JAGUAR XJ6 1994 2.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 331 of 521

Climate Control Systems

No heat

One vent failing to open

/ close

Poor airflow

14.11.3 Associated Faults

Other symptoms that may exist without storing fault codes:

Airlock in system.

Electric water

pump inoperative

Coolant flow valve stuck closed

Faulty engine coolant thermostat

Broken linkage.

Blower motors

- incorrect operation

14.11.4 Panel Communication Check

Action Result

Panel communication

with FACE, FOOT & FACE, FOOT,

SCREEN

& FOOT, DEFROST, RECIRC lines checked - State lamps will illuminate if all is OK. Unlit state lamp

means continuity fault for that specific link. See EDM

for

full check.

0

0

0

Issue 1 August 1994 18 X300 VSM

Page 332 of 521

Climate Control Systems

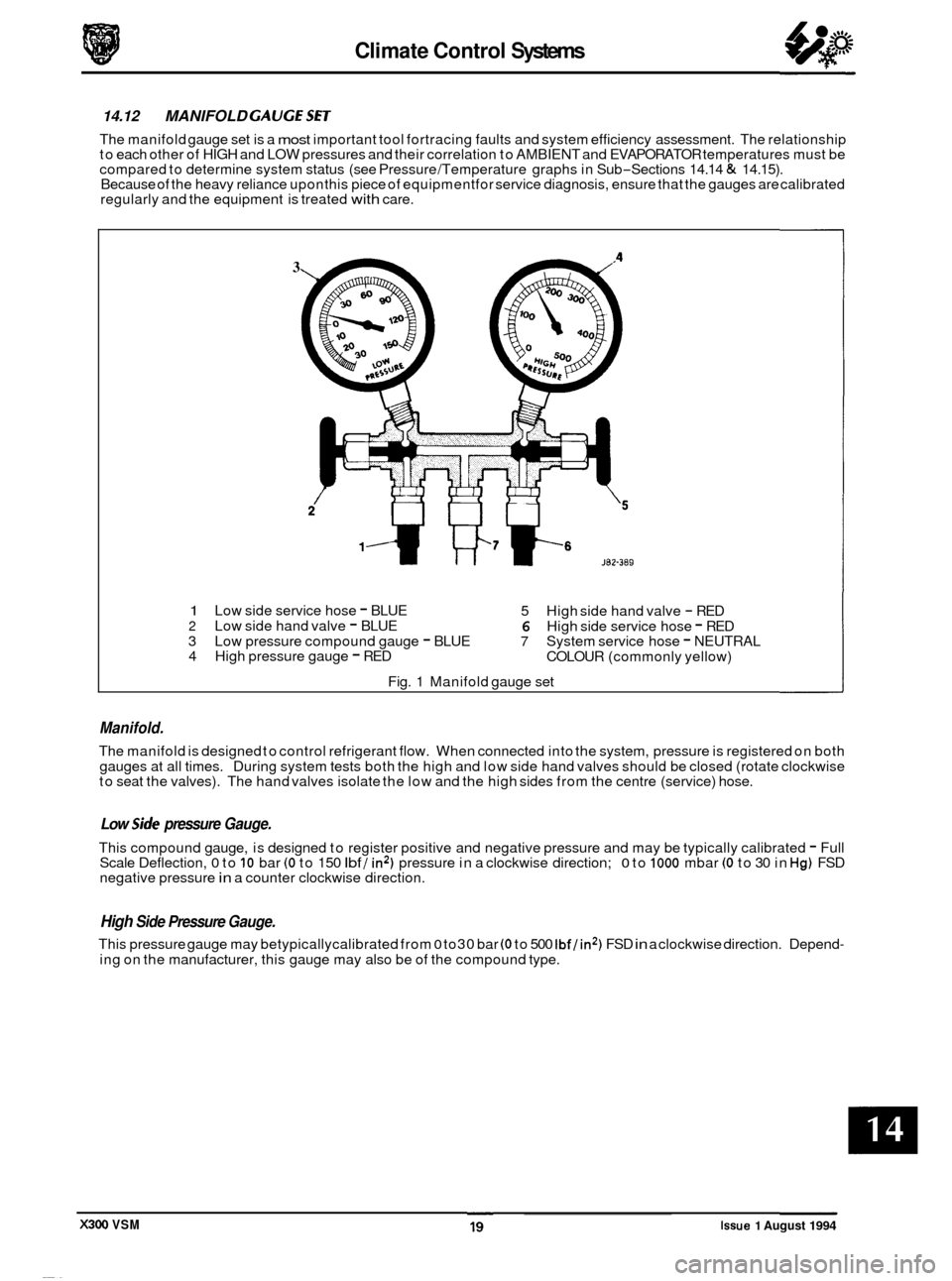

14.12 MANIFOLD GAUGESET

The manifold gauge set is a most important tool fortracing faults and system efficiency assessment. The relationship

to each other of HIGH and LOW pressures and their correlation to AMBIENT and EVAPORATOR temperatures must be

compared to determine system status (see Pressure /Temperature graphs in Sub

-Sections 14.14 & 14.15).

Because of the heavy reliance upon this piece of equipmentfor service diagnosis, ensure that the gauges are calibrated

regularly and the equipment is treated

with care.

3

1 Low side service hose - BLUE

5 High side hand valve - RED 2 Low side hand valve - BLUE 6 High side service hose - RED

3 Low pressure compound gauge - BLUE 7 System service hose - NEUTRAL

4 High pressure gauge - RED

COLOUR (commonly yellow)

Fig. 1 Manifold gauge set

Manifold.

The manifold is designed to control refrigerant flow. When connected into the system, pressure is registered on both

gauges at all times. During system tests both the high and low side hand valves should be closed (rotate clockwise

to seat the valves). The hand valves isolate the low and the high sides from the centre (service) hose.

0 Low side pressure Gauge.

This compound gauge, is designed to register positive and negative pressure and may be typically calibrated - Full

Scale Deflection, 0 to 10 bar (0 to 150 Ibf / in2) pressure in a clockwise direction; 0 to 1000 mbar (0 to 30 in Hg) FSD

negative pressure in a counter clockwise direction.

High Side Pressure Gauge.

This pressure gauge may betypicallycalibrated from 0 to30 bar (0 to 500 Ibf/in2) FSD in a clockwise direction. Depend-

ing on the manufacturer, this gauge may also be of the compound type.

X300 VSM Issue 1 August 1994

Page 333 of 521

Climate Control Systems

14.13 SYSTEM CHECKING WITH MANIFOLD GAUGE Sm

14.13.1 Evacuating the Manifold Gauge Set

Attach the centre (service) hose to a vacuum pump and start the pump. Open fully both high anddow valves and allow

the vacuum to remove air and moisture from the manifold set for at least five minutes.

Turn the vacuum pump off and isolate it from the centre service hose but do not open the hose to atmosphere.

CAUTION: It is imperative that the vacuum pump is not subjected to a positive pressure of any degree. Therefore

the pump must be frtted with an isolation valve at the centre (service hose) connection and this valve

must be closed before the pump is switched off. This operation replaces the 'purge' procedure used on

previous systems. Observe the manufacturefs recommendation with regard to vacuum pump oil

changes.

14.13.2 Connecting the Manifold Gauge Set

CAUTION: Only use hoses with connectors which are dedicated to HFC 134A charge ports.

Attachment of the hose quick release connectors to the high and low side system ports is straightfotward, provided

that the high and low valves are closed and the system is NOT operational.

Assessment of system operating efficiency and fault classification may be achieved by using the facilities on your

Re- covery / Recharging / Recycling station, follow the manufacturers instructions implicitly and observe all safety con- siderations.

WARNING: UNDER NO CIRCUMSTANCES SHOULD THE CONNECTIONS BE MADE WITH THE SYSTEM IN

OPERATION OR THE VALVES OPEN. SHOULD THE VALVES BE OPEN AND A VACUUM PUMP OR

REFRIGERANT CONTAINER ATTACHED, AN EXPLOSION COULD OCCUR AS A RESULT OF HIGH

PRESSURE REFRIGERANT BEING FORCED BACK INTO THE VACUUM PUMP

OR CONTAINER.

14.13.3 Stabilizing the System

Accurate test gauge data will only be attained if the system temperatures and pressures are stabilized.

Ensure that equipment and hoses cannot come into contact with engine moving parts or sources of heat.

It is recommended that a free standing air mover is placed in front of the vehicle to provide air flow through the con- denser / cooling system, see illustration below.

Start the engine, allow

it to attain normal working temperature and set at fast idle (typically 1200 to 1500 rpm). Select full air conditioning performance.

With all temperatures and pressures stable, or displaying symptoms of faults; begin relevant test procedures.

Fig.

1

Issue 1 August 1994 20 X300 VSM

Page 334 of 521

Climate Control Systems

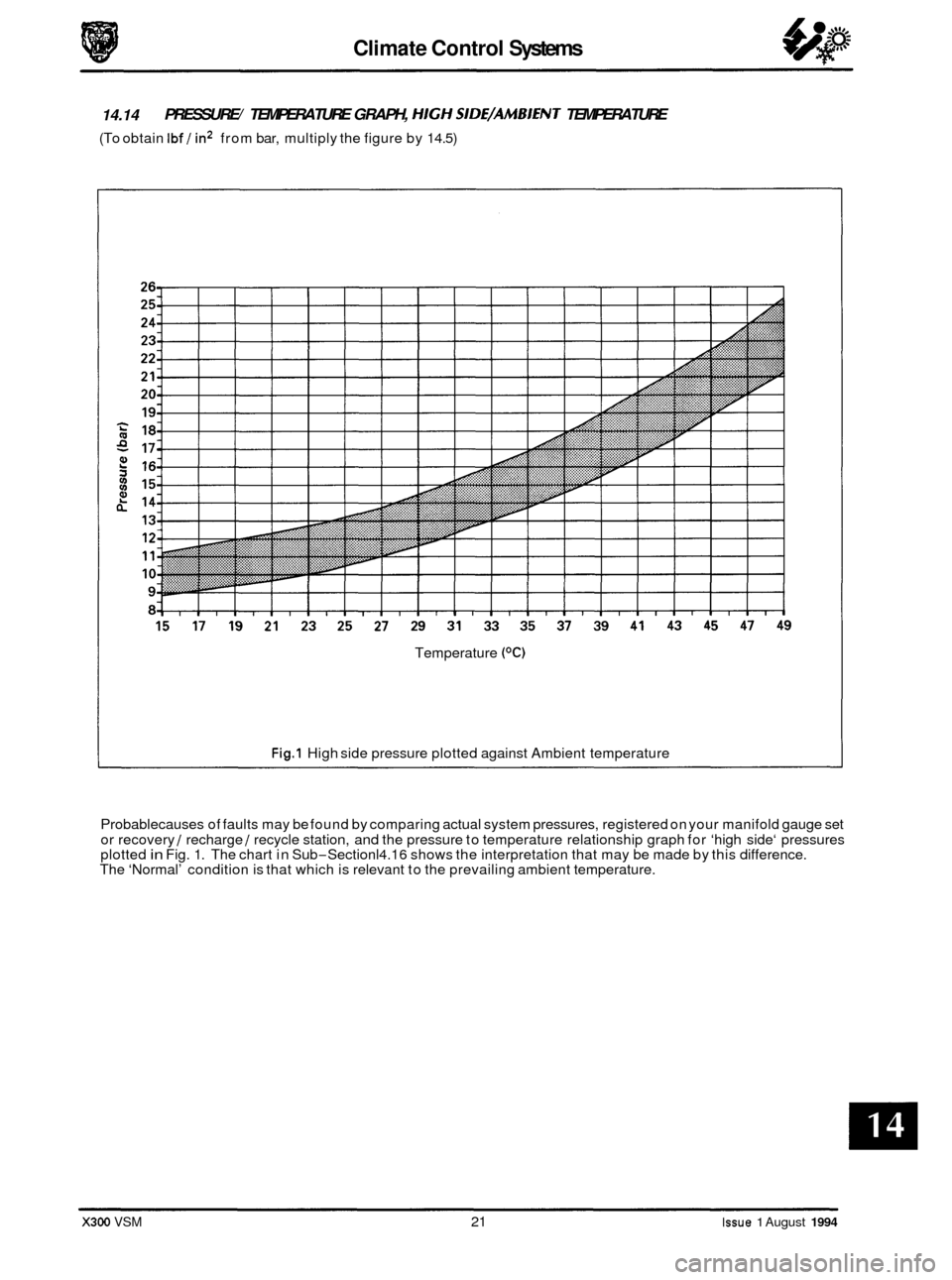

14.14 PRESSURE/ TEMPERATURE GRAPH, HIGH SIDE/AMBIENT TEMPERATURE

(To obtain Ibf / in2 from bar, multiply the figure by 14.5)

Temperature

(OC)

Fig.1 High side pressure plotted against Ambient temperature

0 Probablecauses of faults may be found by comparing actual system pressures, registered on your manifold gauge set

or recovery

/ recharge / recycle station, and the pressure to temperature relationship graph for ‘high side‘ pressures

plotted in Fig. 1. The chart in Sub-Sectionl4.16 shows the interpretation that may be made by this difference.

The ‘Normal’ condition is that which is relevant to the prevailing ambient temperature.

X300 VSM 21 Issue 1 August 1994

Page 335 of 521

Climate Control Systems

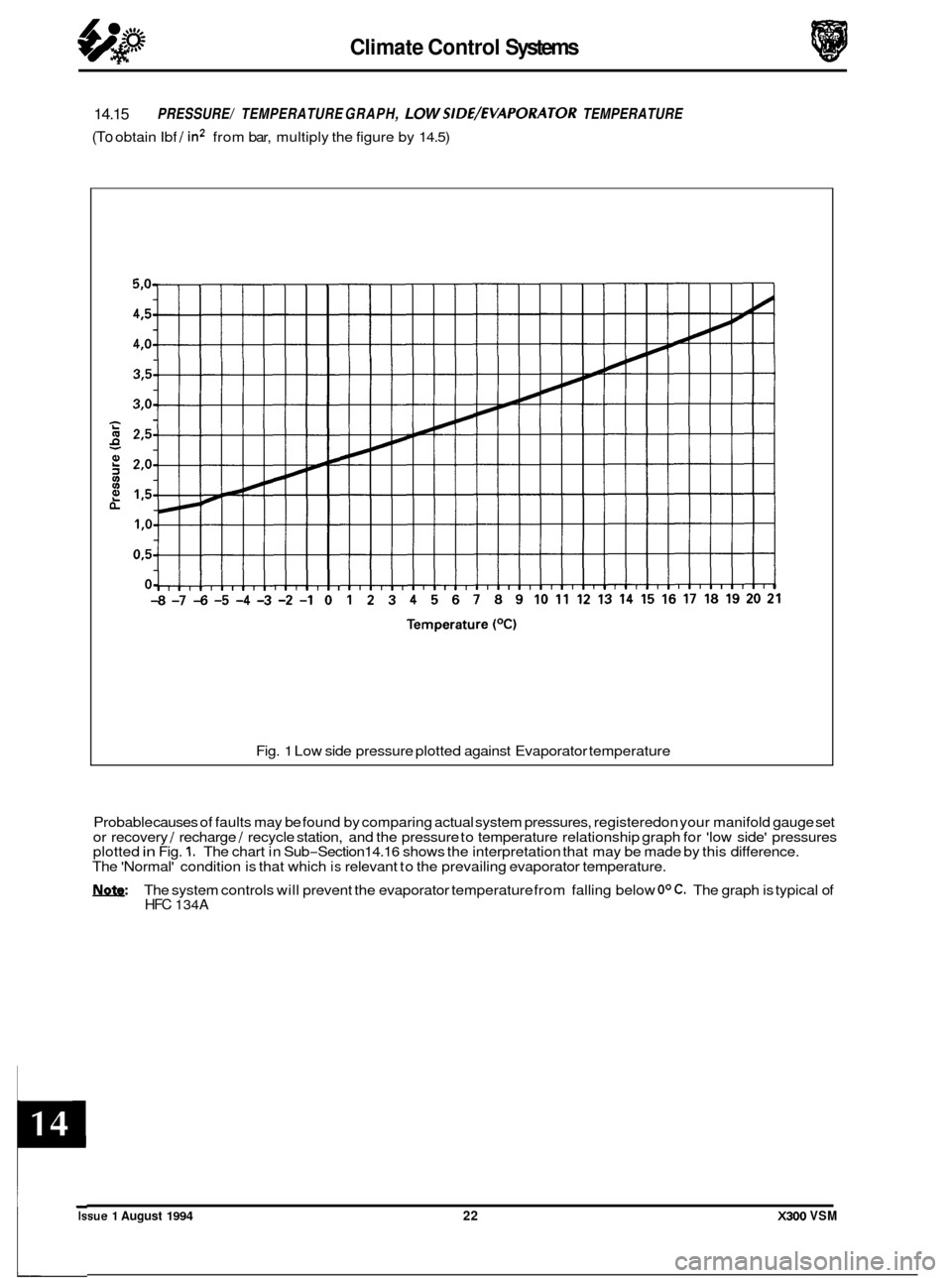

14.15

(To obtain Ibf / in2 from bar, multiply the figure by 14.5)

PRESSURE/ TEMPERATURE GRAPH, LOW SIDE/EVAPORATOR TEMPERATURE

Fig. 1 Low side pressure plotted against Evaporator temperature

Probable causes of faults may be found by comparing actual system pressures, registered on your manifold gauge set

or recovery

/ recharge / recycle station, and the pressure to temperature relationship graph for 'low side' pressures

plotted in Fig. 1. The chart in Sub-Section14.16 shows the interpretation that may be made by this difference.

The 'Normal' condition is that which is relevant to the prevailing evaporator temperature.

The system controls will prevent the evaporator temperature from falling below

OOC. The graph is typical of HFC 134A

0

0

0

Issue 1 August 1994 22 X300 VSM

Page 336 of 521

Climate Control Systems

High Side Gauge

Normal

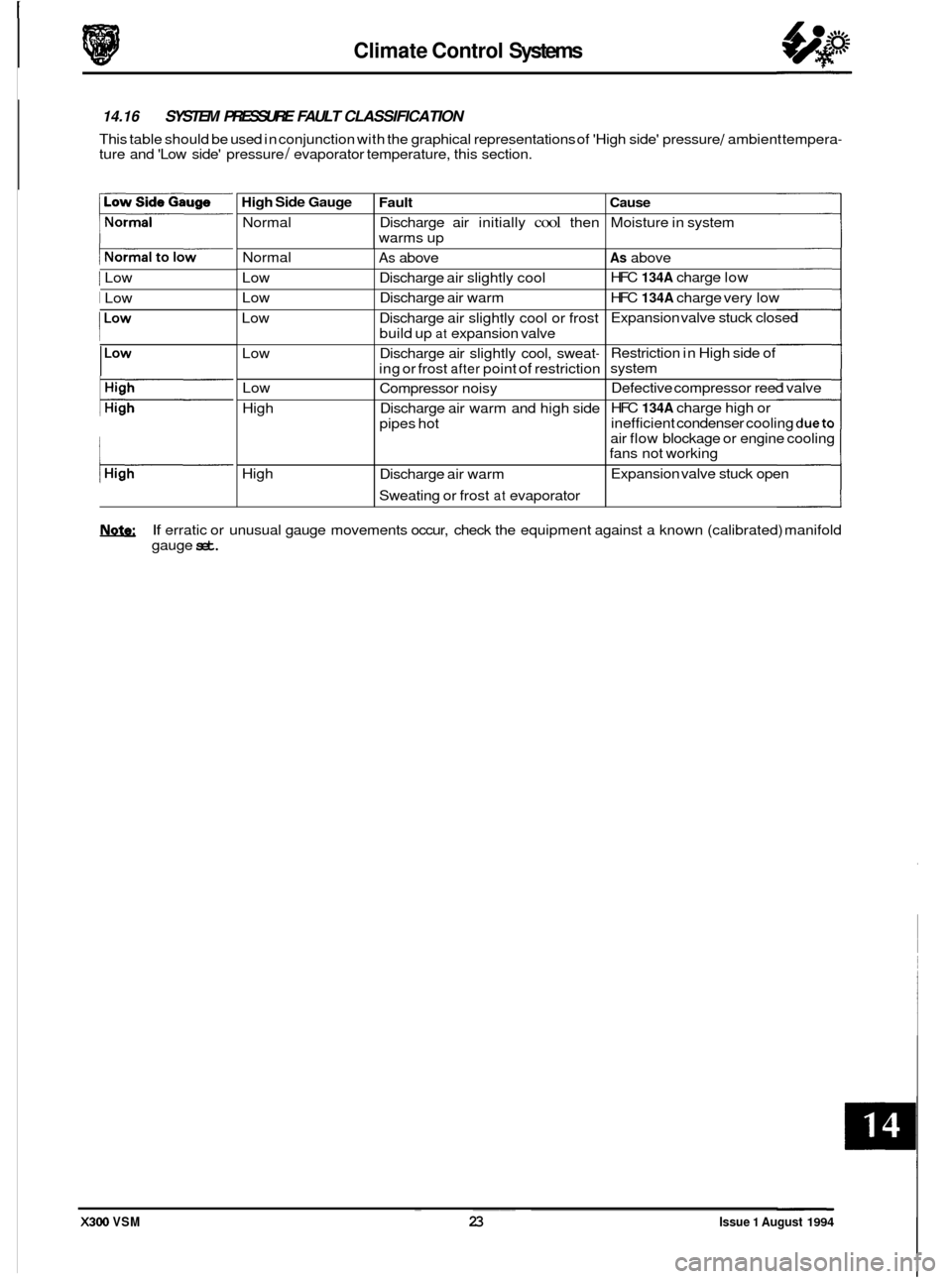

@ 14.16 SYSTEM PRESSURE FAULT CLASSIFICATION

This table should be used in conjunction with the graphical representations of 'High side' pressure / ambient tempera- ture and 'Low side' pressure / evaporator temperature, this section.

Fault Cause

Discharge air initially cool then Moisture in system

warms up

1 Low Normal

Low

Low

Low

Low

I Low

As above As above

Discharge air slightly cool HFC

134A charge

low

Discharge air warm HFC

134A charge very low

Discharge air slightly cool or frost Expansion valve

stuck closed

build up

at expansion valve

Discharge air slightly cool, sweat

- Restriction in High side of

ing or frost

after point of restriction system

I

Low

High

High

I

Compressor noisy Defective compressor

reed valve

Discharge air warm and high side HFC

134A charge

high or

pipes hot inefficient

condenser cooling

dueto

air flow blockage or engine cooling

fans not working

Expansion valve stuck open

Discharge air warm

Sweating or frost

at evaporator

If erratic or unusual gauge movements occur, check the equipment against a known (calibrated) manifold

gauge

set. ~ ~~~

X300 VSM 23 Issue 1 August 1994

Page 337 of 521

24

Page 338 of 521

Electrical cl

.

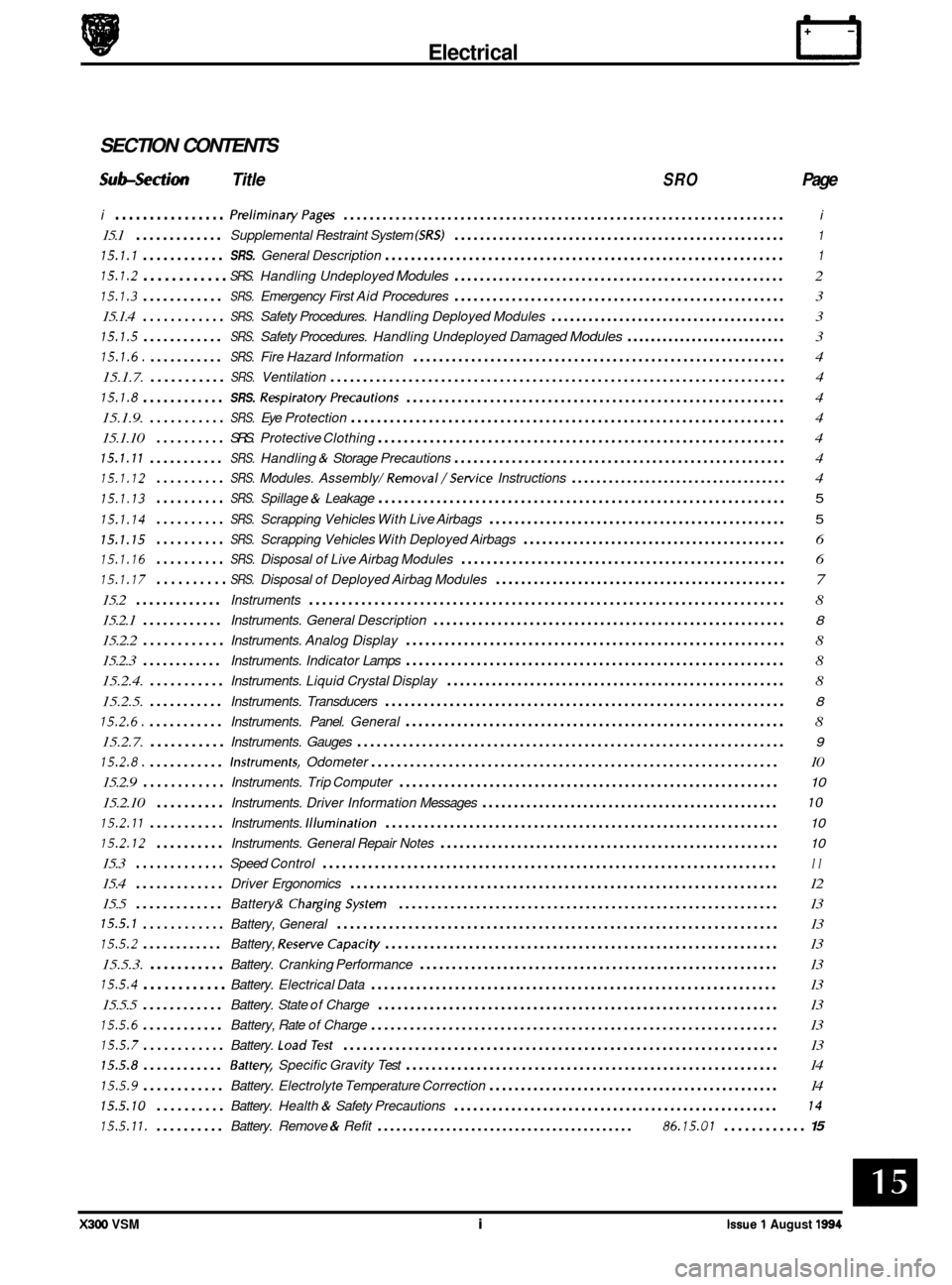

SECTION CONTENTS

Subsection Title SRO Page

i ................ PreliminaryPages .................................................................... i

15.1 ............. Supplemental Restraint System (SRS) .................................................... 1

15.1.1 ............ SRS. General Description .............................................................. 1

15.1.2 ............ SRS. Handling Undeployed Modules .................................................... 2

15.1.3 ............ SRS. Emergency First Aid Procedures .................................................... 3

15.1.4

............ SRS. Safety Procedures. Handling Deployed Modules ...................................... 3

15.1.5 ............ SRS. Safety Procedures. Handling Undeployed Damaged Modules ........................... 3

15.1.6. ........... SRS. Fire Hazard Information .......................................................... 4

15.1.7.

........... SRS. Ventilation ...................................................................... 4

15.1.8 ............ SRS. RespiratoryPrecautions ........................................................... 4

15.1.9.

........... SRS. Eye Protection ................................................................... 4

15.1.10

.......... SRS. Protective Clothing ............................................................... 4

15.1.11 ........... SRS. Handling & Storage Precautions .................................................... 4

15.1.12 .......... SRS. Modules. Assembly/ Removal/Setvice Instructions ................................... 4

15.1.13 .......... SRS. Spillage & Leakage ............................................................... 5

15.1.14 .......... SRS. Scrapping Vehicles With Live Airbags ............................................... 5

15.1.15 .......... SRS. Scrapping Vehicles With Deployed Airbags .......................................... 6

15.1.16 .......... SRS. Disposal of Live Airbag Modules ................................................... 6

15.1.17 .......... SRS. Disposal of Deployed Airbag Modules .............................................. 7

15.2 ............. Instruments ........................................................................\

. 8

15.2.1

............ Instruments. General Description ....................................................... 8

15.2.2 ............ Instruments. Analog Display ........................................................... 8

15.2.3

............ Instruments. Indicator Lamps ........................................................... 8

15.2.4.

........... Instruments. Liquid Crystal Display ..................................................... 8

15.2.5.

........... Instruments. Transducers .............................................................. 8

15.2.6. ........... Instruments. Panel. General ........................................................... 8

15.2.7.

........... Instruments. Gauges .................................................................. 9

15.2.8. ........... Instruments. Odometer ............................................................... 10

15.2.9

............ Instruments. Trip Computer ........................................................... 10

15.2.10 .......... Instruments. Driver Information Messages ............................................... 10

15.2.11 ........... Instruments. Illumination ............................................................. 10

15.2.12 .......... Instruments. General Repair Notes ..................................................... 10

15.3 ............. Speed Control ...................................................................... 11

15.4 ............. Driver Ergonomics .................................................................. 12

15.5

............. Battery& ChargingSystem ........................................................... 13

15.5.1 ............ Battery, General .................................................................... 13

15.5.2 ............ Battery, ReserveCapaci ty ............................................................. 13

15.5.3.

........... Battery. Cranking Performance ........................................................ 13

15.5.4 ............ Battery. Electrical Data ............................................................... 13

15.5.5

............ Battery. State of Charge .............................................................. 13

15.5.6 ............ Battery, Rate of Charge ............................................................... 13

15.5.7 ............ Battery. LoadTest ................................................................... 13

15.5.8 ............ Battey. Specific Gravity Test .......................................................... 14

15.5.9 ............ Battery. Electrolyte Temperature Correction .............................................. 14

15.5.10 .......... Battery. Health & Safety Precautions ................................................... 14

15.5.11. .......... Battery. Remove & Refit ......................................... 86.15.01 ............ 15

e

e

X300 VSM i Issue 1 August 1994

Page 339 of 521

rl Electrical

SECTION CONTENTS

Sub-section Title SRO Page

15.6 .............

15.6.1 ............

15.6.2 ............

15.6.2.1 ..........

15.6.2.2 ..........

15.6.2.3 ..........

15.7 .............

15.8 .............

15.9 .............

15.9.1 ............

15.9.2 ............

15.10 ............

15.10.1 ..........

15.10.2 ..........

15.10.3 ..........

15.10.4 ..........

15.11 ............

15.11.1 ...........

15.12 ............

15.12.1 ..........

15.12.2 ..........

15.12.3 ..........

15.13 ............

15.13.1 ..........

Power Wash & Screen Wash / Wipe .................................................... 16

Windscreen Wipers and Washers. General Description .................................... 16

Windscreen Wipers and Washers. Switch ............................................... 16

Windscreen Wipers and Washers. Single Wipe Operation ................................. 16

Windscreen Wipers and Washers. Programmed Wash / Wipe Operation ..................... 77

Windscreen Wipers and Washers. Headlamp Power Wash Operation ....................... 17

Closures Switching .................................................................. 18

In-Car Entertainment ................................................................ 19

Lamps & Lighting Logic .............................................................. 20

Lamps & Lighting Logic. Exterior Lighting. General Description ............................ 20

Lamps & Lighting Logic. Interior Lighting. General Description ............................ 21

Harnesses &Cables ................................................................. 22

Harnesses

& Cables. Battery Power Distribution Cables. General ........................... 22

Harnesses & Cables. Main Harnesses. General Description ................................ 24

Harnesses & Cables. Link Harnesses. General Description ................................. 26

Harnesses & Cables. Harness Connectors. General Description ............................. 28

Motors and Solenoids ................................................................ 30

Motors and Solenoids. General Description ............................................. 30

Relays ........................................................................\

..... 32

Relays. Engine Compartment. General Description ....................................... 32

Relays. Passenger Compartment. General Description .................................... 34

Relays. Trunk. General Description .................................................... 36

Control Modules .................................................................... 38

Control Modules. General Description ................................................. 38

Page 340 of 521

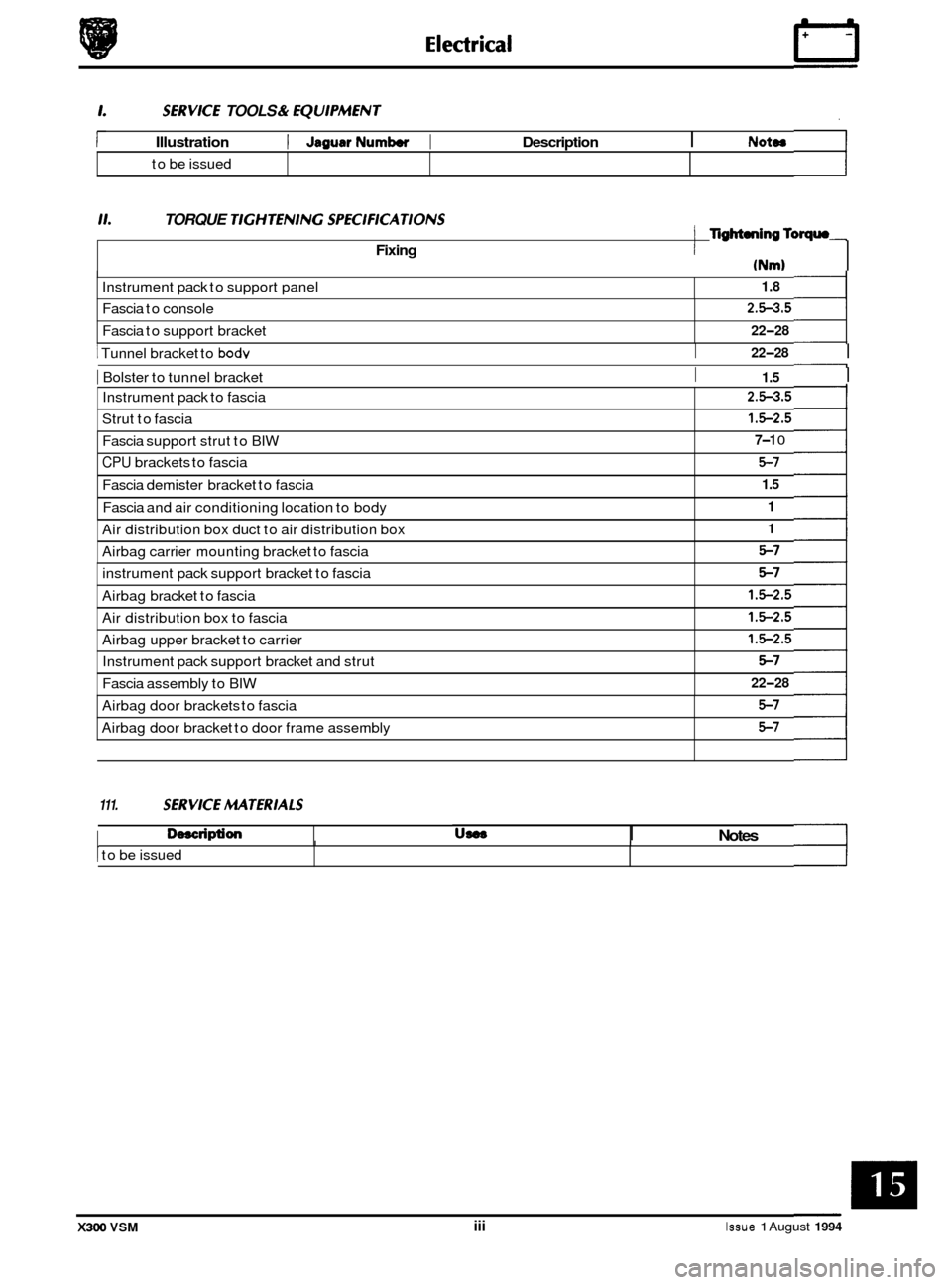

SERVKE TOOLS & EQU1PMENT

Illustration I JagusrNumbw I Description I NOtOS

Instrument pack to support panel

to

be issued

11. TORQUE TlGHTENlNG SPEC1FKATIONS

1.8

Fixing

Fascia to console

Fascia to support bracket

(Nm)

I TigM.ningToqrn

I

2.5-3.5

22-28

Instrument pack to fascia

Strut to fascia 2.5-3.5

1.5-2.5

I I 22-28 1 Tunnel bracket to bodv

I Bolster to tunnel bracket I 1.5 I

Fascia support strut to BIW 7-1 0

CPU brackets to fascia 5-7

Fascia demister bracket to fascia 1.5

Fascia and air conditioning location to body 1

Air distribution box duct to air distribution box

Airbag carrier mounting bracket to fascia 1

5-7

instrument pack support bracket to fascia

Airbag bracket to fascia 5-7

1.5-2.5

Air distribution box to fascia

Airbag upper bracket to carrier 1.5-2.5

1.5-2.5

Instrument pack support bracket and strut

Fascia assembly to BIW 5-7

22-28

111. SERVKE MTERlALS

0, Description

Airbag door brackets to fascia

Airbag door bracket to door frame assembly 5-7

5-7

US08 Notes I I

1 to be issued I I

X300 VSM iii Issue 1 August 1994