electrical JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1873 of 2490

Parking Aid - Rear Parking Aid Sensor

Removal and Installation

Removal

Installation

1.

Raise and support the vehicle.

For additional information, refer to: Jacking

(100-02 Jacking

and Lifting, Descript ion and Operation).

2. Disconnect the electrical connector.

3. CAUTION: Make sure excessiv e pressure or tools are not

used when removing the parkin g aid sensor from the housing.

Remove the rear parking aid sensor.

1. To install, reverse the removal procedure.

Page 1874 of 2490

Parking Aid - Rear Parking Aid Speaker

Removal and Installation

Removal

Installation

1.

Remove the parcel shelf.

For additional information, refer to: Parcel Shelf

(501-05

Interior Trim and Ornamentatio n, Removal and Installation).

2. Reposition the sound insulation.

3. Disconnect the electrical connector.

4. Remove the rear parking aid speaker.

1. To install, reverse the removal procedure.

Page 1882 of 2490

Generator and Regulator - Generator

Description and Operation

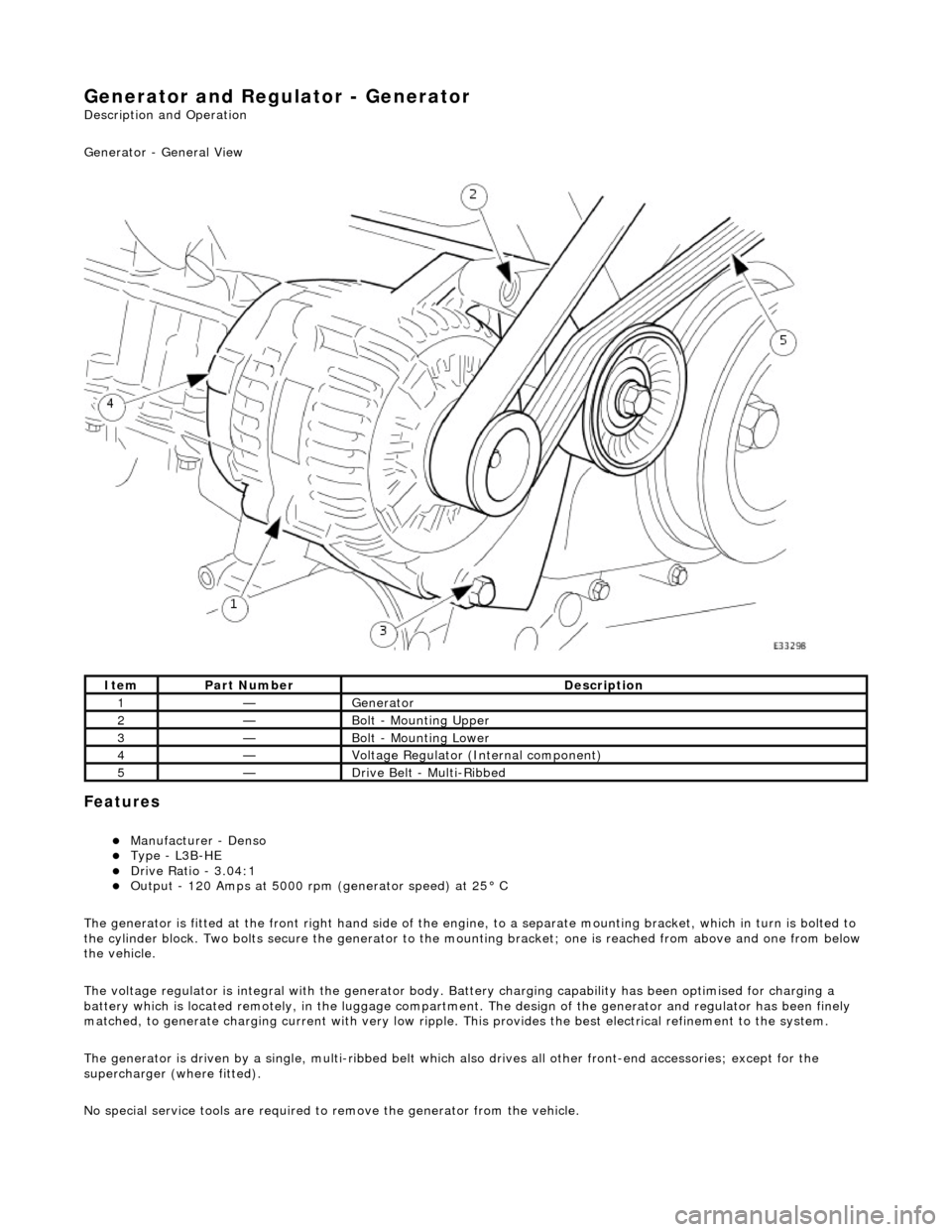

Generator - General View

Features

пЃ¬Manufacturer - Denso пЃ¬Type - L3B-HE пЃ¬Drive Ratio - 3.04:1 пЃ¬Output - 120 Amps at 5000 rpm (generator speed) at 25В° C

The generator is fitted at the front right hand side of the engine, to a sepa rate mounting bracket, which in turn is bolted to

the cylinder block. Two bolts secure th e generator to the mounting bracket; one is reached from above and one from below

the vehicle.

The voltage regulator is integral with th e generator body. Battery charging capabi lity has been optimised for charging a

battery which is located remotely, in the luggage compartment. The design of the generator and regulator has been finely

matched, to generate charging current with very low ripple. This provides the best electrical refinement to the system.

The generator is driven by a single, multi-ribbed belt which also drives all other front-e nd accessories; except for the

supercharger (where fitted).

No special service tools are required to remove the generator from the vehicle.

ItemPart NumberDescription

1—Generator

2—Bolt - Mounting Upper

3—Bolt - Mounting Lower

4—Voltage Regulator (Internal component)

5—Drive Belt - Multi-Ribbed

Page 1887 of 2490

Generator and Regulator - Generator

Diagnosis and Testing

Refer to PDU User Guide

Refer to the PDU User Manual for detailed instructions on testing the charging circuit.

When diagnosing the charging ci rcuit, the PDU indicates only whether the generator is charging or not charging. The reason

for this is that the PDU cannot handle the potential full charging current and that the voltage control circuits are located

within the generator assembly, making th em inaccessible by the PDU directly.

It is possible that the battery has failed. In this case, the voltage output at the generator could be correct, but the voltage

at the battery terminals, and therefore the rest of the vehicl e system, will be adversely affected by the faulty battery.

The same result is given by the PDU if the battery is faulty (generator not faulty), wiring fault (damaged or severe corrosion

at the terminals) or if th e generator is at fault.

Inspection and Verification

The following manual tests help to pinpoint which component is at fault.

Testing the Battery Circuit

Using the Vehicle Battery

Remove the battery cover.

Ensure that all electrical loads are swit ched OFF and that the engine is cool.

Start the engine and allow to IDLE.

Whilst the engine is idling, disconnect the battery negative terminal and, using a digital multimeter (DMM), measure the

voltage between the terminal on the batter y negative cable and the battery positive terminal. If the generator is working,

the measured voltage should be within the range 13V to 15V.

This indicates the system voltage without the battery in circuit. If the generator is inoperative, the engine will stall when t he

ground lead is disconnected.

Repeat the test, using the ground bolt, as indicated (shown dotted on the illustration). There should be hardly any

MechanicalElectrical

Visually check the condition of the drive beltConnections on the rear face of the generator

are fully located?

Check that the belt we ar indicator, located on the automatic belt

tensioner, is within the limit marks

Page 1888 of 2490

detectable difference in the voltage reading (due to minimal current flow); if there is a detectable difference, clean the cable terminal and the adjacent area of the body.

When the voltage has been measured, STOP THE ENGINE.

Reconnect the battery or fit a new battery if it was established that the battery was at fault (Refer to 414-01).

If the cooling fans operate during the above test, the large demand of current will overload the generator and cause the

engine to stall.

If the battery is in a low state of charge the voltage will rise momentarily when the battery is disconnected. However, the

maximum that the voltage can increase to with this new gene rator is 25V and then only for a maximum time of 200 mS.

Using a Substitute Battery

A substitute battery may be fitted for the tests. This batter y must be a known good example and must have been off-charge for at least twelve hours, with a term inal voltage of approximately 12.8V.

Ensure that all electrical loads are swit ched OFF and that the engine is cool.

Start the engine and allow to IDLE.

Measure the voltage across the battery term inals. It should have dropped a little due to the large start current and then

risen to a value of between 13V and 15V.

If the above test (whichever one used) indicates that the generator is not working then the connections on the rear face of

the generator should be checked. If there is a faulty connection, then the ge nerator will not perform correctly no matter

how fast it is driven.

Checking Generator Connections

ItemDescription

1Multi-Plug Connector

2B+ Main Output Terminal

Page 1904 of 2490

Audio Unit - Audio System

Description and Operation

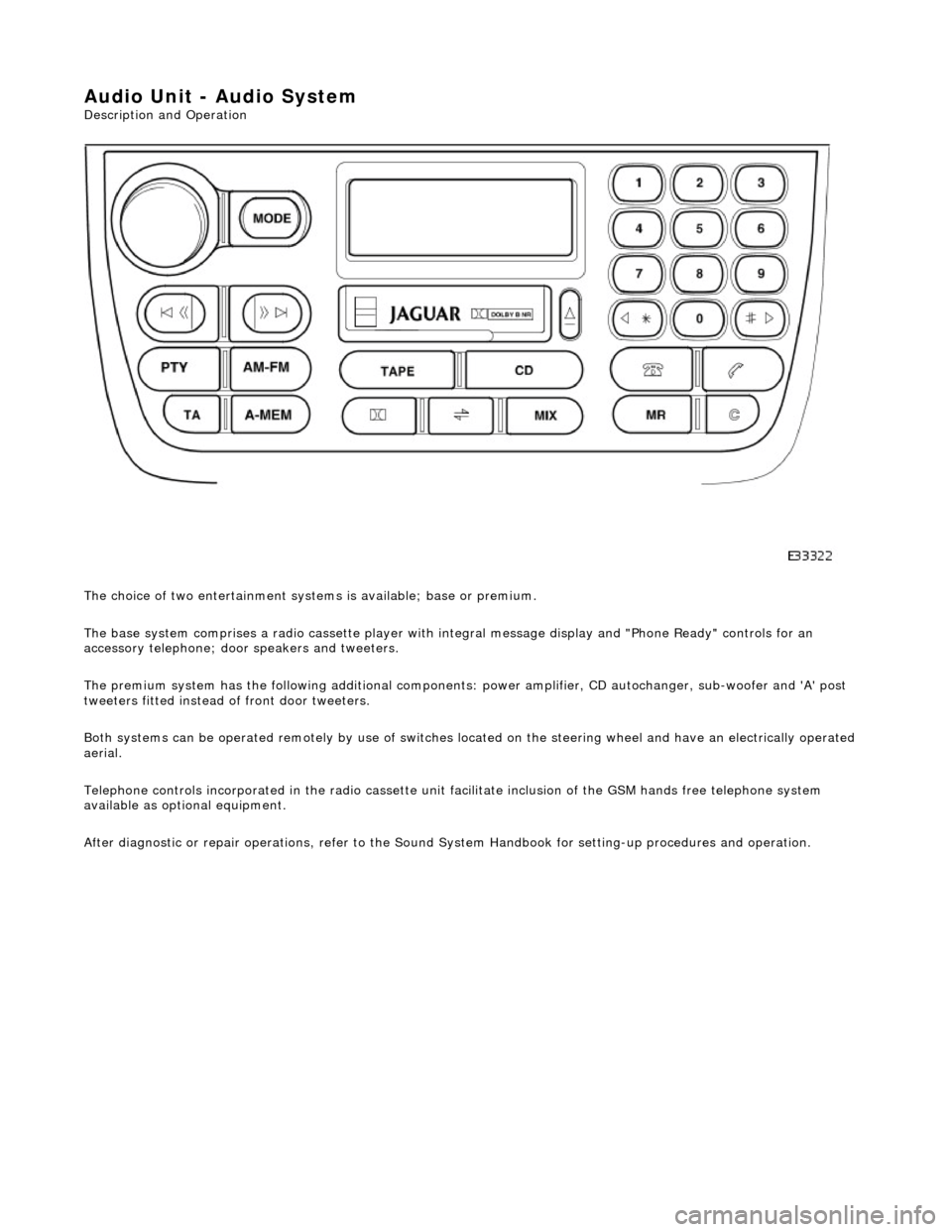

The choice of two entertainment system s is available; base or premium.

The base system comprises a radio cassette player with in tegral message display and "Phone Ready" controls for an

accessory telephone; door speakers and tweeters.

The premium system has the following additional components: power amplifier, CD autochanger, sub-woofer and 'A' post

tweeters fitted instead of front door tweeters.

Both systems can be operated remotely by use of switches loca ted on the steering wheel and have an electrically operated

aerial.

Telephone controls incorporated in the ra dio cassette unit facilitate inclusion of the GSM hands free telephone system

available as optional equipment.

After diagnostic or repair operations, refer to the Sound System Handbook for setting-up procedures and operation.

Page 1908 of 2490

Antenna - Antenna

Description and Operation

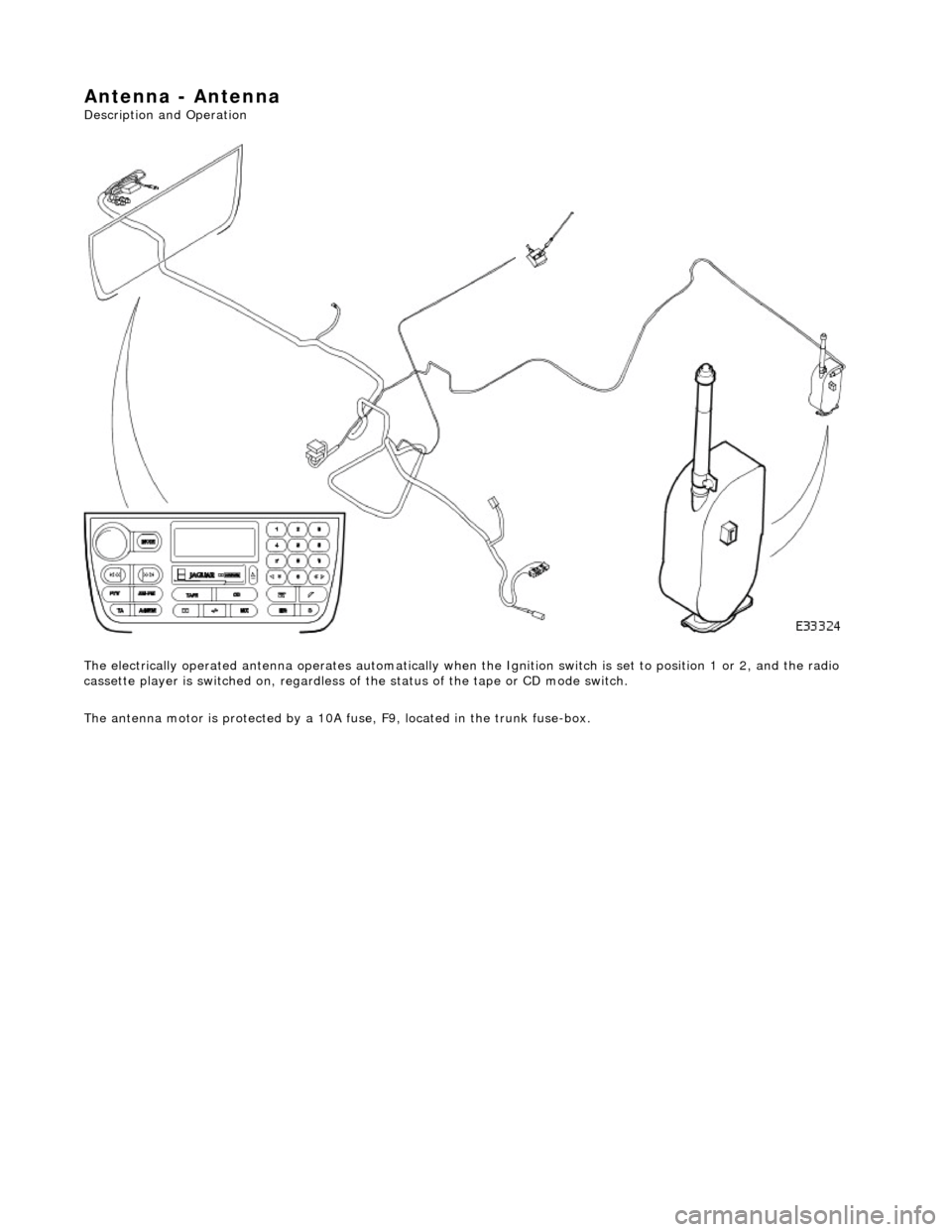

The electrically operated antenna operates automatically when the Ignition switch is set to position 1 or 2, and the radio

cassette player is switched on , regardless of the status of the tape or CD mode switch.

The antenna motor is protected by a 10A fuse, F9, located in the trunk fuse-box.

Page 1920 of 2490

Direction indicator and side marker lamps

Each front direction indicator and side marker lamp is retained in the bumper cover by a lug at one end and a spring clip at

the other end. The side marker lamps are not electrically connected for certain markets.

The side repeater lamps are secured by sp ring clips on the lower edge of the lamp unit. In certain markets Jaguar leaper

badges are substituted for side repeater lamps.

Fog lamps

The fog lamps are located in recesses in the front bump er and secured by three screws. The la mps which are not

interchangeable left to right, are accessed from the rear of the bumper.

Operation

All lamps are controlled by the BPM which provides an appropriate output in response to an input received when a selected

switch is operated.

All lamps receive an input direct from th e BPM with the exception of the main be am, dip beam and front fog lamps which

receive an input from the BPM vi a the respective relays and fuses; refer to section 418-01.

Fault analysis must be undertaken using the PDU. Refer to Diagnosis and Testing.

Consult the relevant Electrical Guid e for details of circuit operation.

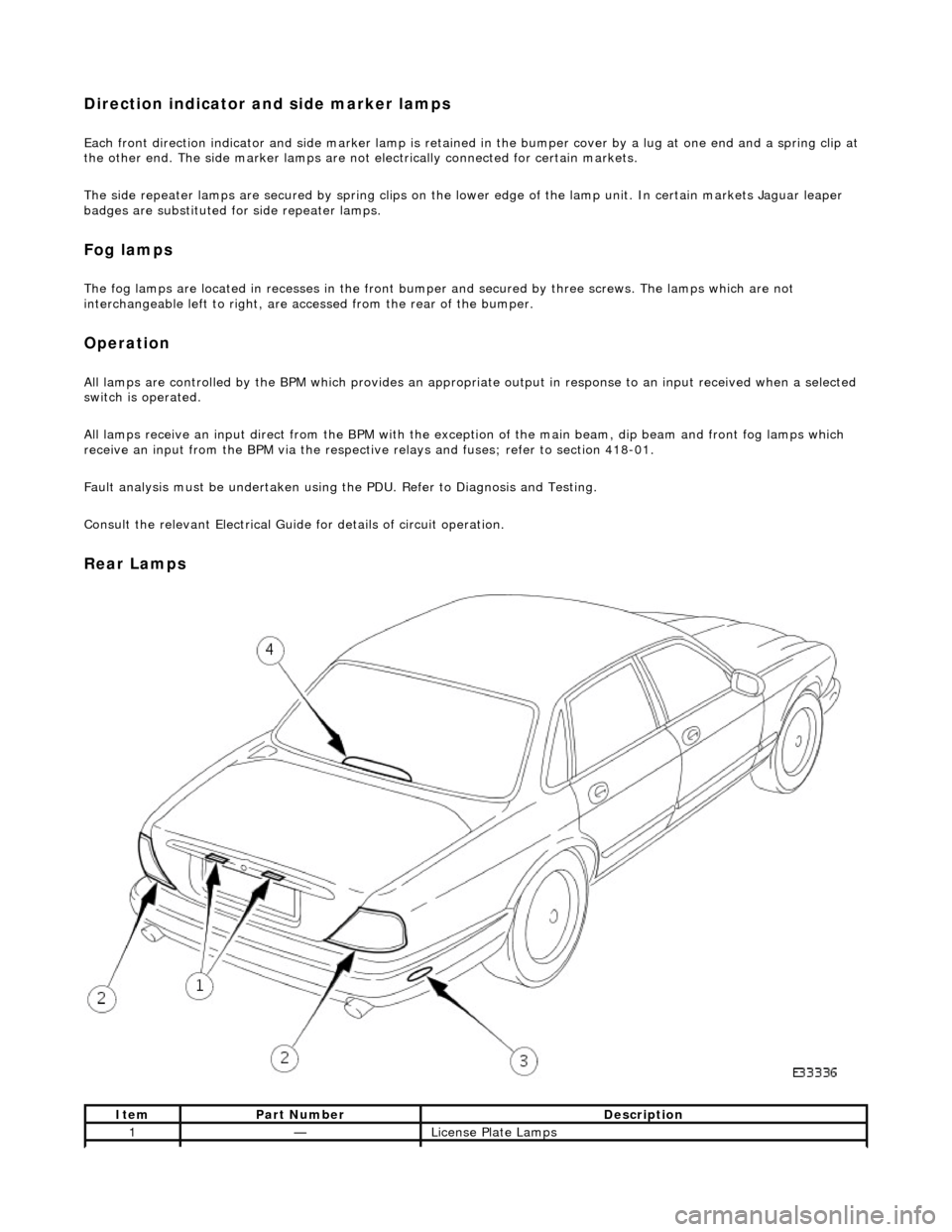

Rear Lamps

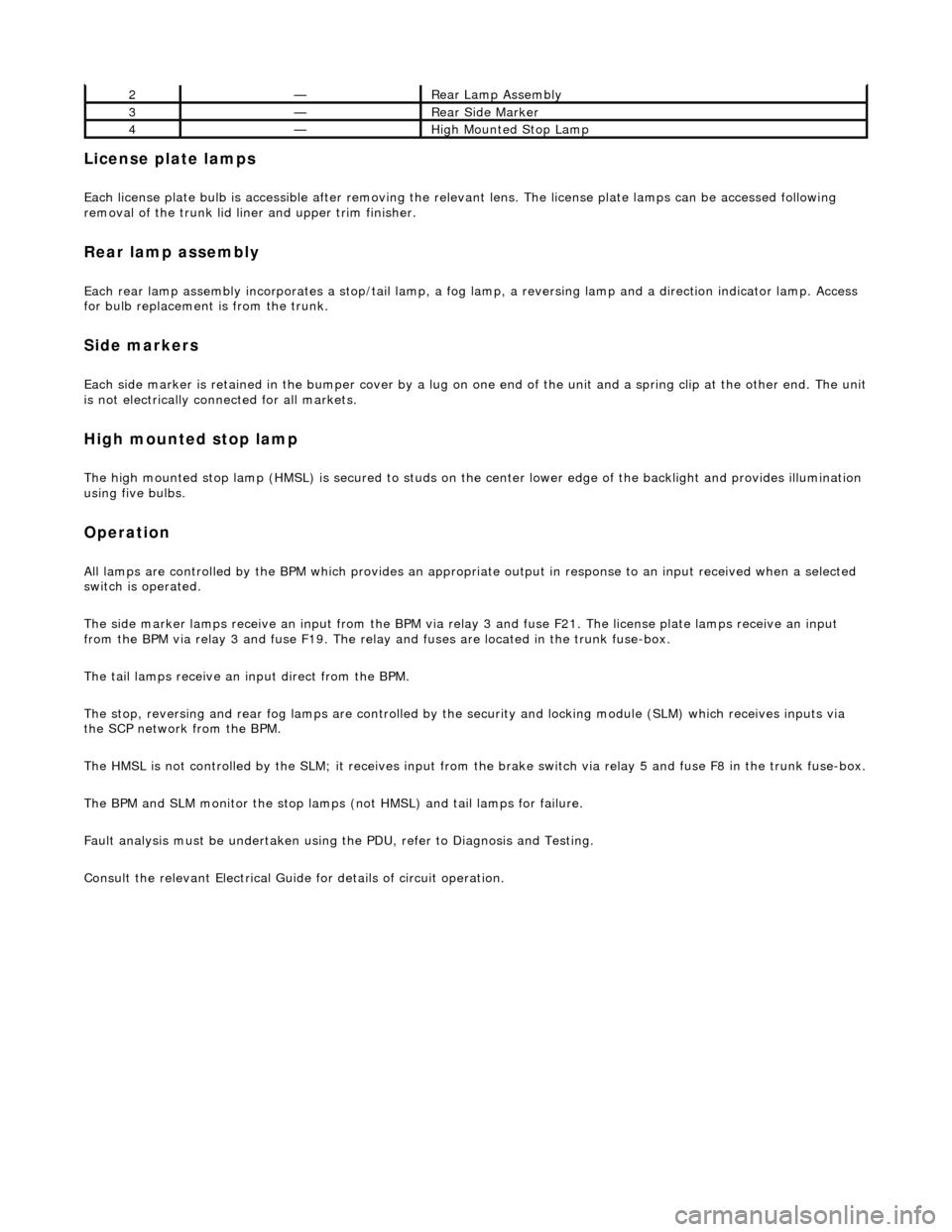

ItemPart NumberDescription

1—License Plate Lamps

Page 1921 of 2490

License plate lamps

Each license plate bulb is accessible after removing the relevant lens. The license plate lamps can be accessed following

removal of the trunk lid liner and upper trim finisher.

Rear lamp assembly

Each rear lamp assembly incorporates a stop/tail lamp, a fog lamp, a reversing lamp and a direction indicator lamp. Access

for bulb replacement is from the trunk.

Side markers

Each side marker is retained in the bumper cover by a lug on one end of the unit and a spring clip at the other end. The unit is not electrically connected for all markets.

High mounted stop lamp

The high mounted stop lamp (HMSL) is secu red to studs on the center lower edge of the backlight and provides illumination

using five bulbs.

Operation

All lamps are controlled by the BPM which pr ovides an appropriate output in response to an input received when a selected

switch is operated.

The side marker lamps receive an input from the BPM via relay 3 and fuse F21. The license plate lamps receive an input

from the BPM via relay 3 and fuse F19. The rela y and fuses are located in the trunk fuse-box.

The tail lamps receive an input direct from the BPM.

The stop, reversing and rear fog lamps are controlled by the security and locking module (SLM) which receives inputs via

the SCP network from the BPM.

The HMSL is not controlled by the SLM; it receives input from the brake switch via relay 5 and fuse F8 in the trunk fuse-box.

The BPM and SLM monitor the stop lamps (n ot HMSL) and tail lamps for failure.

Fault analysis must be undertaken using the PDU, refer to Diagnosis and Testing.

Consult the relevant Electrical Guid e for details of circuit operation.

2—Rear Lamp Assembly

3—Rear Side Marker

4—High Mounted Stop Lamp

Page 1922 of 2490

Exterior Lighting - Exterior Lighting

Diagnosis and Testing

Tests Using the Portable Diagnostic Unit

Refer to PDU User Guide

The complexity of the electronics involved with the various Electronic Control Modules and the multiplexed communication

networks, preclude the use of workshop general electrical test equipment. Therefore, reference should be made to the PDU

User Guide for detailed inst ructions on testing the exterior lamps and circuits.

The PDU systematically tests and analyses the lamp assemblies, the bulbs and the electrical connections to them. It should

be noted that the lamps are not wired direct ly to the switches. Actuation of a switch provides an input signal to the Body

Processor which interpre ts the signal as a request to switch output from the Bo dy Processor, either directly or indirectly to a

specific lamp.

Where a fault involving a lamp is indicated by the PDU, befo re replacing the component, some basic diagnostic methods

may be necessary to confirm that connections are good and that wiring is not damaged.