exhaust JAGUAR X308 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 808 of 2490

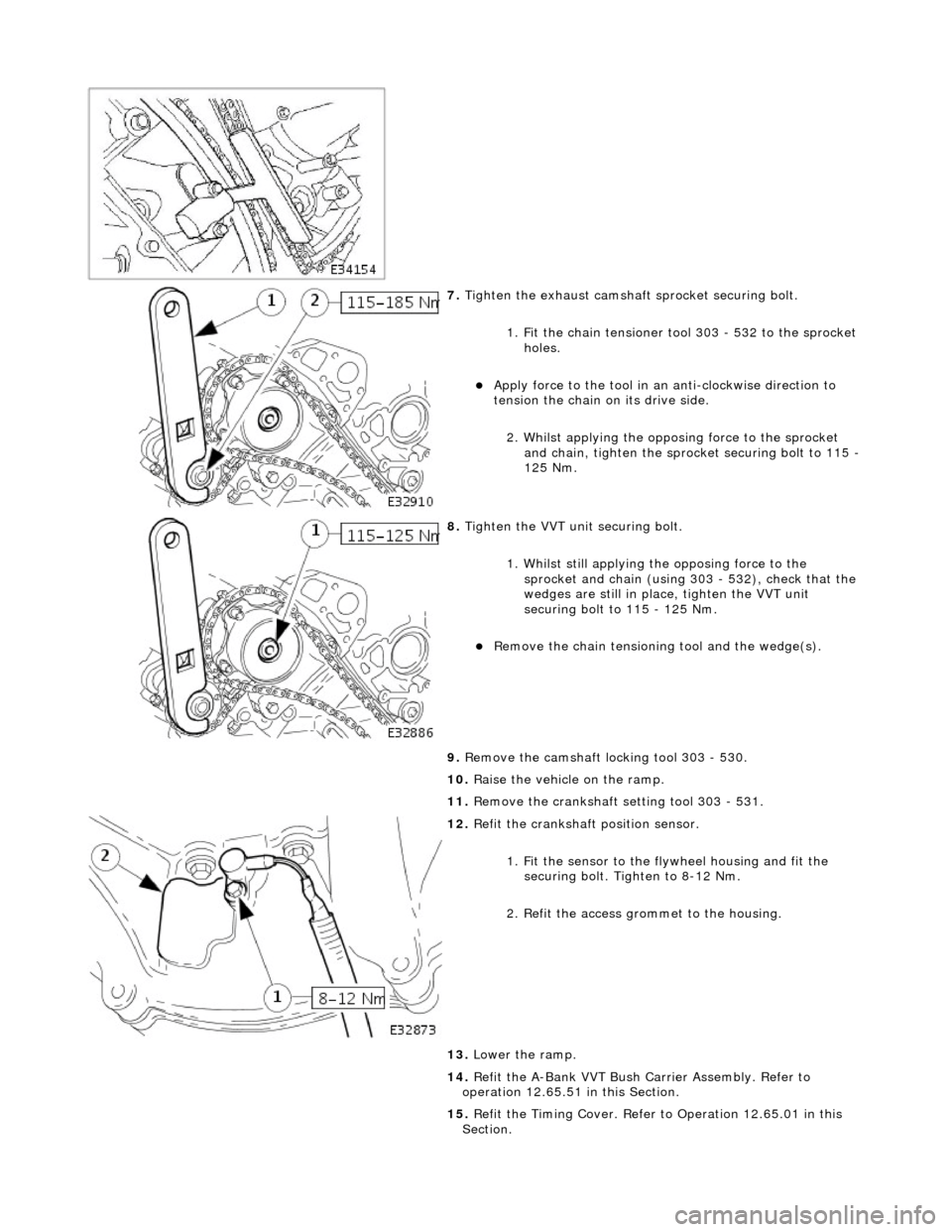

7. Tighten the exhaust camshaft sprocket securing bolt.

1. Fit the chain tensioner tool 303 - 532 to the sprocket holes.

Apply force to the tool in an anti-clockwise direction to

tension the chain on its drive side.

2. Whilst applying the opposing force to the sprocket and chain, tighten the sprock et securing bolt to 115 -

125 Nm.

8. Tighten the VVT unit securing bolt.

1. Whilst still applying the opposing force to the

sprocket and chain (using 303 - 532), check that the

wedges are still in place, tighten the VVT unit

securing bolt to 115 - 125 Nm.

Remove the chain tensioning tool and the wedge(s).

9. Remove the camshaft locking tool 303 - 530.

10. Raise the vehicle on the ramp.

11. Remove the crankshaft setting tool 303 - 531.

12. Refit the crankshaft position sensor.

1. Fit the sensor to the fl ywheel housing and fit the

securing bolt. Tighten to 8-12 Nm.

2. Refit the access grommet to the housing.

13. Lower the ramp.

14. Refit the A-Bank VVT Bush Carrier Assembly. Refer to

operation 12.65.51 in this Section.

15. Refit the Timing Cover. Refer to Operation 12.65.01 in this

Section.

Page 811 of 2490

6. Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

7. Install the crankshaft setting peg 303-531 to the crankshaft

position sensor location.

1. Install the crankshaft setting peg 303-531.

Position the crankshaft so that the setting peg engages

fully into the timing slot.

2. Install and tighten the bolt to secure the setting peg.

8. Lower the vehicle on the ramp.

9. Install the camshaft locking tool 303-530 to Bank 2 camshafts,

aligning the shafts sl ightly as necessary.

10. CAUTION: Use a length of steel strip that will not fall

into the timing cover.

Protect the upper face of the ti ming cover from scratches, when

removing the bolt which secures the sprocket.

1. Place a flat piece of stee l strip along the timing cover

horizontal jointing face, adjacent to the exhaust

camshaft sprocket.

2. Secure the steel strip in place with adhesive tape.

11. A ball-ended hexagon drive bit is required to remove the

sprocket securing bolt. A suitable tool is available from Snap On as (FABLM10E) Long Series 10mm AF.

Page 812 of 2490

Installation

12. Remove the bolt which secures the sprocket to the exhaust

camshaft.

Move the sprocket forward from the camshaft boss.

13. Remove the secondary chain tensioner.

1. Remove the two bolts which secure the tensioner.

Lift the tensioner, sprocket (release it fully from the

camshaft) and ch ain assembly.

2. Remove the tensioner rearward from between the chain.

14. Remove the sprocket if required, or leave it in the chain

resting on the cylinder head.

15. Clean and inspect all relevant components.

1. Install the sprocket to the secondary chain.

1. With the sprocket installe d to the chain, temporarily

position (do not install the securing bolt) the sprocket

onto the camshaft.

2. Adjust the position of the sprocket within the chain to

allow the chain tensioning tool 303-532 to be

approximately vertical, as shown.

Remove the chain tensioni ng tool; during future

operations, do not move the sprocket within the chain.

2. Push the tensioner piston into the body to provide clearance

for installing.

1. Insert a thin rigid wire th rough the hole in the end of

the tensioner piston to displace the ball from the non-

return valve seat.

Page 817 of 2490

Installation

removing the bolt which secures the sprocket. 1. Place a flat piece of stee l strip along the timing cover

horizontal jointing face, adjacent to the exhaust

camshaft sprocket.

2. Secure the steel strip in place with adhesive tape.

11. A ball-ended hexagon drive bit is required to remove the

sprocket securing bolt. A suitable tool is available from Snap On as (FABLM10E) Long Series 10mm AF.

12. Remove the bolt which secures the sprocket to the exhaust

camshaft.

Move the sprocket forward from the camshaft boss.

13. Remove the secondary chain tensioner.

1. Remove the two bolts which secure the tensioner.

Lift the tensioner, sprocket (release it fully from the

camshaft) and ch ain assembly.

2. Remove the tensioner rearward from between the chain.

14. Remove the sprocket if required, or leave it in the chain

resting on the cylinder head.

15. Clean and inspect all relevant components.

1. Install the sprocket to the secondary chain.

1. With the sprocket installe d to the chain, temporarily

position (do not install the securing bolt) the sprocket

onto the camshaft.

2. Adjust the position of the sprocket within the chain to

Page 821 of 2490

6. Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

7. Install the crankshaft setting peg 303-531 to the crankshaft

position sensor location.

1. Install the crankshaft setting peg 303-531.

Position the crankshaft so that the setting peg engages

fully into the timing slot.

2. Install and tighten the bolt to secure the setting peg.

8. Lower the vehicle on the ramp.

9. Install the camshaft locking tool 303-530 to Bank 1 camshafts,

aligning the shafts sl ightly as necessary.

10. CAUTION: Use a length of steel strip that will not fall

into the timing cover.

Protect the upper face of the ti ming cover from scratches, when

removing the bolt which secures the sprocket.

1. Place a flat piece of stee l strip along the timing cover

horizontal jointing face, adjacent to the exhaust

camshaft sprocket.

2. Secure the steel strip in place with adhesive tape.

11. A ball-ended hexagon drive bit is required to remove the

sprocket securing bolt. A suitable tool is available from Snap On as (FABLM10E) Long Series 10mm AF.

Page 822 of 2490

Installation

12. Remove the bolt which secures the sprocket to the exhaust

camshaft.

Move the sprocket forward from the camshaft boss.

13. Remove the secondary chain tensioner.

1. Remove the two bolts which secure the tensioner.

Lift the tensioner, sprocket (release it fully from the

camshaft) and ch ain assembly.

2. Remove the tensioner rearward from between the chain.

14. Remove the sprocket if required, or leave it in the chain

resting on the cylinder head.

15. Clean and inspect all relevant components.

1. Install the sprocket to the secondary chain.

1. With the sprocket installe d to the chain, temporarily

position (do not install the securing bolt) the sprocket

onto the camshaft.

2. Adjust the position of the sprocket within the chain to

allow the chain tensioning tool 303-532 to be

approximately vertical, as shown.

Remove the chain tensioni ng tool; during future

operations, do not move the sprocket within the chain.

2. Push the tensioner piston into the body to provide clearance

for fitting.

1. Insert a thin rigid wire th rough the hole in the end of

the tensioner piston to displace the ball from the non-

return valve seat.

Page 827 of 2490

Installation

removing the bolt which secures the sprocket. 1. Place a flat piece of stee l strip along the timing cover

horizontal jointing face, adjacent to the exhaust

camshaft sprocket.

2. Secure the steel strip in place with adhesive tape.

11. A ball-ended hexagon drive bit is required to remove the

sprocket securing bolt. A suitable tool is available from Snap On as (FABLM10E) Long Series 10mm AF.

12. Remove the bolt which secures the sprocket to the exhaust

camshaft.

Move the sprocket forward from the camshaft boss.

13. Remove the secondary chain tensioner.

1. Remove the two bolts which secure the tensioner.

Lift the tensioner, sprocket (release it fully from the

camshaft) and ch ain assembly.

2. Remove the tensioner rearward from between the chain.

14. Remove the sprocket if required, or leave it in the chain

resting on the cylinder head.

15. Clean and inspect all relevant components.

1. Install the sprocket to the secondary chain.

1. With the sprocket installe d to the chain, temporarily

position (do not install the securing bolt) the sprocket

onto the camshaft.

2. Adjust the position of the sprocket within the chain to

Page 832 of 2490

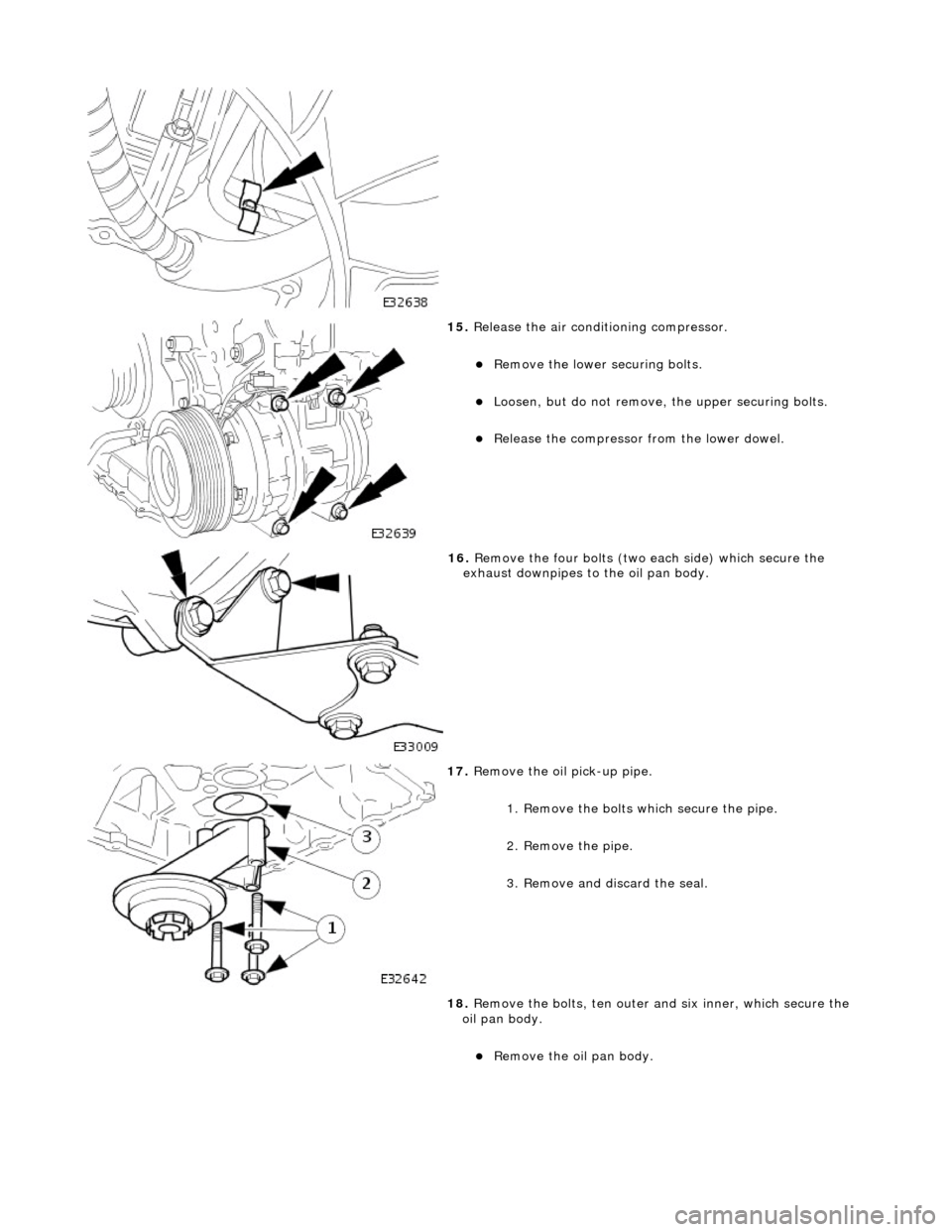

15. Release the air conditioning compressor.

Remove the lower securing bolts.

Loosen, but do not remove, th e upper securing bolts.

Release the compressor from the lower dowel.

16. Remove the four bolts (two each side) which secure the

exhaust downpipes to the oil pan body.

17. Remove the oil pick-up pipe.

1. Remove the bolts which secure the pipe.

2. Remove the pipe.

3. Remove and discard the seal.

18. Remove the bolts, ten outer an d six inner, which secure the

oil pan body.

Remove the oil pan body.

Page 837 of 2490

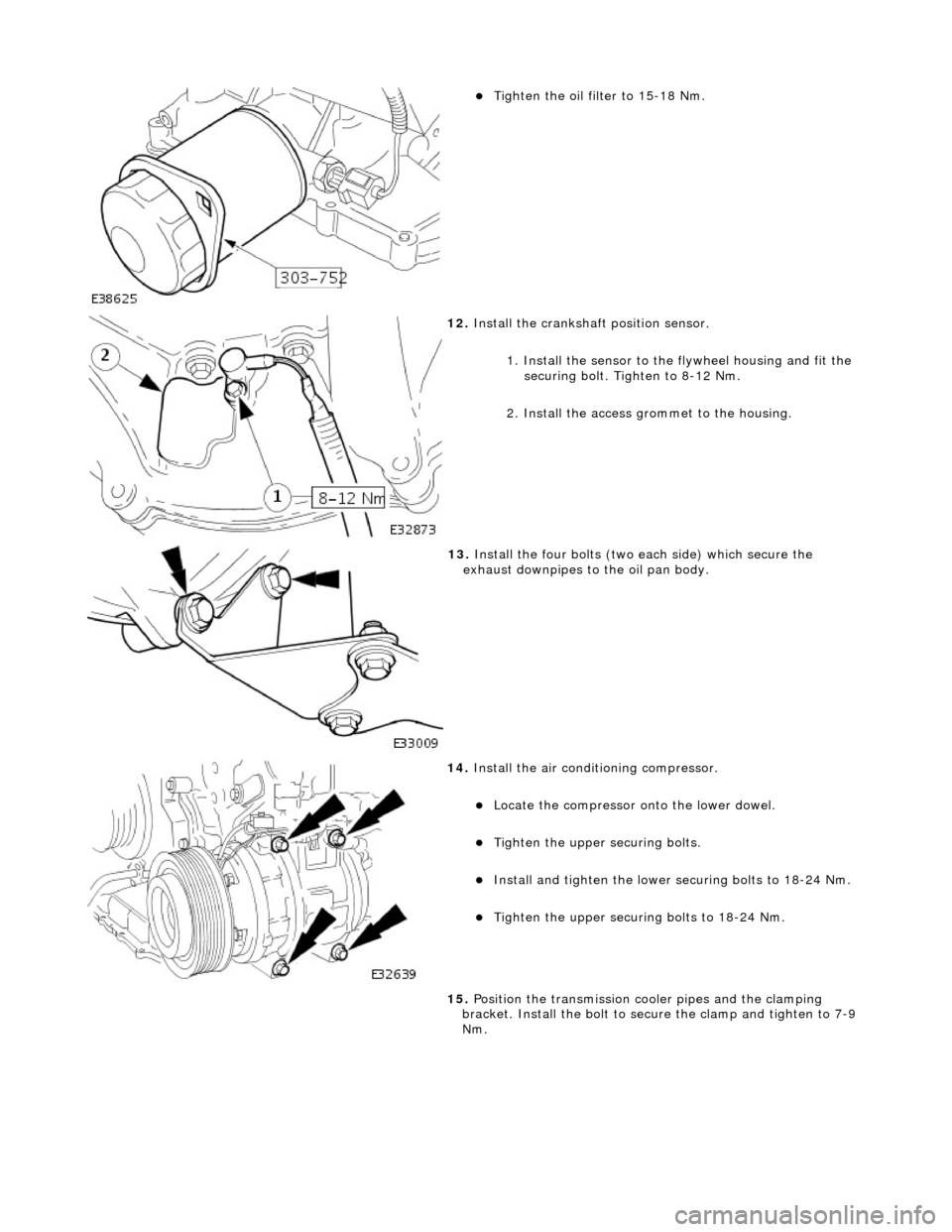

Tighten the oil filter to 15-18 Nm.

12. Install the crankshaft position sensor.

1. Install the sensor to the flywheel housing and fit the

securing bolt. Tighten to 8-12 Nm.

2. Install the access grommet to the housing.

13. Install the four bolts (two each side) which secure the

exhaust downpipes to the oil pan body.

14. Install the air conditioning compressor.

Locate the compressor onto the lower dowel.

Tighten the upper securing bolts.

Install and tighten the lower securing bolts to 18-24 Nm.

Tighten the upper securing bolts to 18-24 Nm.

15. Position the transmission cooler pipes and the clamping

bracket. Install the bolt to secu re the clamp and tighten to 7-9

Nm.

Page 841 of 2490

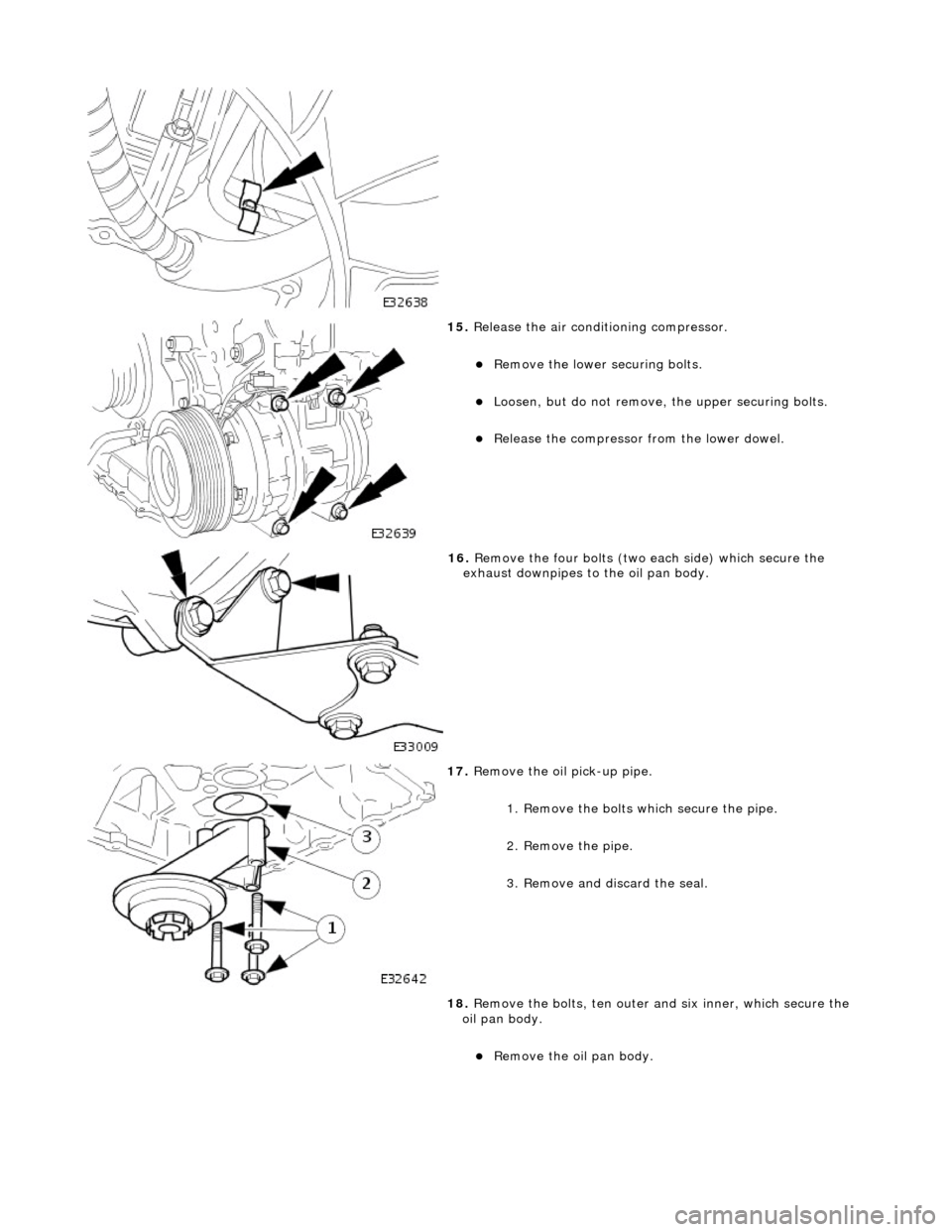

15. Release the air conditioning compressor.

Remove the lower securing bolts.

Loosen, but do not remove, th e upper securing bolts.

Release the compressor from the lower dowel.

16. Remove the four bolts (two each side) which secure the

exhaust downpipes to the oil pan body.

17. Remove the oil pick-up pipe.

1. Remove the bolts which secure the pipe.

2. Remove the pipe.

3. Remove and discard the seal.

18. Remove the bolts, ten outer an d six inner, which secure the

oil pan body.

Remove the oil pan body.