋅

⋅⋅

⋅

m (7.0 kgf ⋅m/51 lb ⋅ft)

25.Install the front propeller shaft.(4 ×4 only)

NOTE: Align alignment marks on the flange.

Torque: 59 N ⋅

⋅⋅

⋅

m (6.0 kgf ⋅m/43 lb ⋅ft)

26.Remove the drain plug from oil pan and drain the fluid.

27.Install the drain plug. Torque: 19 N ⋅

⋅⋅

⋅

m (1.9 kgf ⋅m/14 lb ⋅ft)

28.Pour the transmission oil.

29.Remove suitable stands.

30.Connect battery ground cable.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4134 of 6020

ON-VEHICLE SERVICE (AW30–40LE) 7A3-49

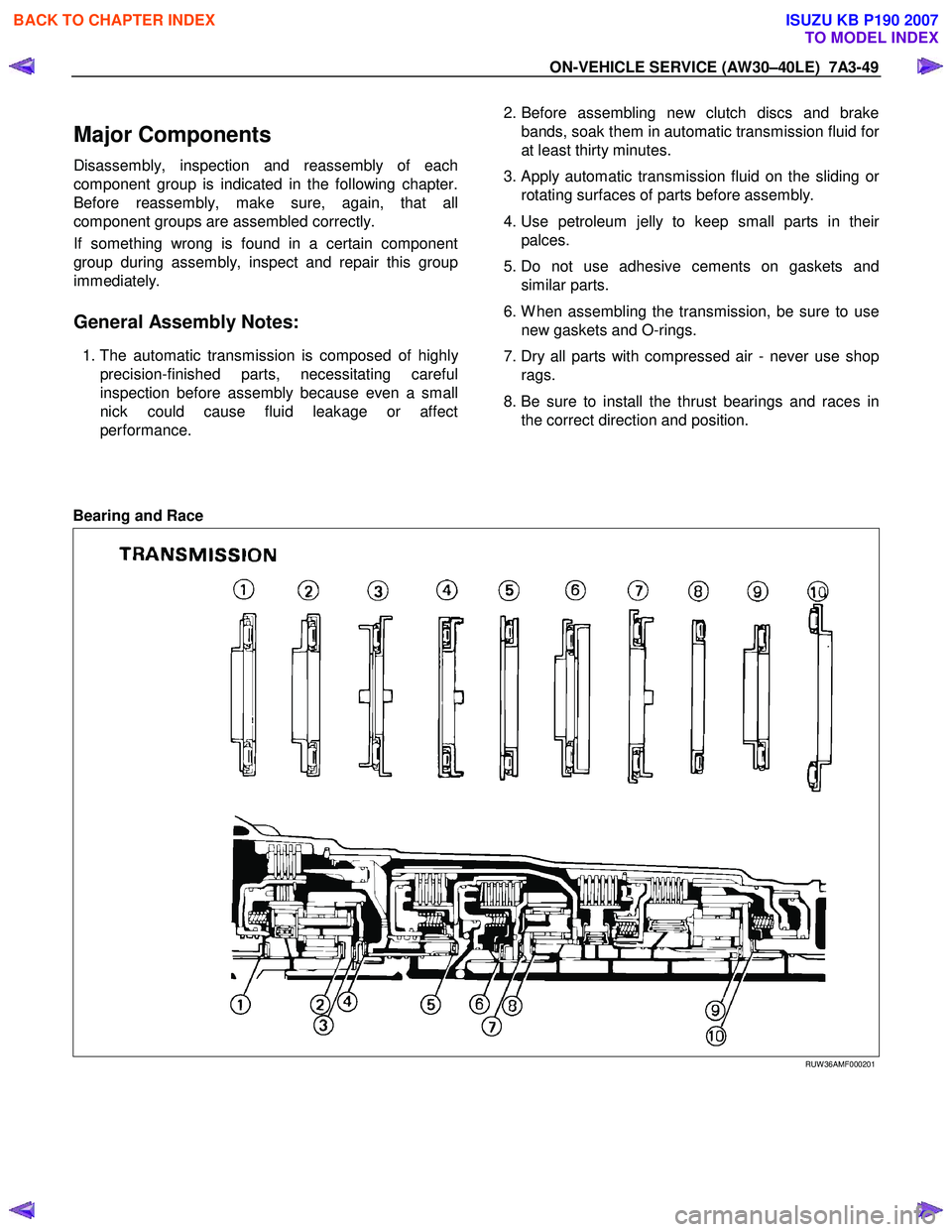

Major Components

Disassembly, inspection and reassembly of each

component group is indicated in the following chapter.

Before reassembly, make sure, again, that all

component groups are assembled correctly.

If something wrong is found in a certain component

group during assembly, inspect and repair this group

immediately.

General Assembly Notes:

1. The automatic transmission is composed of highly

precision-finished parts, necessitating careful

inspection before assembly because even a small

nick could cause fluid leakage or affect

performance.

2. Before assembling new clutch discs and brake

bands, soak them in automatic transmission fluid fo

r

at least thirty minutes.

3. Apply automatic transmission fluid on the sliding o

r

rotating surfaces of parts before assembly.

4. Use petroleum jelly to keep small parts in thei

r

palces.

5. Do not use adhesive cements on gaskets and similar parts.

6. W hen assembling the transmission, be sure to use new gaskets and O-rings.

7. Dry all parts with compressed air - never use shop rags.

8. Be sure to install the thrust bearings and races in the correct direction and position.

Bearing and Race

RUW 36AMF000201

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4135 of 6020

7A3-50 ON-VEHICLE SERVICE (AW30–40LE)

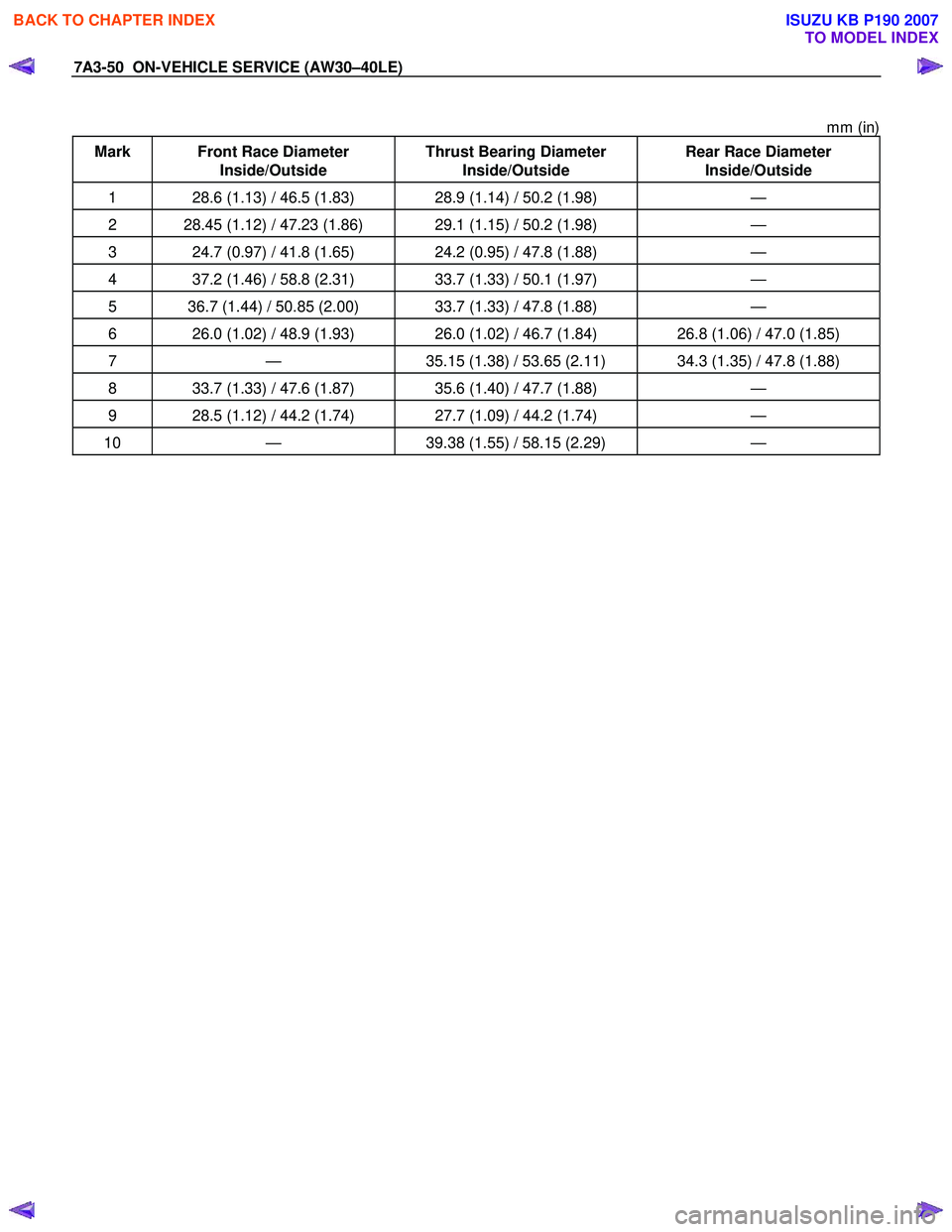

mm (in)

Mark Front Race Diameter Inside/Outside Thrust Bearing Diameter

Inside/Outside Rear Race Diameter

Inside/Outside

1 28.6 (1.13) / 46.5 (1.83) 28.9 (1.14) / 50.2 (1.98) —

2 28.45 (1.12) / 47.23 (1.86) 29.1 (1.15) / 50.2 (1.98) —

3 24.7 (0.97) / 41.8 (1.65) 24.2 (0.95) / 47.8 (1.88) —

4 37.2 (1.46) / 58.8 (2.31) 33.7 (1.33) / 50.1 (1.97) —

5 36.7 (1.44) / 50.85 (2.00) 33.7 (1.33) / 47.8 (1.88) —

6 26.0 (1.02) / 48.9 (1.93) 26.0 (1.02) / 46.7 (1.84) 26.8 (1.06) / 47.0 (1.85)

7 — 35.15 (1.38) / 53.65 (2.11) 34.3 (1.35) / 47.8 (1.88)

8 33.7 (1.33) / 47.6 (1.87) 35.6 (1.40) / 47.7 (1.88) —

9 28.5 (1.12) / 44.2 (1.74) 27.7 (1.09) / 44.2 (1.74) —

10 — 39.38 (1.55) / 58.15 (2.29) —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4136 of 6020

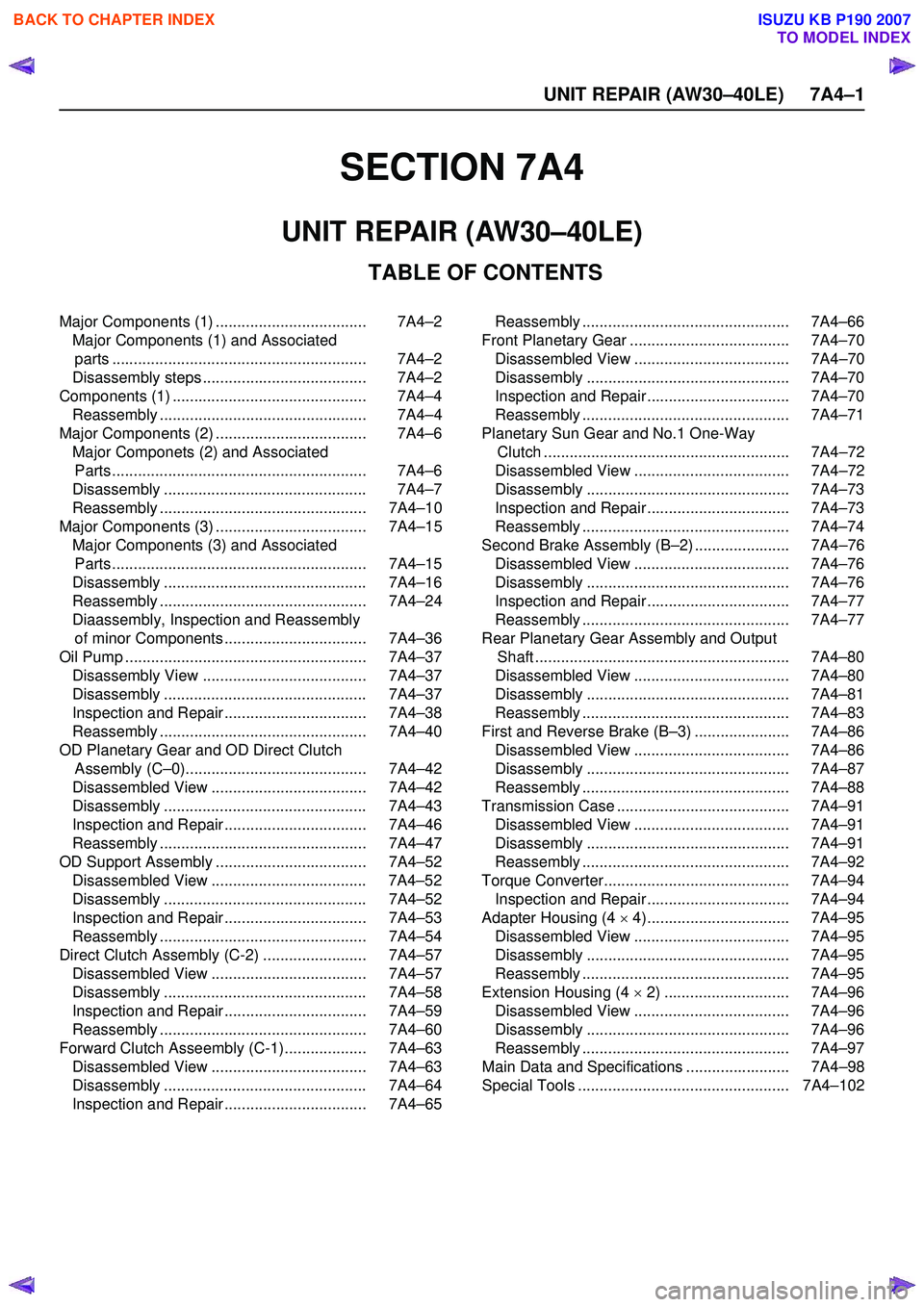

UNIT REPAIR (AW30–40LE) 7A4–1

SECTION 7A4

TABLE OF CONTENTS

UNIT REPAIR (AW30–40LE)

Major Components (1) ................................... 7A4–2Major Components (1) and Associatedparts ........................................................... 7A4–2

Disassembly steps ...................................... 7A4–2

Components (1) ............................................. 7A4–4 Reassembly ................................................ 7A4–4

Major Components (2) ................................... 7A4–6 Major Componets (2) and Associated Parts ........................................................... 7A4–6

Disassembly ............................................... 7A4–7

Reassembly ................................................ 7A4–10

Major Components (3) ................................... 7A4–15 Major Components (3) and AssociatedParts ........................................................... 7A4–15

Disassembly ............................................... 7A4–16

Reassembly ................................................ 7A4–24

Diaassembly, Inspection and Reassembly of minor Components ................................. 7A4–36

Oil Pump ........................................................ 7A4–37 Disassembly View ...................................... 7A4–37

Disassembly ............................................... 7A4–37

Inspection and Repair ................................. 7A4–38

Reassembly ................................................ 7A4–40

OD Planetary Gear and OD Direct Clutch Assembly (C–0).......................................... 7A4–42

Disassembled View .................................... 7A4–42

Disassembly ............................................... 7A4–43

Inspection and Repair ................................. 7A4–46

Reassembly ................................................ 7A4–47

OD Support Assembly ................................... 7A4–52 Disassembled View .................................... 7A4–52

Disassembly ............................................... 7A4–52

Inspection and Repair ................................. 7A4–53

Reassembly ................................................ 7A4–54

Direct Clutch Assembly (C-2) ........................ 7A4–57 Disassembled View .................................... 7A4–57

Disassembly ............................................... 7A4–58

Inspection and Repair ................................. 7A4–59

Reassembly ................................................ 7A4–60

Forward Clutch Asseembly (C-1)................... 7A4–63 Disassembled View .................................... 7A4–63

Disassembly ............................................... 7A4–64

Inspection and Repair ................................. 7A4–65 Reassembly ................................................ 7A4–66

Front Planetary Gear ..................................... 7A4–70 Disassembled View .................................... 7A4–70

Disassembly ............................................... 7A4–70

Inspection and Repair ................................. 7A4–70

Reassembly ................................................ 7A4–71

Planetary Sun Gear and No.1 One-Way Clutch ......................................................... 7A4–72

Disassembled View .................................... 7A4–72

Disassembly ............................................... 7A4–73

Inspection and Repair ................................. 7A4–73

Reassembly ................................................ 7A4–74

Second Brake Assembly (B–2) ...................... 7A4–76 Disassembled View .................................... 7A4–76

Disassembly ............................................... 7A4–76

Inspection and Repair ................................. 7A4–77

Reassembly ................................................ 7A4–77

Rear Planetary Gear Assembly and Output Shaft ........................................................... 7A4–80

Disassembled View .................................... 7A4–80

Disassembly ............................................... 7A4–81

Reassembly ................................................ 7A4–83

First and Reverse Brake (B–3) ...................... 7A4–86 Disassembled View .................................... 7A4–86

Disassembly ............................................... 7A4–87

Reassembly ................................................ 7A4–88

Transmission Case ........................................ 7A4–91 Disassembled View .................................... 7A4–91

Disassembly ............................................... 7A4–91

Reassembly ................................................ 7A4–92

Torque Converter........................................... 7A4–94 Inspection and Repair ................................. 7A4–94

Adapter Housing (4 × 4)................................. 7A4–95

Disassembled View .................................... 7A4–95

Disassembly ............................................... 7A4–95

Reassembly ................................................ 7A4–95

Extension Housing (4 × 2) ............................. 7A4–96

Disassembled View .................................... 7A4–96

Disassembly ............................................... 7A4–96

Reassembly ................................................ 7A4–97

Main Data and Specifications ........................ 7A4–98

Special Tools ................................................. 7A4–102

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4137 of 6020

7A4–2 UNIT REPAIR (AW30–40LE)

Major Components (1)

Major Components (1) and Associated parts

RTW77AMF003801

EndOFCallout

Disassembly steps

1. Remove the torque converter.

2. Remove the select lever.

Legend (1) Torque converter

(2) Neutral start switch

(3) Elbow

(4) Oil temperature sensor

(5) Breather hose (6) Output revolution sensor

(7) Adapter housing

(8) Transmission assembly

(9) Select lever

(10) Input revolution sensor

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4138 of 6020

UNIT REPAIR (AW30–40LE) 7A4–3

3. Remove the neutral start switch (Mode switch). Unstake the lock washer.

Remove the nut and bolt, and then remove the

neutral start switch.

Remove the lock washer.

RTW77ASH003401

4. Remove the two elbows from transmission case.

240RY00001

5. Remove the oil temperature sensor.

6. Remove the breather hose.

7. Remove the Input revolution sensor.

8. Remove the output revolution sensor (4 ×4).

9. Remove the output revolution sensor (4 ×2).

10. Remove the speedometer sensor, speedometer driven gear and plate (4 ×2).

11. Remove the extension housing (4 ×2).

12. Remove the adapter housing (4 ×4). 13. Remove the transmission assembly.

Install special tool to the transmission unit.

Holding fixture: 5-8840-2152-0 (1)

Holding fixture base: 5-8840-0003-0 (2)

RTW77ASH003301

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4139 of 6020

7A4–4 UNIT REPAIR (AW30–40LE)

Components (1)

Reassembly

1. Install a new gasket and the extension housing(4×2) to the transmission case.

Torque: 36 N·m (3.7 kgf·m/27 Ib ·ft)

2. Install the speedometer driven gear, plate, and speedometer sensor (4 ×2).

Torque:

Plate bolt – 15 N·m (1.5 kgf·m/11 Ib ·ft)

Speedometer sensor – 25 N·m (2.5 kgf·m/18 Ib ·ft)

3. Install the adapter housing (4 ×4).

Remove any gasket material on the contacting

surfaces of the adapter housing and transmission

case.

241RY00020

Apply liquid gasket (TB1281 –B or its equivalent)

(1) and install the apply gaskets (2) to the adapter

housing as shown in the figure.

Install the adapter housing to the transmission

case.

Torque: 36 N·m (3.7 kgf·m/27 Ib ·ft)

4. Install the neutral start switch. Using the transmission select lever, fully turn the

manual valve lever shaft back and return two

notches.

It is now in neutral.

Insert the neutral start switch onto the manual

valve lever shaft and temporarily tighten the

adjusting bolt.

Install the lock washer and nut.

Torque: 7 N·m (0.7 kgf·m/61 Ib ·in)

Align the neutral standard line and the switch

groove and tighten the adjusting bolt.

Torque: 13 N·m (1.3 kgf·m/113 Ib ·in)

Bend the tabs of the lock washer.

NOTE: Bend at least two of the lock washer tabs.

RUW17ASH013601

5. Install the oil temperature sensor to the transmission case.

Torque: 15 N·m (1.5 kgf·m/11 Ib ·ft)

RTW77ASH003501

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4140 of 6020

UNIT REPAIR (AW30–40LE) 7A4–5

6. Install the elbow. Coat new O-rings with ATF, install them to the two

elbows.

Install the two elbows as shown in the figure.

Torque: 29 N ·m (3.0 kgf ·m/22 Ib ·ft)

RTW77ASH003601

7. Install the select lever.

8. Install the output revolution sensor (4 ×2).

9. Install the output revolution sensor (4 ×4).

10. Install the input revolution sensor.

11. Install the breather hose.

12. Install the torque converter. Using calipers and a straightedge, measure the

distance from the installed surface of the

transmission housing to top of the torque converter

nut.

Correct distance: 13.5 mm (0.53 in)

240RY00005

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007