JAGUAR XJ6 1994 2.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 291 of 521

Page 292 of 521

Body Components & Trim -

13.3.39 Roof lining (Headlining), Description

The roof lining is a one piece construction of 6mm thick polyurethane foam, covered with brush finish, suede effect,

knitted polyester.

13.3.40 Roof lining; Renew

. Position front seats fully rearwards and recline the passen-

. Disconnect vehicle battery ground lead.

. Remove:

ger

seat squab.

0 Sliding roof flange (where fitted).

0 Front passenger door.

0 Rear console (where fitted).

0 Center console.

0 Sunblind and bezel.

0 Combined grab handle and coat hook.

0 Rear quarter upper trim pad LH & RH.

0 Cantrail crash roll.

0 Illuminated sun visor.

0 Roof console.

9 Release multi-plug connectors from clips at roof console

Remove roof console retaining clip from headlining.

. Remove security sensors (where fitted) and disconnect

. Release roof lining to body tags and lower roof lining.

. Remove the roof lining:

Position the roof lining with the rear corner through the

passenger side rear door and the opposite cornerthrough

the driver side rear door.

. Position the roof lining across the car with the roof console

cut-out straddling 'B'-'C' post.

. Tip the roof lining forward against bottom of fascia with

rear edge of roof lining diagonally across door aperture.

. Carefully feed the roof lining out of the passenger side

front door, easing the edge cut-outs over the door aper- ture and any other obstruction.

aperture.

multi

-plugs.

. To

refit, carry out reversal of the above procedure.

X300 VSM 37 Issue 1 August 1994

Page 293 of 521

13.4 TRUNK

13.4.1 Trunk, Description

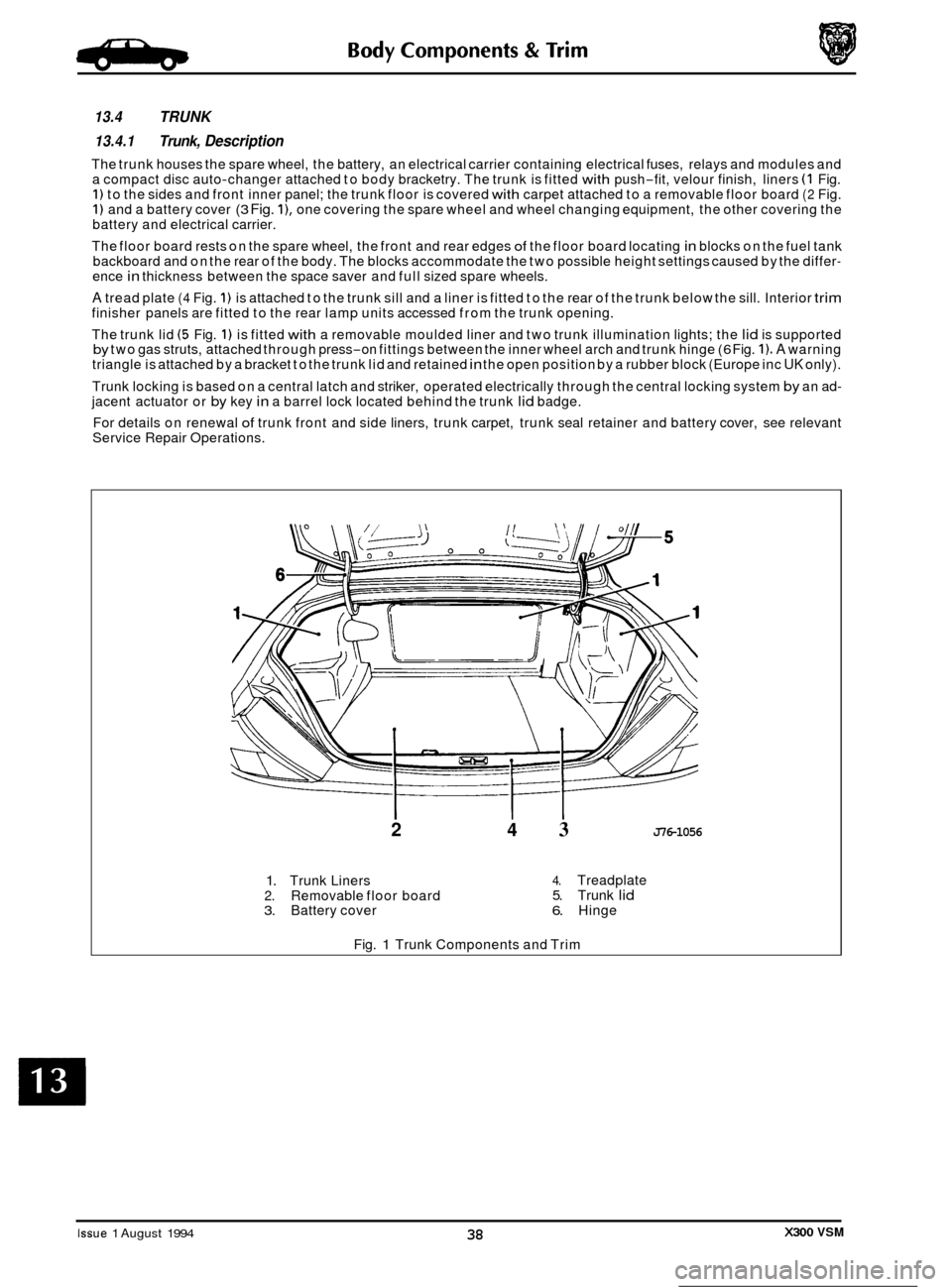

The trunk houses the spare wheel, the battery, an electrical carrier containing electrical fuses, relays and modules and

a compact disc auto-changer attached to body bracketry. The trunk is fitted with push-fit, velour finish, liners (1 Fig. 1) to the sides and front inner panel; the trunk floor is covered with carpet attached to a removable floor board (2 Fig. 1) and a battery cover (3 Fig. I), one covering the spare wheel and wheel changing equipment, the other covering the

battery and electrical carrier.

The floor board rests on the spare wheel, the front and rear edges

of the floor board locating in blocks on the fuel tank

backboard and on the rear of the body. The blocks accommodate the two possible height settings caused by the differ- ence in thickness between the space saver and full sized spare wheels.

A tread plate (4 Fig. 1) is attached to the trunk sill and a liner is fitted to the rear of the trunk below the sill. Interior trim finisher panels are fitted to the rear lamp units accessed from the trunk opening.

The trunk lid

(5 Fig. 1) is fitted with a removable moulded liner and two trunk illumination lights; the lid is supported by two gas struts, attached through press-on fittings between the inner wheel arch and trunk hinge (6 Fig. 1). A warning

triangle is attached by a bracket to the trunk lid and retained in the open position by a rubber block (Europe inc UK only).

Trunk locking is based on a central latch and striker, operated electrically through the central locking system

by an ad- jacent actuator or by key in a barrel lock located behind the trunk lid badge.

For details on renewal

of trunk front and side liners, trunk carpet, trunk seal retainer and battery cover, see relevant

Service Repair Operations.

2 4 3 J76-1056

1. Trunk Liners 2. Removable floor board 3. Battery cover

4. Treadplate 5. Trunk lid 6. Hinge

Fig.

1 Trunk Components and Trim

Issue 1 August 1994 X300 VSM 38

Page 294 of 521

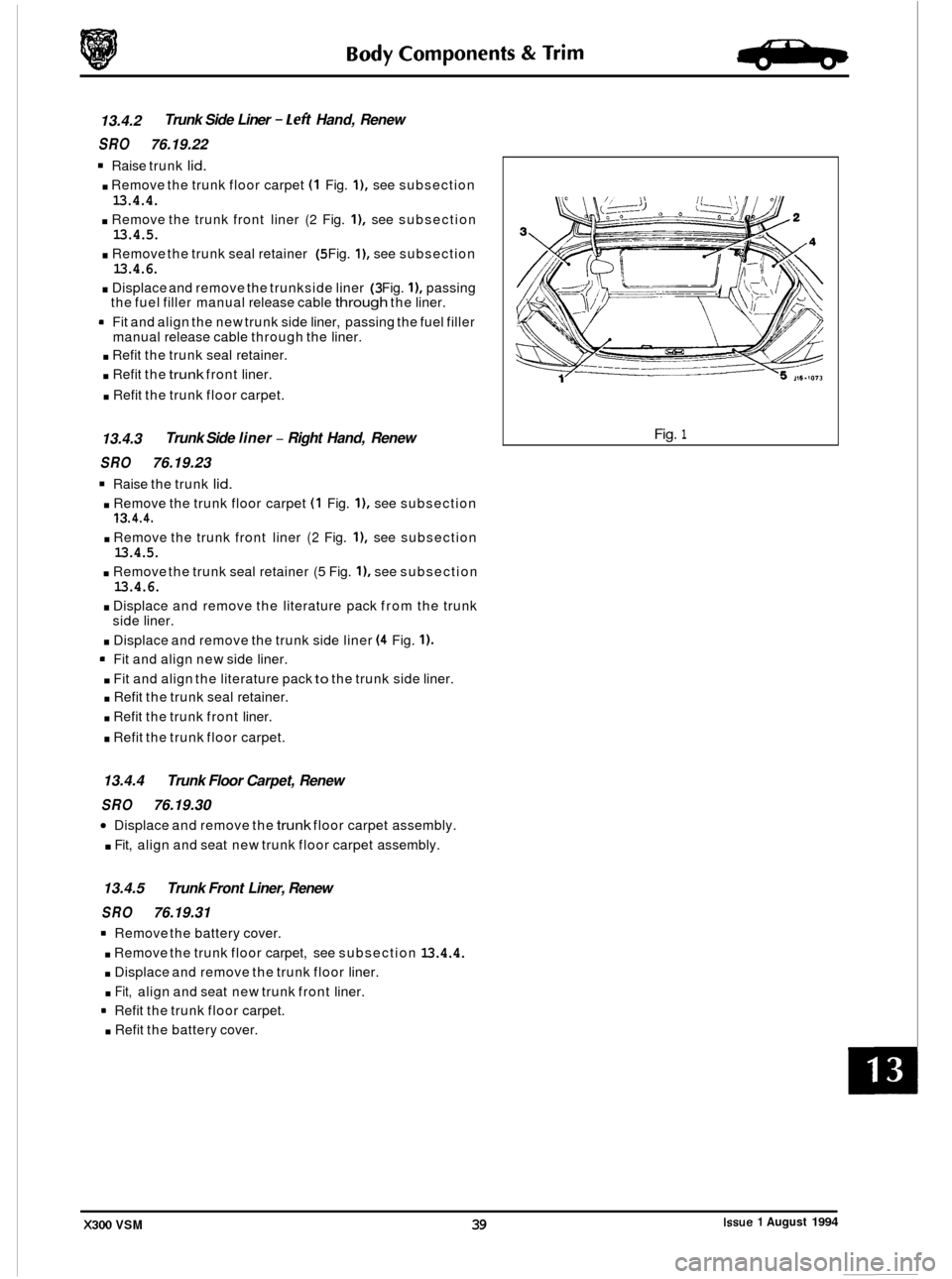

13.4.2

SRO 76.19.22

Raise trunk lid.

. Remove the trunk floor carpet (1 Fig. I), see subsection

13.4.4.

. Remove the trunk front liner (2 Fig. I), see subsection 13.4.5.

. Remove the trunk seal retainer (5 Fig. I), see subsection 13.4.6.

. Displace and remove the trunkside liner (3 Fig. I), passing

the fuel filler manual release cable through the liner.

9 Fit and align the new trunk side liner, passing the fuel filler

manual release cable through the liner.

. Refit the trunk seal retainer.

. Refit the trunk front liner.

. Refit the trunk floor carpet.

Trunk Side Liner - Left Hand, Renew

13.4.3 Trunk

Side liner

- Right Hand, Renew

SRO 76.19.23

Raise the trunk lid.

. Remove the trunk floor carpet (1 Fig. I), see subsection

. Remove the trunk front liner (2 Fig. I), see subsection

. Remove the trunk seal retainer (5 Fig. I), see subsection

. Displace and remove the literature pack from the trunk

. Displace and remove the trunk side liner (4 Fig. 1).

' Fit and align new side liner.

. Fit and align the literature pack to the trunk side liner.

. Refit the trunk seal retainer.

. Refit the trunk front liner.

. Refit the trunk floor carpet.

13.4.4.

13.4.5.

13.4.6.

side liner.

13.4.4 Trunk Floor Carpet, Renew

SRO 76.19.30

Displace and remove the trunk floor carpet assembly. 0

. Fit, align and seat new trunk floor carpet assembly.

13.4.5 Trunk Front Liner, Renew

SRO 76.19.31

Remove the battery cover.

. Remove the trunk floor carpet, see subsection 13.4.4.

. Displace and remove the trunk floor liner.

. Fit, align and seat new trunk front liner.

* Refit the trunk floor carpet.

. Refit the battery cover.

Fig. 1

Issue 1 August 1994 X300 VSM 39

Page 295 of 521

. Remove the trunk floor carpet, see sub-section 13.4.4.

. Displace and remove the left and right hand tail light

. Undo and remove the trunk seal retainer securing bolts

. Displace and remove the trunk seal retainer.

. Fit and fully seat the new trunk seal retainer.

Fit and fully tighten the trunkseal retainer securing bolts.

. Fit and fully seat the tail light covers.

. Refit the trunk floor carpet.

13.4.7 Trunk Lid Striker, Adjust

Disconnect vehicle battery ground lead.

. Remove the rear finisher.

. Slacken the striker plate securing bolts and adjust the

striker to ensure that the luggage compartment lid aligns

covers.

(arrowed on Fig.

1).

176.107L ___----

Fig. 1

Page 296 of 521

Body Components & Trim d-!P

13.4.12 Trunk Lid Lock Mechanism, Renew

. Open the trunk and remove the mechanism cover.

. Disconnect the operating rod from the remote linkage.

Removethe two lock assembly securing bolts, remove the

lock from the trunk. lid and remove the assembly from the

vehicle.

. To refit, carry out reversal of the above procedure.

13.4.13 Trunk Lid Gas Strut, Adjust, Renew

Open the trunk.

. Insert a screwdriver and remove the strut from the top

. Fit the strut to the lower pivot first to aid re-assembly.

= To refit, carry out reversal of the above procedure, chang-

pivot and repeat the operation for the lower pivot.

ing one strut at a time.

13.4.14 Trunk Lid Hinge, Renew

. Open the trunk.

. Remove the hinge cover.

Cut and remove the harness straps from the RH hinge and

move the harness away.

Note:

. Remove the upper hinge securing bolts.

. Remove the lower hinge fixings.

. To refit, carry out reversal of the above procedure, ensur- ing that the alignment of the trunk buffers is set relative to

the fenders. Ensure

that the lid is adequatelysupported and that

paint damage cannot occur.

13.4.15 Trunk Rear Liner, Renew

. Disconnect vehicle battery ground lead.

. Peel backthe floor carpet and sound insulation for access.

. Remove the tread plate.

. Remove the trunk rear liner.

. To refit, carry out reversal of the above procedure.

Issue 1 August 1994 X300 VSM 41

Page 297 of 521

Body Components & Trim a

13.5 HOOD

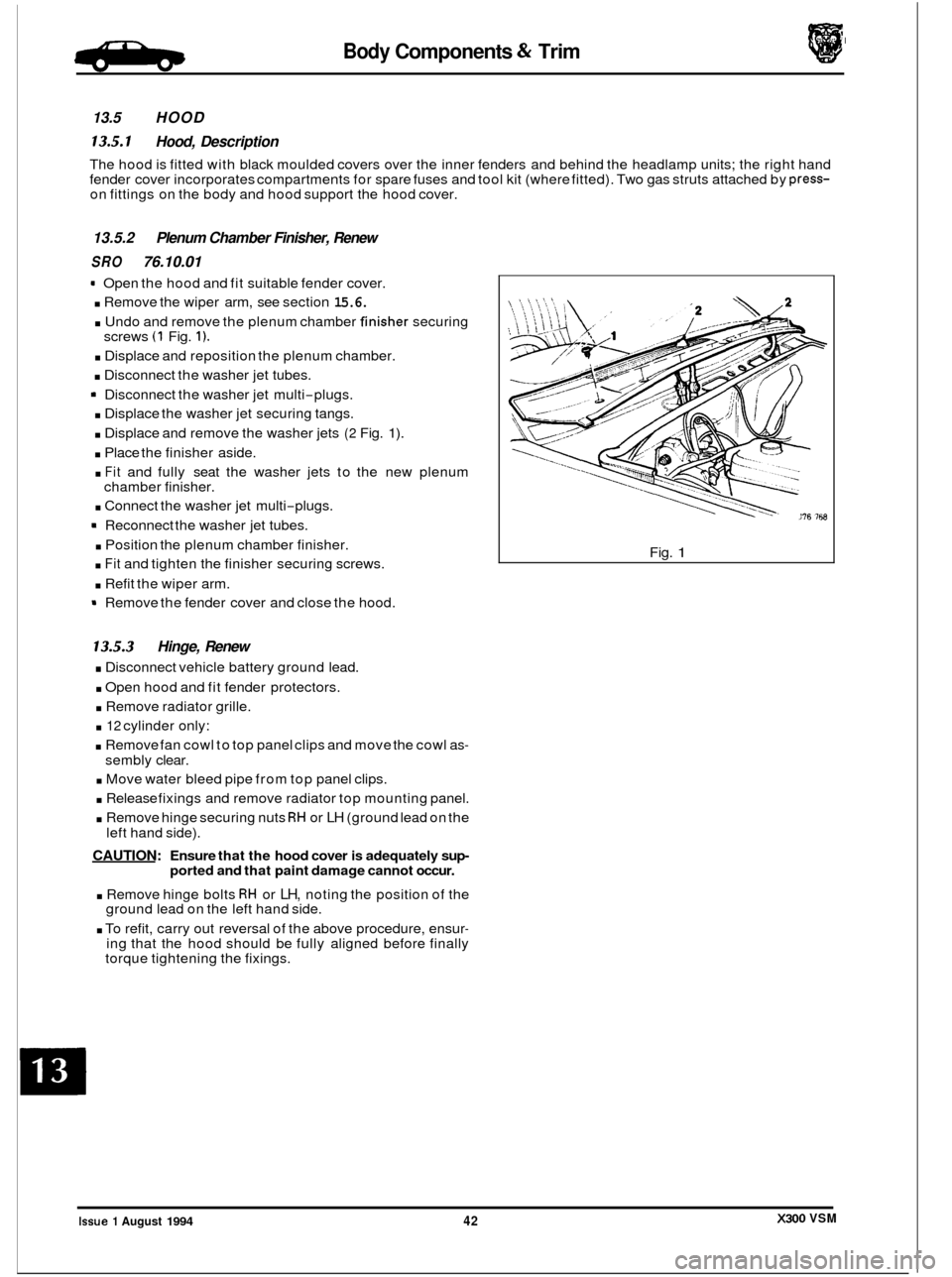

13.5.1 Hood, Description

The hood is fitted with black moulded covers over the inner fenders and behind the headlamp units; the right hand

fender cover incorporates compartments for spare fuses and tool kit (where fitted). Two gas struts attached by press- on fittings on the body and hood support the hood cover.

13.5.2 Plenum Chamber Finisher, Renew

SRO 76.10.01

9 Open the hood and fit suitable fender cover.

. Remove the wiper arm, see section 15.6.

. Undo and remove the plenum chamber finis..er securing

. Displace and reposition the plenum chamber.

. Disconnect the washer jet tubes.

9 Disconnect the washer jet multi-plugs.

. Displace the washer jet securing tangs.

. Displace and remove the washer jets (2 Fig. 1).

. Place the finisher aside.

. Fit and fully seat the washer jets to the new plenum

. Connect the washer jet multi-plugs.

9 Reconnect the washer jet tubes.

. Position the plenum chamber finisher.

. Fit and tighten the finisher securing screws.

. Refit the wiper arm.

9 Remove the fender cover and close the hood.

screws

(1 Fig. 1).

chamber

finisher.

13.5.3 Hinge, Renew

. Disconnect vehicle battery ground lead.

. Open hood and fit fender protectors.

. Remove radiator grille.

. 12 cylinder only:

. Remove fan cowl to top panel clips and move the cowl as-

sembly clear.

. Move water bleed pipe from top panel clips.

. Release fixings and remove radiator top mounting panel.

. Remove hinge securing nuts RH or LH (ground lead on the

CAUTION: Ensure that the hood cover is adequately sup- ported and that paint damage cannot occur.

. Remove hinge bolts RH or LH, noting the position of the

ground lead on the left hand side.

. To refit, carry out reversal of the above procedure, ensur- ing that the hood should be fully aligned before finally

torque tightening the fixings.

left

hand side).

I

0

Fig. 1

X300 VSM Issue 1 August 1994 42

Page 298 of 521

Body Components & Trim

13.5.4 GasStrut, Renew

. Disconnect vehicle battery ground lead.

. Open the hood and fit fender protectors.

CAUTION: Ensure that the hood cover is adequately sup ported and that paint damage cannot occur.

. Release upper strut pivot retaining clip and detach the

. Repeat for the lower pivot and remove the gas strut.

To refit, carry out reversal of the above procedure.

strut from the pivot.

13.5.5 Hood

Lock RH or LH, Renew

Open the hood and disconnect the lock operating cable

from the lock.

. Remove the bolts securing the lock to the body and re- move the lock.

. To refit, carry out reversal of the above procedure. Align

the lock with the striker prior to tightening.

13.5.6 Hood Lock Control Cable RH or LH, Renew

Slacken theclamp bolt securing thecabletothe lockactua- tor.

= Disconnect the cable from the lock and from the mounting

clip.

Release the cable from the bulkhead mounting clips and

remove the tie wraps securing the cable to the pipes and

harnesses.

. Remove the cable from the remaining large tie wraps.

. Open the front door.

. Remove the underscuttle pad.

. Pull the release handle and disconnect the cable from the

release handle and bracket.

Pull the cable through the bulkhead grommet and discard.

To refit, carry out reversal of the above procedure.

13.5.7 Hood Striker Assembly, Renew

. ODen the hood, slacken the locknut and unscrew the

sthker.

. Renew any damaged components and reassemble. - . A distance of 62mm from the end of the striker to the lock-

Adjust the striker until the hood is flush with the fender.

nut may be used as an initial setting.

13.5.8

. With the hood raised: slacken the clamp bolt which se- cures the cable to the lock actuator. Repeat the procedure

for the other side.

Hood Lock Release Handle, Renew

Open the driver side door.

. Remove the underscuttle pad.

. Disconnect the inner cablesfrom the hood release handle.

. Remove the bolts securing the hood release handle to the

body, remove the cables from the handle and remove

from the vehicle.

To refit, carry out reversal of the above procedure.

X300 VSM 43 Issue 1 August 1994

Page 299 of 521

Body Components & Trim #ib

13.6 GLAZING (FIXED)

13.6.1 Glazing (Fixed), Description

The fixed glazing comprises internal and external driving mirrors, sunvisor mirror and rear quarter light glass; see Ap- pendix A4, Body Components and Trim for details of the windscreen and rear screen glazing.

13.6.2 Interior Mirror, Renew

. Disconnect vehicle battery ground lead.

. Rotate mirror stem approximately one quarter turn clock- wise to release stem from spring contact on windscreen

boss.

. Disconnect mirror harness.

To refit, locate mirror stem base on windscreen boss with

stem parallel to top of windscreen, ie one quarter turn dis- placed from normal position; apply firmly over boss and

turn anti-clockwise to lock stem on windscreen boss.

. Reconnect mirror harness.

13.6.3

. Disconnect vehicle battery ground lead.

. Lower the sunvisor.

. Raise the sunvisor cover and remove the lenses.

Remove the screws securing the mirror to the sunvisor

and remove the mirror.

. To refit, carry out reversal of the above procedure, taking

care to correctly locate switch and bulb holders priortose-

curing the mirror.

Sun Visor Mirror Assembly, Renew

13.6.4 Exterior Mirror, Renew

= Disconnect vehicle battery ground lead.

Remove door trim pad veneer panel and upper trim pad.

9 Remove the cheater by sliding off.

. Remove mirror fixings.

. Disconnect the mirror harness block connectors.

. Remove the mirror securing screws and remove the mir-

ror assembly.

. To refit, carry out reversal of the above procedure.

13.6.5 Exterior Mirror Glass, Renew

. Switch ignition on and position the mirrorto inboard posi-

. Disconnect vehicle battery ground lead.

. Slide assembly outboard and pull outwards.

. To refit, carry out reversal of the above procedure.

tion.

Issue 1 August 1994 44 X300 VSM

Page 300 of 521