lamp JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1806 of 2490

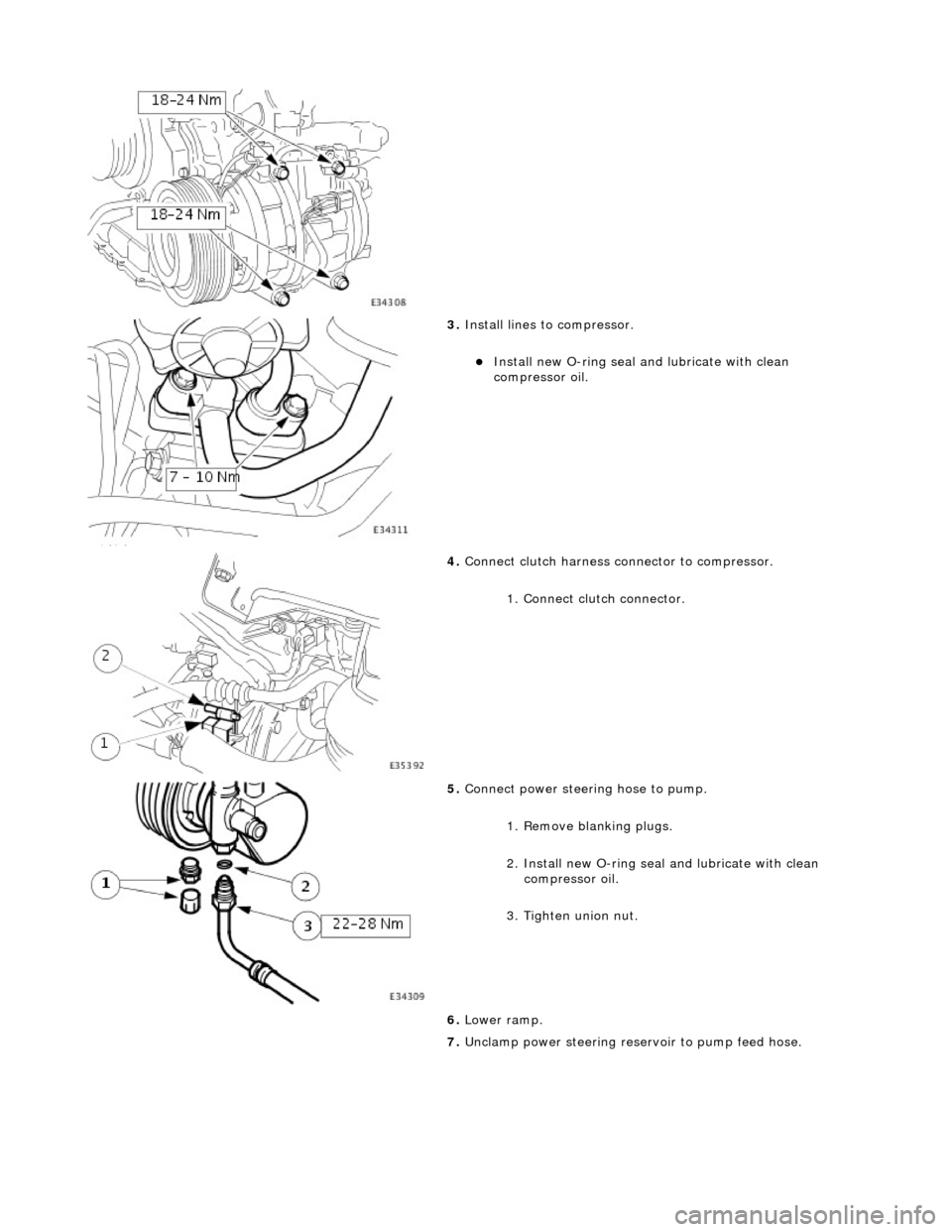

3. Install lines to compressor.

Install new O-ring seal and lubricate with clean

compressor oil.

4. Connect clutch harness connector to compressor.

1. Connect clutch connector.

5. Connect power steering hose to pump.

1. Remove blanking plugs.

2. Install new O-ring seal and lubricate with clean

compressor oil.

3. Tighten union nut.

6. Lower ramp.

7. Unclamp power steering rese rvoir to pump feed hose.

Page 1822 of 2490

Ref #12 DEF (resumes the system on at the previous temperature setting).

Button (switch) logic

All buttons with an integral LED state lamp conform to the following operating logic.

When the state lamp is lit the relevant func tion is operational. From this condition, pressing the button will de-activate the

function, confirmed by the LED being de-energized and the pres ence of a single audible 'beep'. A single 'beep' will

accompany the state lamp to confirm function re-selection.

1. 1. ON / OFF and manual fan speed.

Pressing this knob activates the system ON at the last settin g or switches the system OFF. Rotate the knob clockwise to

increase and anti-clockwise to decrease fan speed and thus airflow.

With the system OFF, ram air is available by the selected air di stribution mode (indicated by state lamp). Air flow will NOT

occur unless a manual air distribution mo de is selected, this air being unconditioned and flow dependent upon vehicle

speed.

• NOTE: The blowers are inhibited until the engine coolant te mperature is > 35°C, unless DEFROST, FACE or DEMIST modes

are selected.

2. 2. Manual Air Recirculation

Closes the outside air intakes of the blower asse mblies and recirculates air within the vehicle.

Two options of control are available :

Timed Recirculation. Pressing the button for less than 1.5 seconds lights up the LED (confirmed by a single bleep).

This provides recirculation of interior air for a period of approximately 5 minutes. Pressing the button within five

minutes returns the system to fresh air intake mode.

Continuous Recirculation. Pressing and holding the button for more than 1.5 seconds lights up the LED (confirmed by two beeps). This provides continuous reci rculation of interior air. Pressing the button returns the system to fresh air

intake mode.

• NOTE: Avoid using manual air recirculatio n for prolonged periods in cold weather, this may result in interior misting of

glass.

3. 3. Temperature Scale Selection

Press the appropriate button to display temperatures in degrees Celsius or Fahrenheit.

4. 4. Manual Fan Speed

Rotating the fan speed control knob (to vary fan speed) will di splay a proportional number of horizontal bars on the LCD.

There are total of eleven manual fan speeds available.

5. 5. Temperature Display

Indicator of internal demand temperatur e or external ambient temperature. The external ambient is updated every 4

seconds when the road speed > 25 km / h.

6. 6. Scale

Selected temperature scale, Celsius or Fahrenheit.

7. 7. External temperature

Symbol indicates when this option is selected

Page 1823 of 2490

8.8. Automatic

Symbol indicates when the control of , temperature, fan speed and air distribution are all in Auto mode.

9. 9. External

There are two modes of external ambient temperature selection;

Quick Display. Pressing the button for <1.5 seconds (con firmed by a single bleep) will display the external

temperature for 4 seconds.

Continuous Display. Pressing and holding the button fo r >1.5 seconds (confirmed by two beeps) displays the

external ambient temperature continuously, the value of which will be updated every 4 seconds given that vehicle

road speed is > 25 km/h. Pressing the button again fo r <1.5 seconds resets to the previous display.

• NOTE: Continuous external temperature display will be cancel led when the ignition is switched OFF but not during engine

cranking.

10. 10. A/C

This push-on / push-off button will either select or deselect (as indicated by the state lamp) the refrigeration system.

The refrigeration system is automatically engaged when the Auto button is pressed.

• NOTE: Interior misting of screens may be reduced by continuous operation of th e refrigeration system.

11. 11. Auto

When selected and the state lamp lit, A/C mode will be operat ional and control of vent outlet temperature, fans speed and

air distribution will be automatic.

AUTO mode will disengage should manual air distribution or defrost buttons be operated or the manual fan speed knob be

rotated.

• NOTE: Automatic temperature control is constantly main tained irrespective of selected manual overrides.

12. 12. Defrost

Push-on push-off button, which when engaged will direct all air to the front and side glass at maximum fan speed. The

heated windshield (if fitted) will also be energized for a timed cycle of 6,5 minute s, but may be cancelled by pressing the

HEATED WINDSHIELD (F) button. Pressing 'DEF' again will retu rn to the last setting with automatic temperature control

being maintained.

Directing warm and humid air onto a cold screen can produce interior misting of screens. Operating the climate control

system without the refrigerati on system operating will exacerbate this problem.

• NOTE: Directing cold air onto the screen in warm humid conditions can produce external condensation.

13. 13. Heated Windshield (F)

Pressing the heated windshield button (whe re fitted) will energize the electrically heated windshield elements for a timed

cycle of 6,5 minutes; pressing the button again will cancel the request. Should the engine stall or the ignition be turned

OFF, the timer will be cleare d and the function cancelled.

• NOTE: The heated windshield may be activated with the cl imate control system OFF but the engine must be running.

In very cold ambient temperatures, icing of the interior of the glass is possible when the climate control system is operating

in AUTO mode; to reduce this poss ibility the A/CCM provides automatic operation of the heated windshield.

With the following conditions met, the heated windshield will automatically energize but the state lamp will NOT be lit.

Page 1826 of 2490

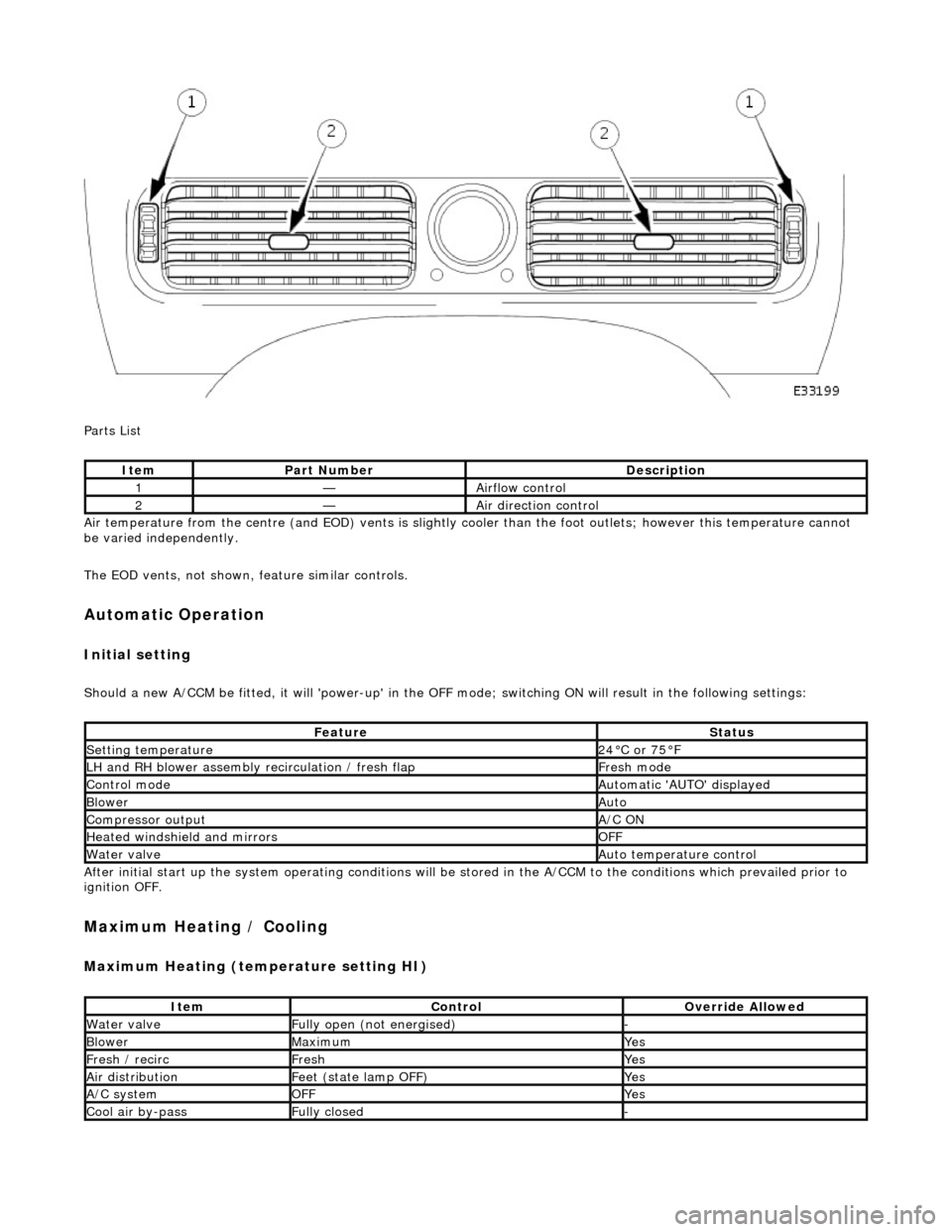

Parts List

Air temperature from the centre (and EOD) vents is slightly cooler than the foot outlets; however this temperature cannot

be varied independently.

The EOD vents, not shown, feature similar controls.

Automatic Operation

Initial setting

Should a new A/CCM be fitted, it will 'power-up' in the OFF mode; switching ON will result in the following settings:

After initial start up the system operating conditions will be st ored in the A/CCM to the conditions which prevailed prior to

ignition OFF.

Maximum Heating / Cooling

Maximum Heating (temperature setting HI)

ItemPart NumberDescription

1—Airflow control

2—Air direction control

FeatureStatus

Setting temperature24°C or 75°F

LH and RH blower assembly recirculation / fresh flapFresh mode

Control modeAutomatic 'AUTO' displayed

BlowerAuto

Compressor outputA/C ON

Heated windshield and mirrorsOFF

Water valveAuto temperature control

ItemControlOverride Allowed

Water valveFully open (not energised)-

BlowerMaximumYes

Fresh / recircFreshYes

Air distributionFeet (state lamp OFF)Yes

A/C systemOFFYes

Cool air by-passFully closed-

Page 1827 of 2490

Maximum Cooling (temperature setting LO)

Air Conditioning Control Module (A/CCM)

Location

The A/CCM is located on the right hand side of the air conditioning unit and controls all system functions.

The temperature within the passenger compartment is continually compared with the temperature selected on the control

panel LCD. The A/CCM receives data input signals and compares these with signal s from the system temperature sensors

and feedback devices. Based on this information the A/CCM adjusts the air outlet temperatur e, airflow and distribution from

the air conditioning system in to the passenger compartment.

Identification

ItemControlOverride Allowed

Water valveFully closed (energised)-

BlowerMaximumYes

Fresh / recircRecirculationYes

Air distributionFace (state lamp OFF)Yes

A/C systemONYes

Cool air by-passFully open-

Page 1854 of 2490

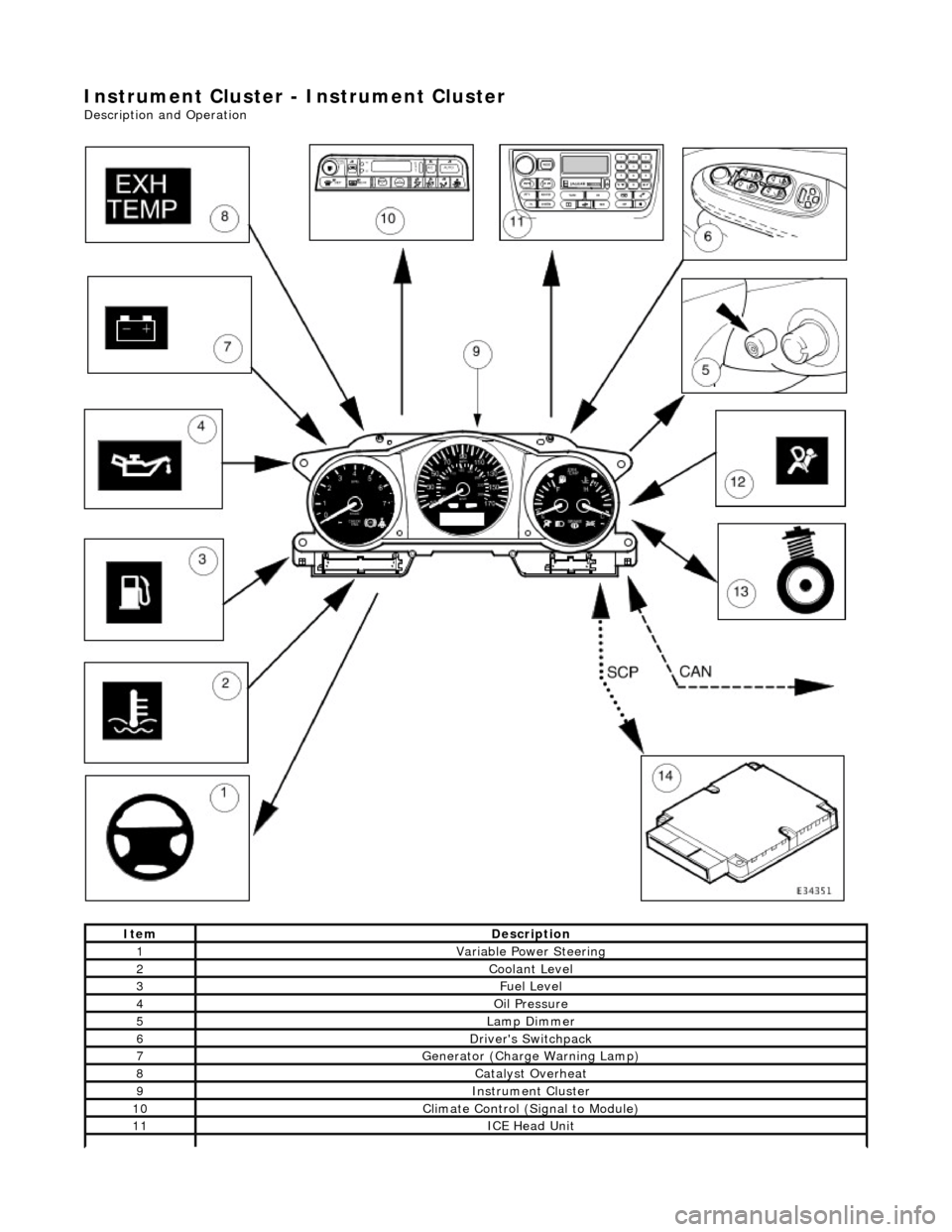

Instrument Cluster - Instrument Cluster

Description and Operation

ItemDescription

1Variable Power Steering

2Coolant Level

3Fuel Level

4Oil Pressure

5Lamp Dimmer

6Driver's Switchpack

7Generator (Charge Warning Lamp)

8Catalyst Overheat

9Instrument Cluster

10Climate Control (Signal to Module)

11ICE Head Unit

Page 1855 of 2490

The In

strument Cluster is the primary electronic control module for the speedomete

r, tachometer, coolant temperature, fuel

level, driver information (Message Centre) and warning lamps.

The Instrument Cluster also:

- provides input / output informatio n signals for use by other modules.

- acts as a protocol converter (software language translator - the languages used on each network are very similar, but

neither can be directly interp reted by the opposite system) for communication between all modules on both the CAN and

SCP multiplexed networks. The Instrument Cluster is the only module on the vehicle which communicates between the two

networks.

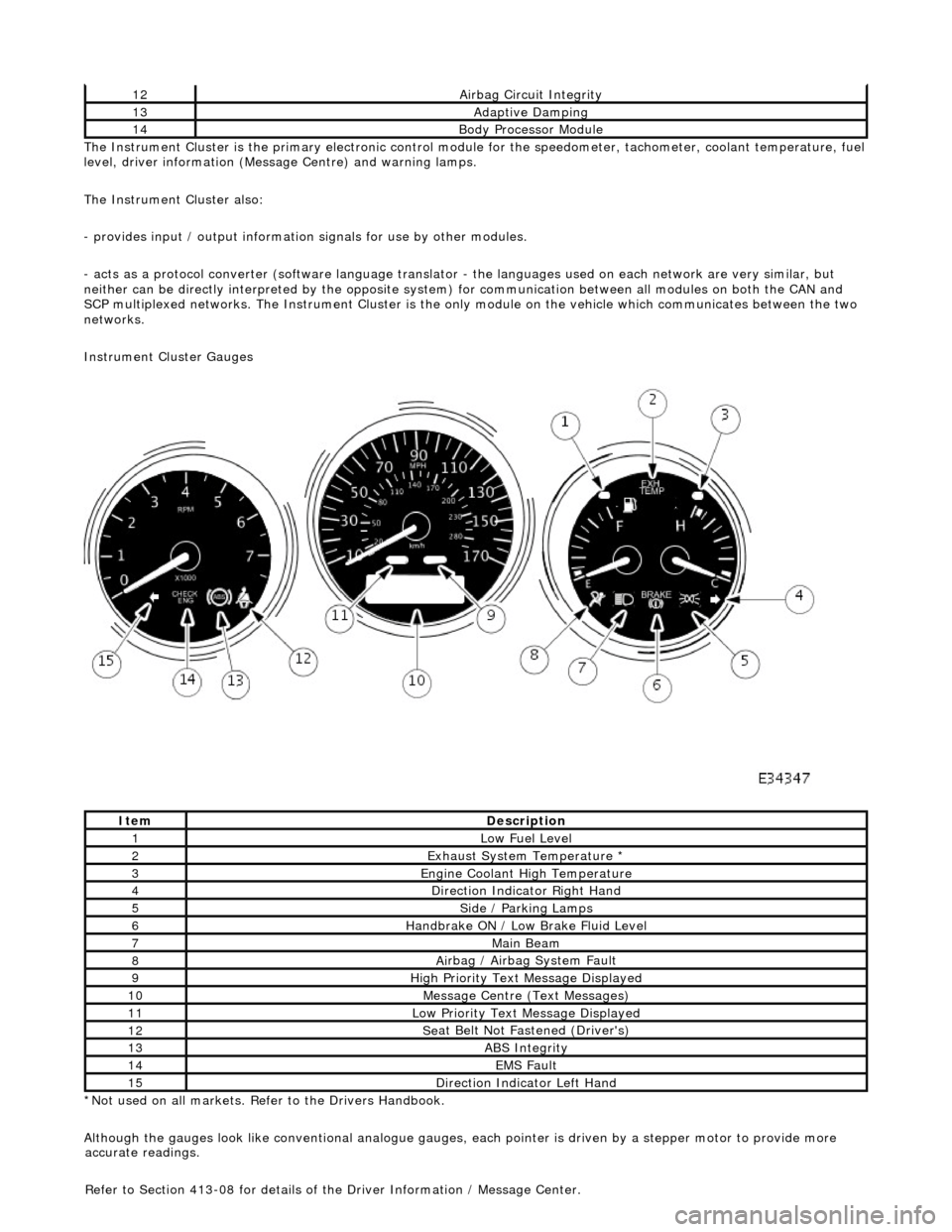

Instrument Cluster Gauges

*Not used on all markets. Refer to the Drivers Handbook.

Although the gauges look like conventional analogue gauges, each pointer is driven by a stepper motor to provide more

12Ai

rbag Circuit Integrity

13Adaptive Damping

14Body Processor

Module

It

em

De

scription

1Low Fu

el Level

2Exhaus

t System Temperature *

3E

ngine Coolant High Temperature

4Di

rection Indicator Right Hand

5Side

/ Parking Lamps

6Handbrake ON / Low

Bra

ke Fluid Level

7Main

Beam

8Ai

rbag / Airbag System Fault

9Hi

gh Priority Text

Message Displayed

10M

essage Centre (Text Messages)

11Low Pri

ority Text Message Displayed

12Se

at Belt Not Fa

stened (Driver's)

13ABS Integrity

14EMS Fault

15D

irection Indicator Left Hand

accu

rate readings.

Refer to Section 413-08 for details of the Driver Information / Message Center.

Page 1856 of 2490

Instrument Cluster - Ins

trument Cluster

D

iagn

osis and Testing

Tests U

s

ing the Portable Diagnostic Unit

Re

fe

r to PDU User Guide

The c

o

mplexity of the electronics involved with the Instrument Cluster and the two multiplexed communication networks

which are connected to it, preclude the use of workshop genera l electrical test equipment. Therefore, reference should be

made to the PDU User Guide for detailed instructions on testing the Instrument Clus ter and associated circuits.

The PDU systematically test s and analyses all functions of the Instrument Clus ter, the various systems controlled by it and

individual sensors which are attached to each separate system.

Where a fault involving a remote sensor e. g. water temperature sensor, is indicated, before replacing the component, some

basic diagnostic methods may be necessary to confirm that connections are good and that wiring is not damaged.

Diagnostics using the PDU is via the CAN network, accessed at the diagnostic connector on the car.

Replaceable Parts

The only replaceable part s

are, General Illumination Bulbs, Direction Indicator Warning Bu

lbs and Main Beam Warning Bulb,

which are all of the conventional filament type. Other warning lamps are LEDs and are not replaceable.

Page 1857 of 2490

Instrume

nt Cluster - Instrument Cluster

Re

moval and Installation

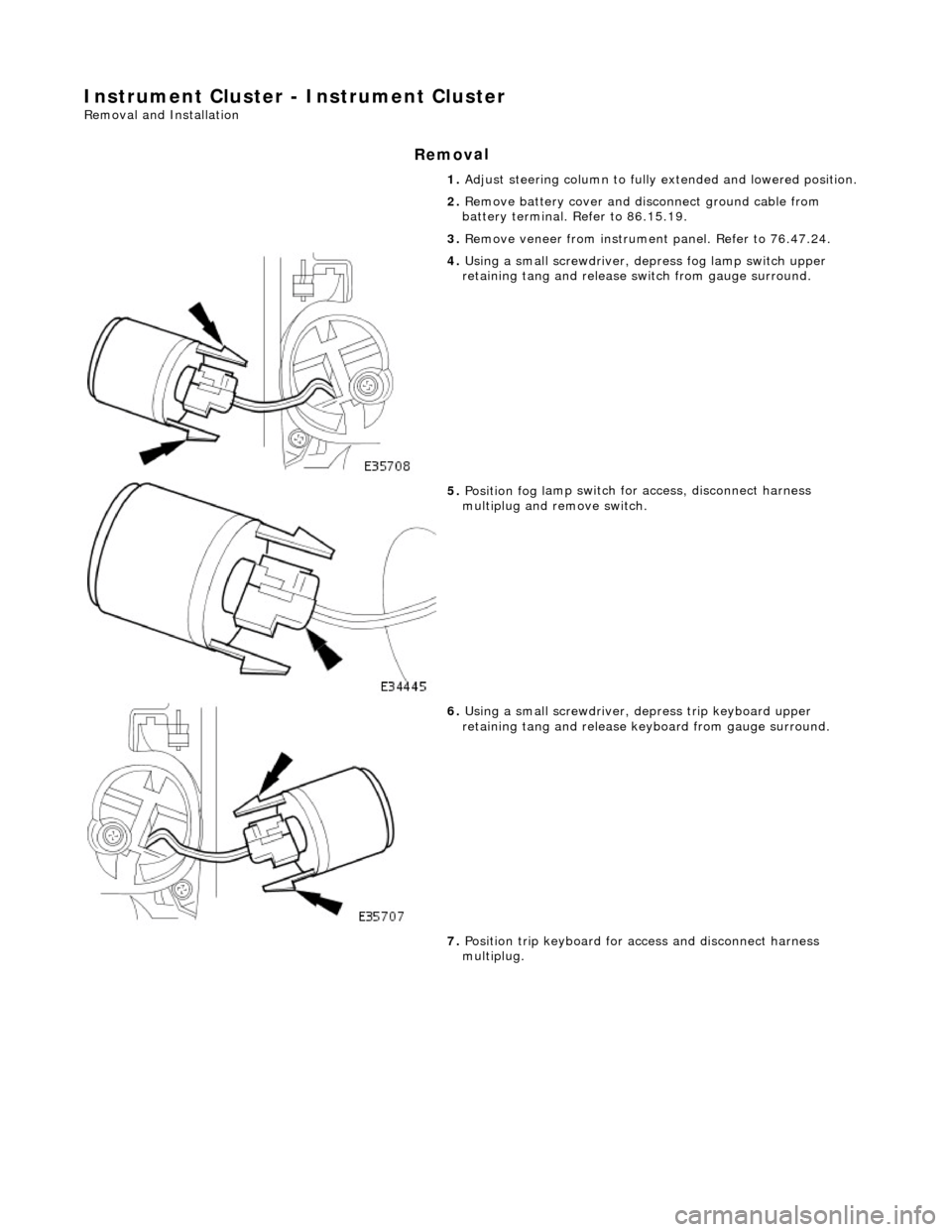

Remov

al

1.

Adjust steer

ing column to full

y extended and lowered position.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

3. Remove veneer from instrument panel. Refer to 76.47.24.

4. Using a small

screwdriver, de

press fog lamp switch upper

retaining tang and release sw itch from gauge surround.

5. Position fog l

amp switch fo

r access, disconnect harness

multiplug and remove switch.

6. Using a small

screwdriver, depress trip keyboard upper

retaining tang and release ke yboard from gauge surround.

7. Position trip keyboard for ac cess and disconnect harness

multiplug.

Page 1858 of 2490

In

stallation

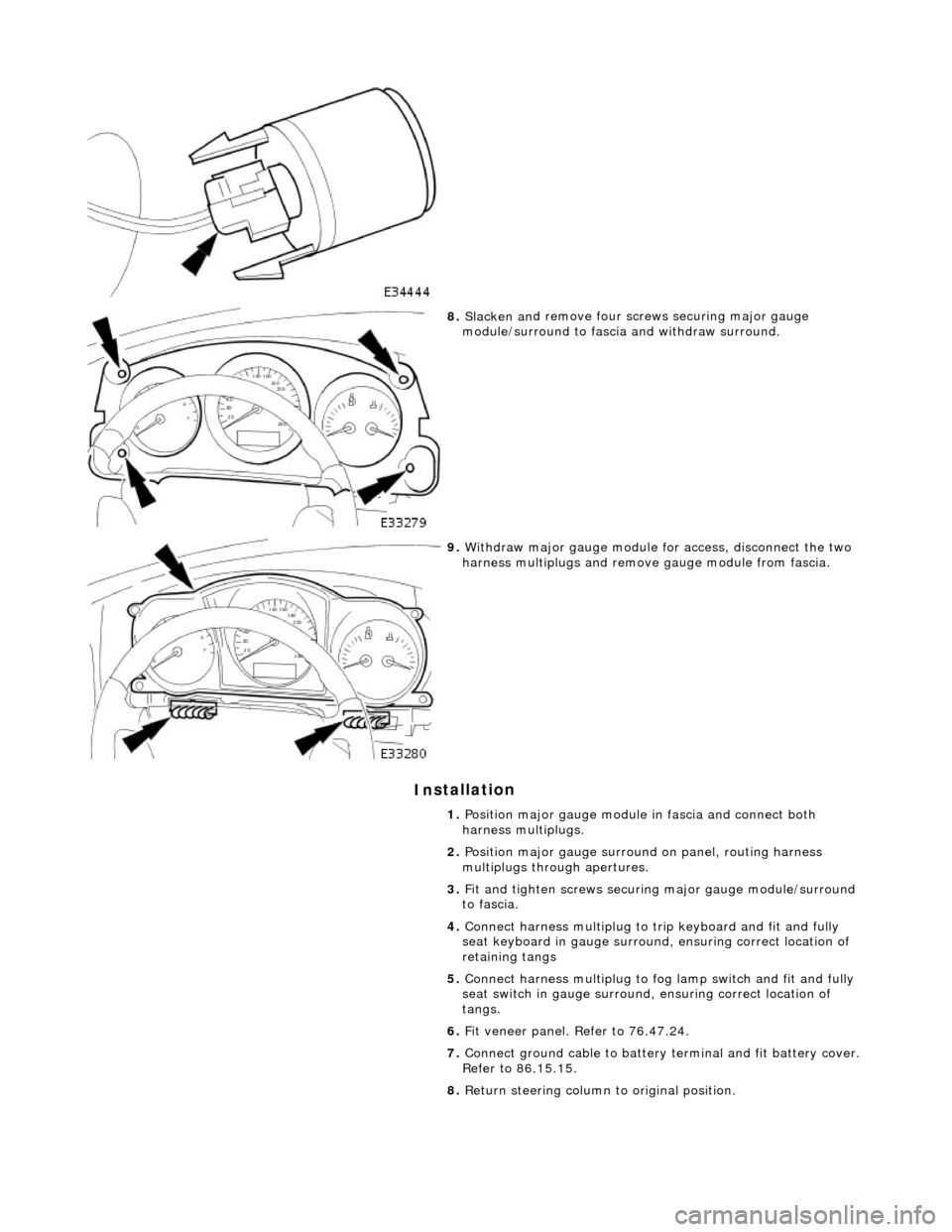

8.

Slac ken an

d remove four screws securing major gauge

module/surround to fascia and withdraw surround.

9. With draw major gau

ge module fo

r access, disconnect the two

harness multiplugs and remove gauge module from fascia.

1. Position major gauge module in fascia and connect both

harness multiplugs.

2. Position major gauge surround on panel, routing harness

multiplugs through apertures.

3. Fit and tighten screws securing major gauge module/surround

to fascia.

4. Connect harness multiplug to tr ip keyboard and fit and fully

seat keyboard in gauge surround, ensuring correct location of

retaining tangs

5. Connect harness multiplug to fog lamp switch and fit and fully

seat switch in gaug e surround, ensuring correct location of

tangs.

6. Fit veneer panel. Refer to 76.47.24.

7. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

8. Return steering column to original position.