sensor JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 932 of 2490

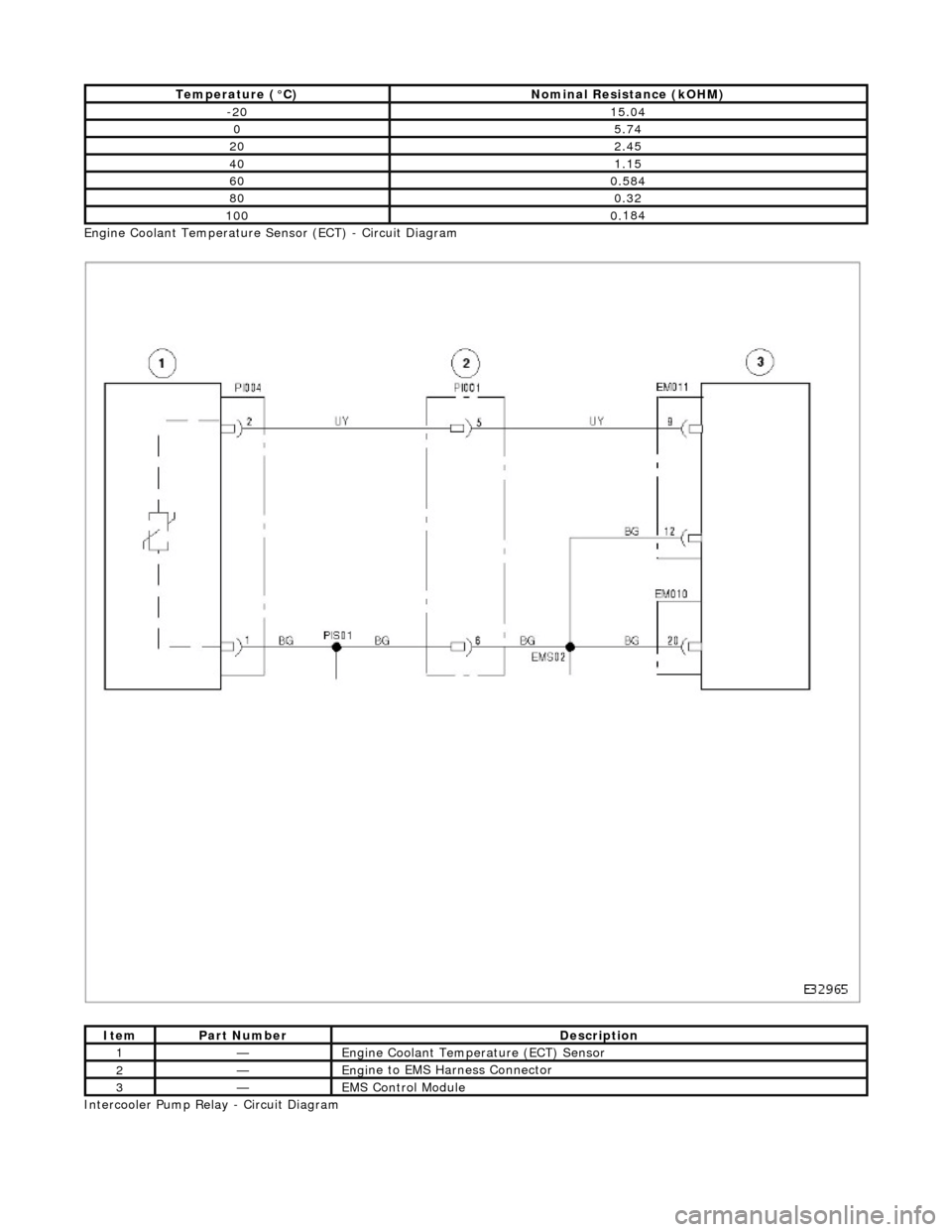

Engi

ne Coolant Temperature Sensor (ECT) - Circuit Diagram

Intercooler Pump Relay - Circuit Diagram

T emper

ature (°C)

No

mi

nal Resistance (kOHM)

-2

015 .0

4

05.7

4

202.45

401.15

600.

584

800.3

2

1000.

184

ItemPar

t

Number

De

scrip

tion

1—Eng

i

ne Coolant Temperature (ECT) Sensor

2—Eng

i

ne to EMS Harness Connector

3—EMS Con

trol Modu

le

Page 934 of 2490

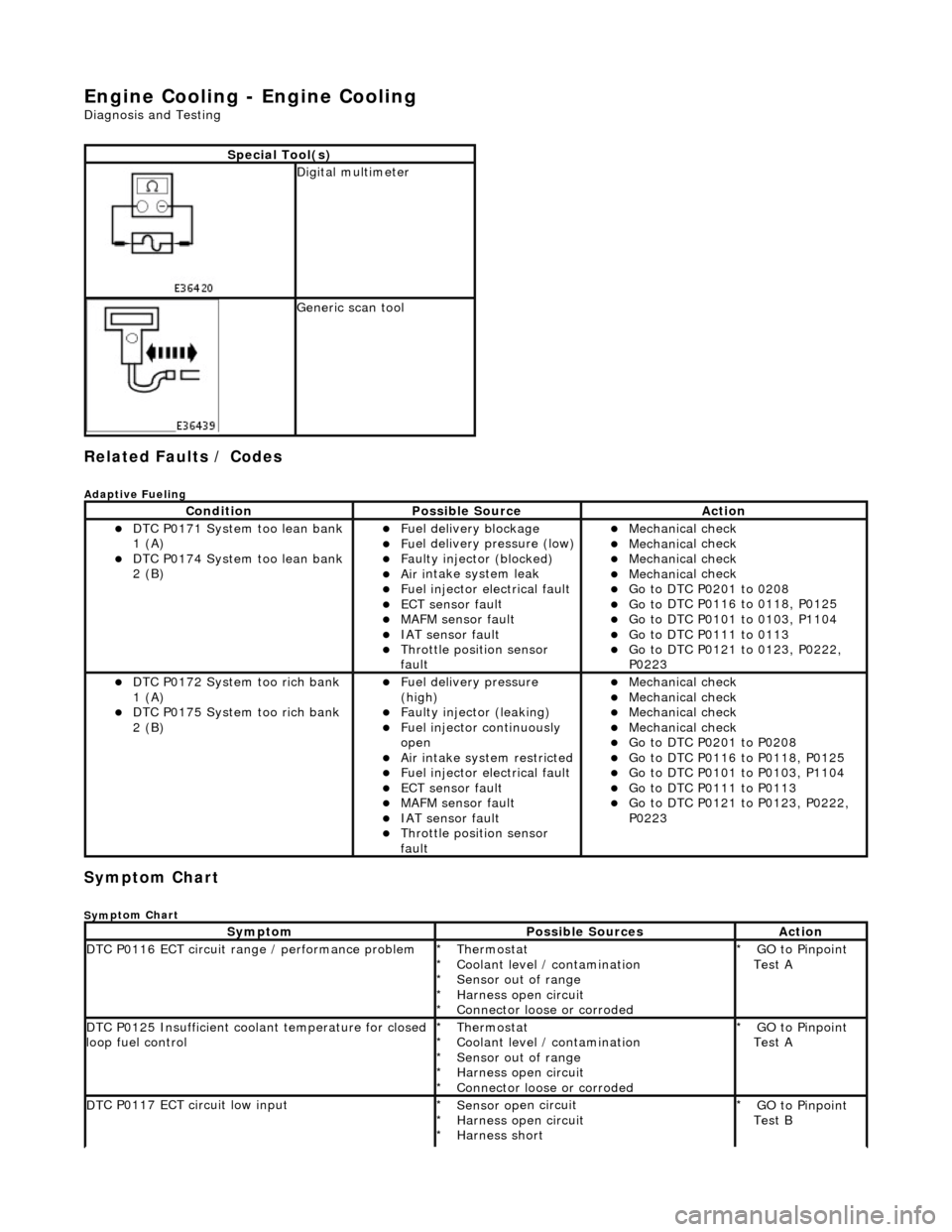

Engine Cooling - Engine Cooling

Diagn

osis and Testing

Related Faults / Codes

Adaptive

Fue

ling

Sym

p

tom Chart

Sy

m

ptom Chart

S

p

ecial Tool(s)

D

i

gital multimeter

Generi

c scan tool

Conditi

on

Possib

l

e Source

Acti

o

n

D

T

C P0171 System too lean bank

1 (A)

D T

C P0174 System too lean bank

2 (B)

Fuel delivery blockage Fu

el delivery pressure (low)

F

a

ulty injector (blocked)

Ai

r i

ntake system leak

F

u

el injector electrical fault

ECT sensor

faul

t

MAFM sensor fault IAT se

nsor fault

Thro

tt

le position sensor

fault

Mec hanica

l check

Mec

hanica

l check

Mec

hanica

l check

Mec

hanica

l check

Go t

o DTC P020

1 to 0208

Go t

o

DTC P0116 to 0118, P0125

Go t

o

DTC P0101 to 0103, P1104

Go t

o DTC P011

1 to 0113

Go t

o

DTC P0121 to 0123, P0222,

P0223

D T

C P0172 System too rich bank

1 (A)

D T

C P0175 System too rich bank

2 (B)

F u

el delivery pressure

(high)

F a

ulty injector (leaking)

F

u

el injector continuously

open

Ai r i

ntake system restricted

Fu

el injector electrical fault

ECT sensor

faul

t

MAFM sensor fault IAT sensor fault

Thrott

le position sensor

fault

Mec hanica

l check

Mec

hanica

l check

Mec

hanica

l check

Mec

hanica

l check

Go t

o DTC P020

1 to P0208

Go t

o

DTC P0116 to P0118, P0125

Go t

o

DTC P0101 to P0103, P1104

Go t

o DTC P011

1 to P0113

Go t

o

DTC P0121 to P0123, P0222,

P0223

Sy m

ptom

Possib

l

e Sources

Acti

o

n

D

T

C P0116 ECT circuit range / performance problem

Thermostat

Coo

l

ant level / contamination

Sensor out of range

Harness open circuit

Connector loose or corroded

*

*

*

*

*

GO to Pinpoint

Test A

*

D

T

C P0125 Insufficient coolant temperature for closed

loop fuel control

Thermostat

Coo l

ant level / contamination

Sensor out of range

Harness open circuit

Connector loose or corroded

*

*

*

*

*

GO to Pinpoint

Test A

*

D

T

C P0117 ECT circuit low input

Sensor o

p

en circuit

Harness open circuit

Harness short

*

*

*

GO to Pinpoint

Test B

*

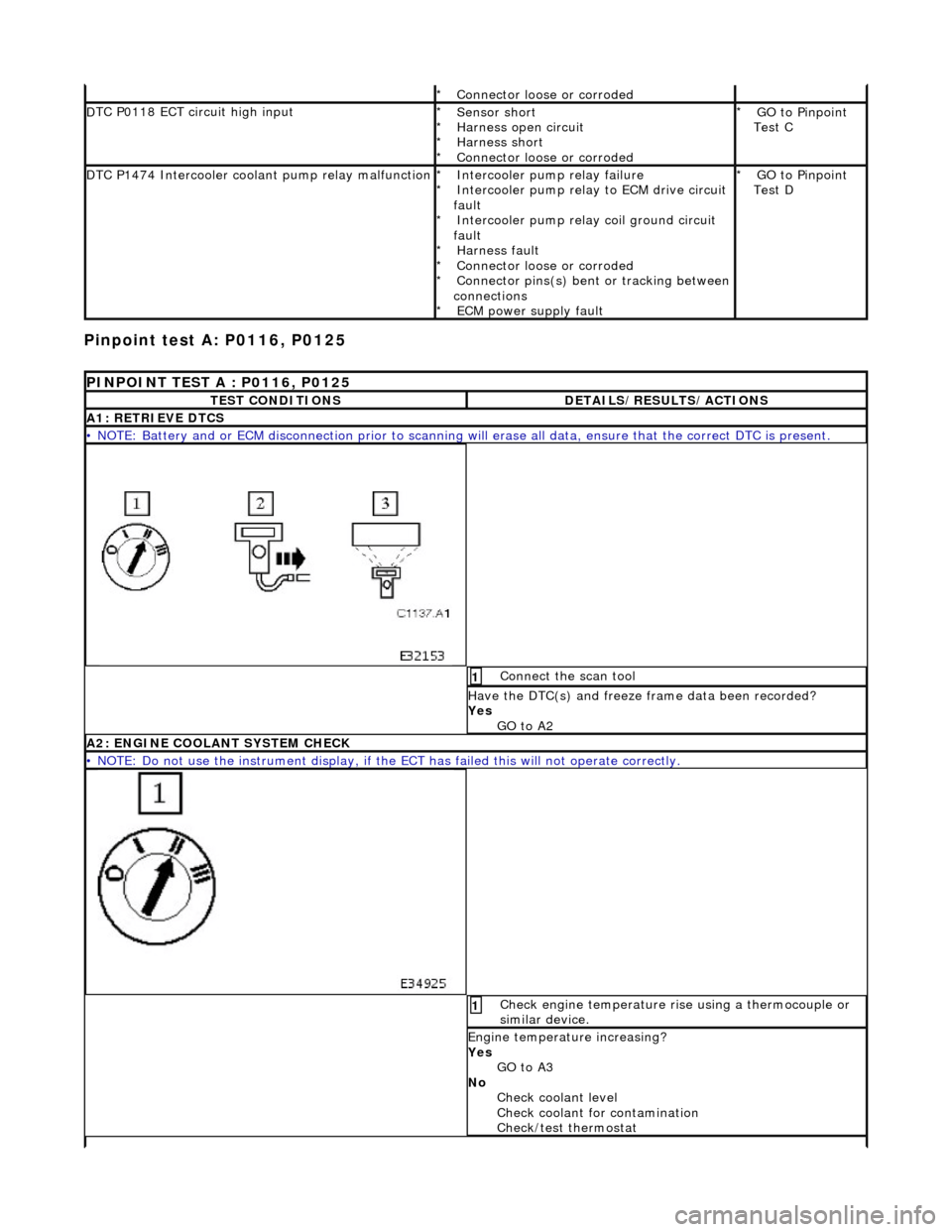

Page 935 of 2490

Pinpoint test

A: P0116, P0125

Connector

loose or corroded

*

D

TC P0118 ECT circuit high input

Sensor short

Harness open circui

t

Harness short

Connector loose or corroded

*

*

*

*

GO to Pinpoint

Test C

*

D

TC P1474 Intercooler coolant pump relay malfunction

Intercooler pump relay

failure

Intercooler pump relay to ECM drive circuit

fault Intercooler pump relay coil ground circuit

fault Harness fault

Connector loose or corroded

Connector pins(s) bent or tracking between

connections ECM power supply fault

*

*

*

*

*

*

*

GO to Pinpoint

Test D

*

P

INPOINT TEST A : P0116, P0125

T

EST CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1

: RETRIEVE DTCS

•

NOTE: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Conne

ct the scan tool

1

Have the DTC(s) and fr

eeze

frame data been recorded?

Yes GO to A2

A2: ENGINE

COOLANT SYSTEM CHECK

•

NOTE: Do not use the instrument display, if th

e ECT has failed this will not operate correctly.

Chec

k engine temperature rise using a thermocouple or

similar device.

1

Engine

temperature increasing?

Yes GO to A3

No Check coolant level

Check coolant for contamination

Check/test thermostat

Page 936 of 2490

A3: CHECK ECT SE

NSOR RANGE

All

o

w the engine to achieve any noted temperature within

the specified range, refer to temperature / resistance

relationship table or graph

1

I g

nition switch to position 0

2

D

i

sconnect PI004

Re

ar

of top hose

3

Meas

ure t

he resistance between sensor pins 1 and 2.

4

Tem

p

erature / resistance relationship OK?

Yes GO to A4

No Remove sensor and check temperature / resistance

relationship for 3 different temperatures. Renew as

required and test the syst em for normal operation.

A4: CHECK

HARNESS

CONTINUITY

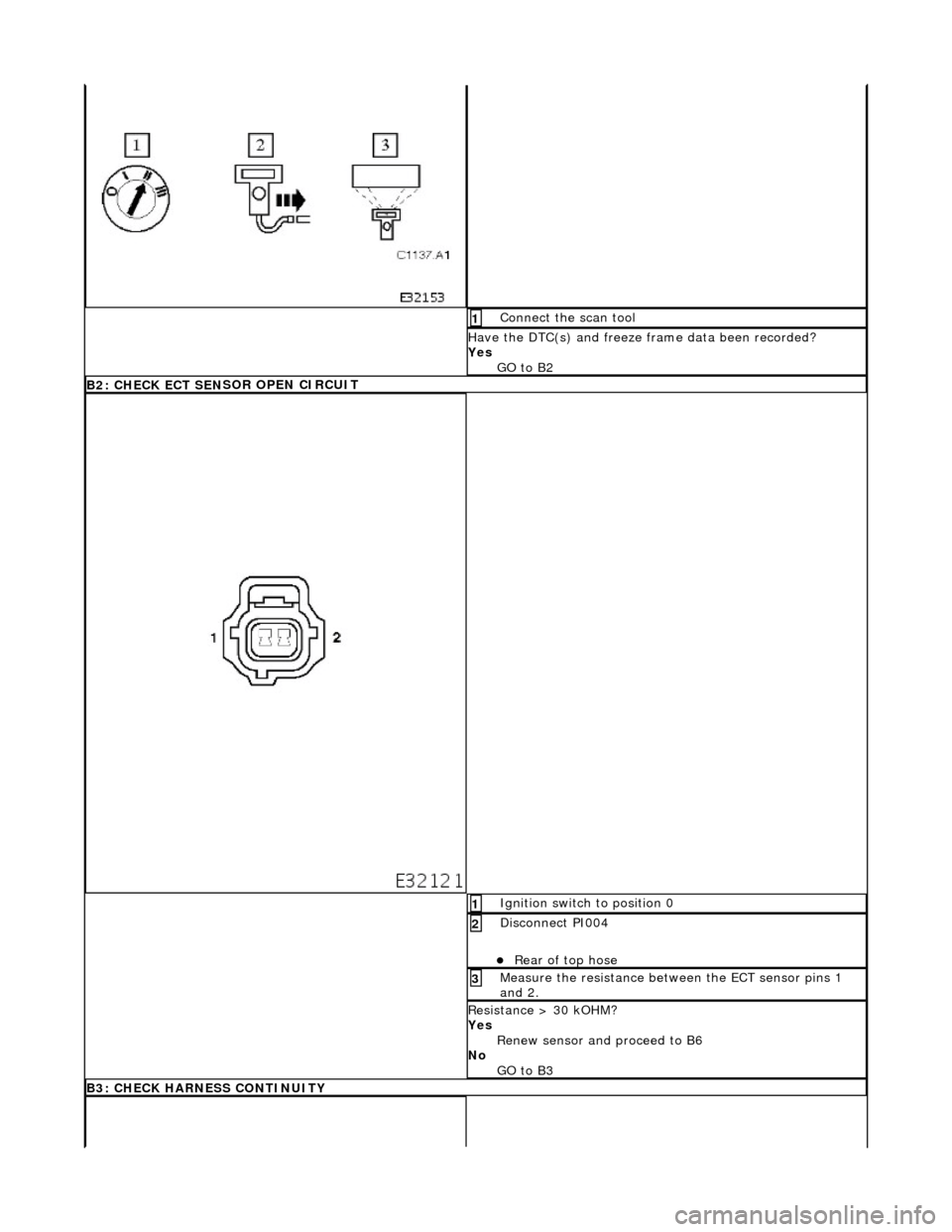

Page 940 of 2490

Connect

the scan tool

1

Have the DTC(s) and fr

eeze f

rame data been recorded?

Yes GO to B2

B2: CHECK ECT SEN

S

OR OPEN CIRCUIT

Ig

nition switch to position 0

1

D

i

sconnect PI004

Re

ar

of top hose

2

Meas

ure t

he resistance between the ECT sensor pins 1

and 2.

3

Re si

stance > 30 kOHM?

Yes Renew sensor and proceed to B6

No GO to B3

B3: CHECK HARNESS

CONTINUITY

Page 945 of 2490

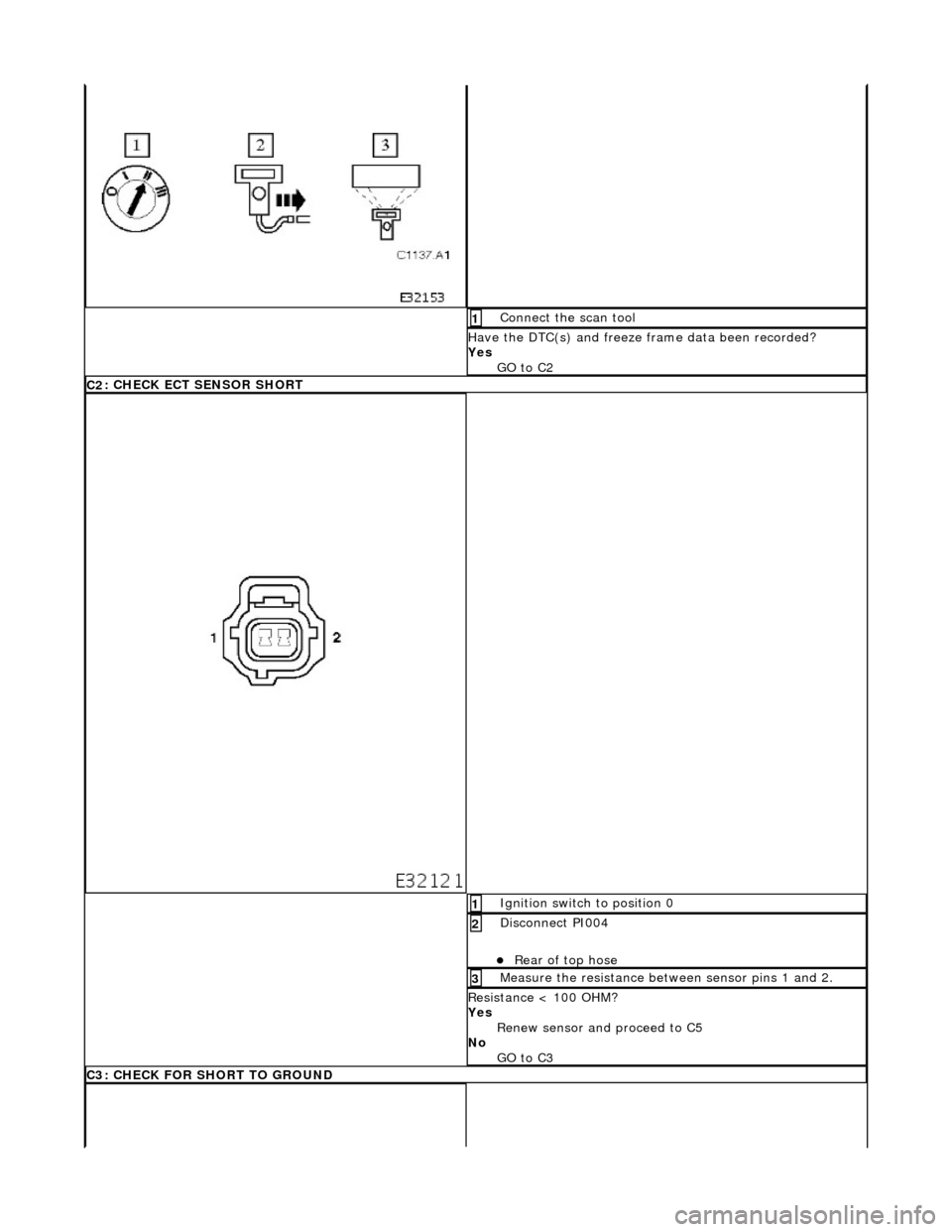

Conne

ct the scan tool

1

Have the DTC(s) and fr

eeze

frame data been recorded?

Yes GO to C2

C2

: CHECK ECT SENSOR SHORT

I

gnition switch to position 0

1

D

isconnect PI004

Re

ar of top hose

2

Meas

ure the resistance between sensor pins 1 and 2.

3

Re

sistance < 100 OHM?

Yes Renew sensor and proceed to C5

No GO to C3

C3

: CHECK FOR SHORT TO GROUND

Page 963 of 2490

Engine Cooling - Coolant Expansi

on Tank

Re

moval and Installation

Remov

al

1.

O

pen the engine compartment and fit paintwork protection

sheets.

2. R

emove the centre trim panel

from the engine compartment.

1. Remove the left hand side enclosure panel.

2. Remove the centre trim panel.

3. Ensure that the cooling system is cool and very carefully,

remove the pressure cap.

4. Place a cloth under the expansion tank to absorb any spillage

caused by disconnecting the hoses.

5. R

elease the hoses (Quick Fit connections) from the expansion

tank.

1. Release the hose, expansion tank to thermostat housing (coolant outlet pipe on supercharged

engines).

2. Release the hose, expansion tank to recovery tank.

3. Release the hose, expansion tank to radiator..

6. Fit blanking plugs to the pipes and the tank.

7. Re

move the expansion tank from the mounting.

1. Disconnect the coolant level sensor connector.

2. Remove the nuts which secures the tank.

8. Remove the expansion tank from the vehicle.

1. Use a pipe clamp to clam p the bottom hose branch.

2. Release the pipe clip an d move it along the pipe.

3. Disconnect the tank from the bottom hose and

Page 964 of 2490

In

stallation

re

move it from the vehicle.

9. Empty any surplus coolant from the expansion tank into a

drain tray.

10. Remove the cloth from the engine and clean any spillage from

the engine bay.

11 . R

emove the coolant level sensor

by carefully levering it

downwards at one side.

1. Installation is th e reverse of the re moval procedure.

Page 965 of 2490

Engine Cooling - Coolant Outlet Pipe

Re

moval and Installation

Remov

al

Installation

1.

O

pen the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the outlet pipe.

3. Di

sconnect the hoses and multi-plug from the coolant outlet

pipe.

1. Release and reposition th e hose clip, and disconnect

the top hose.

2. Release and reposition th e hose clip, and disconnect

the heater hose.

3. Disconnect the multi-plug from the temperature sensor and unscrew the sens or from the outlet pipe.

4. Release and reposition the hose clip along the bypass

hose.

4. R

emove the coolant outlet pipe.

1. Remove the four bolts which secure the outlet pipe.

2. Remove the outlet pipe from the bypass hose and

from the cylinder heads.

5. Remove and discard the sealing rings from the outlet pipe

grooves.

1. Installation is the reverse of the remova l procedure. Use new

sealing rings on the coolant outlet pipe.

2. Tighten the coolant outlet pipe bolts to 10-14 Nm If replacing

the coolant temperature sensor, tighten to 15-19 Nm.

3. Refill the cooling system as de scribed in General Procedures.

Page 966 of 2490

Engine Cooling - Coolant Outlet Pipe

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the outlet pipe.

3. Disc onne

ct the top hose and br

eather pipe from the coolant

outlet pipe.

1. Release and reposition th e hose clip, and disconnect

the top hose.

2. Release and disconnect the breather pipe quick fit connector.

3. Disconnect the multi-plug from the temperature sensor and unscrew the sens or from the outlet pipe.

4. Release and reposition the hose clip along the bypass

hose.

4. Disc

onnect the bottom hose

from the thermostat housing.

1. Release and reposition th e hose clip along the hose.

2. Disconnect the bottom hose.

5. Disc

onnect the coolant outlet pipe from the cylinder heads.

1. Remove the four bolts which secure the outlet pipe.

2. Remove the outlet pipe from the bypass hose and

from the cylinder heads (still connected to the

heater hose).

6. Release and reposition the clip which secures the heater hose

to the outlet pipe and disconnect the hose. Remove the outlet

pipe.

7. Remove the thermostat from the outlet pipe.

1. Remove the three bolts which secure the thermostat cover to the outlet pipe.

2. Remove the thermostat cover, the thermostat and

the seal from the outlet pipe. Discard the seal.