Circuit ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1104 of 6020

6E-70 Engine Control System (4JH1)

DTC P0100 (Symptom Code B) (Flash Code 65)

Circuit Description

The mass air flow (MAF) sensor is an air flow meter that

measures the amount of air that enters the engine. It is

fitted between the air cleaner and turbocharger. A small

quantity of air that enters the engine indicates

deceleration or idle speed. A large quantity of air that

enters the engine indicates acceleration or a high load

condition. The MAF sensor has the following circuits.

• Ignition voltage circuit

• 5 volts reference circuit

• Low reference circuit

• MAF sensor signal circuit

The engine control module (ECM) monitors the MAF

sensor signal for voltage outside the normal range o

f

the MAF sensor. If the ECM detects an excessively low

MAF sensor signal voltage, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

• The engine is running.

Condition for Setting the DTC

• The ECM calculated MAF is lower than -18.6 kg/h

for 5 seconds. This indicates the ECM detects that

the MAF sensor signal voltage is smaller than a

predetermined range during engine run.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM uses a MAF substitution of 1600 mg/strk

for engine control.

• The ECM uses an EGR solenoid valve control

substitution of 10%.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL that the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice: • W rong direction of MAF sensor installation will

cause this DTC to set.

• Contaminated or restricted MAF sensor will cause

this DTC to set.

• The MAF Sensor parameter on the scan tool will

only update with engine running.

Test Description

The number below refers to the step number on the

diagnostic table.

7. If the MAF sensor signal circuit between the ECM

and the sensor is short to ground or any low reference

circuits, the sensor 5 volts reference voltage low DTC

P0100 (Symptom Code 9) will set.

8. If the MAF sensor signal circuit between the ECM

and the sensor is normal, the sensor signal voltage high

DTC P0100 (Symptom Code C) will set.

DTC P0100 (Symptom Code B) (Flash Code 65)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle for 30 seconds.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Inspect the ECM (10A) fuse (EB-4) in the engine room fuse block.

Is the ECM (10A) fuse (EB-4) open?

Go to Step 4 Go to Step 5

4 Replace the ECM (10A) fuse (EB-4). If the fuse continues to open, repair the short to ground on one

of the circuits that is fed by the ECM (10A) fuse (EB-

4) or replace the shorted attached component fed by

the ECM (10A) fuse (EB-4).

Did you complete the repair?

Go to Step 17

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1105 of 6020

Engine Control System (4JH1) 6E-71

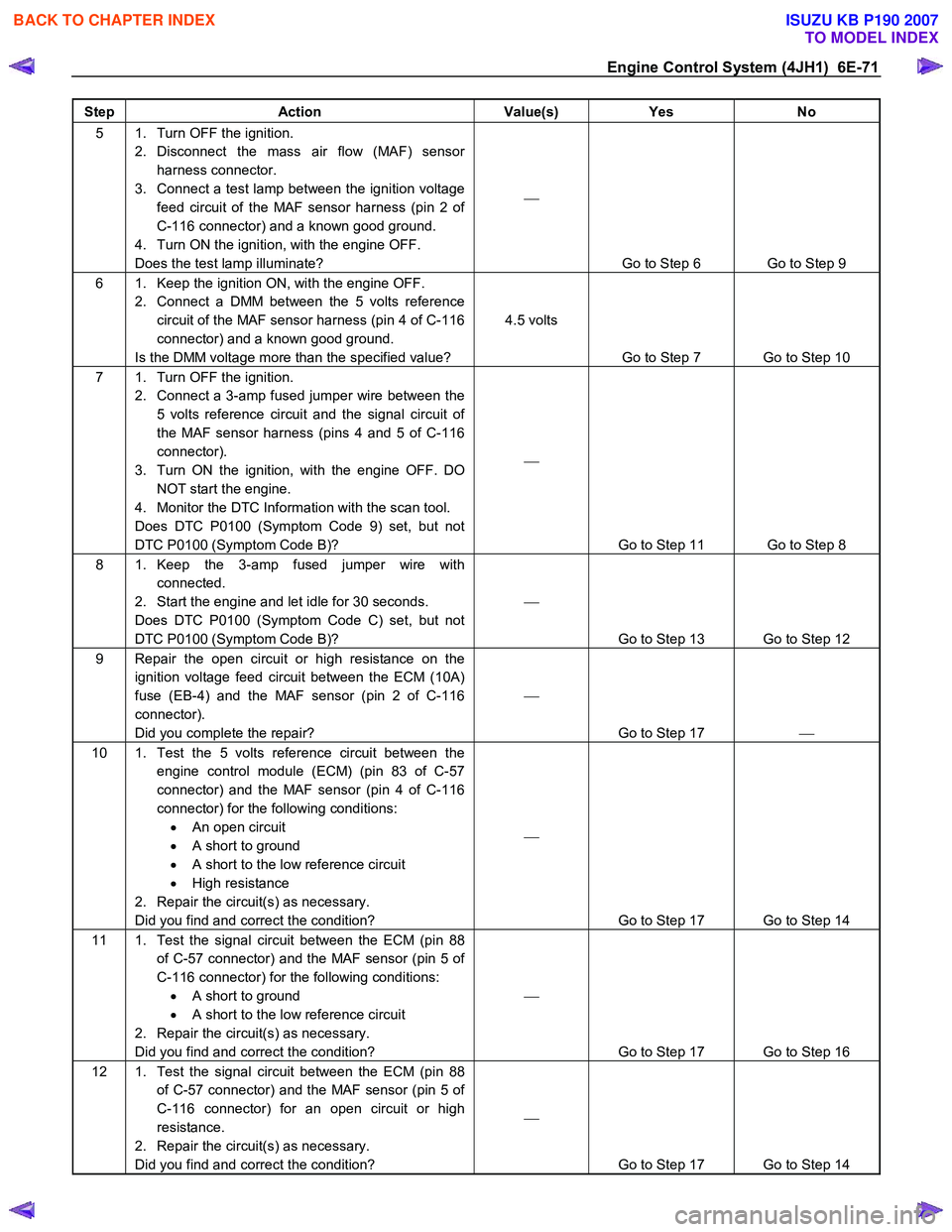

Step Action Value(s) Yes No

5 1. Turn OFF the ignition.

2. Disconnect the mass air flow (MAF) sensor harness connector.

3. Connect a test lamp between the ignition voltage feed circuit of the MAF sensor harness (pin 2 of

C-116 connector) and a known good ground.

4. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate?

Go to Step 6 Go to Step 9

6 1. Keep the ignition ON, with the engine OFF. 2. Connect a DMM between the 5 volts reference circuit of the MAF sensor harness (pin 4 of C-116

connector) and a known good ground.

Is the DMM voltage more than the specified value? 4.5 volts

Go to Step 7 Go to Step 10

7 1. Turn OFF the ignition. 2. Connect a 3-amp fused jumper wire between the 5 volts reference circuit and the signal circuit of

the MAF sensor harness (pins 4 and 5 of C-116

connector).

3. Turn ON the ignition, with the engine OFF. DO NOT start the engine.

4. Monitor the DTC Information with the scan tool.

Does DTC P0100 (Symptom Code 9) set, but not

DTC P0100 (Symptom Code B)?

Go to Step 11 Go to Step 8

8 1. Keep the 3-amp fused jumper wire with connected.

2. Start the engine and let idle for 30 seconds.

Does DTC P0100 (Symptom Code C) set, but not

DTC P0100 (Symptom Code B)?

Go to Step 13 Go to Step 12

9 Repair the open circuit or high resistance on the ignition voltage feed circuit between the ECM (10A)

fuse (EB-4) and the MAF sensor (pin 2 of C-116

connector).

Did you complete the repair?

Go to Step 17

10 1. Test the 5 volts reference circuit between the

engine control module (ECM) (pin 83 of C-57

connector) and the MAF sensor (pin 4 of C-116

connector) for the following conditions: • An open circuit

• A short to ground

• A short to the low reference circuit

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 14

11 1. Test the signal circuit between the ECM (pin 88 of C-57 connector) and the MAF sensor (pin 5 of

C-116 connector) for the following conditions: • A short to ground

• A short to the low reference circuit

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 16

12 1. Test the signal circuit between the ECM (pin 88 of C-57 connector) and the MAF sensor (pin 5 of

C-116 connector) for an open circuit or high

resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 14

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1106 of 6020

6E-72 Engine Control System (4JH1)

Step Action Value(s) Yes No

13 1. Turn OFF the ignition.

2. Inspect for an intermittent and for poor connections at the harness connector of the MAF

sensor (pins 2, 4 and 5 of C-116 connector).

3. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 15

14 1. Turn OFF the ignition. 2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for poor connections on the MAF sensor circuits at the

harness connector of the ECM (pins 83 and 88 of

C-57 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 16

15 Replace the MAF sensor. Refer to Mass Air Flow Sensor Replacement in this section.

Did you complete the replacement?

Go to Step 17

16 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 17

17 1. Reconnect all previously disconnected fuse or

harness connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Accelerate the engine between idle and W .O.T. (accelerator pedal full travel) many times while

observing the DTC Information with the scan

tool.

Did the DTC fail this ignition?

Go to Step 3 Go to Step 18

18 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1107 of 6020

Engine Control System (4JH1) 6E-73

DTC P0100 (Symptom Code C) (Flash Code 65)

Circuit Description

The mass air flow (MAF) sensor is an air flow meter that

measures the amount of air that enters the engine. It is

fitted between the air cleaner and turbocharger. A small

quantity of air that enters the engine indicates

deceleration or idle speed.

A large quantity of air that

enters the engine indicates acceleration or a high load

condition. The MAF sensor has the following circuits.

• Ignition voltage circuit

• 5 volts reference circuit

• Low reference circuit

• MAF sensor signal circuit

The engine control module (ECM) monitors the MAF

sensor signal for voltage outside the normal range o

f

the MAF sensor. If the ECM detects an excessively high

MAF sensor signal voltage, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

• The engine is running.

Condition for Setting the DTC

• The ECM calculated MAF is higher than 984 kg/h

for 10 seconds. This indicates the ECM detects

that the MAF sensor signal voltage is higher than a

predetermined range during engine run.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM uses a MAF substitution of 1600 mg/strk

for engine control.

• The ECM uses an EGR solenoid valve control

substitution of 10%.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice: • The MAF Sensor parameter on the scan tool will

only update with engine running.

Test Description

The number below refers to the step number on the

diagnostic table.

3. If the MAF sensor signal circuit between the ECM

and the sensor is normal, the sensor signal voltage lo

w

DTC P0100 (Symptom Code B) will set.

DTC P0100

(Symptom Code C) (Flash Code 65)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle for 30 seconds.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Disconnect the mass air flow (MAF) sensor harness connector.

3. Start the engine and let idle for 30 seconds.

4. Monitor the DTC Information with the scan tool.

Does DTC P0100 (Symptom Code B) set, but not

DTC P0100 (Symptom Code C)?

Go to Step 4 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1108 of 6020

6E-74 Engine Control System (4JH1)

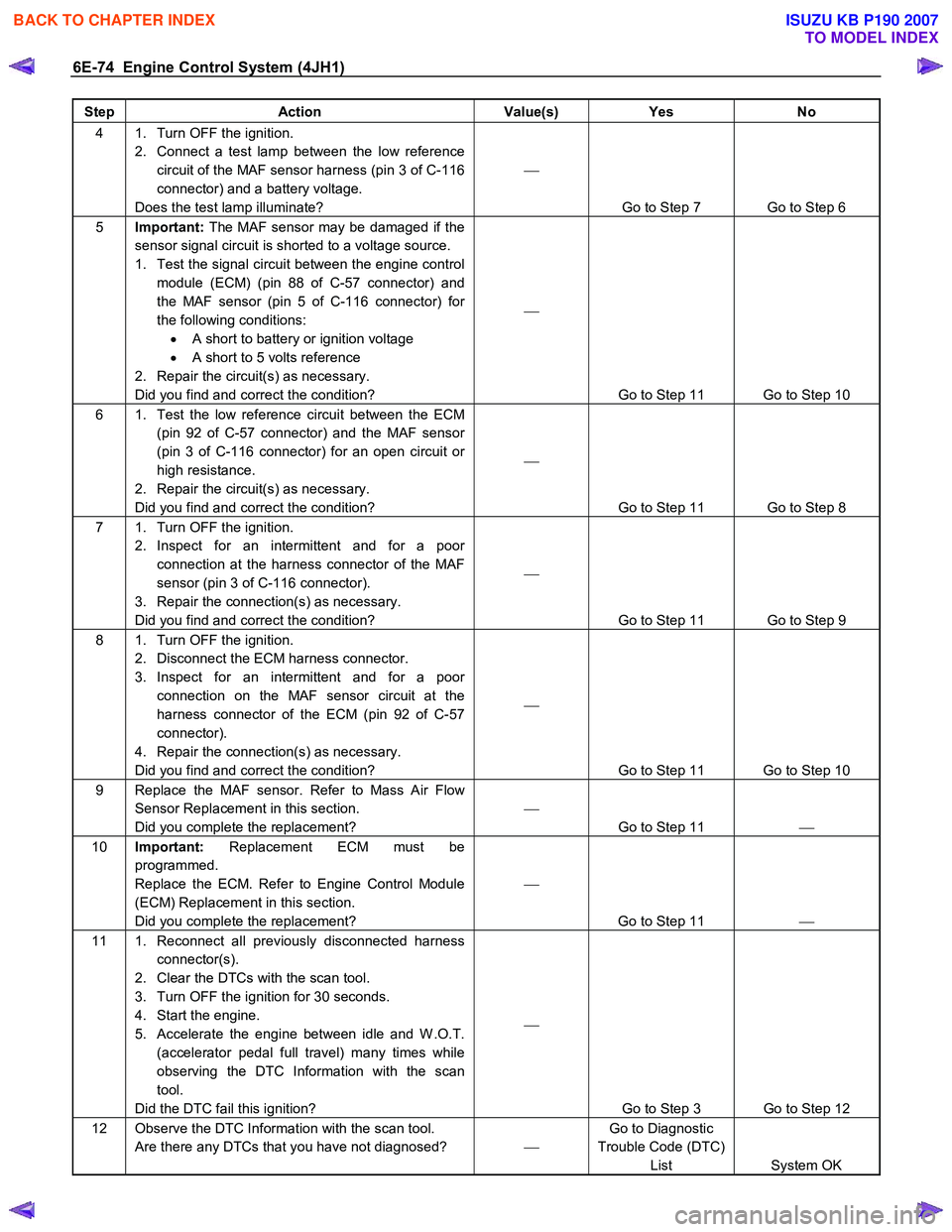

Step Action Value(s) Yes No

4 1. Turn OFF the ignition.

2. Connect a test lamp between the low reference circuit of the MAF sensor harness (pin 3 of C-116

connector) and a battery voltage.

Does the test lamp illuminate?

Go to Step 7 Go to Step 6

5 Important: The MAF sensor may be damaged if the

sensor signal circuit is shorted to a voltage source.

1. Test the signal circuit between the engine control module (ECM) (pin 88 of C-57 connector) and

the MAF sensor (pin 5 of C-116 connector) for

the following conditions: • A short to battery or ignition voltage

• A short to 5 volts reference

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 11 Go to Step 10

6 1. Test the low reference circuit between the ECM (pin 92 of C-57 connector) and the MAF sensor

(pin 3 of C-116 connector) for an open circuit or

high resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 11 Go to Step 8

7 1. Turn OFF the ignition. 2. Inspect for an intermittent and for a poor connection at the harness connector of the MAF

sensor (pin 3 of C-116 connector).

3. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 11 Go to Step 9

8 1. Turn OFF the ignition. 2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for a poor connection on the MAF sensor circuit at the

harness connector of the ECM (pin 92 of C-57

connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 11 Go to Step 10

9 Replace the MAF sensor. Refer to Mass Air Flow Sensor Replacement in this section.

Did you complete the replacement?

Go to Step 11

10 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 11

11 1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Accelerate the engine between idle and W .O.T. (accelerator pedal full travel) many times while

observing the DTC Information with the scan

tool.

Did the DTC fail this ignition?

Go to Step 3 Go to Step 12

12 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1109 of 6020

Engine Control System (4JH1) 6E-75

DTC P0105 (Symptom Code 1) (Flash Code 34)

Circuit Description

The vacuum pressure sensor is installed to the

turbocharger wastegate control hose and it detects the

regulated vacuum pressure to the turbocharge

r

wastegate valve. The vacuum pressure sensor is a

transducer that varies voltage according to changes in

the vacuum pressure inside the vacuum hose. The

vacuum pressure sensor has the following circuits.

• 5 volts reference circuit

• Low reference circuit

• Vacuum pressure sensor signal circuit

The engine control module (ECM) supplies 5 volts to

the vacuum pressure sensor on the 5 volts reference

circuit. The ECM also provides a ground on the lo

w

reference circuit. The vacuum pressure sensor provides

a signal to the ECM on the vacuum pressure signal

circuit which is relative to the vacuum pressure changes

in the turbocharger wastegate valve control hose. The

ECM should detect a low signal voltage at a high

vacuum pressure and high signal voltage at a lo

w

vacuum pressure. The ECM monitors the vacuum

pressure sensor signal for voltage outside the normal

range of the vacuum pressure sensor. If the ECM

detects an excessively high vacuum pressure senso

r

signal voltage, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the vacuum pressure

sensor signal voltage is more than 4.4 volts for 3

seconds.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

• The ECM uses a barometric pressure of 615 hPa

for turbocharger wastegate valve control.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Test Description

The number below refers to the step number on the

diagnostic table.

3. If the vacuum pressure sensor signal circuit between

the ECM and the sensor is normal, the sensor signal

voltage low DTC P0105 (Symptom Code 2) will set.

DTC P0105 (Symptom Code 1) (Flash Code 34)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Disconnect the vacuum pressure sensor harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with the scan tool.

Does DTC P0105 (Symptom Code 2) set, but not

DTC P0105 (Symptom Code 1)?

Go to Step 4 Go to Step 6

4 1. Turn OFF the ignition. 2. Connect a test lamp between the low reference circuit of the vacuum pressure sensor harness

(pin 2 of C-124 connector) and battery voltage.

Does the test lamp illuminate?

Go to Step 5 Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1110 of 6020

6E-76 Engine Control System (4JH1)

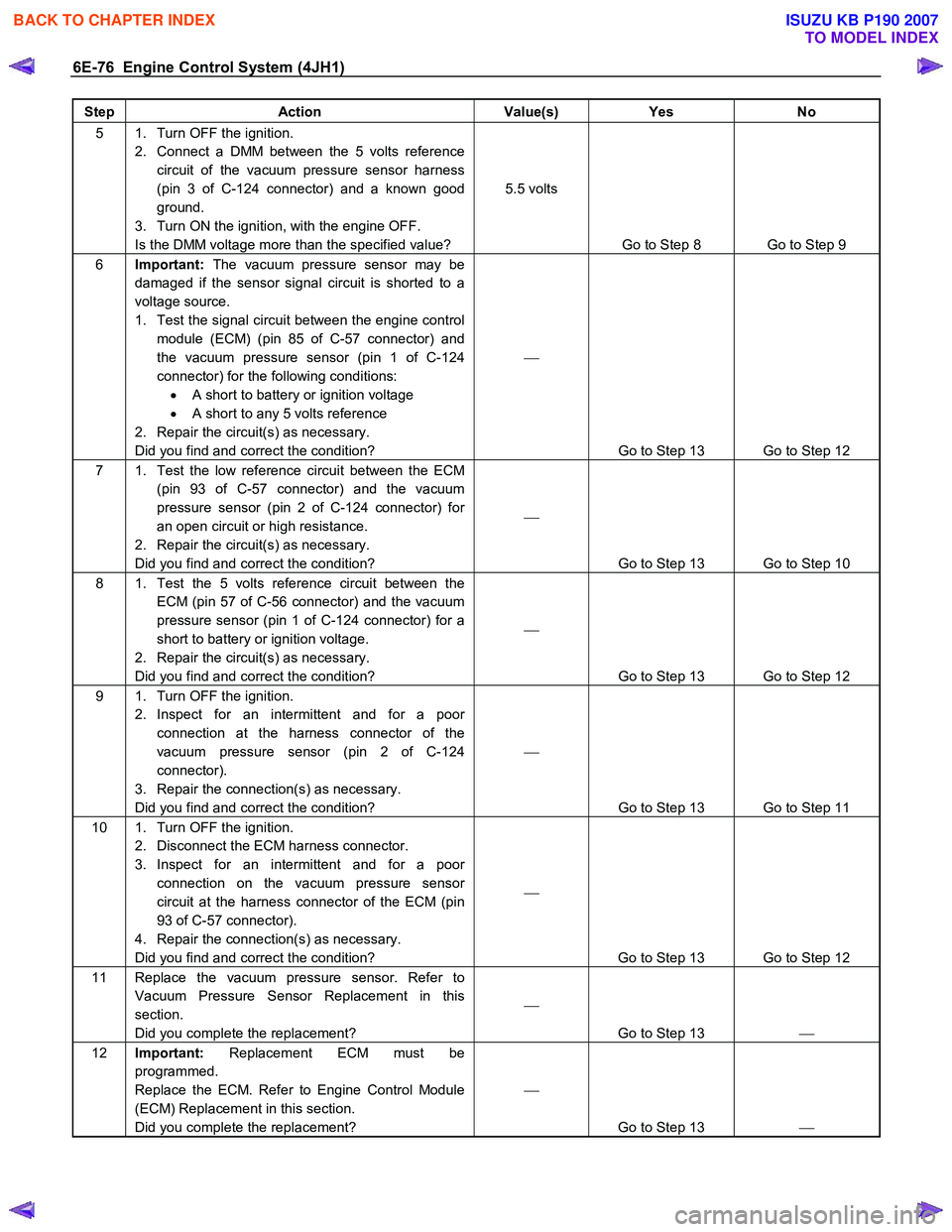

Step Action Value(s) Yes No

5 1. Turn OFF the ignition.

2. Connect a DMM between the 5 volts reference circuit of the vacuum pressure sensor harness

(pin 3 of C-124 connector) and a known good

ground.

3. Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than the specified value? 5.5 volts

Go to Step 8 Go to Step 9

6 Important: The vacuum pressure sensor may be

damaged if the sensor signal circuit is shorted to a

voltage source.

1. Test the signal circuit between the engine control module (ECM) (pin 85 of C-57 connector) and

the vacuum pressure sensor (pin 1 of C-124

connector) for the following conditions: • A short to battery or ignition voltage

• A short to any 5 volts reference

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 13 Go to Step 12

7 1. Test the low reference circuit between the ECM (pin 93 of C-57 connector) and the vacuum

pressure sensor (pin 2 of C-124 connector) for

an open circuit or high resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 13 Go to Step 10

8 1. Test the 5 volts reference circuit between the ECM (pin 57 of C-56 connector) and the vacuum

pressure sensor (pin 1 of C-124 connector) for a

short to battery or ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 13 Go to Step 12

9 1. Turn OFF the ignition. 2. Inspect for an intermittent and for a poor connection at the harness connector of the

vacuum pressure sensor (pin 2 of C-124

connector).

3. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 13 Go to Step 11

10 1. Turn OFF the ignition. 2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for a poor connection on the vacuum pressure sensor

circuit at the harness connector of the ECM (pin

93 of C-57 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 13 Go to Step 12

11 Replace the vacuum pressure sensor. Refer to Vacuum Pressure Sensor Replacement in this

section.

Did you complete the replacement?

Go to Step 13

12 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 13

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1112 of 6020

6E-78 Engine Control System (4JH1)

DTC P0105 (Symptom Code 2) (Flash Code 34)

Circuit Description

The vacuum pressure sensor is installed to the

turbocharger wastegate control hose and it detects the

regulated vacuum pressure to the turbocharge

r

wastegate valve. The vacuum pressure sensor is a

transducer that varies voltage according to changes in

the vacuum pressure inside the vacuum hose. The

vacuum pressure sensor has the following circuits.

• 5 volts reference circuit

• Low reference circuit

• Vacuum pressure sensor signal circuit

The engine control module (ECM) supplies 5 volts to

the vacuum pressure sensor on the 5 volts reference

circuit. The ECM also provides a ground on the lo

w

reference circuit. The vacuum pressure sensor provides

a signal to the ECM on the vacuum pressure signal

circuit which is relative to the vacuum pressure changes

in the turbocharger wastegate valve control hose. The

ECM should detect a low signal voltage at a high

vacuum pressure and high signal voltage at a lo

w

vacuum pressure. The ECM monitors the vacuum

pressure sensor signal for voltage outside the normal

range of the vacuum pressure sensor. If the ECM

detects an excessively low vacuum pressure senso

r

signal voltage, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the vacuum pressure

sensor signal voltage is less than 0.5 volts for 3

seconds.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

• The ECM uses a barometric pressure of 615 hPa

for turbocharger wastegate valve control.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Test Description

The number below refers to the step number on the

diagnostic table.

4. If the vacuum pressure sensor signal circuit between

the ECM and the sensor is normal, the sensor signal

voltage high DTC P0105 (Symptom Code 1) will set.

DTC P0105 (Symptom Code 2) (Flash Code 34)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Disconnect the vacuum pressure sensor harness connector.

3. Connect a DMM between the 5 volts reference circuit of the vacuum pressure sensor harness

(pin 3 of C-124 connector) and a known good

ground.

4. Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than the specified value? 4.5 volts

Go to Step 4 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1113 of 6020

Engine Control System (4JH1) 6E-79

Step Action Value(s) Yes No

4 1. Turn OFF the ignition.

2. Connect a 3-amp fused jumper wire between the 5 volts reference circuit and the signal circuit of

the vacuum pressure sensor harness (pins 1 and

3 of C-124 connector).

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with the scan tool.

Does DTC P0105 (Symptom Code 1) set, but not

DTC P0105 (Symptom Code 2)?

Go to Step 7 Go to Step 6

5 1. Test the 5 volts reference circuit between the engine control module (ECM) (pin 82 of C-57

connector) harness and the vacuum pressure

sensor (pin 3 of C-124 connector) for the

following conditions: • An open circuit

• A short to ground

• A short to the low reference circuit

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 11 Go to Step 8

6 1. Test the signal circuit between the ECM (pin 85 of C-57 connector) and the vacuum pressure

sensor (pin 1 of C-124 connector) for the

following conditions: • An open circuit

• A short to ground

• A short to the low reference circuit

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 11 Go to Step 8

7 1. Turn OFF the ignition. 2. Inspect for an intermittent and for poor connections at the harness connector of the

vacuum pressure sensor (pins 1 and 3 of C-124

connector).

3. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 11 Go to Step 9

8 1. Turn OFF the ignition. 2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for poor connections on the vacuum pressure sensor

circuits at the harness connector of the ECM

(pins 82 and 85 of C-57 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 11 Go to Step 10

9 Replace the vacuum pressure sensor. Refer to Vacuum Pressure Sensor Replacement in this

section.

Did you complete the replacement?

Go to Step 11

10 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 11

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1115 of 6020

Engine Control System (4JH1) 6E-81

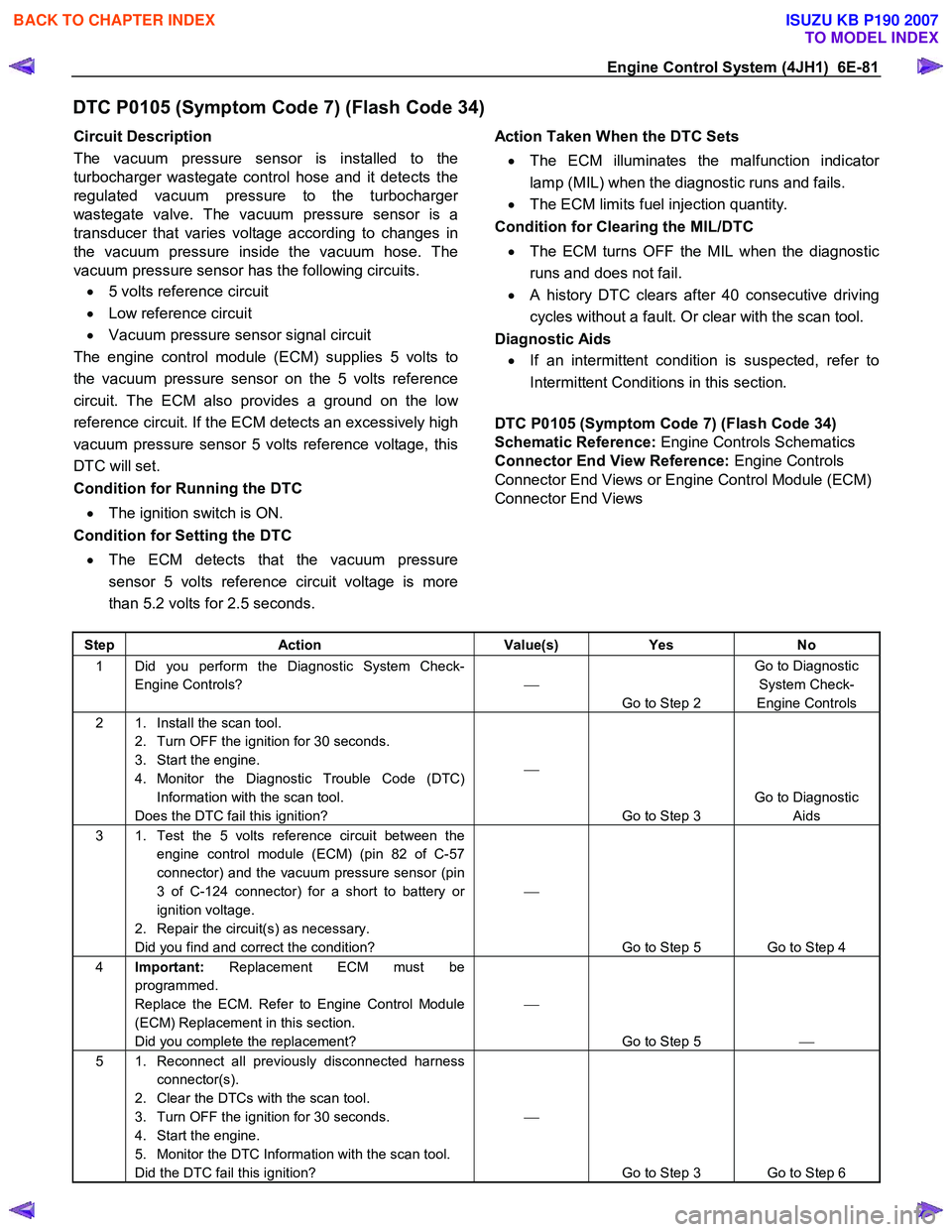

DTC P0105 (Symptom Code 7) (Flash Code 34)

Circuit Description

The vacuum pressure sensor is installed to the

turbocharger wastegate control hose and it detects the

regulated vacuum pressure to the turbocharge

r

wastegate valve. The vacuum pressure sensor is a

transducer that varies voltage according to changes in

the vacuum pressure inside the vacuum hose. The

vacuum pressure sensor has the following circuits.

• 5 volts reference circuit

• Low reference circuit

• Vacuum pressure sensor signal circuit

The engine control module (ECM) supplies 5 volts to

the vacuum pressure sensor on the 5 volts reference

circuit. The ECM also provides a ground on the lo

w

reference circuit. If the ECM detects an excessively high

vacuum pressure sensor 5 volts reference voltage, this

DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the vacuum pressure

sensor 5 volts reference circuit voltage is more

than 5.2 volts for 2.5 seconds.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

DTC P0105 (Symptom Code 7) (Flash Code 34)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Test the 5 volts reference circuit between the engine control module (ECM) (pin 82 of C-57

connector) and the vacuum pressure sensor (pin

3 of C-124 connector) for a short to battery or

ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 5 Go to Step 4

4 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 5

5 1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Monitor the DTC Information with the scan tool.

Did the DTC fail this ignition?

Go to Step 3 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007