electrical JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2054 of 2490

Interior Trim and Ornamentation - Interior Trim

Description and Operation

Carpets

The passenger compartment carpet is a one piece moulded constr uction with integral sound deadening material, heel mats

and driver's footrest. The carpet is attach ed to the vehicle floor by plastic clips fitted below the door treadplates. Removal of the carpet necessitates re moval of the front seats, lifting of the centre console rear extens ion and removal of the heelboard

carpet.

Fascia

The full width, slush moulded, soft feel PVC fascia is mounted on an injection moulded armature and is faced with wood

veneer. In addition to the air conditioning and central, outer and demisting vents, it accepts instrument packs dedicated to

market requirements and a centrally mounted analogue clock.

Doors

The one-piece door casings are trimmed in UEV to match the seating, with wood veneer at the waistline and a carpet insert

at the front lower corner. Each casing is secured to the door inner panel by fir tree press fast eners along the lower section,

two armrest fixings at the centre and vene er panel dowels and fixings at the top. The armrests which are common to front

and rear doors, are trimmed in matching leather or UEV according to specification. The door switchpacks, dedicated to

driver and front or rear passenger, are in corporated in the armrests. A speaker is in stalled in the lower section of each door

and a tweeter is incorporated behind each interior door handle escutcheon. Where premium ICE is fitted, the front tweeters

are installed in the upper A posts.

A, B, C and D Posts

On each side,a grained UEV finisher trimmed to match the headlining is secured to the 'A' post and cantrail by fir tree

fasteners locating in BIW apertures. The upper 'D' post finisher is trimmed and secured in the same manner. The single

piece'B/C' post finishers, also finished in grained matching UEV, each have a front se at belt exit aperture and are secured to

the BIW by four spring clips and two fir tree fasteners.

Headlining

The one-piece headlining consists of a 6mm thick polyurethane foam membrane covered with suede effect knitted polyester. The headlining is secured to the BIW roof by body tangs, the roof console, sun visors, combined grab handles and coat

hooks, the cantrail finishers and where fitt ed, the sliding roof finisher and clips.

Trunk

Carpet covered trims line the trunk and are secured by fir tr ee fasteners to the sides and front inner panel. The carpet

covered, two-section, removable trunk fl oor provides access to the spare wheel and wheel changing equipment, the battery

and electrical carrier. The floor board rests on the spare wheel, with the front and rear edges locating in blocks on the fuel

tank backboard and the rear of the body. The support blocks provide for two floor he ight settings to accommodate either a

space saver or full size spare wheel.A moulded finisher covering the rear of the trunk below the sill is secured to the rear

panel by tabs and fir tree fasteners. Finish er panels fitted to the rear lamp units provide trunk interior access to the lamps.

The trunk lid underside is fitted with a removabl e moulded liner and two trunk illumination lights.

Page 2059 of 2490

Interior Trim and Ornamentation - C-Pillar Trim Panel

Removal and Installation

Removal

1. Remove the passenger assist handle.

For additional information, refer to: Passenger Assist Handle

(501-05 Interior Trim and Ornamentation, Removal and

Installation).

2. Detach the rear courtesy/reading light.

3. Remove the rear courtesy/reading light.

пЃ¬Disconnect the electrical connector.

4. Detach the door aperture weatherstrip.

5. Detach the C-pillar trim panel fi r tree fasteners from the BIW.

6. Remove the C-pillar trim pa nel and discard the fir tree

fasteners.

Page 2076 of 2490

Interior Trim and Ornamentation - Headliner

Removal and Installation

Removal

Vehicles with roof opening panel

All vehicles

1. Remove the roof opening panel trim.

For additional information, refer to: Roof Opening Panel Trim

(501-17 Roof Opening Panel, Removal and Installation).

2. Remove both C-pill ar trim panels.

For additional information, refer to: C

-Pillar Trim Panel (501-05

Interior Trim and Ornamentatio n, Removal and Installation).

3. Remove both A-pill ar trim panels.

For additional information, refer to: A

-Pillar Trim Panel (501-05

Interior Trim and Ornamentatio n, Removal and Installation).

4. Remove the overhead console.

For additional information, refer to: Overhead Console

(501-12

Instrument Panel and Console, Removal and Installation).

5. Remove the rear window glass.

For additional information, refer to: Rear Window Glass

(501-

11 Glass, Frames and Mechanis ms, Removal and Installation).

6. Disconnect the anti-theft se nsors electrical connector.

7. CAUTION: With the aid of an other technician, support the

headliner to ensure it is not folded or creased during removal.

Remove both sun visors.

For additional information, refer to: Sun Visor

(501-05 Interior

Trim and Ornamentation, Re moval and Installation).

8. NOTE: Left-hand shown, right-hand similar.

Detach the retaining screw cove r from the headliner retaining

trim.

9. NOTE: Left-hand shown, right-hand similar.

Remove the headline r retaining trim.

Page 2077 of 2490

Installation

All vehicles

пЃ¬Remove the retaining screw.

10. With the aid of another tech nician, lower the headliner.

11. With the aid of another techni cian, remove the headliner.

12. NOTE: Left-hand shown, right-hand similar.

Detach the anti-theft sensors.

13. NOTE: Left-hand shown, right-hand similar.

Remove the anti-t heft sensors.

1. Disconnect the electrical connector.

1. NOTE: Left-hand shown, right-hand similar.

Page 2078 of 2490

Install the anti-theft sensors. 1. Connect the electrical connector.

2. NOTE: Left-hand shown, right-hand similar.

Attach the anti-theft sensors.

3. CAUTION: With the aid of an other technician, support the

headliner.

Install the headliner.

4. With the aid of another tech nician, raise the headliner.

5. CAUTION: Support the headliner to ensure it is not folded or creased during installation.

• NOTE: Left-hand shown, right-hand similar.

Install the headliner retaining trims.

пЃ¬Install the retaining screw.

6. NOTE: Left-hand shown, right-hand similar.

Attach the screw cover.

Page 2079 of 2490

Vehicles with roof opening panel

7. Install both sun visors.

For additional information, refer to: Sun Visor (501-05 Interior

Trim and Ornamentation, Re moval and Installation).

8. Install the rear window glass.

For additional information, refer to: Rear Window Glass

(501-

11 Glass, Frames and Mechanis ms, Removal and Installation).

9. Fit the electrical connectors into the retaining clips at the

overhead console location.

10. Install the overhead console.

For additional information, refer to: Overhead Console

(501-12

Instrument Panel and Console, Removal and Installation).

11. Install both C-pillar trim panels.

For additional information, refer to: C

-Pillar Trim Panel (501-05

Interior Trim and Ornamentatio n, Removal and Installation).

12. Install both A-pillar trim panels.

For additional information, refer to: A

-Pillar Trim Panel (501-05

Interior Trim and Ornamentatio n, Removal and Installation).

13. Install the roof opening panel trim.

For additional information, refer to: Roof Opening Panel Trim

(501-17 Roof Opening Panel, Removal and Installation).

Page 2111 of 2490

Rear View Mirrors - Rear View Mirrors

Description and Operation

Interior Rear View Mirror

The interior rear view mirror is an elec trochromic unit that automatically darken s to prevent glare from following vehicle

lights. This automatic function is selected by pressing the switch at the bottom of the mirror. Pressing the switch again

cancels this function. An LE D then illuminates when automatic dipping is operative.

A Night Sentinel light sensing unit also incorporated in the mi rror casing, provides for automatic control of the vehicle lights.

Door Rear View Mirrors

The door mirrors are cheater mounted, colo r-keyed units, remote electrically adjustable and heated. Adjustment of both

mirrors is carried out from the driver's door switchpack. A slider switch selects the mirror to be adjusted, and a disc switch

adjusts the selected mirror to the required position.

Page 2121 of 2490

Seating - Seats Description and Operation

Front Seats

All front seats are equipped with electric height adjustment. In addition, both front seats are available with manual or power forward

and rearward adjustment, manual or powe r operated headrest adjustment, 12 way elec tric adjustment, memory controlled 12 way

adjustment and integral seat heating. A side air bag module is installed in the outboard squab wing of each front seat. Each se at has a

non-handed, one-piece frame incorporating cushion and squab frames , side air bag suppoort bracket and seat adjuster mechanisms.

Sear switchpacks are installed on the outboa rd side of driver and passenger seats, and control modules are installed in the bas e of each

seat. Both the driver and front passenger seat ar e secured to the vehicle floor at four points.

Rear Seats

The standard rear seat is of the fixed, bench type with full wi dth removable cushion. Two individual rear seats are fitted to certain long

wheelbase models. Both types of rear seat are available with thermostatically controlled heating of the cushion and squab. Indi vidual

rear seats are electrically adjustable for squab recline (via fore and aft moveme nt), head restraint height and lumbar support. Separate

motors provide adjustment of each seat cushion and head restraint and an electrica lly-driven air compressor provides variation of

lumbar support. Seat adjustment is controll ed via switches installed on a panel in a rear extension to the centre console.

Page 2171 of 2490

Seating - Rear Seat Cushion Heater Mat

Removal and Installation

Removal

Installation

1.

Remove the rear seat cushion. Fo r additional information, refer

to the procedure in this section: Rear Seat Cushion

.

2. Remove the seat cushion cover.

3. Detach the seat cushion heater element electrical connectors.

4. Remove the seat cushion heater element.

1. To install, reverse the removal procedure.

Page 2179 of 2490

Glass, Frames and Mechanisms - Glass, Frames and Mechanisms

Description and Operation

Fixed Glass

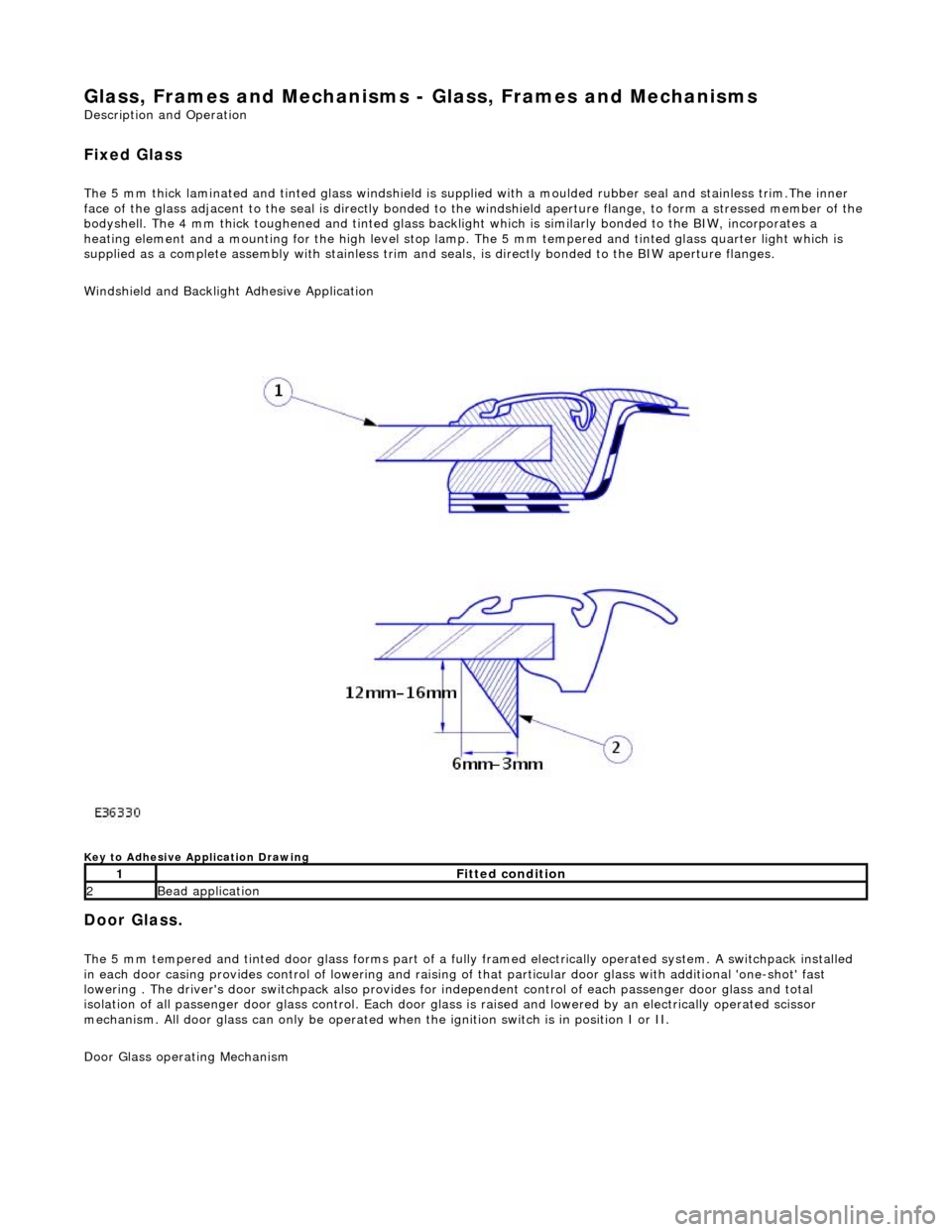

The 5 mm thick laminated and tinted glas s windshield is supplied with a moulded rubber seal and stainless trim.The inner

face of the glass adjacent to the seal is directly bonded to the windshield aperture flange, to form a stressed member of the

bodyshell. The 4 mm thick toughened and tinted glass backlight which is similarly bonded to the BIW, incorporates a

heating element and a mounting for the high level stop lamp. The 5 mm tempered and tinted glass quarter light which is

supplied as a complete assembly with stainless trim and seals, is directly bonded to the BIW aperture flanges.

Windshield and Backlight Adhesive Application

Key to Adhesive Application Drawing

Door Glass.

The 5 mm tempered and tinted door glass forms part of a fully framed electrically operated system. A switchpack installed

in each door casing provides control of lowering and raising of that particular d oor glass with additional 'one-shot' fast

lowering . The driver's door switchpack also provides for independent control of each passenger door glass and total

isolation of all passenger door glass control. Each door glas s is raised and lowered by an electrically operated scissor

mechanism. All door glass can only be operated wh en the ignition switch is in position I or II.

Door Glass operating Mechanism

1Fitted condition

2Bead application