JAGUAR XFR 2010 1.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1291 of 3039

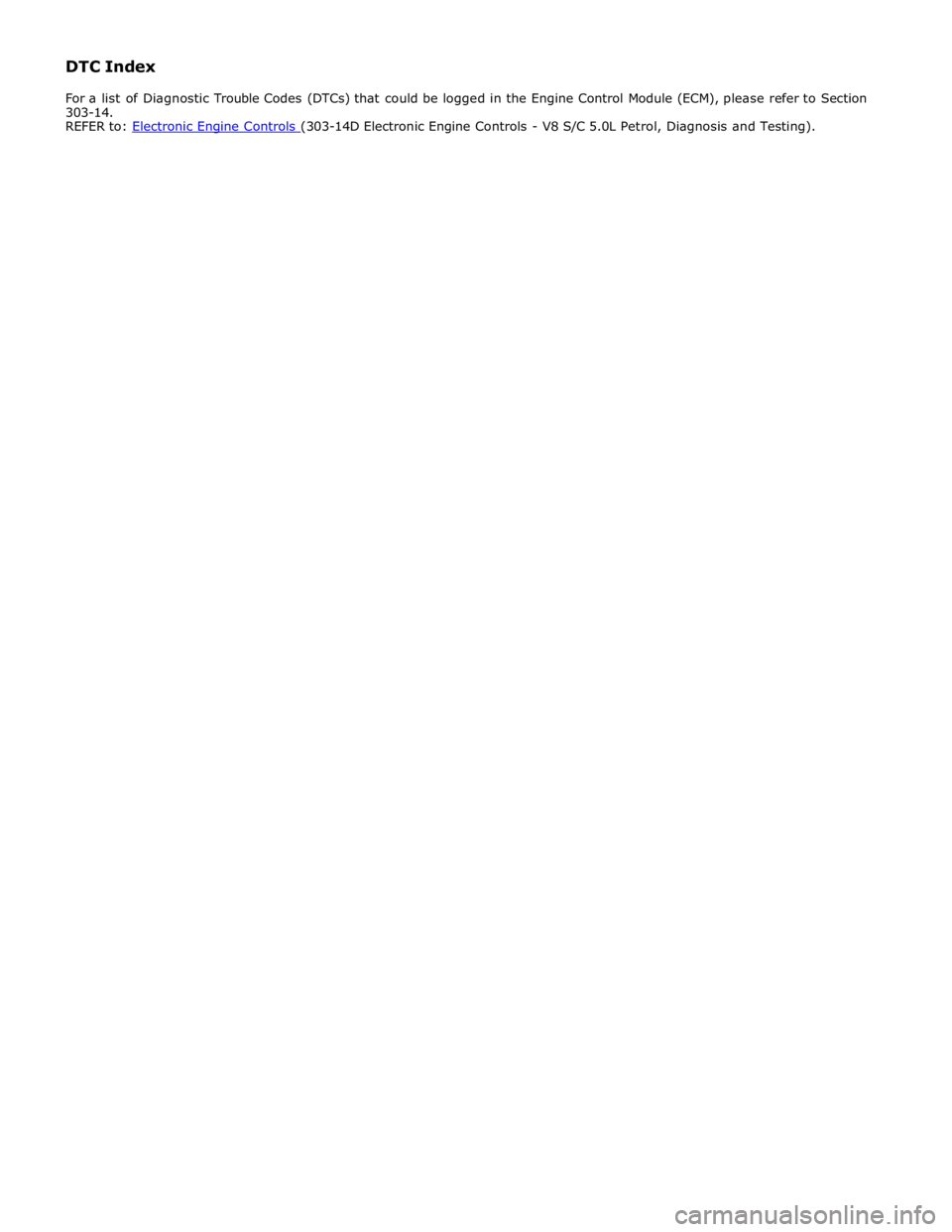

1 Cover 2 Screw (7 off) 3 Air cleaner element 4 Tray 5 Bolt 6 Grommet 7 Support www.JagDocs.com

Page 1292 of 3039

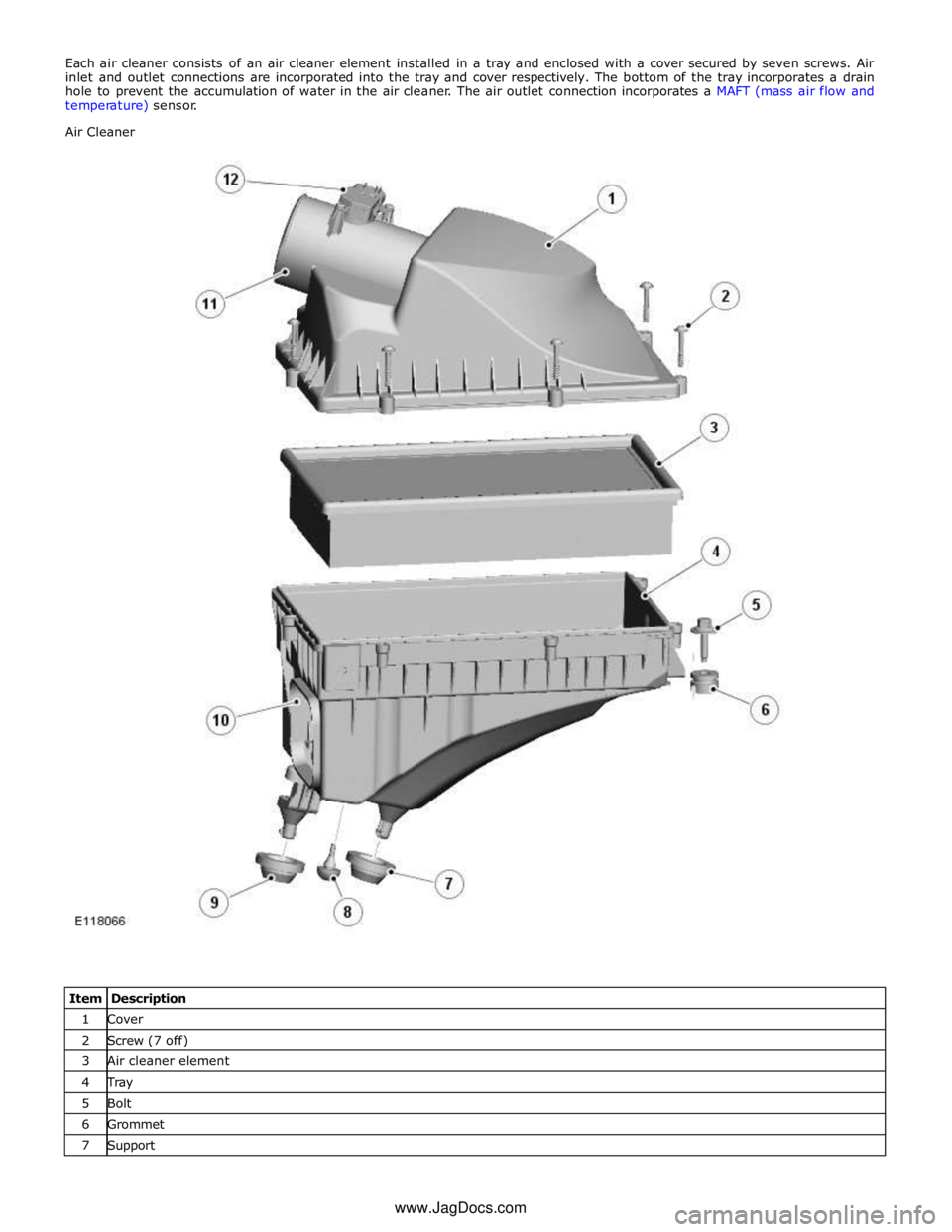

9 Support 10 Inlet connection 11 Outlet connection 12 MAFT sensor The outlet tubes and T-piece duct direct the air from the air cleaners to the electric throttle. Hose clamps connect the outlet

tubes and T-piece duct together, and to the air cleaners and the electric throttle. A grommet and bracket attached the T-piece

duct to a bracket on the RH cylinder head. The two outlet tubes and the T-piece duct each incorporate a quarter wave resonator to reduce air induction noise.

The LH (left-hand) outlet tube incorporates a connector stub for the engine full load breather pipe.

The T-piece duct incorporates a connector stub for the vacuum tube of the bypass valve actuator on the supercharger.

SUPERCHARGER AND INTAKE MANIFOLDS

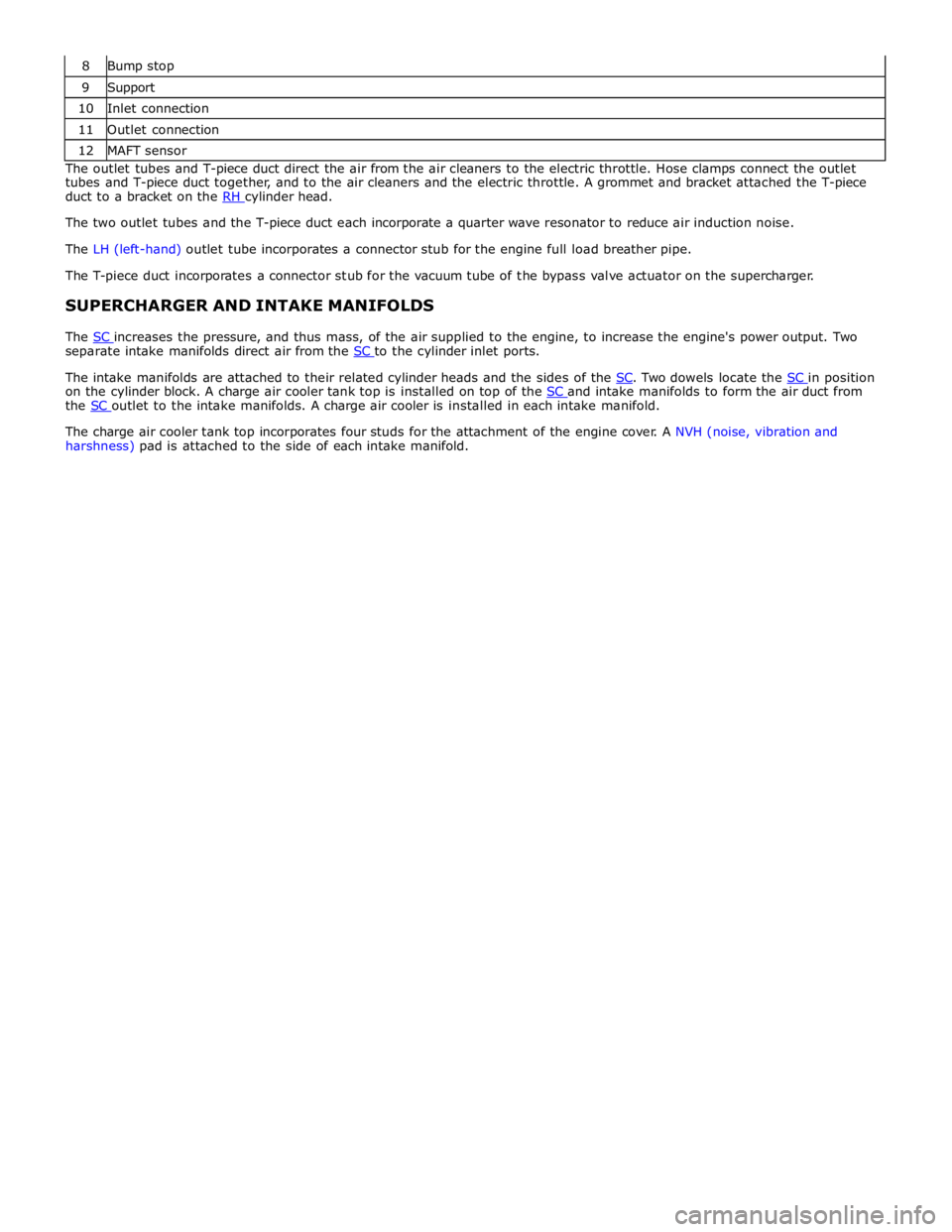

The SC increases the pressure, and thus mass, of the air supplied to the engine, to increase the engine's power output. Two separate intake manifolds direct air from the SC to the cylinder inlet ports.

The intake manifolds are attached to their related cylinder heads and the sides of the SC. Two dowels locate the SC in position on the cylinder block. A charge air cooler tank top is installed on top of the SC and intake manifolds to form the air duct from the SC outlet to the intake manifolds. A charge air cooler is installed in each intake manifold.

The charge air cooler tank top incorporates four studs for the attachment of the engine cover. A NVH (noise, vibration and

harshness) pad is attached to the side of each intake manifold.

Page 1293 of 3039

1 Engine cover rear attachment points 2 Vacuum connector stub 3 MAPT (manifold absolute pressure and temperature) sensor 4 SC filler/level plug 5 Symposer inlet pipe connection 6 Dowels 7 Engine cover front attachment points 8 EVAP (evaporative emissions) connector stub 9 Part load breather connector stub 10 MAP (manifold absolute pressure ) sensor 11 Bypass valve pneumatic actuator 12 Outlet ports 13 Inlet port 14 Pulley 15 Coolant inlet and outlet connections Supercharger and Intake Manifolds - Assembled

Page 1294 of 3039

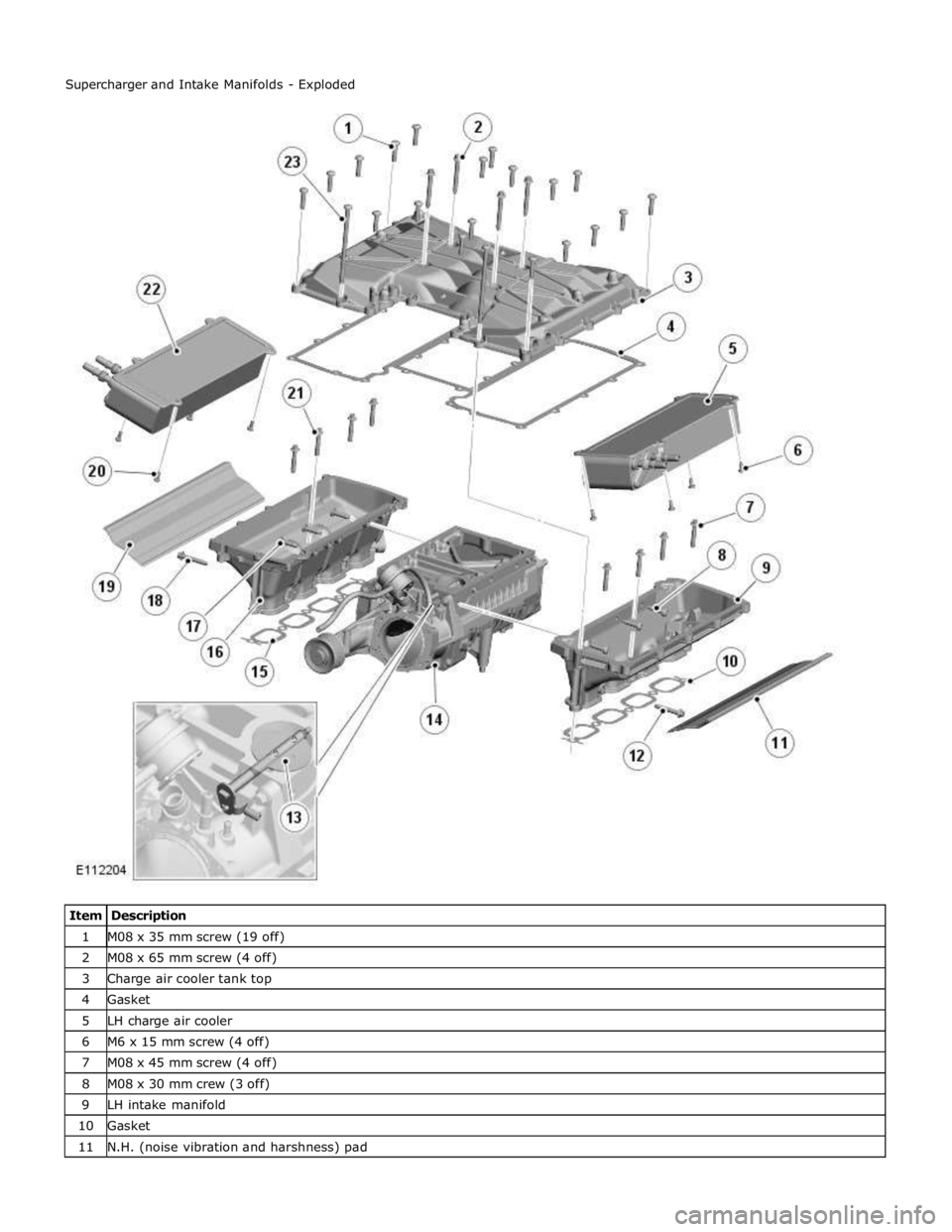

1 M08 x 35 mm screw (19 off) 2 M08 x 65 mm screw (4 off) 3 Charge air cooler tank top 4 Gasket 5 LH charge air cooler 6 M6 x 15 mm screw (4 off) 7 M08 x 45 mm screw (4 off) 8 M08 x 30 mm crew (3 off) 9 LH intake manifold 10 Gasket 11 N.H. (noise vibration and harshness) pad

Page 1295 of 3039

13 Bypass valve 14 SC 15 Gasket 16 RH intake manifold 17 M08 x 30 mm crew (3 off) 18 M08 x 50 mm screw 19 N.H. pad 20 M6 x 15 mm screw (4 off) 21 M08 x 45 mm screw (4 off) 22 RH charge air cooler 23 M08 x 150 mm screw Supercharger

The SC is a Roots blower with high angle helix rotors driven at 2.1 x engine speed by the secondary belt of the accessory drive.

The two rotors of the SC are contained in a housing. The ends of the rotors are supported in bearings in the front cover and the bearing plate. A rear cover seals the bearing plate and incorporates a filler/level plug for lubricant. A pulley transfers power

from the accessory drive to the shaft of one of the rotors.

A pneumatic actuator on the front cover is attached to a by-pass valve in the housing. The bypass valve regulates a flow of air

from the outlet of the SC back to the inlet side of the rotors, to control the outlet pressure of the SC. Hoses connect the pneumatic actuator to the throttle T-piece of the air ducts, upstream of the electric throttle, and to the front cover, downstream

of the electric throttle. A lever connects the actuating rod of the pneumatic actuator to the shaft of the bypass

valve. A screw in the front cover limits movement of the lever in the closed direction to allow calibration of the SC output. The front cover also incorporates:

The SC air inlet and mounting face for the electric throttle. A connector stub for the part load breather.

A MAP (manifold absolute pressure) sensor.

A connector stub for a hose from the EVAP (evaporative emission) canister purge valve.

Intake Manifolds

Each intake manifold is attached to the SC with three screws and a bolt. Two dowels ensure correct alignment of each intake manifold. The RHD (right-hand drive) intake manifold incorporates a connection port for the noise feedback system. The LH intake manifold incorporates:

A connector stub for the brake vacuum system.

A MAPT (manifold absolute pressure and temperature) sensor.

Page 1296 of 3039

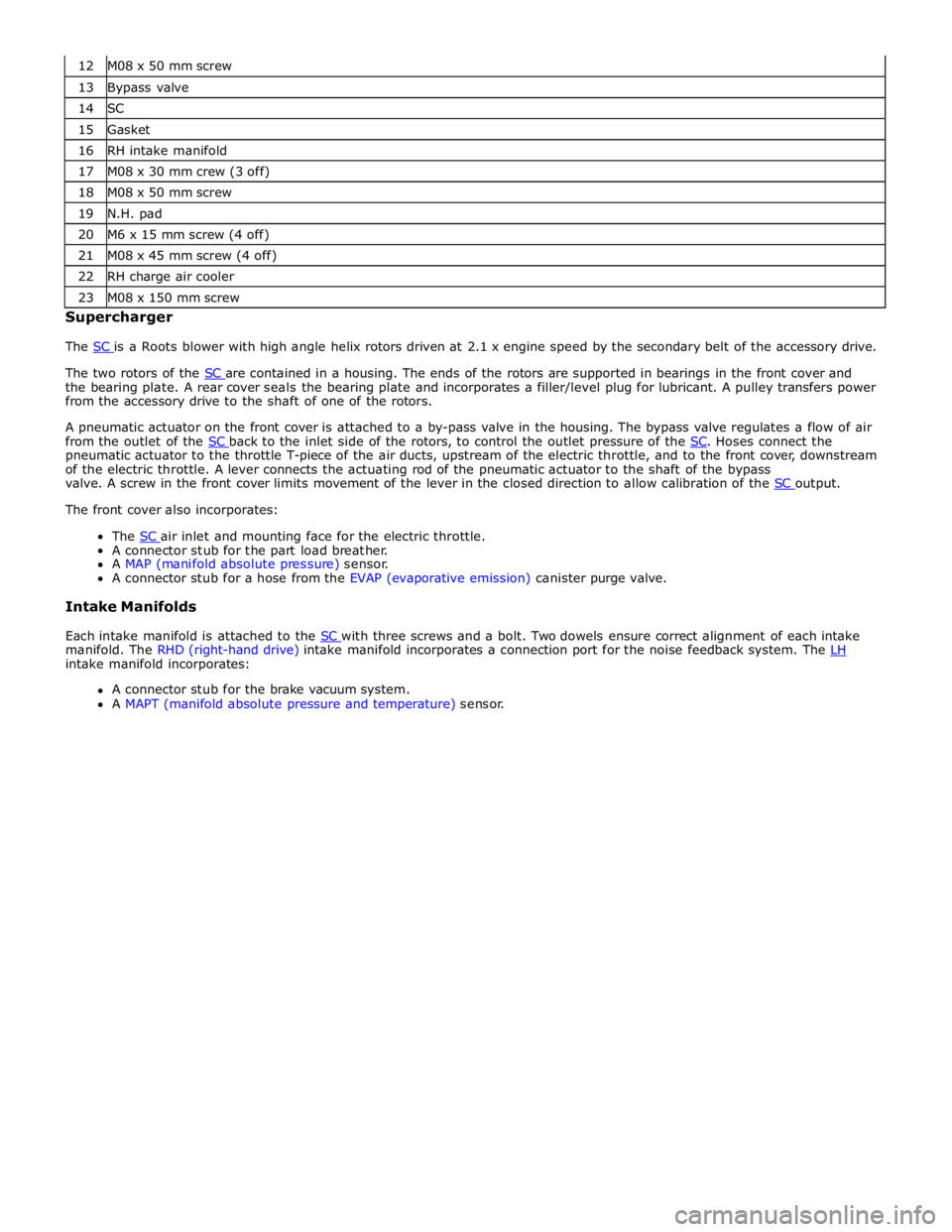

1 Outlet adapter 2 Clip 3 Feedback tube 4 Clip 5 Hose seal 6 Resonator 7 Vacuum hose - tuning valve to pneumatic actuator 8 Inlet pipe 9 Pneumatic valve 10 Symposer 11 Vacuum hose - tuning valve to brake vacuum system 12 Grommet assembly 13 Tuning valve 14 Outlet pipe NOISE FEEDBACK SYSTEM

www.JagDocs.com

Page 1297 of 3039

Symposer System

The symposer system modifies induction sound waves of a specific frequency range, at given engine settings, to produce the

required engine sound. The symposer system consists of:

An inlet pipe and flange.

A symposer and pneumatic valve assembly. A

tuning valve and associated vacuum tubes.

An outlet pipe.

An outlet adapter.

The inlet pipe and flange transfer induction noise from the RH intake manifold to the symposer. The pipe is a push fit on the symposer and the flange, which is attached to the rear face of the RH intake manifold.

The symposer contains two pairs of chambers, one pair on the inlet side and one pair on the outlet side. The inlet pipe

connects to one of the chambers on the inlet side of the symposer, and the pneumatic valve connects to one of the chambers

on the outlet side of the symposer. A calibrated orifice in the inlet pipe connection on the symposer limits the range of sound

waves that pass through it. A 'paddle' installed in a diaphragm forms the separating wall in each pair of chambers. The paddle

is able to pivot about its lateral axis where it passes through the wall that separates the two pairs of chambers.

Symposer

Item Description 1 Diaphragm 2 Paddle 3 Isolator 4 Inlet chamber (sealed) 5 Outlet chamber (open to pneumatic valve) 6 Screw (8 off) 7 Pneumatic valve 8 Outlet chamber 9 Inlet chamber (open to inlet pipe) 10 Inlet pipe connection

Page 1298 of 3039

The tuning valve controls the application of vacuum pressure to the pneumatic valve. Two screws attach the tuning valve to the

same bracket as the symposer and pneumatic valve. The tuning valve is a normally-closed solenoid-operated valve installed in

the vacuum line between a T-connection in the brake vacuum system and the pneumatic valve. A vent cap on the tuning valve

allows atmospheric pressure into the vacuum line to the pneumatic valve when the tuning valve is closed.

The outlet pipe carries sound from the pneumatic valve to the feedback tube via the outlet adapter. The outlet pipe is a push

fit on the pneumatic valve and in the outlet adapter. A screw attaches the outlet adapter to an engine harness bracket

installed between the two intake manifolds.

Feedback Tube

The feedback tube transfers the sound from the symposer system to the resonator. Clips secure the feedback tube to the

outlet adapter of the symposer system and to the resonator.

Resonator

The resonator directs the sound from the feedback tube into the passenger compartment. The resonator is installed in the

passenger compartment side of the engine bulkhead, on two mounting grommets each consisting of an isolator and a

compression limiter. A hose seal isolates the resonator where it passes through the secondary bulkhead.

Page 1299 of 3039

Published: 11-May-2011

Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol - Intake Air

Distribution and Filtering

Diagnosis and Testing

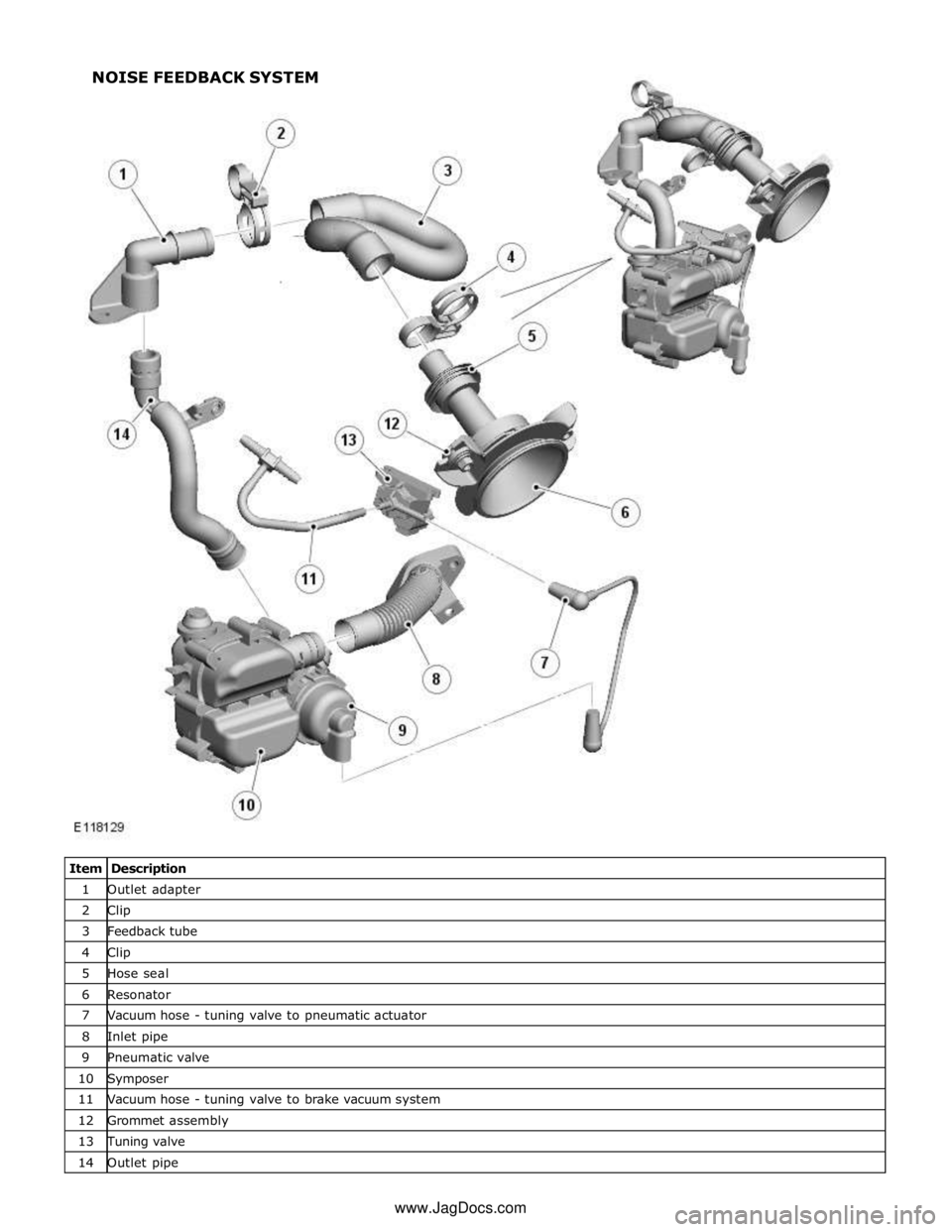

Principles of Operation

For a detailed description of the intake air distribution and filtering system and operation, refer to the relevant Description and

Operation section of the workshop manual. REFER to: (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol)

Intake Air Distribution and Filtering (Description and Operation), Intake Air Distribution and Filtering (Description and Operation), Intake Air Distribution and Filtering (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection

Mechanical Electrical

Hoses and ducts (damage/connections)

Air cleaner element (contaminated/blocked)

Restricted air intake

Supercharger

Supercharger (cooling fan) drive belt

Supercharger seals and gaskets

Charge air coolers (damage/connection)

Mass Air Flow (MAF) sensor

Manifold Absolute Pressure (MAP) sensor

Manifold Absolute Pressure/Temperature (MAPT) sensor

Throttle body

Harness (security/damage)

Connections (security/damage)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Causes Action Vehicle does not

start/hard

starting/poor

performance

Restricted/Blocked air intake

Restricted/Blocked air

cleaner element Clear the restriction. Replace the air cleaner element as necessary.

Refer to the relevant workshop manual section. Excessive intake

noise

Intake pipe

disconnected/damaged after

the air cleaner

Air cleaner assembly

incorrectly

assembled/damaged Check the intake system and hoses for correct installation/damage.

Refer to the relevant workshop manual section. Lack of boost

Supercharger drive belt

broken/slipping

Supercharger fault

Supercharger air intake fault

Major air leakage (after the

supercharger) Check the supercharger and drive belt. Check the charge air coolers.

Refer to the relevant workshop manual section. Noise

Supercharger drive belt

slipping

Supercharger fault

Major air leakage (after the

supercharger) Check the supercharger and drive belt. Remove the supercharger drive

belt and recheck for noise. Turn the supercharger by hand and check

for excessive resistance. Check for excessive play at the supercharger

pulley. Check the charge air coolers. Refer to the relevant workshop

manual section.

Page 1300 of 3039