valve JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 648 of 2490

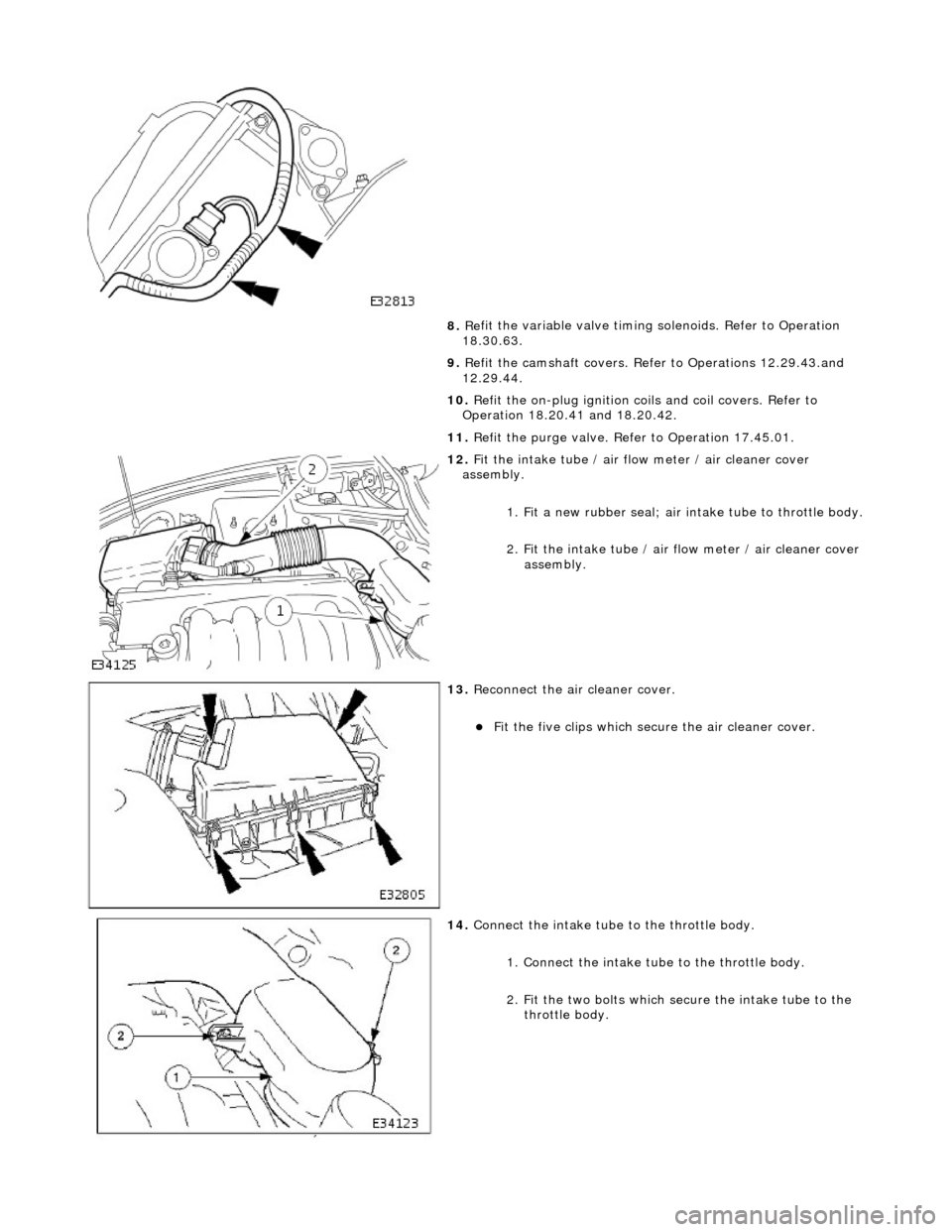

8. Re

fit the variable valve timing

solenoids. Refer to Operation

18.30.63.

9. Refit the camshaft covers. Refer to Operations 12.29.43.and

12.29.44.

10. Refit the on-plug ignition coils and coil covers. Refer to

Operation 18.20.41 and 18.20.42.

11. Refit the purge valve. Refer to Operation 17.45.01.

12 . F

it the intake tube / air flow meter / air cleaner cover

assembly.

1. Fit a new rubber seal; air in take tube to throttle body.

2.

Fit the intake tube / air

flow meter / air cleaner cover

assembly.

13 . R

econnect the air cleaner cover.

F

it

the five clips which secu

re the air cleaner cover.

14. Co

nnect the intake tube to the throttle body.

1. Connect the intake tube to the throttle body.

2. Fit the two bolts which secure the intake tube to the throttle body.

Page 653 of 2490

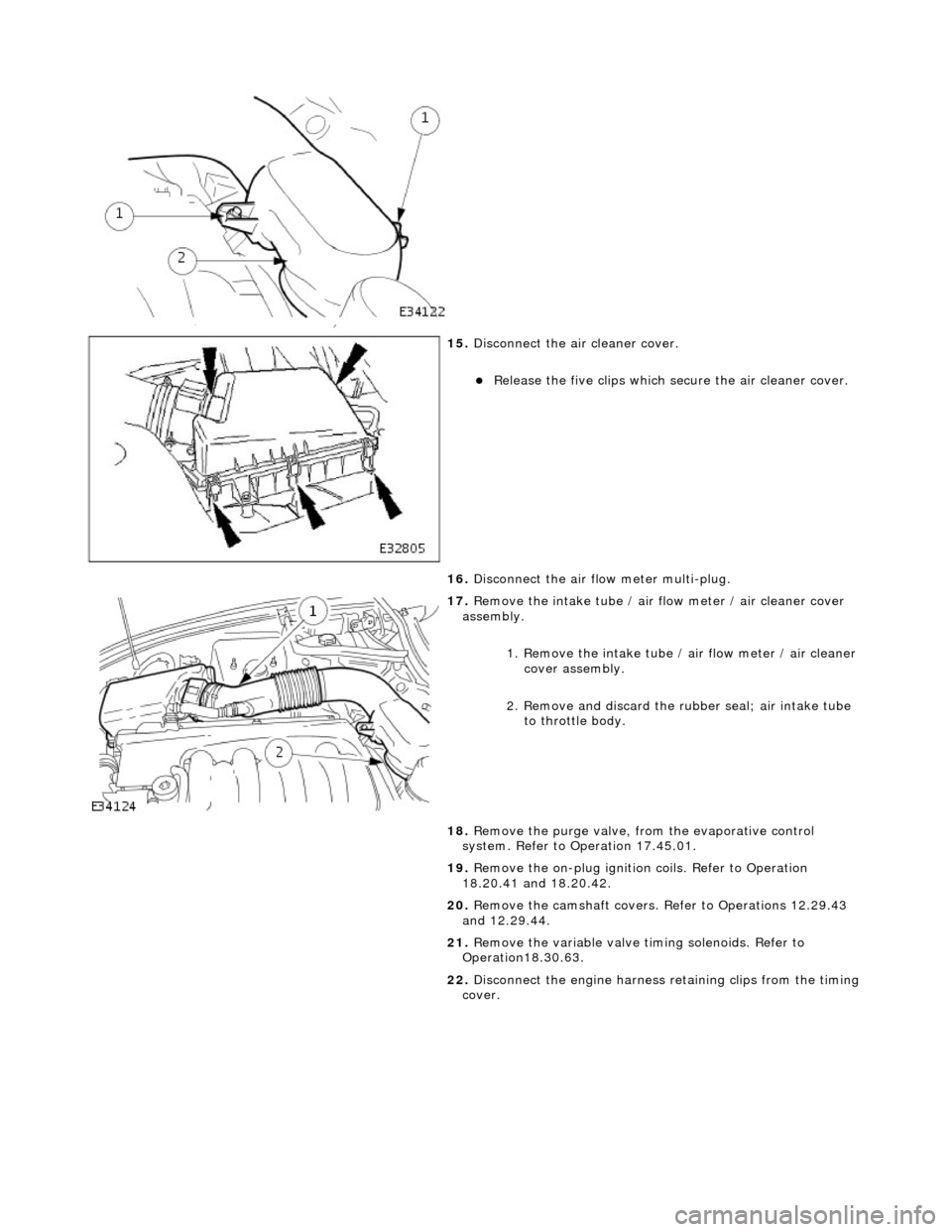

15

.

Disconnect the air cleaner cover.

R

elease the five clips which se

cure the air cleaner cover.

16. Disconnect the air flow meter multi-plug.

17

.

Remove the intake tube / air flow meter / air cleaner cover

assembly.

1. Remove the intake tube / air flow meter / air cleaner

cover assembly.

2. Remove and discard the ru bber seal; air intake tube

to throttle body.

18. Remove the purge valve, fro m the evaporative control

system. Refer to Operation 17.45.01.

19. Remove the on-plug ignition coils. Refer to Operation

18.20.41 and 18.20.42.

20. Remove the camshaft covers. Refer to Operations 12.29.43

and 12.29.44.

21. Remove the variable valve ti ming solenoids. Refer to

Operation18.30.63.

22. Disconnect the engine harness retaining clips from the timing

cover.

Page 657 of 2490

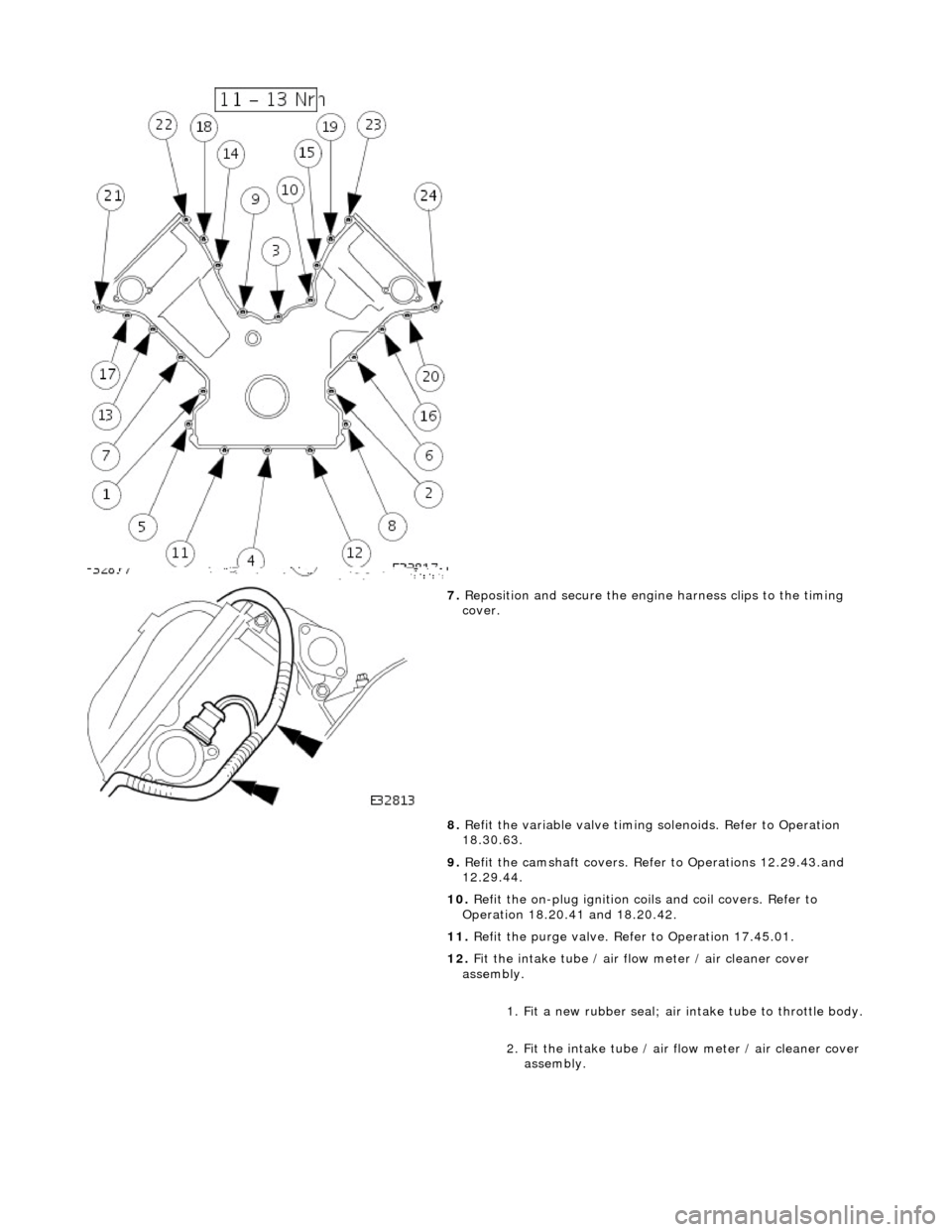

7. Reposition and secure the engine harness clips to the timing

cover.

8. Refit the variable valve timing solenoids. Refer to Operation

18.30.63.

9. Refit the camshaft covers. Refer to Operations 12.29.43.and

12.29.44.

10. Refit the on-plug ignition coils and coil covers. Refer to

Operation 18.20.41 and 18.20.42.

11. Refit the purge valve. Refer to Operation 17.45.01.

12. Fit the intake tube / air flow meter / air cleaner cover

assembly.

1. Fit a new rubber seal; air in take tube to throttle body.

2. Fit the intake tube / air flow meter / air cleaner cover

assembly.

Page 661 of 2490

2. Fit the camshaft caps to their respective locations (5 to 9 from the front) and in the correct orientation

(arrow to front of engine).

3. Fit and tighten the cap securing bolts. Tighten evenly,

in stages, to 9 - 11 Nm.

3. Fit the camshaft locking tool 303 - 530 (fitted for following

operation) align the camshaft as necessary.

4. Refit Exhaust Camshaft Sprocket . Refer to Operation 12.65.74.

5. With the camshaft (303 - 530) and crankshaft (303 - 531)

setting tools removed, after the previous operation, adjust the

valve clearances on the exhaus t camshaft. refer to Operation

12.29.48.

6. Move the engine compartment co ver from the service position

and connect the gas struts.

7. Remove the paint protection sheets and close the cover.

8. Connect the battery and fit the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.

Page 663 of 2490

2. Fit the camshaft caps to their respective locations (5 to 9 from the front) and in the correct orientation

(arrow to front of engine).

3. Fit and tighten the cap securing bolts. Tighten evenly,

in stages, to 9 - 11 Nm.

3. Fit the camshaft locking tool 303 - 530 (fitted for following

operation) align the camshaft as necessary.

4. Refit Exhaust Camshaft Sprocket . Refer to Operation 12.65.73.

5. With the camshaft (303 - 530) and crankshaft (303 - 531)

setting tools removed, after the previous operation, adjust the

valve clearances on the exhaus t camshaft. refer to Operation

12.29.48.

6. Move the engine compartment co ver from the service position

and connect the gas struts.

7. Remove the paint protection sheets and close the cover.

8. Connect the battery and fit the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.

Page 666 of 2490

Installation

12. Remove the bolt which secures the sprocket to the exhaust

camshaft.

Move the sprocket forward from the camshaft boss.

Remove the sprocket and leav e the chain resting on the

cylinder head.

13. Clean and inspect all relevant components.

1. Push the tensioner piston into the body to provide clearance

for installing. Tensioner fitted to cylinder head.

1. Insert a thin rigid wire th rough the hole in the end of

the tensioner piston to displace the ball from the non-

return valve seat.

2. With the wire in position, press the piston fully into the tensioner body.

Remove the wire.

2. Install the sprocket to the secondary chain.

1. With the sprocket installe d to the chain, temporarily

position (do not install the securing bolt) the sprocket

onto the camshaft.

2. Adjust the position of the sprocket within the chain to

allow the chain tensioning tool 303-532 to be

approximately vertical, as shown.

3. Install the cams haft sprocket.

Apply force to the tool (303-532) in an anti-clockwise

direction to tension the chain on its drive side.

Whilst applying the opposing force to the sprocket and

chain, tighten the sprocket securing bolt to 115-125 Nm.

Remove the chain tensioning tool.

Page 670 of 2490

Installation

removing the bolt which secures the sprocket. 1. Place a flat piece of stee l strip along the timing cover

horizontal jointing face, adjacent to the exhaust

camshaft sprocket.

2. Secure the steel strip in place with adhesive tape.

11. A ball-ended hexagon drive bit is required to remove the

sprocket securing bolt. A suitable tool is available from Snap On as (FABLM10E) Long Series 10mm AF.

12. Remove the bolt which secures the sprocket to the exhaust

camshaft.

Move the sprocket forward from the camshaft boss.

Remove the sprocket and leav e the chain resting on the

cylinder head.

13. Clean and inspect all relevant components.

1. Push the tensioner piston into the body to provide clearance

for installing. Tensioner fitted to cylinder head.

1. Insert a thin rigid wire th rough the hole in the end of

the tensioner piston to displace the ball from the non-

return valve seat.

2. With the wire in position, press the piston fully into the tensioner body.

Remove the wire.

2. Install the sprocket to the secondary chain.

1. With the sprocket installe d to the chain, temporarily

position the sprocket onto the camshaft.

2. Adjust the position of the sprocket within the chain to

allow the chain tensioning tool 303-532 to be

approximately vertical, as shown.

Page 674 of 2490

Installation

12. Remove the bolt which secures the sprocket to the exhaust

camshaft.

Move the sprocket forward from the camshaft boss.

13. Remove the secondary chain tensioner. The tensioner piston

cannot be pushed into the body with the assembly in position.

1. Remove the two bolts which secure the tensioner.

Lift the tensioner, sprocket (release it fully from the

camshaft) and ch ain assembly.

2. Remove the tensioner rearward from between the chain.

14. Remove the sprocket and leav e the chain resting on the

cylinder head.

15. Clean and inspect all relevant components.

1. Install the sprocket to the secondary chain.

1. With the sprocket installe d to the chain, temporarily

position (do not install the securing bolt) the sprocket

onto the camshaft.

2. Adjust the position of the sprocket within the chain to

allow the chain tensioning tool 303-532 to be

approximately vertical, as shown.

Remove the chain tensioni ng tool; during future

operations, do not move the sprocket within the chain.

2. Push the tensioner piston into the body to provide clearance

for installing.

1. Insert a thin rigid wire th rough the hole in the end of

the tensioner piston to displace the ball from the non-

return valve seat.

Page 680 of 2490

allow the chain tensioning tool 303-532 to be approximately vertical, as shown.

Remove the chain tensioni ng tool; during future

operations, do not move the sprocket within the chain.

2. Push the tensioner piston into the body to provide clearance

for installing.

1. Insert a thin rigid wire th rough the hole in the end of

the tensioner piston to displace the ball from the non-

return valve seat.

2. With the wire in position, press the piston fully into the tensioner body.

Remove the wire.

3. Install the chain tensioner between the chain path.

1. Reposition the sprocket, still captive in the chain, upwards for access.

2. Install the chain tensioner between the sprockets.

Position the cam sprocket, chain and tensioner assembly

into position and locate the sprocket onto the camshaft

spigot.

4. Install the chain tensioner to the engine.

1. Fully seat the sprocket onto the camshaft and install the securing bolt, hand tight.

2. Install the two bolts which secure the tensioner and tighten to 10-14 Nm.

5. Install the cams haft sprocket.

Install the chain tensioner tool 303-532 to the sprocket

holes.

Apply force to the tool in an anti-clockwise direction to

tension the chain on its drive side.

Page 701 of 2490

1. Fit the camshaft to position in the cylinder head, with the timing flats uppermost.

2. Fit the camshaft caps to their respective locations (0 to 4 from the front) and in the correct orientation

(arrow to front of engine).

3. Fit and tighten the cap securing bolts. Tighten evenly,

in stages, to 9 - 11 Nm.

3. Fit the camshaft locking tool 303 - 530 (fitted for following

operation) align the camshaft as necessary.

4. Refit the VVT Unit to the A-Bank. Refer to Operation 12.65.71.

This also includes the VVT Bu sh Carrier Assembly, Primary

Chain and Tensioner.

5. With the camshaft (303 - 530) and crankshaft (303 - 531)

setting tools removed, after the previous operation, adjust the

valve clearances on the inlet camshaft. refer to Operation

12.29.48.

6. Refit the Timing Cover. Re fer to Operation 12.65.01.

7. Move the engine compartment co ver from the service position

and connect the gas struts.

8. Remove the paint protection sheets and close the cover.

9. Connect the battery and fit the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.