check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3462 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–184

Step Action Yes No

9 Replace the accelerator pedal assembly. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

W as the repair completed? Go to Step 11 —

10 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 11 —

11 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the APP Sensor Circuit DTCs fail this ignition cycle? Go to Step 2 Go to Step 12

12 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.51 DTC P2177 or P2179

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P2177 Fuel Trim System Lean at Cruise or Accel Bank 1

• DTC P2179 Fuel Trim System Lean at Cruise or Accel Bank 2

Circuit Description

The engine control module (ECM) controls the air / fuel metering system to provide the best possible combination of

driveability, fuel economy, and emission control. Fuel delivery is controlled differently during Open and Closed Loop.

During Open Loop, the ECM determines fuel delivery based on sensor signals without heated oxygen sensor (HO2S)

input. During Closed Loop, the HO2S inputs are added and used by the ECM to calculate short and long term fuel trim

fuel delivery adjustments. If the HO2S indicate a lean condition, fuel trim values will be above 0 percent. If the HO2S

indicate a rich condition, fuel trim values will be below 0 percent. Short term fuel trim values change rapidly in response

to the HO2S signals. Long term fuel trim makes coarse adjustments to maintain an air / fuel ratio of 14.7:1. If the ECM

detects an excessively lean condition, this DTC sets.

Conditions for Running the DTC

• Before the ECM can report DTC P2177 or P2179 failed, DTCs P0101, P0121, P0122, P0123, P0133, P0153,

P0221, P0222, P0223, P0336, P0338, P0443, P0458, P0459, P0461, P0462, P0463, P2066, P2067, and P2068

must run and pass.

• The fuel system is in closed loop.

• The long fuel trim is active.

• The engine coolant temperature (ECT) is more than 60° C.

• The evaporative emission (EVAP) canister purge solenoid valve is not enabled.

• The intake air temperature (IAT) is less than 60° C.

• The fuel level is more than 11.6 percent.

• The amount of air flow into the engine is more than 7,000 grams.

• DTC P2177 and P2179 runs continuously once the above conditions are met for at least 300 seconds.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3463 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–185

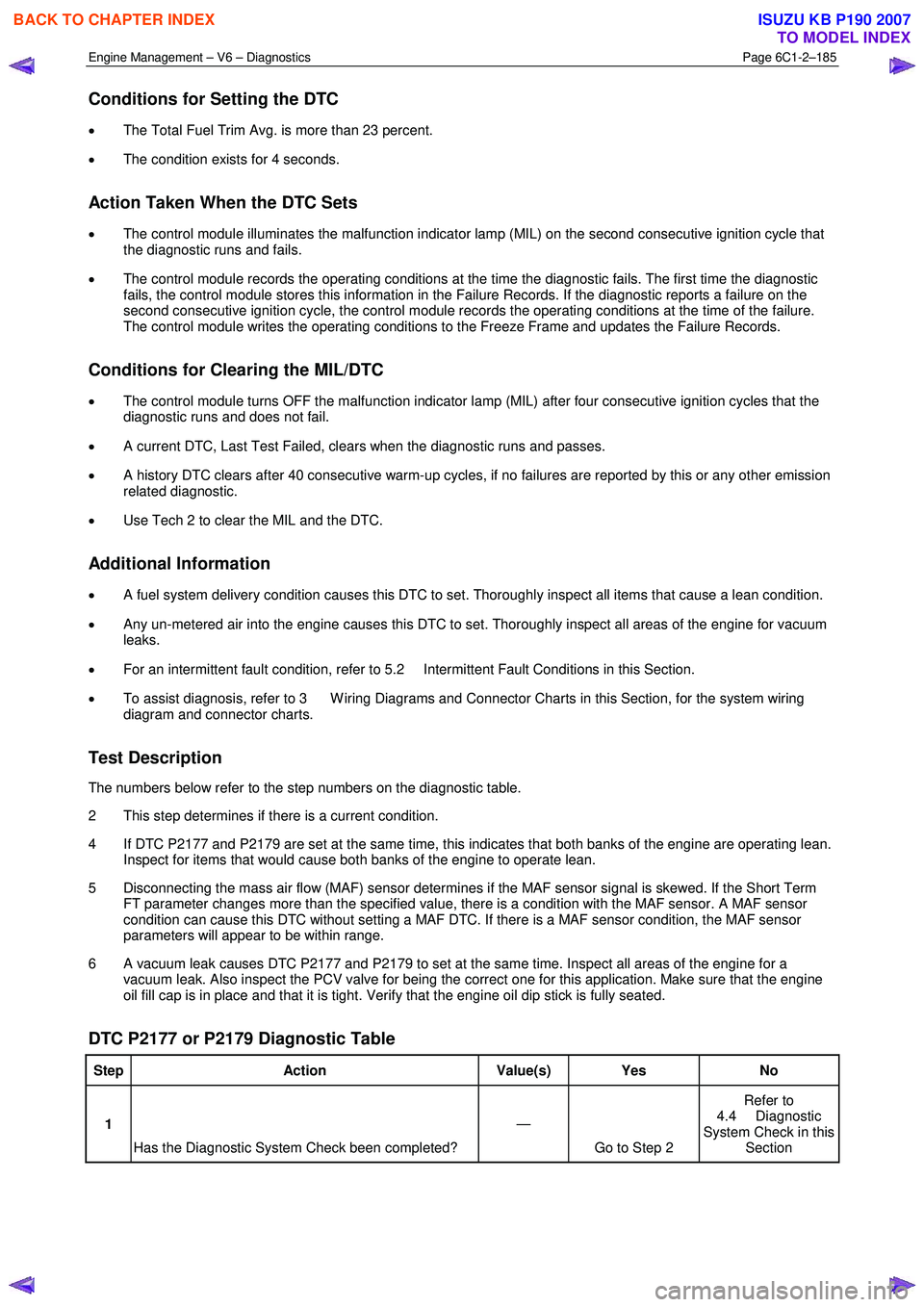

Conditions for Setting the DTC

• The Total Fuel Trim Avg. is more than 23 percent.

• The condition exists for 4 seconds.

Action Taken When the DTC Sets

• The control module illuminates the malfunction indicator lamp (MIL) on the second consecutive ignition cycle that

the diagnostic runs and fails.

• The control module records the operating conditions at the time the diagnostic fails. The first time the diagnostic

fails, the control module stores this information in the Failure Records. If the diagnostic reports a failure on the

second consecutive ignition cycle, the control module records the operating conditions at the time of the failure.

The control module writes the operating conditions to the Freeze Frame and updates the Failure Records.

Conditions for Clearing the MIL/DTC

• The control module turns OFF the malfunction indicator lamp (MIL) after four consecutive ignition cycles that the

diagnostic runs and does not fail.

• A current DTC, Last Test Failed, clears when the diagnostic runs and passes.

• A history DTC clears after 40 consecutive warm-up cycles, if no failures are reported by this or any other emission

related diagnostic.

• Use Tech 2 to clear the MIL and the DTC.

Additional Information

• A fuel system delivery condition causes this DTC to set. Thoroughly inspect all items that cause a lean condition.

• Any un-metered air into the engine causes this DTC to set. Thoroughly inspect all areas of the engine for vacuum

leaks.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

2 This step determines if there is a current condition.

4 If DTC P2177 and P2179 are set at the same time, this indicates that both banks of the engine are operating lean. Inspect for items that would cause both banks of the engine to operate lean.

5 Disconnecting the mass air flow (MAF) sensor determines if the MAF sensor signal is skewed. If the Short Term FT parameter changes more than the specified value, there is a condition with the MAF sensor. A MAF sensor

condition can cause this DTC without setting a MAF DTC. If there is a MAF sensor condition, the MAF sensor

parameters will appear to be within range.

6 A vacuum leak causes DTC P2177 and P2179 to set at the same time. Inspect all areas of the engine for a vacuum leak. Also inspect the PCV valve for being the correct one for this application. Make sure that the engine

oil fill cap is in place and that it is tight. Verify that the engine oil dip stick is fully seated.

DTC P2177 or P2179 Diagnostic Table

Step Action Value(s) Yes No

1

Has the Diagnostic System Check been completed? —

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3464 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–186

2 NOTE

If any DTCs are set, except P2177 or

P2179, refer to those DTCs before

proceeding with this diagnostic.

1 Idle the engine at the normal operating temperature.

2 Check that the fuel system is operating in Closed Loop.

3 Observe the Total Fuel Trim Avg. parameter for bank 1 or bank 2 with a scan tool.

Is the Total Fuel Trim Avg. less than the specified

value indicated? 23%

Go to Step 3 Go to Step 4

3 1 Use Tech 2 to clear the DTC/s.

2 Ignition OFF for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the Conditions for Running the DTC.

Does the DTC fail this ignition cycle? —

Go to Step 4 Refer to Additional

Information in this DTC

4 Are both banks of the engine operating lean? —

Go to Step 5 Go to Step 7

5 1 Start the engine.

NOTE

Additional DTCs will set when the MAF

sensor disconnected.

2 Disconnect the mass air flow (MAF) sensor harness connector while the engine is operating.

3 Observe the Short Term FT parameter for bank 1 and bank 2, using Tech 2.

4 Reconnect the MAF sensor after completing this step.

Does the Short Term FT parameter for both banks of

the engine change more than the specified value with

the MAF sensor disconnected? 20%

Go to 7.6

DTC

P0101, P0102 or P0103in this Section Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3467 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–189

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

2 This step determines whether the fault is present.

4 If DTC P2178 and DTC P2180 set at the same time, then both banks of the engine are operating rich. Inspect items that would cause both banks of the engine to operate rich.

5 Disconnecting the mass air flow (MAF) sensor determines if the MAF sensor signal is skewed. If the Short Term FT parameter changes more than the specified value, there is a condition with the MAF sensor. A MAF sensor

condition can cause this DTC without setting a MAF DTC. If there is a MAF sensor condition, the MAF sensor

parameters will appear to be within range.

DTC P2178 or P2180 Diagnostic Table

Step Action Value(s) Yes No

1

Has the Diagnostic System Check been completed? —

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 NOTE

If any DTCs are set, except P2178 and

DTC P2180, refer to those DTCs before

proceeding with this diagnostic.

1 Idle the engine at the normal operating temperature.

2 Check that the fuel system is in Closed Loop.

3 Observe the Total Fuel Trim Avg. parameter for bank 1 and / or bank 2 with Tech 2.

Is the Total Fuel Trim Avg. less than the specified

value? –22%

Go to Step 3 Go to Step 4

3 1 Observe the Freeze Frame and / or the Failure

records data for this DTC.

2 Turn the ignition OFF for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you observed

from the Freeze Frame and / or the Failure

records data.

Does the DTC fail this ignition cycle? —

Go to Step 4 Refer to Additional

Information in this DTC.

4 Are both banks of the engine operating rich? —

Go to Step 5 Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3470 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–192

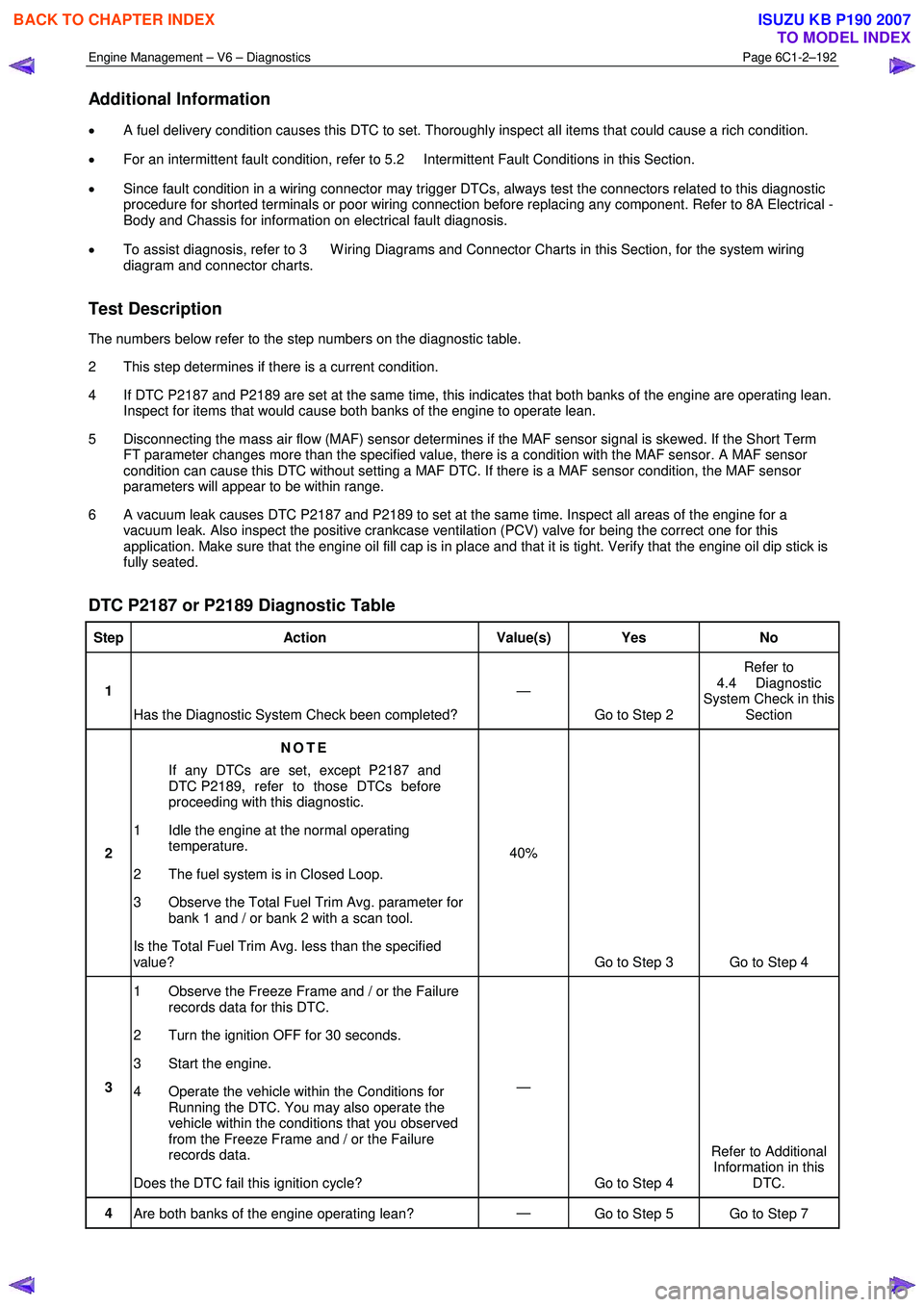

Additional Information

• A fuel delivery condition causes this DTC to set. Thoroughly inspect all items that could cause a rich condition.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

2 This step determines if there is a current condition.

4 If DTC P2187 and P2189 are set at the same time, this indicates that both banks of the engine are operating lean. Inspect for items that would cause both banks of the engine to operate lean.

5 Disconnecting the mass air flow (MAF) sensor determines if the MAF sensor signal is skewed. If the Short Term FT parameter changes more than the specified value, there is a condition with the MAF sensor. A MAF sensor

condition can cause this DTC without setting a MAF DTC. If there is a MAF sensor condition, the MAF sensor

parameters will appear to be within range.

6 A vacuum leak causes DTC P2187 and P2189 to set at the same time. Inspect all areas of the engine for a vacuum leak. Also inspect the positive crankcase ventilation (PCV) valve for being the correct one for this

application. Make sure that the engine oil fill cap is in place and that it is tight. Verify that the engine oil dip stick is

fully seated.

DTC P2187 or P2189 Diagnostic Table

Step Action Value(s) Yes No

1

Has the Diagnostic System Check been completed? —

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 NOTE

If any DTCs are set, except P2187 and

DTC P2189, refer to those DTCs before

proceeding with this diagnostic.

1 Idle the engine at the normal operating temperature.

2 The fuel system is in Closed Loop.

3 Observe the Total Fuel Trim Avg. parameter for bank 1 and / or bank 2 with a scan tool.

Is the Total Fuel Trim Avg. less than the specified

value? 40%

Go to Step 3 Go to Step 4

3 1 Observe the Freeze Frame and / or the Failure

records data for this DTC.

2 Turn the ignition OFF for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you observed

from the Freeze Frame and / or the Failure

records data.

Does the DTC fail this ignition cycle? —

Go to Step 4 Refer to Additional

Information in this DTC.

4 Are both banks of the engine operating lean? —

Go to Step 5 Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3473 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–195

Action Taken When the DTC Sets

• The control module activates the malfunction indicator lamp (MIL) on the second consecutive ignition cycle that

the diagnostic runs and fails.

• The control module records the operating conditions at the time the diagnostic fails. The first time the diagnostic

fails, the control module stores this information in the Failure Records. If the diagnostic reports a failure on the

second consecutive ignition cycle, the control module records the operating conditions at the time of the failure.

The control module writes the operating conditions to the Freeze Frame and updates the Failure Records.

Conditions for Clearing the MIL/DTC

• The control module turns OFF the malfunction indicator lamp (MIL) after four consecutive ignition cycles that the

diagnostic runs and does not fail.

• A current DTC, Last Test Failed, clears when the diagnostic runs and passes.

• A history DTC clears after 40 consecutive warm-up cycles, if no failures are reported by this or any other emission

related diagnostic.

• Use Tech 2 to clear the MIL and the DTC.

Additional Information

• A fuel delivery condition causes this DTC to set. Thoroughly inspect all items that cause a rich condition.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

2 This step determines whether the fault is present.

4 If DTC P2188 and P2190 set at the same time, then both banks of the engine are operating rich. Inspect items that would cause both banks to operate rich.

5 Disconnecting the mass air flow (MAF) sensor determines if the MAF sensor signal is skewed. If the Short Term FT parameter changes more than the specified value, there is a condition with the MAF sensor. A MAF sensor

condition can cause this DTC without setting a MAF DTC. If there is a MAF sensor condition, the MAF sensor

parameters will appear to be within range.

DTC P2188 or P2190 Diagnostic Table

Step Action Value(s) Yes No

1

Has the Diagnostic System Check been completed? —

Go to Step 2 Refer to

4.4 Diagnostic System Check in this Section

2 NOTE

If any DTCs are set, except P2188 and

P2190, refer to those DTCs before

proceeding with this diagnostic.

1 Idle the engine at the normal operating temperature.

2 Check that the fuel system is in Closed Loop.

3 Observe the Total Fuel Trim Avg. parameter for bank 1 and / or bank 2 with Tech 2.

Is the Total Fuel Trim Avg. less than the specified

value? –40%

Go to Step 3 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3476 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–198

• The rear fuel trim, long and short term, is more than a threshold.

• This DTC sets after the air flow coming into the engine accumulates to more than 200 grams and the above

conditions are met for more than 4 seconds.

Condition 2

• The ECM detects that the rear HO2S is operating too rich while the ECM is commanding a lean air / fuel mixture.

• This DTC sets after the air flow coming into the engine accumulates to more than 800 grams and the above

condition is met for more than 4 seconds.

Action Taken When the DTC Sets

• The ECM activates the malfunction indicator lamp (MIL) on the second consecutive ignition cycle that the

diagnostic runs and fails.

• The ECM records the operating conditions at the time the diagnostic fails. The first time the diagnostic fails, the

control module stores this information in the Failure Records. If the diagnostic reports a failure on the second

consecutive ignition cycle, the control module records the operating conditions at the time of the failure. The

control module writes the operating conditions to the Freeze Frame and updates the Failure Records.

Conditions for Clearing the MIL/DTC

• The control module turns OFF the malfunction indicator lamp (MIL) after four consecutive ignition cycles that the

diagnostic runs and does not fail.

• A current DTC, Last Test Failed, clears when the diagnostic runs and passes.

• A history DTC clears after 40 consecutive warm-up cycles, if no failures are reported by this or any other emission

related diagnostic.

• Use Tech 2 to clear the MIL and the DTC.

Additional Information

• A HO2S fault condition may cause this DTC to set. Thoroughly inspect all items that could cause a lean condition.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Since a fault condition in a wiring connector may trigger DTCs, always test the connectors related to this

diagnostic procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A

Electrical - Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

2 This step determines if a condition exists.

5 This step is testing for a rear HO2S sensor circuit condition. A circuit condition sets this DTC.

8 This step is testing for an intermittent circuit condition. Thoroughly inspect the HO2S circuits for an intermittent circuit condition.

9 This step is testing for an intermittent circuit condition. Thoroughly inspect the HO2S circuits for an intermittent circuit condition.

DTC P2195 or P2197 Diagnostic Table

Step Action Value(s) Yes No

1

Has the Diagnostic System Check been completed? —

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3481 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–203

DTC P2196 or P2198 Diagnostic Table

Step Action Value(s) Yes No

1

Has the Diagnostic System Check been completed? —

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Allow the engine to reach operating temperature.

2 Operate the vehicle within the parameters specified in Conditions for Running the DTC.

3 Observe the diagnostic trouble code (DTC) information, using Tech 2.

Did DTC P2196 or DTC P2198 fail this ignition? —

Go to Step 4 Go to Step 3

3 1 Observe the Freeze Frame and / or the Failure

records data for this DTC.

2 Turn the ignition OFF for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you observed

from the Freeze Frame and / or the Failure

records data.

Does the DTC fail this ignition cycle? —

Go to Step 4 Refer to Additional

Information in this DTC.

4 Is DTC P0041, P0137, P0138, P0140, P0157, P0158,

or P0160 also set? —

Go to the

appropriate DTC Table in this Section Go to Step 5

5 1 Operate the engine above 1,200 RPM for

30 seconds.

2 Observe the appropriate rear HO2S voltage, using Tech 2.

Is the voltage less than the specified value? 1,050 mV

Go to Step 8 Go to Step 6

6 1 Ignition OFF.

2 Disconnect the appropriate rear heated oxygen sensor (HO2S).

3 Ignition ON, engine OFF.

4 Observe the appropriate rear HO2S voltage parameter with Tech 2.

Is the voltage within the specified range? 350 – 550 mV

Go to Step 12 Go to Step 7

7 1 Test the appropriate rear HO2S signal circuit for

a short to voltage. Refer to 8A Electrical - Body

and Chassis.

Did you find and correct the condition? —

Go to Step 19 Go to Step 14

8 1 Shake the related HO2S harnesses for the front

sensor between the HO2S harness connector

and the engine control module (ECM) while

monitoring the appropriate HO2S lambda

parameter.

Does the HO2S parameter change abruptly while

moving the related harnesses? —

Go to Step 15 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3484 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–206

• The engine is running.

Conditions for Setting the DTC

DTC P2227

The ECM detects the BARO pressure changed greater than 5 kPa within 20 seconds or the BARO pressure changed

greater than 30 kPa since the last ignition cycle.

DTC P2228

The ECM detects the BARO sensor signal voltage is less than 0.20 V.

DTC P2229

The ECM detects the BARO sensor signal voltage is greater than 4.8 V for longer than 2.0 seconds.

Conditions for Clearing DTC

The BARO pressure sensor circuit DTCs are Type ‘B’ DTC. Refer to 1.4 Diagnostic Trouble Codes in this Section, for

action taken when a Type ‘B’ DTC sets and conditions for clearing Type ‘B’ DTCs.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the BARO Sensor operation.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

4 Test signal circuit of the BARO sensor. This circuit should display a voltage within the specified range.

5 Measures the integrity of the TP sensor low reference circuit. Removal of the ECM Fuse 29 enables the ECM to power down completely prior to the test procedure.

DTC P2227 P2228 or P2229 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC P2227, P2228 or P2229 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3486 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–208

Step Action Yes

No

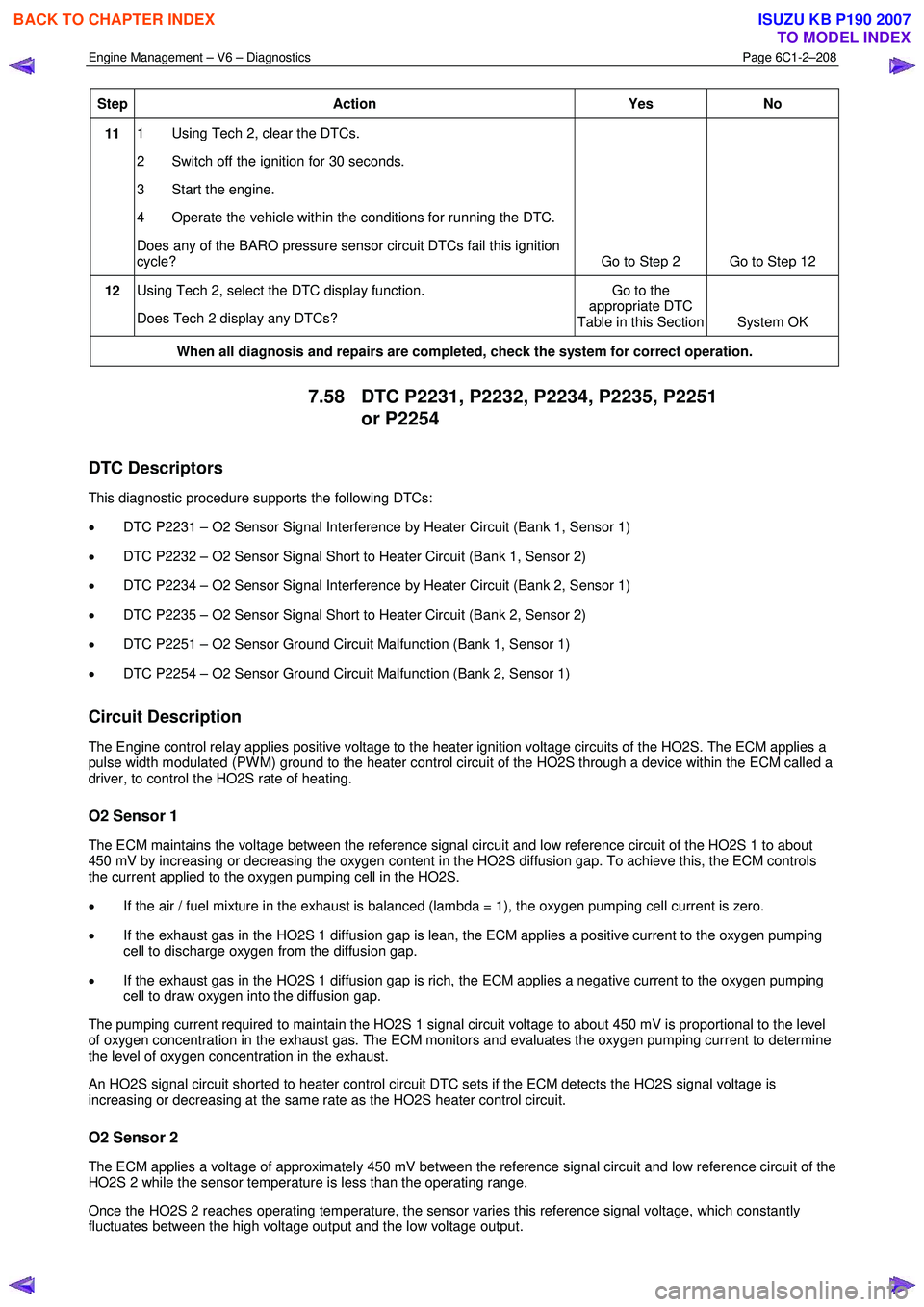

11 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the BARO pressure sensor circuit DTCs fail this ignition

cycle? Go to Step 2 Go to Step 12

12 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.58 DTC P2231, P2232, P2234, P2235, P2251

or P2254

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P2231 – O2 Sensor Signal Interference by Heater Circuit (Bank 1, Sensor 1)

• DTC P2232 – O2 Sensor Signal Short to Heater Circuit (Bank 1, Sensor 2)

• DTC P2234 – O2 Sensor Signal Interference by Heater Circuit (Bank 2, Sensor 1)

• DTC P2235 – O2 Sensor Signal Short to Heater Circuit (Bank 2, Sensor 2)

• DTC P2251 – O2 Sensor Ground Circuit Malfunction (Bank 1, Sensor 1)

• DTC P2254 – O2 Sensor Ground Circuit Malfunction (Bank 2, Sensor 1)

Circuit Description

The Engine control relay applies positive voltage to the heater ignition voltage circuits of the HO2S. The ECM applies a

pulse width modulated (PW M) ground to the heater control circuit of the HO2S through a device within the ECM called a

driver, to control the HO2S rate of heating.

O2 Sensor 1

The ECM maintains the voltage between the reference signal circuit and low reference circuit of the HO2S 1 to about

450 mV by increasing or decreasing the oxygen content in the HO2S diffusion gap. To achieve this, the ECM controls

the current applied to the oxygen pumping cell in the HO2S.

• If the air / fuel mixture in the exhaust is balanced (lambda = 1), the oxygen pumping cell current is zero.

• If the exhaust gas in the HO2S 1 diffusion gap is lean, the ECM applies a positive current to the oxygen pumping

cell to discharge oxygen from the diffusion gap.

• If the exhaust gas in the HO2S 1 diffusion gap is rich, the ECM applies a negative current to the oxygen pumping

cell to draw oxygen into the diffusion gap.

The pumping current required to maintain the HO2S 1 signal circuit voltage to about 450 mV is proportional to the level

of oxygen concentration in the exhaust gas. The ECM monitors and evaluates the oxygen pumping current to determine

the level of oxygen concentration in the exhaust.

An HO2S signal circuit shorted to heater control circuit DTC sets if the ECM detects the HO2S signal voltage is

increasing or decreasing at the same rate as the HO2S heater control circuit.

O2 Sensor 2

The ECM applies a voltage of approximately 450 mV between the reference signal circuit and low reference circuit of the

HO2S 2 while the sensor temperature is less than the operating range.

Once the HO2S 2 reaches operating temperature, the sensor varies this reference signal voltage, which constantly

fluctuates between the high voltage output and the low voltage output.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007