Circuit ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 804 of 6020

TROUBLESHOOTING 6 – 19

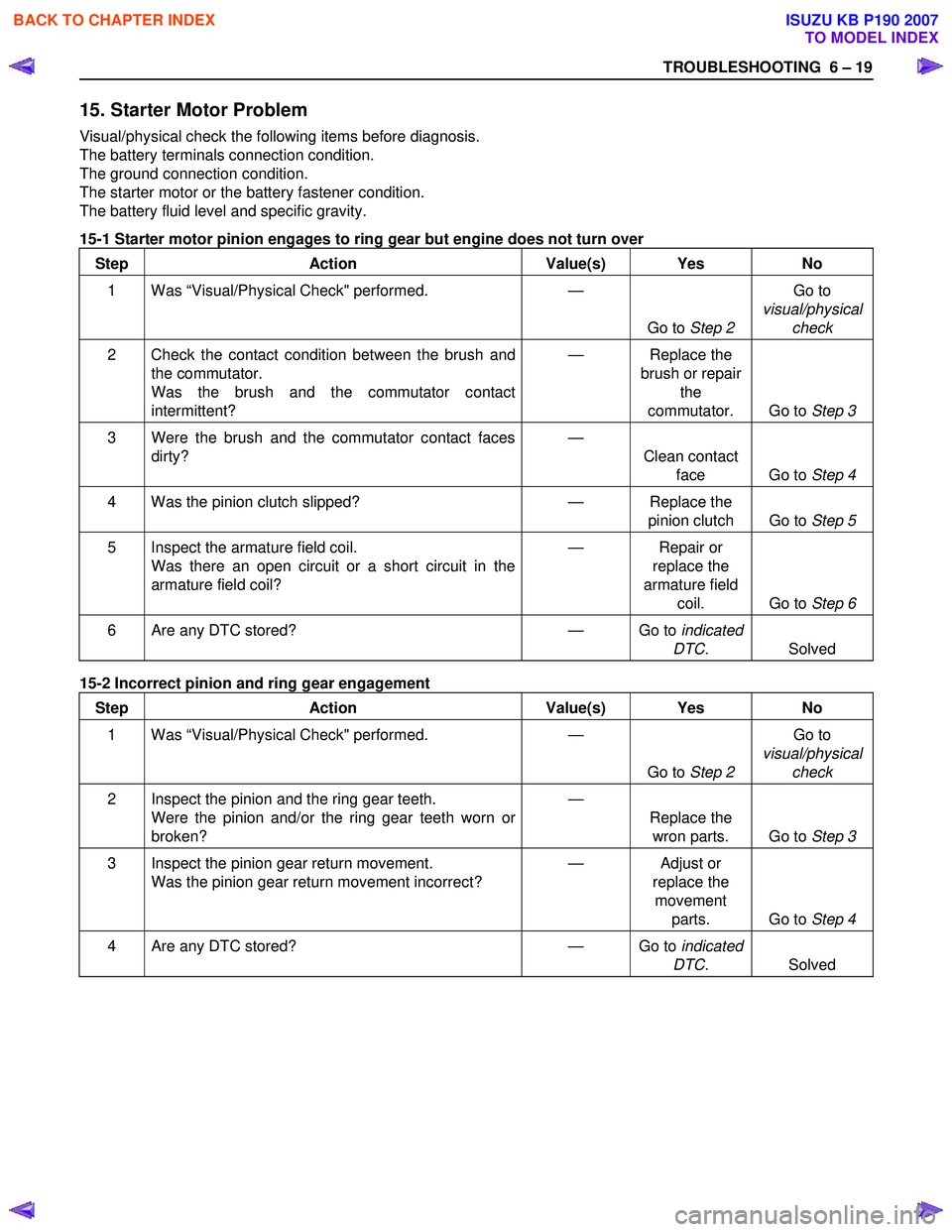

15. Starter Motor Problem

Visual/physical check the following items before diagnosis.

The battery terminals connection condition.

The ground connection condition.

The starter motor or the battery fastener condition.

The battery fluid level and specific gravity.

15-1 Starter motor pinion engages to ring gear but engine does not turn over

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Check the contact condition between the brush and

the commutator.

Was the brush and the commutator contact

intermittent? —

Replace the

brush or repair the

commutator. Go to Step 3

3 Were the brush and the commutator contact faces

dirty?

—

Clean contact face Go to Step 4

4 Was the pinion clutch slipped? — Replace the

pinion clutch Go to Step 5

5 Inspect the armature field coil.

Was there an open circuit or a short circuit in the

armature field coil? —

Repair or

replace the

armature field coil. Go to Step 6

6 Are any DTC stored? — Go to indicated

DTC. Solved

15-2 Incorrect pinion and ring gear engagement

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Inspect the pinion and the ring gear teeth.

Were the pinion and/or the ring gear teeth worn or

broken? —

Replace the wron parts. Go to Step 3

3 Inspect the pinion gear return movement.

Was the pinion gear return movement incorrect? —

Adjust or

replace the movement parts. Go to Step 4

4 Are any DTC stored? — Go to indicated

DTC. Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 951 of 6020

ENGINE COOLING 6B – 7

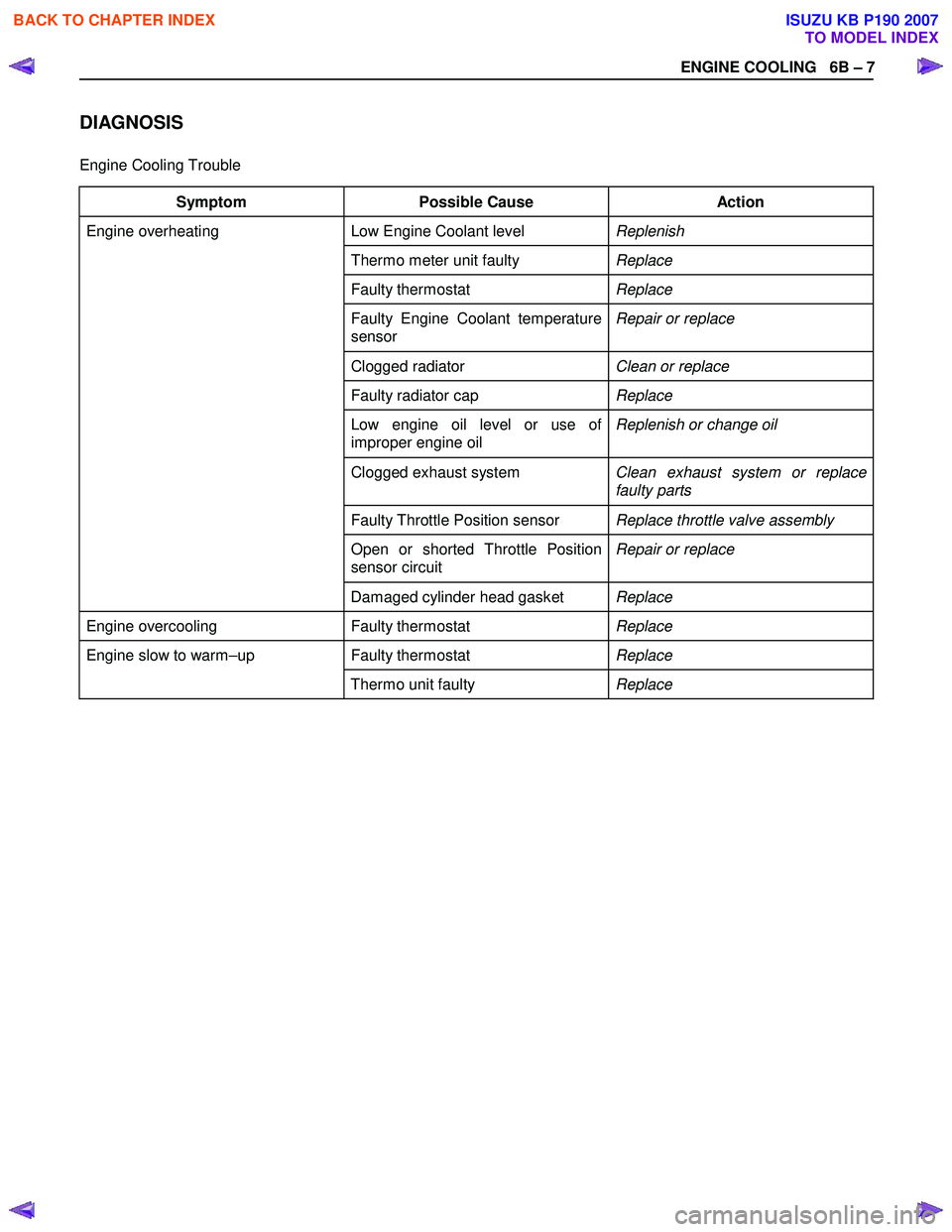

DIAGNOSIS

Engine Cooling Trouble

Symptom Possible Cause Action

Low Engine Coolant level Replenish

Thermo meter unit faulty Replace

Faulty thermostat Replace

Faulty Engine Coolant temperature

sensor Repair or replace

Clogged radiator

Clean or replace

Faulty radiator cap Replace

Low engine oil level or use of

improper engine oil Replenish or change oil

Clogged exhaust system

Clean exhaust system or replace

faulty parts

Faulty Throttle Position sensor Replace throttle valve assembly

Open or shorted Throttle Position

sensor circuit Repair or replace

Engine overheating

Damaged cylinder head gasket Replace

Engine overcooling Faulty thermostat Replace

Faulty thermostat Replace Engine slow to warm–up

Thermo unit faulty Replace

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1004 of 6020

ENGINE ELECTRICAL 6D – 3

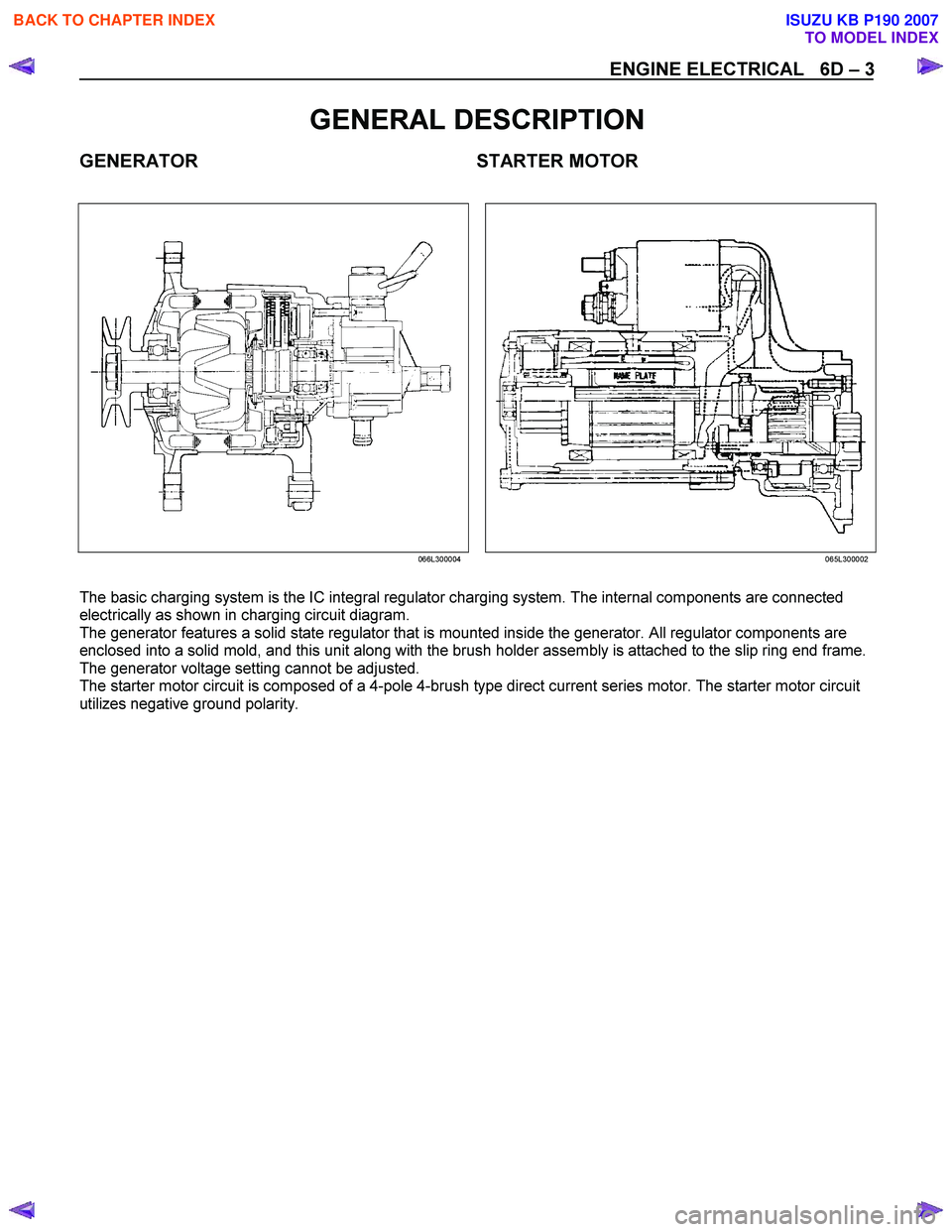

GENERAL DESCRIPTION

GENERATOR STARTER MOTOR

066L300004 065L300002

The basic charging system is the IC integral regulator charging system. The internal components are connected

electrically as shown in charging circuit diagram.

The generator features a solid state regulator that is mounted inside the generator. All regulator components are

enclosed into a solid mold, and this unit along with the brush holder assembly is attached to the slip ring end frame.

The generator voltage setting cannot be adjusted.

The starter motor circuit is composed of a 4-pole 4-brush type direct current series motor. The starter motor circuit

utilizes negative ground polarity.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1005 of 6020

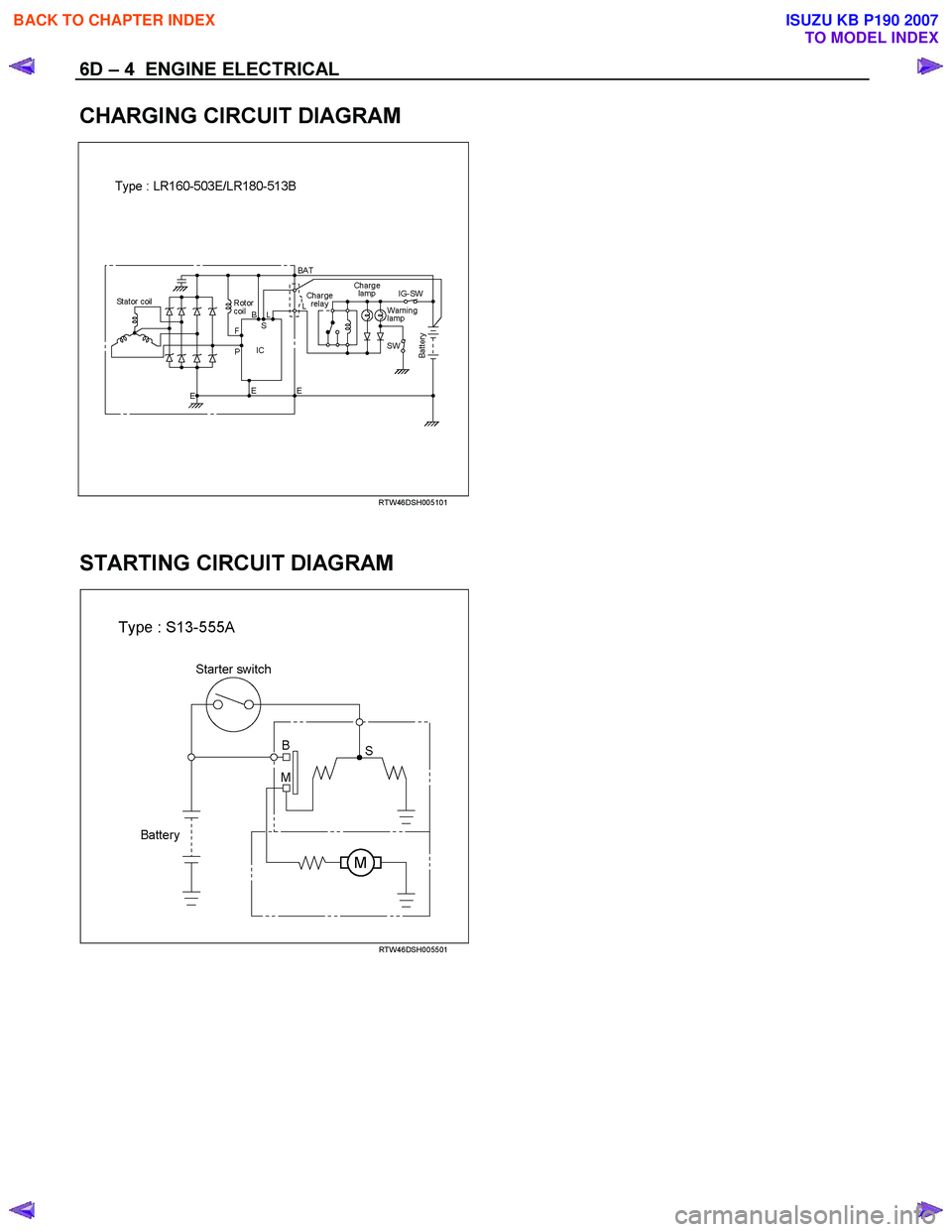

6D – 4 ENGINE ELECTRICAL

CHARGING CIRCUIT DIAGRAM

RTW46DSH005101

STARTING CIRCUIT DIAGRAM

RTW46DSH005501

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1015 of 6020

6D – 14 ENGINE ELECTRICAL

RECTIFIER ASSEMBLY

RTW46DSF000301

1. Voltmeter

2. Switch 1

3. DC regulated power supply

4. Lamp 2

5. Lamp 1

6. Switch 3

7. Switch 2

8. Pulse generator

9. Output signal

Test circuit

Refer to the judgment criteria shown in the Table below.

Carefully check Items 1~5. If all the items are OK, the IC

regulator is normal.

Circuit components

1 DC regulated power supply 0~20 volts variable with output of 1 ampere or more

2 Lamps (2)

12 volts, 1.4~3.4 watts

3 Switches (3)

-----

4 DC voltmeter

0~30 volts, 0.5 grade

5 Pulse generator (Oscillator)

5~30 volt output at a frequency of 1kHz

Judgment criteria

Lamp condition

No. Switch

1 Switch

2 Switch

3 Voltmeter

reading Lamp 1 Lamp 2 Remarks

1

ON OFF OFF On

(dim) ON Initial excitation check

2

ON ON OFF 12V

On or

flashing Full excitation check

3

ON ON OFF 16V Off or

on (dim) OFF

Lamp 1 off or dimly lit when the

voltmeter shows less than 12 volts or

16 volts

4 OFF ON OFF 12V On or

flashing Stator and brush separation check

5

ON ON ON 18V On ON

Excess voltage check

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1027 of 6020

6D – 26 ENGINE ELECTRICAL

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacement if excessive wear or damage is discovered during

inspection.

ARMATURE

1. Measure the commutator run-out. Replace the commutator if the measured run-out

exceeds the specified limit.

Commutator Run-Out mm (in)

Standard Limit

0.05 (0.002) 0.2 (0.008)

RTW46DSH003501

2. Check the commutator mica segments for excessive

wear.

3. Measure the mica segment depth.

Mica Segment Depth mm (in)

Standard Limit

0.5 ∼ 0.8 (0.020 ∼ 0.030) 0.2 (0.008)

065RY00025

If the mica segment depth is less than the standard but

more than the limit, the commutator may be reground.

If the mica segment depth is less than the limit, the

commutator must be replaced.

4. Measure the commutator outside diameter.

Commutator Outside Diameter mm (in)

Standard Limit

36.5 (1.44) 35.5 (1.40)

If the measured outside diameter is less than the specified

limit, the commutator must be replaced.

065RY00026

RTW46DSH003601

5. Use a circuit tester to check the armature for

grounding.

1 Hold one probe of the circuit tester against the commutator segment.

2 Hold the other circuit tester probe against the armature core.

If the circuit tester indicates continuity, the armature is grounded.

The armature must be replaced.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1028 of 6020

ENGINE ELECTRICAL 6D – 27

RTW46DSH003701

6. Use the circuit tester to check the armature for

continuity.

1 Hold the circuit tester probes against two commutator segments.

2 Repear Step 1 at different segments of the armature core.

There should be continuity between all segments of the commutator.

If there is not, the armature must be replaced.

RTW46DSH003801

YOKE

1. Use a circuit tester to check the field winding ground.

1 Hold one circuit tester probe against the field winding end or brush.

2 Hold the other circuit tester probe against the bare surface of the yoke body.

There should be no continuity. If there is continuity, the field coil is grounded.

The yoke must be replaced.

RTW46DSH003901

2. Use the circuit tester to check the field winding

continuity.

1 Hold one circuit tester probe against the “M ”

terminal lead wire.

2 Hold the other circuit tester probe against the field winding brush.

There should be continuity. If there is no continuity, the yoke must be replaced.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1029 of 6020

6D – 28 ENGINE ELECTRICAL

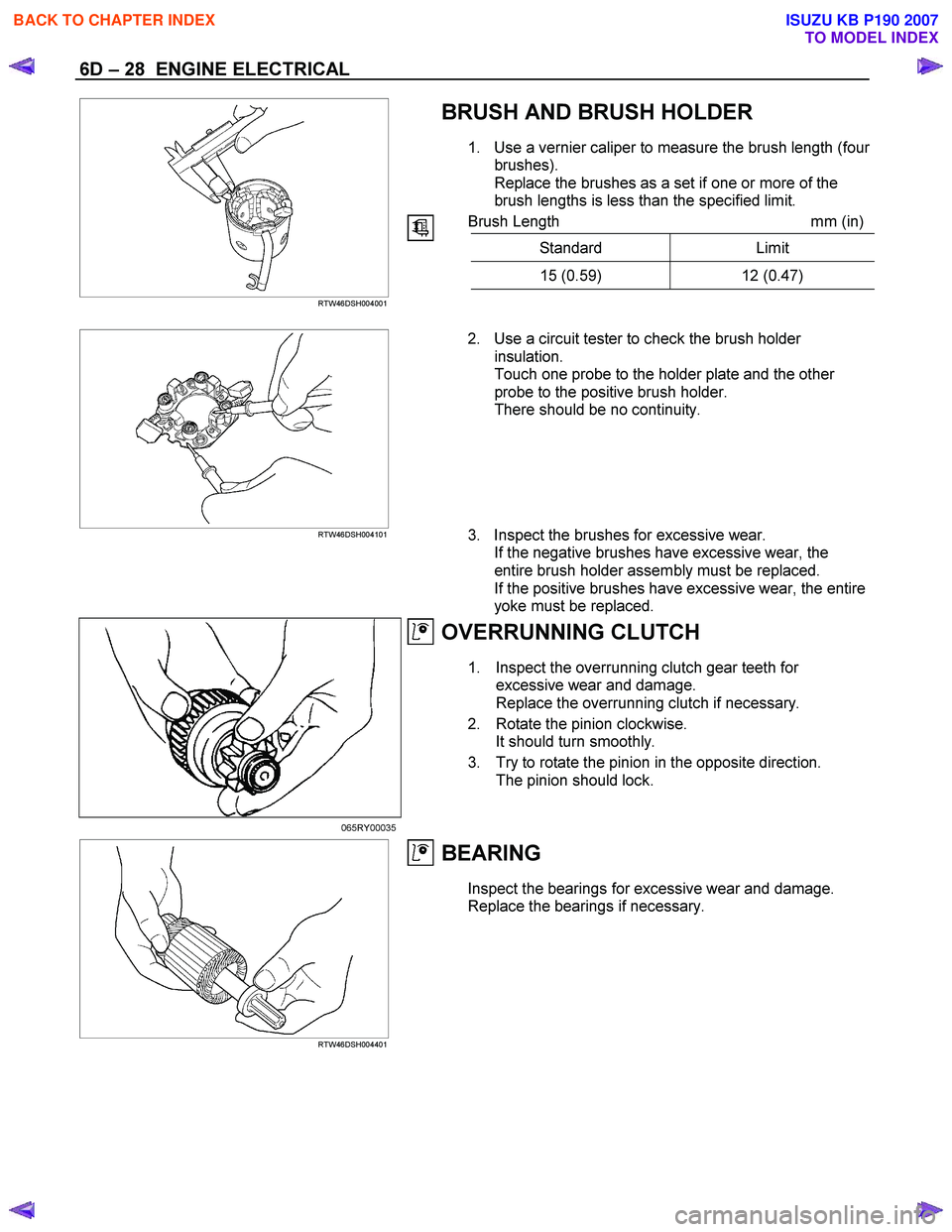

BRUSH AND BRUSH HOLDER

1. Use a vernier caliper to measure the brush length (four

brushes).

Replace the brushes as a set if one or more of the

brush lengths is less than the specified limit.

Brush Length mm (in)

Standard Limit

15 (0.59) 12 (0.47)

RTW46DSH004001

RTW46DSH004101

2. Use a circuit tester to check the brush holder

insulation.

Touch one probe to the holder plate and the other

probe to the positive brush holder.

There should be no continuity.

3. Inspect the brushes for excessive wear. If the negative brushes have excessive wear, the

entire brush holder assembly must be replaced.

If the positive brushes have excessive wear, the entire

yoke must be replaced.

OVERRUNNING CLUTCH

1. Inspect the overrunning clutch gear teeth for excessive wear and damage.

Replace the overrunning clutch if necessary.

2. Rotate the pinion clockwise. It should turn smoothly.

3. Try to rotate the pinion in the opposite direction. The pinion should lock.

065RY00035

RTW46DSH004401

BEARING

Inspect the bearings for excessive wear and damage.

Replace the bearings if necessary.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1034 of 6020

ENGINE ELECTRICAL 6D – 33

PRE-HEATING SYSTEM

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacement if excessive wear of damage is discovered during

inspection.

VISUAL CHECK

Check the main fuses and glow indicator for damage.

Replace the part(s) if required.

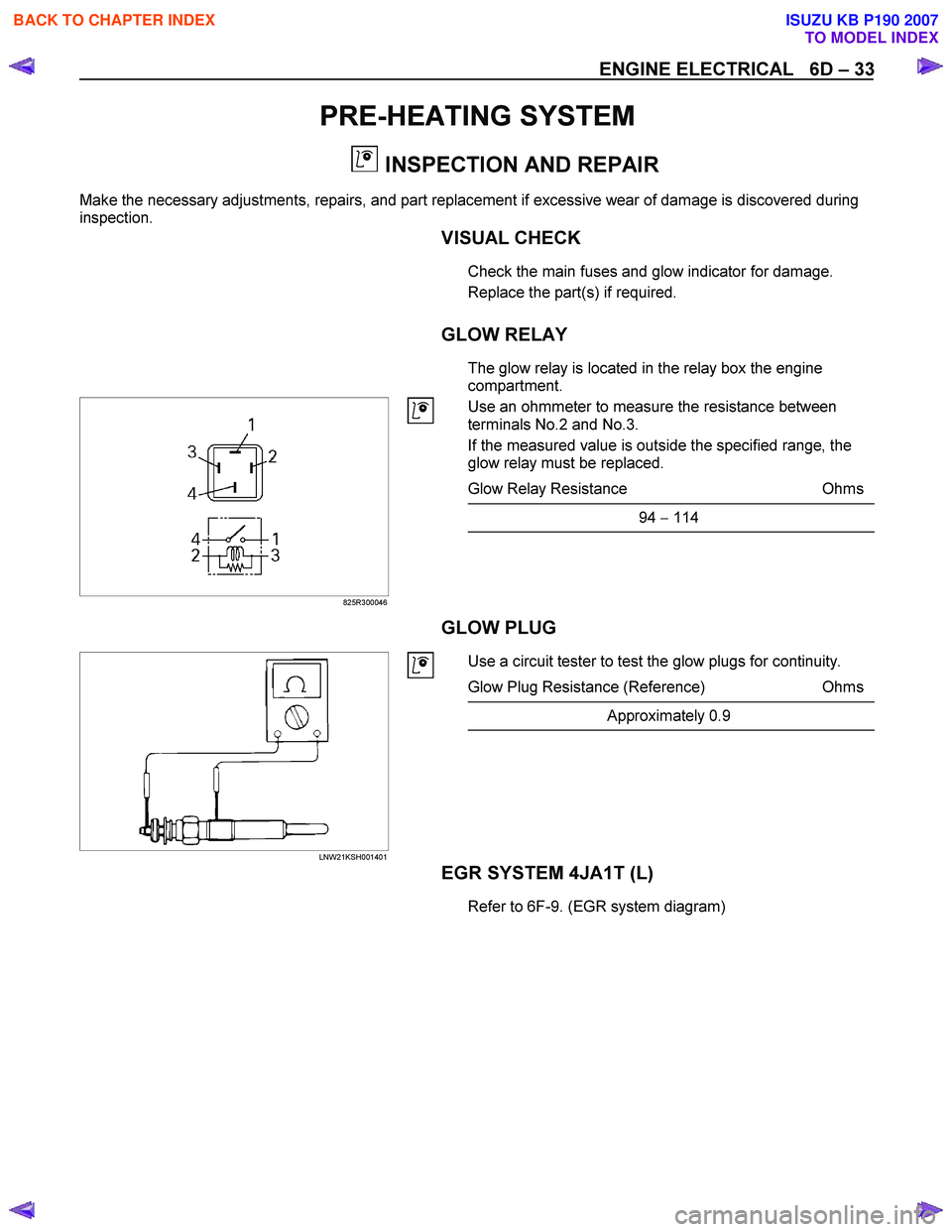

GLOW RELAY

The glow relay is located in the relay box the engine

compartment.

825R300046

Use an ohmmeter to measure the resistance between

terminals No.2 and No.3.

If the measured value is outside the specified range, the

glow relay must be replaced.

Glow Relay Resistance Ohms

94 − 114

GLOW PLUG

LNW21KSH001401

Use a circuit tester to test the glow plugs for continuity.

Glow Plug Resistance (Reference) Ohms

Approximately 0.9

EGR SYSTEM 4JA1T (L)

Refer to 6F-9. (EGR system diagram)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1037 of 6020

Engine Control System (4JH1) 6E-3

Rough, Unstable, or In co rr ect Idle And

Stallin g........................................................... .6E -260

Cut Out, Mi sses.............................................. .6E -262

Su rge s/Chuggle s............................................ .6E -263

La ck of Po wer, Sluggi shne ss, Spongine ss .... .6E -266

He sitation, Sag, Stu mble................................ .6E -268

Fuel Kno ck /Co mbu stion Noi se ....................... .6E -270

Poor F uel E cono my........................................ .6E -271

E xc ess ive S moke (B la ck S m oke) ................. .6E -272

E xc ess ive S moke (W hite S moke) ................. .6E -273

Repair In str u ctions ............................................ .6E -275

Engine Control Module (ECM) Replacement ..6E-275

Service Programming System (SPS)

Description .....................................................6E-276

Service Programming System (SPS)

(Remote Procedure) ......................................6E-277

Service Programming System (SPS)

(Pass-Thru Procedure) ..................................6E-278

Accelerator Pedal Position (APP) Sensor

Replacement ..................................................6E-279

Crankshaft Position Sensor (CKP) Sensor

Replacement ..................................................6E-279

EGR Solenoid Valve Replacement .................6E-280

Engine Coolant Temperature Coolant

(ECT) Sensor Replacement ...........................6E-280

Mass Air Flow (MAF) / Intake Air Temperature

Sensor Replacement......................................6E-280

Turbocharger Solenoid Valve Replacement

[High Altitude Spec] ........................................6E-281

Vacuum Pressure Sensor Replacement

[High Altitude Spec] ........................................6E-281

Vehicle Speed Sensor (VSS) Replacement ....6E-282

Description And Operation .................................6E-283 Engine Control Module (ECM) .......................6E-283

Engine Control Component Description ..........6E-284

Fuel Injection System Description ...................6E-288

Low Pressure Fuel Circuit Description ............6E-290

High Pressure Fuel Circuit Description ...........6E-291

Timing Control Device Description ..................6E-294

Exhaust Gas Recirculation (EGR) System

Description .....................................................6E-297

Turbocharger Description................................6E-298

Special Tools And Equipment ............................6E-299 Special Tools and Equipment .........................6E-299

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007