lower JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 159 of 2490

Front Susp

ension - Wheel

Knuckle and Wheel Hub Assembly Conversion

Re

moval and Installation

Remov

al

S

pecial Tool(s)

R

oad spring compressor

204-111 (JD115)

Taper separator

211-098 (JD 100)

Front

suspension ball joint splitter

204-192 (JD 219)

Bal

l joint splitter

204-293

1. Raise front of vehicle and support on stands. Refer to Section

100-02.

2. Remove appropriate road wheel. Refer to 74.20.05.

3. Remove brake disc. Refer to 70.10.12.

4. Using wire or string, secure brak e caliper to road spring to take

weight off brake hose.

5. Raise vehicle sufficient to provide access for special tool 204-

111.

6. R

emove nut and bolt securing stabilizer bar link arm to lower

wishbone.

7. Remove nut securing link arm ba ll joint to stabilizer bar and

remove link arm from vehicle.

Page 160 of 2490

8. Inst

all special tool 204-111 in road spring.

Slacken tool

adjuster to suit spring length.

Fit adaptor and th

rust collar.

Positi

on stem of tool in center of spring passing dowel

through slot in su spension turret.

9. WA

RNING: WHEN TURNING TOOL ADJUSTER, ENSURE

THAT TOOL STEM DOES NOT ROTATE AND DISTURB POSITION

OF DOWEL IN SUSPENSION TURRET.

Engage dowel of special tool 204-111 in suspension turret and

rotate to position across slot.

10 . Lower veh

icle onto stands.

11 . R

otate tool adjuster to tension spring.

12. Remove wheel speed sensor se curing screw and withdraw

sensor from vertical link.

Page 162 of 2490

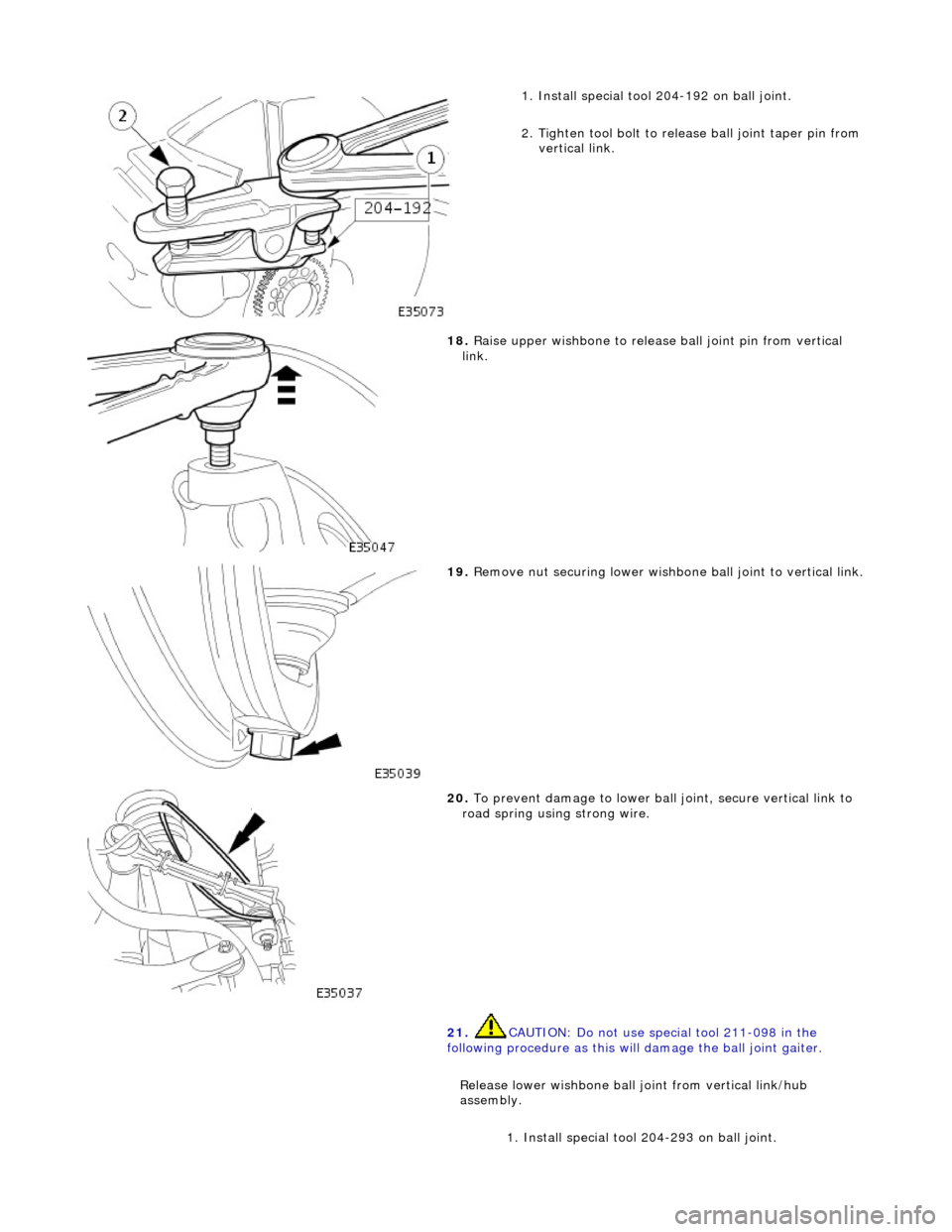

1.

Install special tool 204-192 on ball joint.

2. Tighten tool bolt to rele ase ball joint taper pin from

vertical link.

18 . Raise

upper wishbone to release

ball joint pin from vertical

link.

19 . R

emove nut securing lower wishbone

ball joint to vertical link.

20. To

prevent damage to lower ball

joint, secure vertical link to

road spring using strong wire.

21. CAUTION: Do not use special tool 211-098 in the

following procedure as this will damage the ball joint gaiter.

Release lower wishbone ball joint from vertical link/hub

assembly. 1. Install special tool 204-293 on ball joint.

Page 163 of 2490

I

nstallation

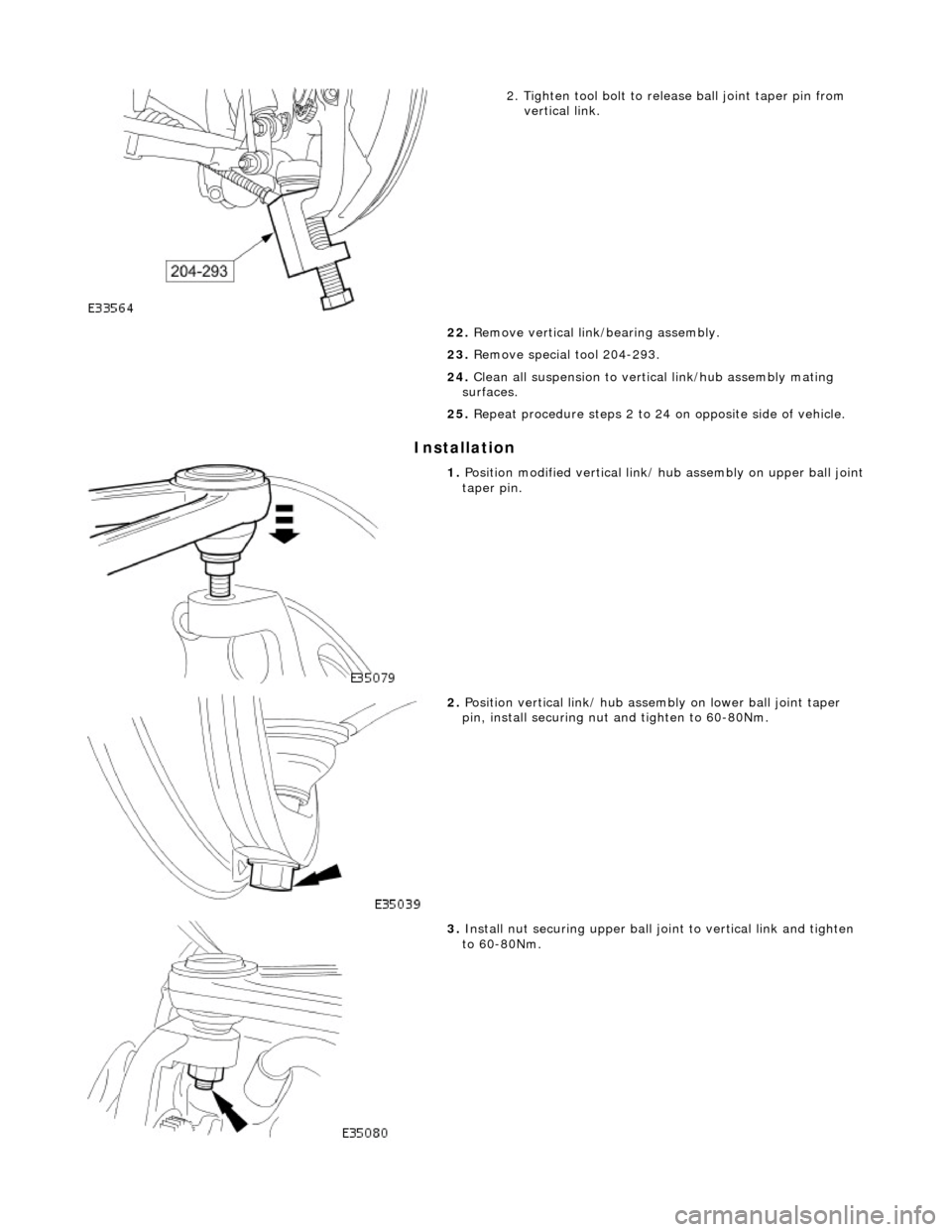

2

. Tighten tool bolt to rele

ase ball joint taper pin from

vertical link.

22. Remove vertical link/bearing assembly.

23. Remove special tool 204-293.

24. Clean all suspension to vertical link/hub assembly mating

surfaces.

25. Repeat procedure steps 2 to 24 on opposite side of vehicle.

1. Position modi

fied vertical link/

hub assembly on upper ball joint

taper pin.

2. Position verti

cal link/ hub asse

mbly on lower ball joint taper

pin, install securing nut and tighten to 60-80Nm.

3. Install nu

t securing upper ball jo

int to vertical link and tighten

to 60-80Nm.

Page 164 of 2490

4. Po

sition tie rod ball joint taper

pin on steering arm and install

and tighten securing nut to 71-85Nm.

5. Instal

l wheel speed sensor.

Positi

on wheel speed sensor on vertical link.

Inst

al

l sensor securing bolt

and tighten to 8-10Nm.

6. Remove wire temporarily securing vertical link to road spring.

7. Install br ake disc.

8. Re

lease tension on road spring.

Ro

tate adjuster of special tool 204-111 to release spring

tension.

R e

move special tool and adaptor from spring.

9. Position new link ass

embly on

lower wishbone and install but

do not tighten bolt.

10. Position new link arm ball joint stud in stabilizer bar and

install but do not tighten nut.

Page 165 of 2490

11

.

Tighten new link arm to wishbone nut and bolt to 41-54Nm.

12

.

Secure new link arm to stabilizer bar.

Tigh

ten link arm to stabilizer bar nut to 60-80Nm.

Check that ball

joint freed

om of movement has been

maintained.

13. Install road wheel. Refer to 74.20.05.

14. Repeat procedure steps 1 to 13 on opposite side of vehicle.

15. Raise front of vehicle, remove stands and lower vehicle.

16. Carry out steering geometry an d wheel alignment checks and

if necessary adjust. Refer to 57.65.01.

Page 166 of 2490

Rear Su

spension -

Lubric

ants, Fluids, Sealants and Adhesives

Torques

UnitSp

ecification

Loctite27

0

Greas eShell Retin a

x 'A'

Greas

eCastro l 'NT

R'

Com

p

onent

Nm

N

u

t - hub to axle shaft

3

04 -

336

Nu

t -

hub carrier pivot pin

88

-

118

Bol

t

- ABS sensor to hub carrier

8-1

0

Nu

t - stabilizer bar link to lower wishbone.

30

-40

Nu

t - stabilizer bar to link assembly.

30

-40

Bolts -

monostrut to body mounting brackets

88

-

118

Bolt

s

- monostrut to wishbone tie assembly

77

-

103

Bolts

- bu

mp stop to body

26

-34

Bol t

- damper lower mounting

80

-

100

N

u

t - damper top

31

-39

Bolts -

damper mounting plate to body

17

-23

Page 170 of 2490

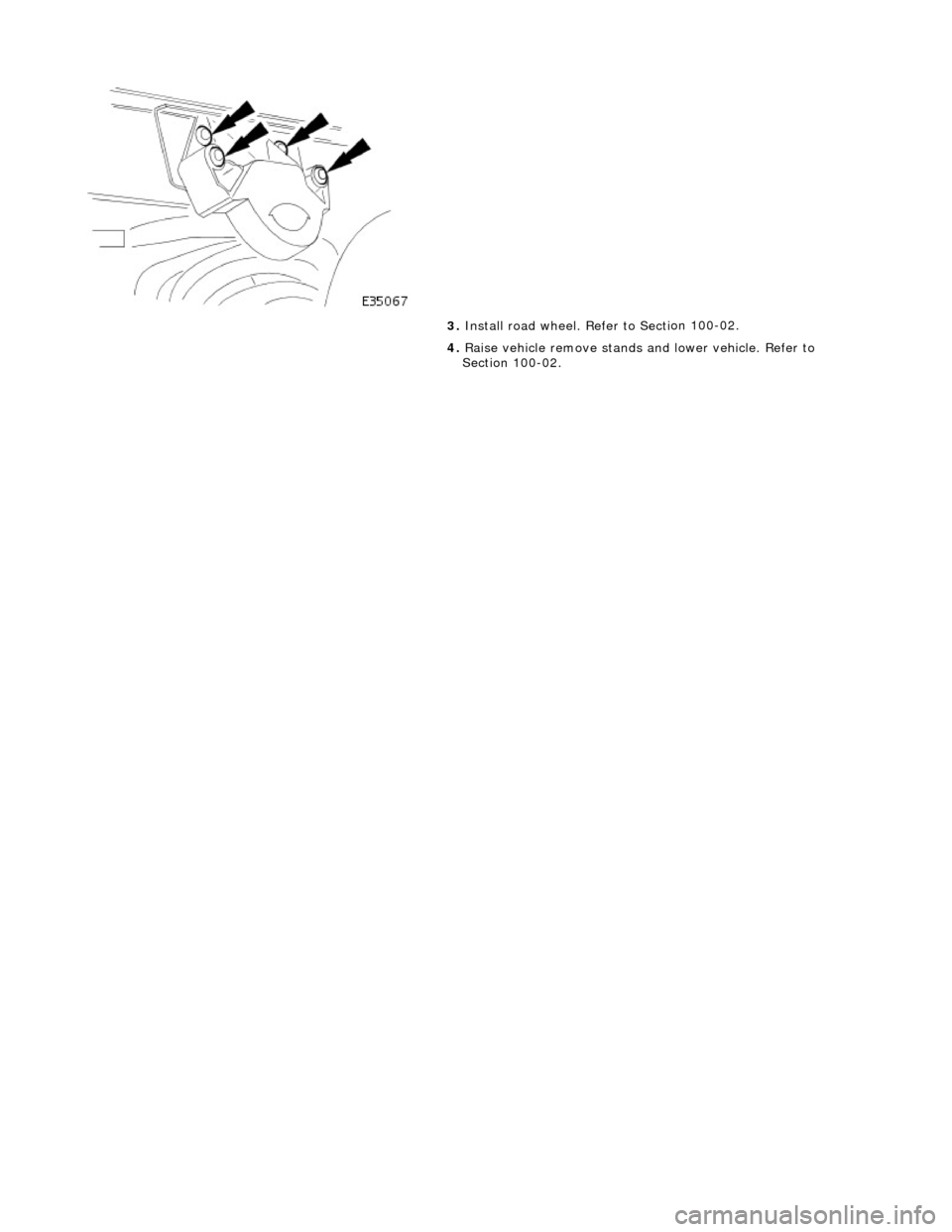

3.

Install road wheel. Re fer to Secti

on 100-02.

4. Raise vehicle remove stands and lower vehicle. Refer to

Section 100-02.

Page 173 of 2490

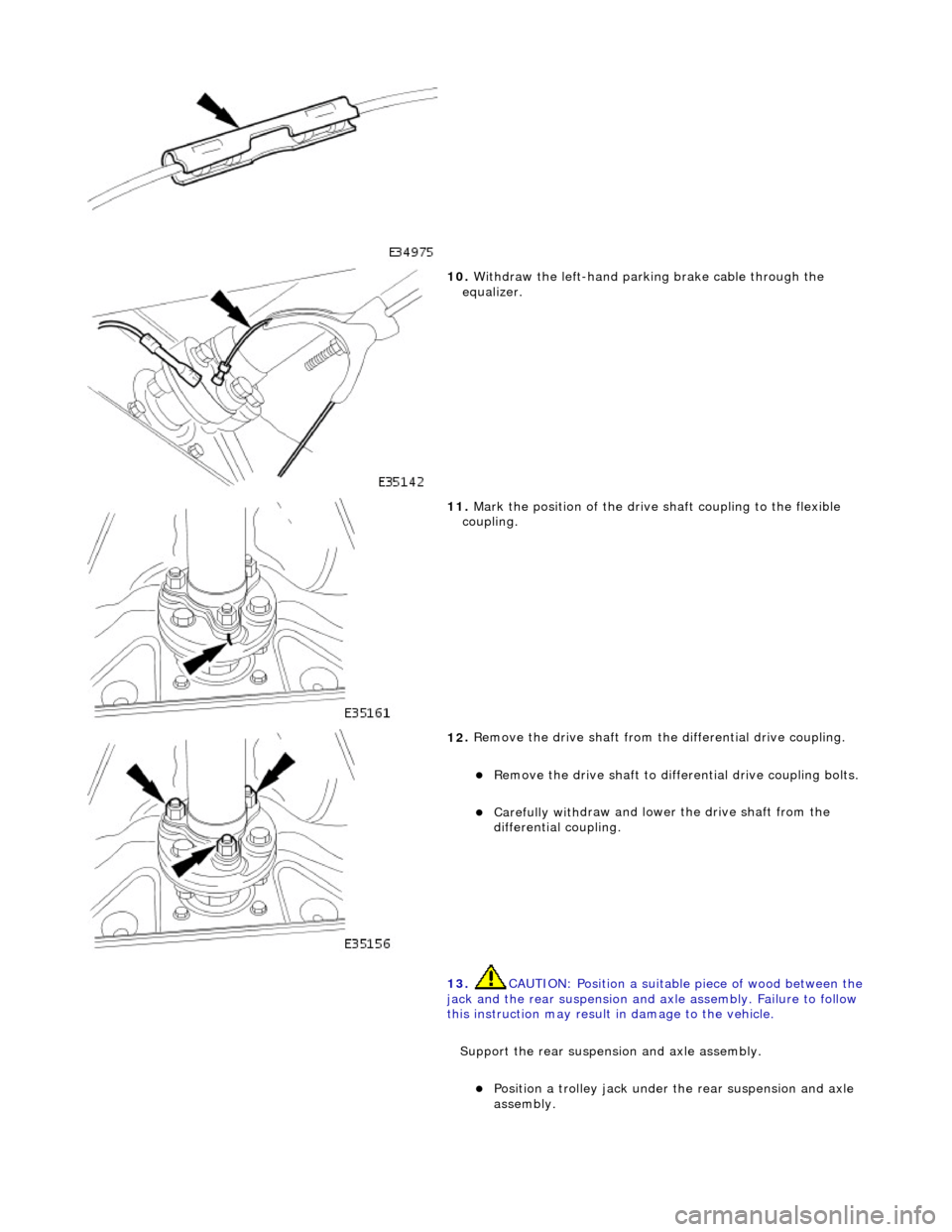

10

.

Withdraw the left-hand parking brake cable through the

equalizer.

11

.

Mark the position of the drive shaft coupling to the flexible

coupling.

12

.

Remove the drive shaft from the differential drive coupling.

R

emove the drive shaft to differential drive coupling bolts.

Carefully with

draw and lower the drive shaft from the

differential coupling.

13. CAUTION: Position a suitable piece of wood between the

jack and the rear suspension and axle assembly. Failure to follow

this instruction may result in damage to the vehicle.

Support the rear suspension and axle assembly.

Posi

tion a trolley jack under the rear suspension and axle

assembly.

Page 175 of 2490

I

nstallation

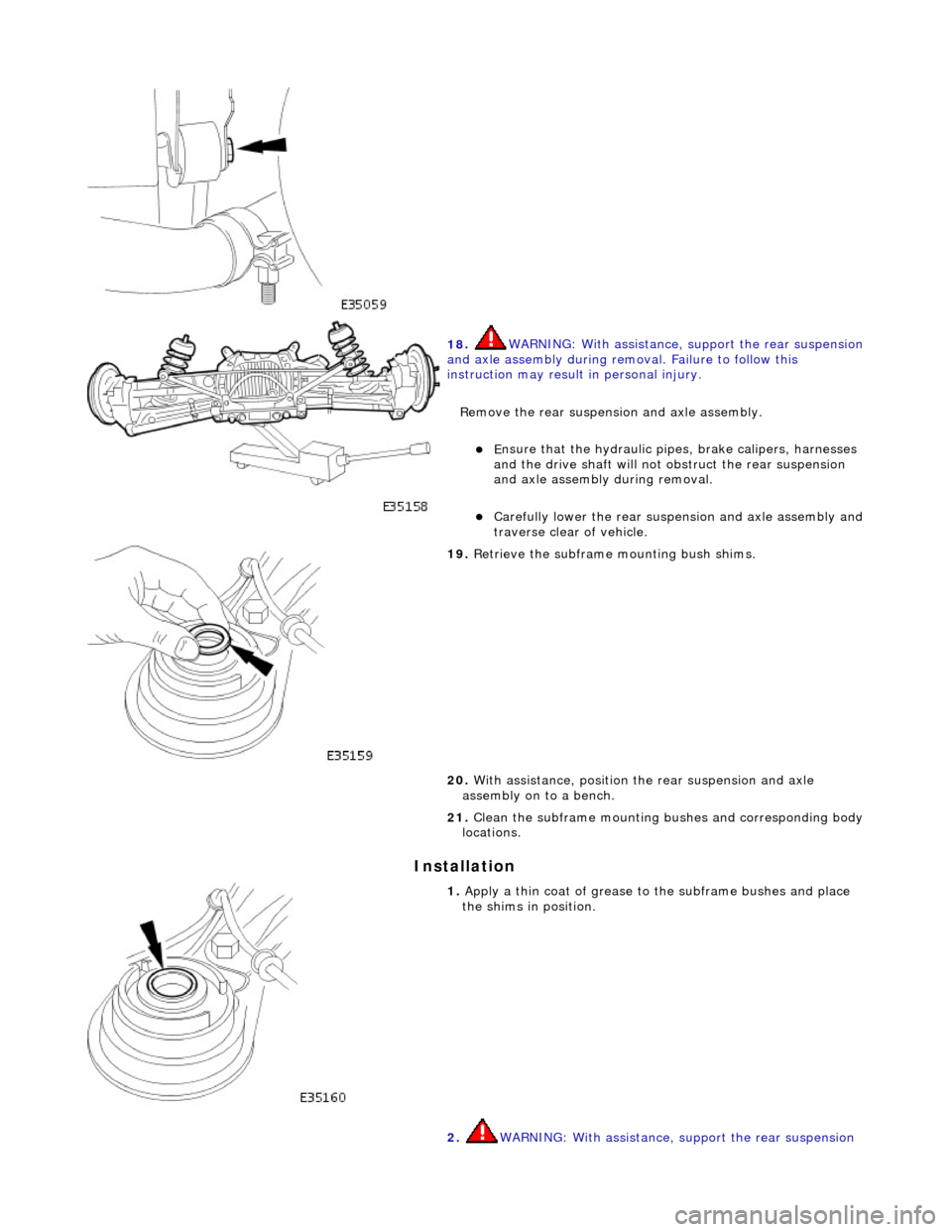

18

.

WARNING: With assistance, support the rear suspension

and axle assembly during remo val. Failure to follow this

instruction may result in personal injury.

Remove the rear suspensi on and axle assembly.

E

nsure that the hydr

aulic pipes, brake calipers, harnesses

and the drive shaft will not obstruct the rear suspension

and axle assembly during removal.

Carefull

y lower the rear suspen

sion and axle assembly and

traverse clear of vehicle.

19

.

Retrieve the subframe mounting bush shims.

20. With assistance, position th e rear suspension and axle

assembly on to a bench.

21. Clean the subframe mounting bushes and corresponding body

locations.

1. Apply a th

in coat of grease to the subframe bushes and place

the shims in position.

2. WARNING: With assistance, support the rear suspension