JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1851 of 2198

BODY PANEL SURFACE PREPARATION

(1) The area that will be covered by the tape

stripe/decal must be cleaned with an cleaning solu-

tion to remove any residue paint.

(2) Freshly painted surfaces must be thoroughly

dry.

(3) Clean painted surface with a commercial wax

and silicone removal solution. Wipe surface with a

clean cloth and allow to dry.

REPLACEMENT ON ONE PANEL

For large tape stripes/decals, use a clean sponge

and apply ample wetting solution to the adhesive

side of the tape stripe/decal, and to the painted panel

surface.

The wetting solution will permit ease of tape

stripe/decal movement when positioning it on the

panel.

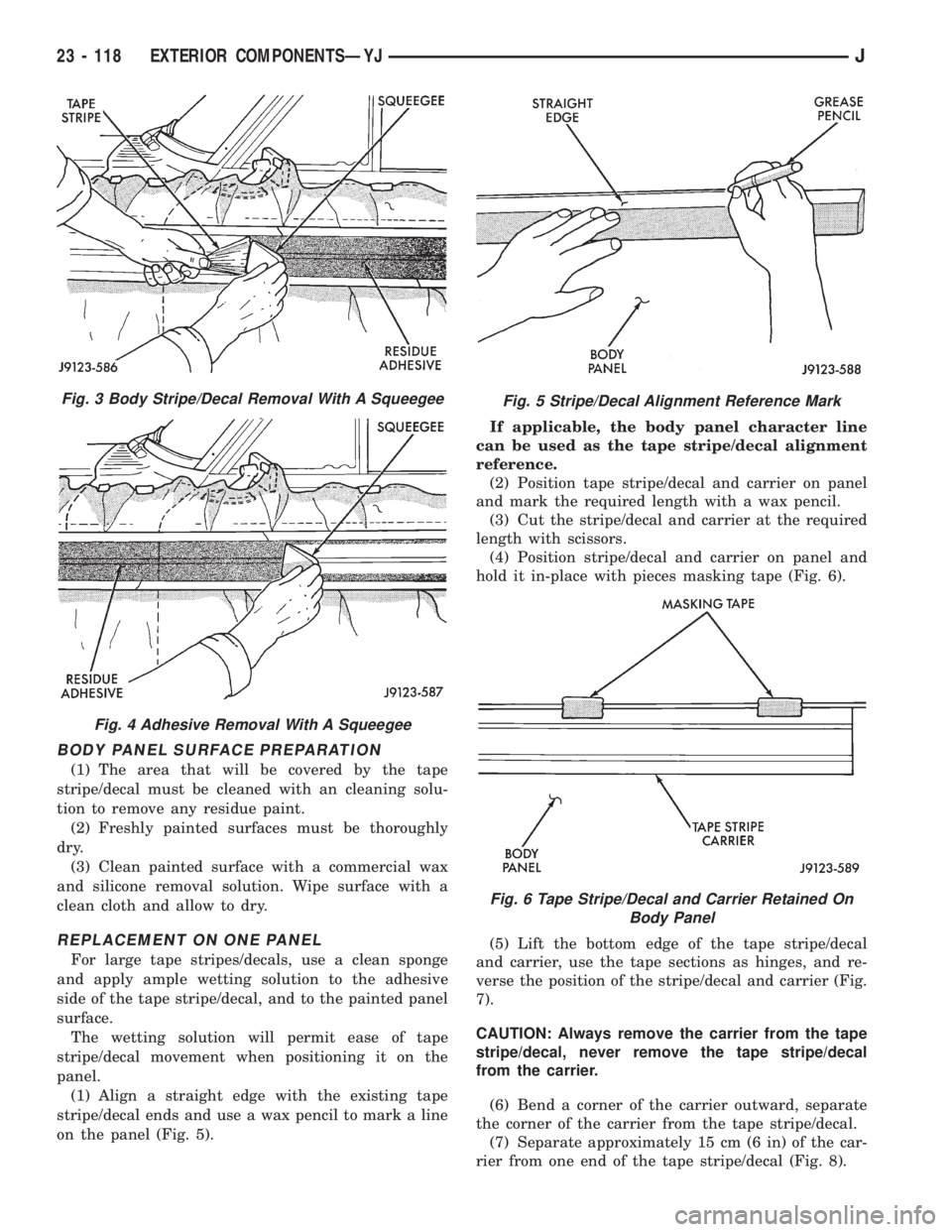

(1) Align a straight edge with the existing tape

stripe/decal ends and use a wax pencil to mark a line

on the panel (Fig. 5).If applicable, the body panel character line

can be used as the tape stripe/decal alignment

reference.

(2) Position tape stripe/decal and carrier on panel

and mark the required length with a wax pencil.

(3) Cut the stripe/decal and carrier at the required

length with scissors.

(4) Position stripe/decal and carrier on panel and

hold it in-place with pieces masking tape (Fig. 6).

(5) Lift the bottom edge of the tape stripe/decal

and carrier, use the tape sections as hinges, and re-

verse the position of the stripe/decal and carrier (Fig.

7).

CAUTION: Always remove the carrier from the tape

stripe/decal, never remove the tape stripe/decal

from the carrier.

(6) Bend a corner of the carrier outward, separate

the corner of the carrier from the tape stripe/decal.

(7) Separate approximately 15 cm (6 in) of the car-

rier from one end of the tape stripe/decal (Fig. 8).

Fig. 3 Body Stripe/Decal Removal With A Squeegee

Fig. 4 Adhesive Removal With A Squeegee

Fig. 5 Stripe/Decal Alignment Reference Mark

Fig. 6 Tape Stripe/Decal and Carrier Retained On

Body Panel

23 - 118 EXTERIOR COMPONENTSÐYJJ

Page 1852 of 2198

(8) Return the tape stripe/decal back to its original

position. If a wetting solution is used, position the

adhesive side of the tape stripe/decal on the panel.

Apply wetting solution to the outside of the tape

stripe/decal. Use firm strokes with a squeegee to ad-

here the tape stripe/decal to the body.

(9) Hold tape stripe/decal firmly against the panel

surface while separating the carrier from the tape

stripe/decal (Fig. 9).

(10) Where applicable, extend the tape stripe/decal

12 mm (1/2 in) beyond the door edge. Next, wrap it

around on the flange and adhere it to the door flange

(Fig. 10).Use care to avoid trapping air under

the tape stripe/decal.Where necessary, trim excess

tape stripe/decal.

(11) If applicable, remove the cover from the face of

the tape stripe/decal.

(12) Inspect tape stripe/decal with reflected light to

check for defects that could have developed during

the installation process. Remove all air and/or mois-

ture bubbles.COMPLETE REPLACEMENT

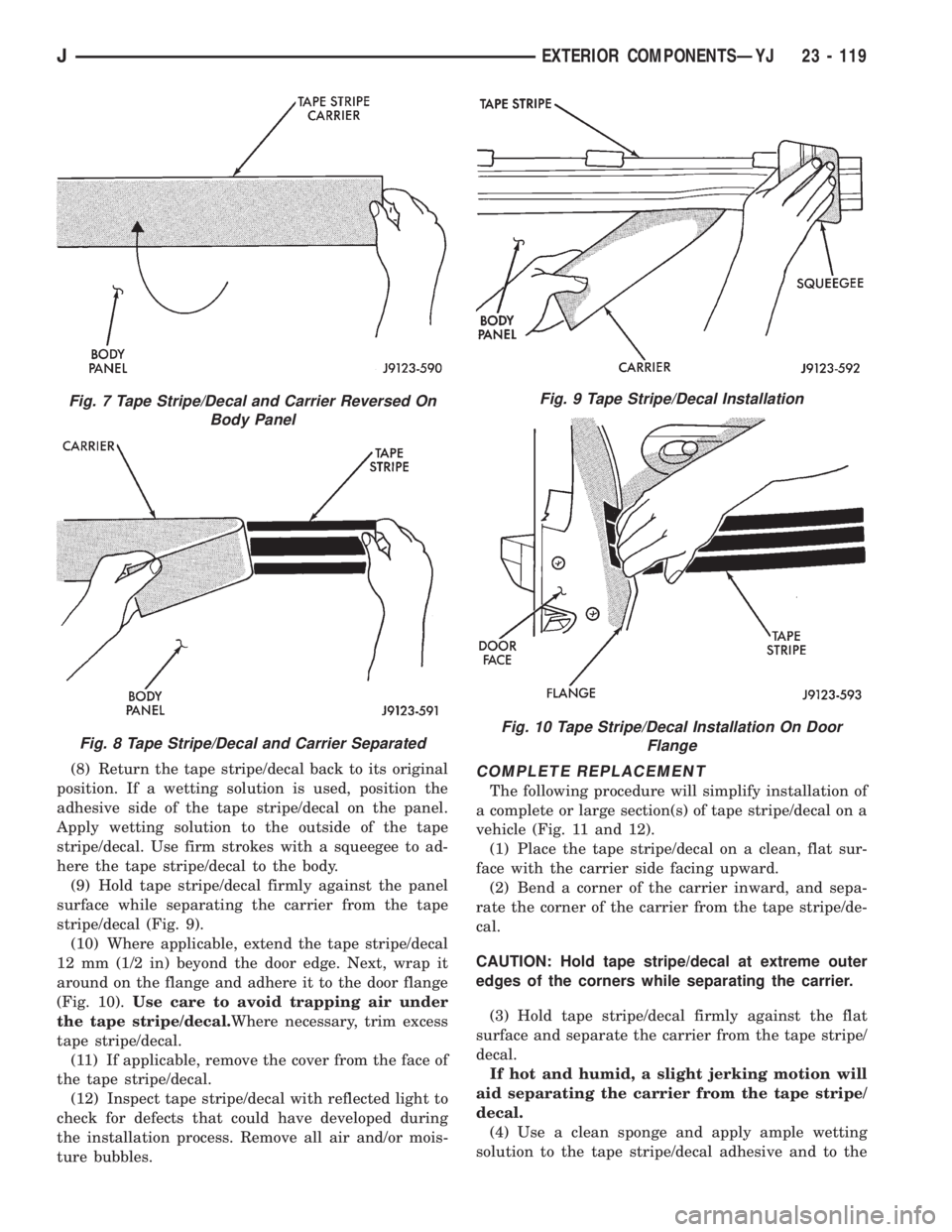

The following procedure will simplify installation of

a complete or large section(s) of tape stripe/decal on a

vehicle (Fig. 11 and 12).

(1) Place the tape stripe/decal on a clean, flat sur-

face with the carrier side facing upward.

(2) Bend a corner of the carrier inward, and sepa-

rate the corner of the carrier from the tape stripe/de-

cal.

CAUTION: Hold tape stripe/decal at extreme outer

edges of the corners while separating the carrier.

(3) Hold tape stripe/decal firmly against the flat

surface and separate the carrier from the tape stripe/

decal.

If hot and humid, a slight jerking motion will

aid separating the carrier from the tape stripe/

decal.

(4) Use a clean sponge and apply ample wetting

solution to the tape stripe/decal adhesive and to the

Fig. 7 Tape Stripe/Decal and Carrier Reversed On

Body Panel

Fig. 8 Tape Stripe/Decal and Carrier Separated

Fig. 9 Tape Stripe/Decal Installation

Fig. 10 Tape Stripe/Decal Installation On Door

Flange

JEXTERIOR COMPONENTSÐYJ 23 - 119

Page 1853 of 2198

painted panel surface. The solution will permit ease

of tape stripe/decal movement when positioning it on

the panel.

(5) Position adhesive-coated side of tape stripe/de-

cal on the panel with the bottom aligned with char-

acter line. Where applicable:

²align the end of the replacement tape stripe/decal

with the end of the existing tape stripe/decal, and

correctly align the index darts and index notches.

(6) If a complete replacement tape stripe/decal is

not being installed:

²Position the replacement tape stripe/decal section

at the center of the repair area.

²Align it with the existing tape stripe/decal and al-

low at least 12 mm (1/2 in) of the tape stripe/decal

section to overlap the existing tape stripe/decal

edges.(7) Apply wetting solution to the outer side of the

tape stripe/decal to allow the squeegee to freely slide

while adhering the stripe/decal to the panel.

CAUTION: Avoid unnecessary pulling and stretch-

ing at the ends of the tape stripe/decal because this

could cause it to tear.

(8) Position and slide a squeegee from the center to

the ends of the tape stripe/decal. This will ensure

complete bonding of the tape stripe/decal to the

painted panel surface.

(9) If a wrinkle is trapped in the tape stripe/decal

during the squeegee operation, stop. Lift wrinkled

area and re-align stripe/decal with panel character

line.Do not lift the tape stripe/decal if only a

few air bubbles exist.

(10) Where applicable, allow 12 mm (1/2 in) extra

tape stripe/decal to extend beyond the edges to be

folded over.

(11) Fold the excess tape stripe/decal back onto in-

side flange area.Use care to avoid trapping air

under the tape stripe/decal.Where necessary, trim

excess tape stripe/decal.

(12) Inspect tape installation with reflected light to

detect any defects that could have developed during

the installation.

(13) Remove all air and moisture bubbles from the

tape stripe/decal with a needle or pin.

(14) Install any removed components and clean the

vehicle as necessary.

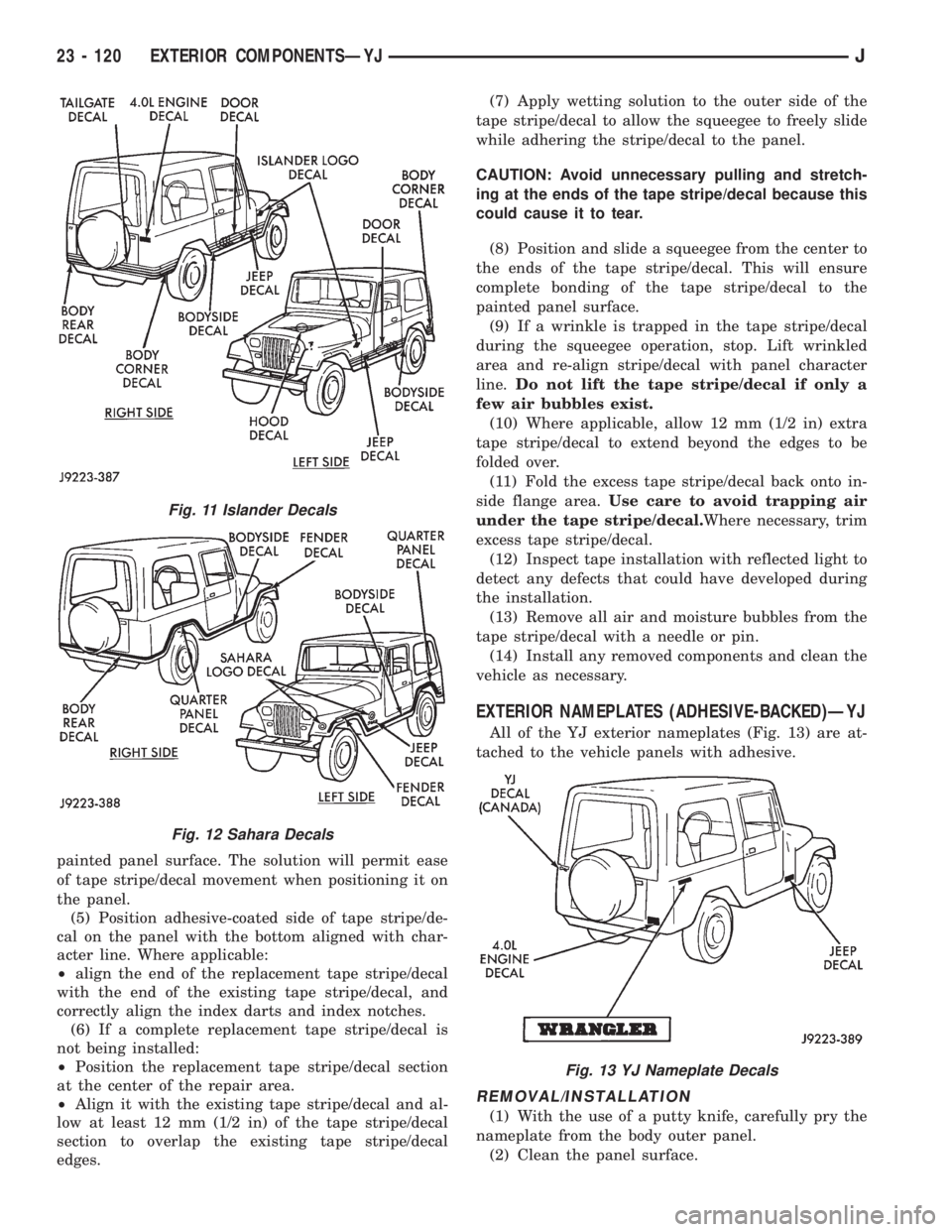

EXTERIOR NAMEPLATES (ADHESIVE-BACKED)ÐYJ

All of the YJ exterior nameplates (Fig. 13) are at-

tached to the vehicle panels with adhesive.

REMOVAL/INSTALLATION

(1) With the use of a putty knife, carefully pry the

nameplate from the body outer panel.

(2) Clean the panel surface.

Fig. 11 Islander Decals

Fig. 12 Sahara Decals

Fig. 13 YJ Nameplate Decals

23 - 120 EXTERIOR COMPONENTSÐYJJ

Page 1854 of 2198

(3) Position the replacement nameplate on the

panel and apply inward force to seat it.

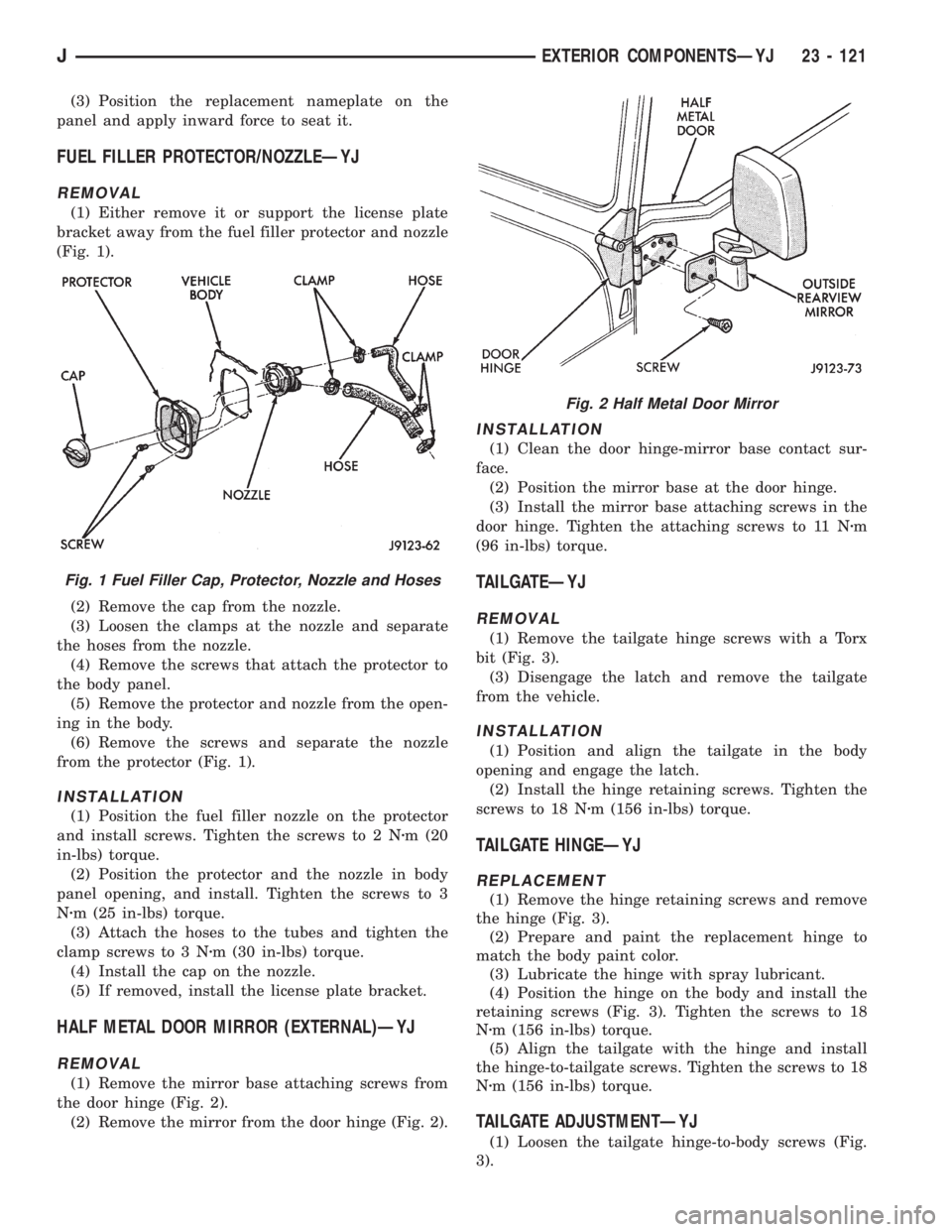

FUEL FILLER PROTECTOR/NOZZLEÐYJ

REMOVAL

(1) Either remove it or support the license plate

bracket away from the fuel filler protector and nozzle

(Fig. 1).

(2) Remove the cap from the nozzle.

(3) Loosen the clamps at the nozzle and separate

the hoses from the nozzle.

(4) Remove the screws that attach the protector to

the body panel.

(5) Remove the protector and nozzle from the open-

ing in the body.

(6) Remove the screws and separate the nozzle

from the protector (Fig. 1).

INSTALLATION

(1) Position the fuel filler nozzle on the protector

and install screws. Tighten the screws to 2 Nzm (20

in-lbs) torque.

(2) Position the protector and the nozzle in body

panel opening, and install. Tighten the screws to 3

Nzm (25 in-lbs) torque.

(3) Attach the hoses to the tubes and tighten the

clamp screws to 3 Nzm (30 in-lbs) torque.

(4) Install the cap on the nozzle.

(5) If removed, install the license plate bracket.

HALF METAL DOOR MIRROR (EXTERNAL)ÐYJ

REMOVAL

(1) Remove the mirror base attaching screws from

the door hinge (Fig. 2).

(2) Remove the mirror from the door hinge (Fig. 2).

INSTALLATION

(1) Clean the door hinge-mirror base contact sur-

face.

(2) Position the mirror base at the door hinge.

(3) Install the mirror base attaching screws in the

door hinge. Tighten the attaching screws to 11 Nzm

(96 in-lbs) torque.

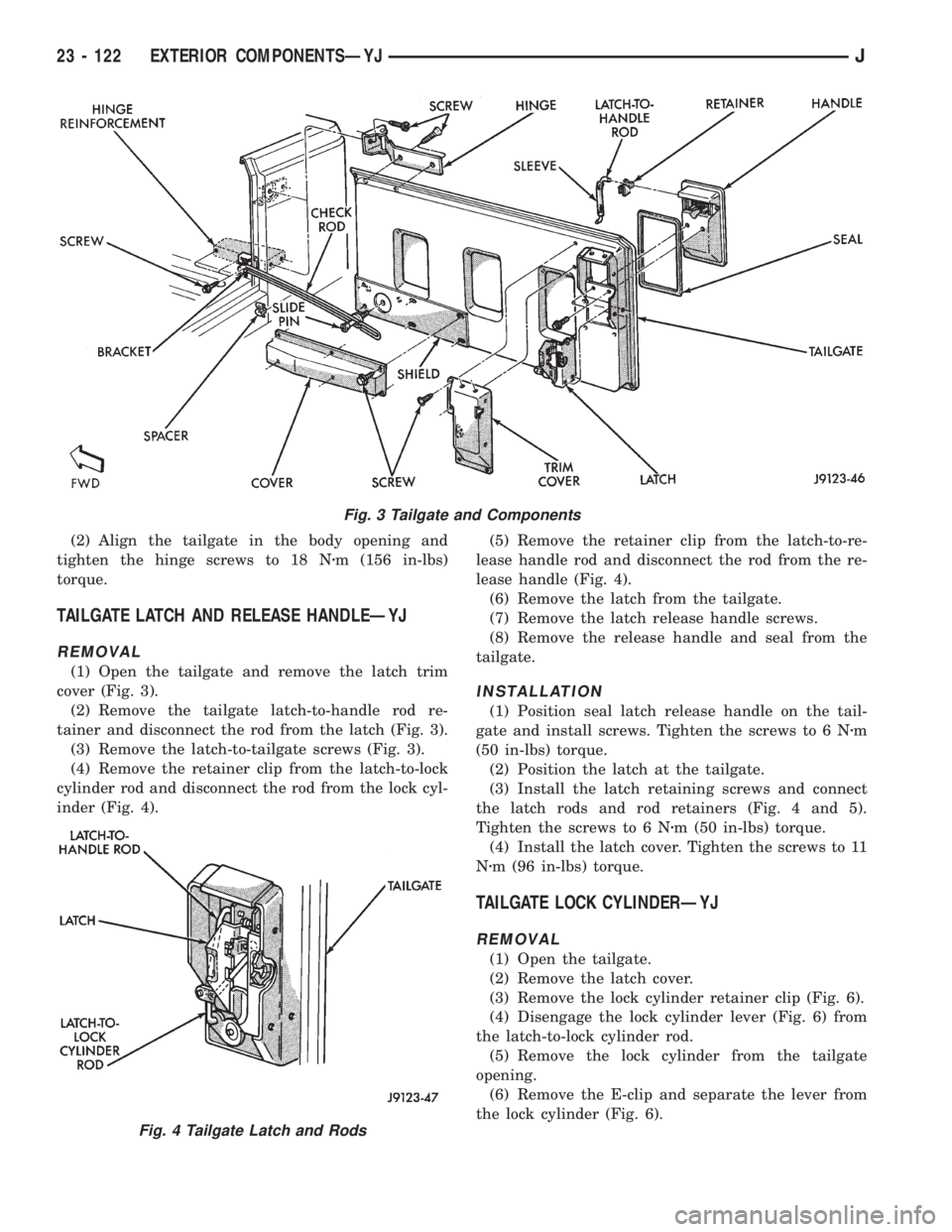

TAILGATEÐYJ

REMOVAL

(1) Remove the tailgate hinge screws with a Torx

bit (Fig. 3).

(3) Disengage the latch and remove the tailgate

from the vehicle.

INSTALLATION

(1) Position and align the tailgate in the body

opening and engage the latch.

(2) Install the hinge retaining screws. Tighten the

screws to 18 Nzm (156 in-lbs) torque.

TAILGATE HINGEÐYJ

REPLACEMENT

(1) Remove the hinge retaining screws and remove

the hinge (Fig. 3).

(2) Prepare and paint the replacement hinge to

match the body paint color.

(3) Lubricate the hinge with spray lubricant.

(4) Position the hinge on the body and install the

retaining screws (Fig. 3). Tighten the screws to 18

Nzm (156 in-lbs) torque.

(5) Align the tailgate with the hinge and install

the hinge-to-tailgate screws. Tighten the screws to 18

Nzm (156 in-lbs) torque.

TAILGATE ADJUSTMENTÐYJ

(1) Loosen the tailgate hinge-to-body screws (Fig.

3).

Fig. 1 Fuel Filler Cap, Protector, Nozzle and Hoses

Fig. 2 Half Metal Door Mirror

JEXTERIOR COMPONENTSÐYJ 23 - 121

Page 1855 of 2198

(2) Align the tailgate in the body opening and

tighten the hinge screws to 18 Nzm (156 in-lbs)

torque.

TAILGATE LATCH AND RELEASE HANDLEÐYJ

REMOVAL

(1) Open the tailgate and remove the latch trim

cover (Fig. 3).

(2) Remove the tailgate latch-to-handle rod re-

tainer and disconnect the rod from the latch (Fig. 3).

(3) Remove the latch-to-tailgate screws (Fig. 3).

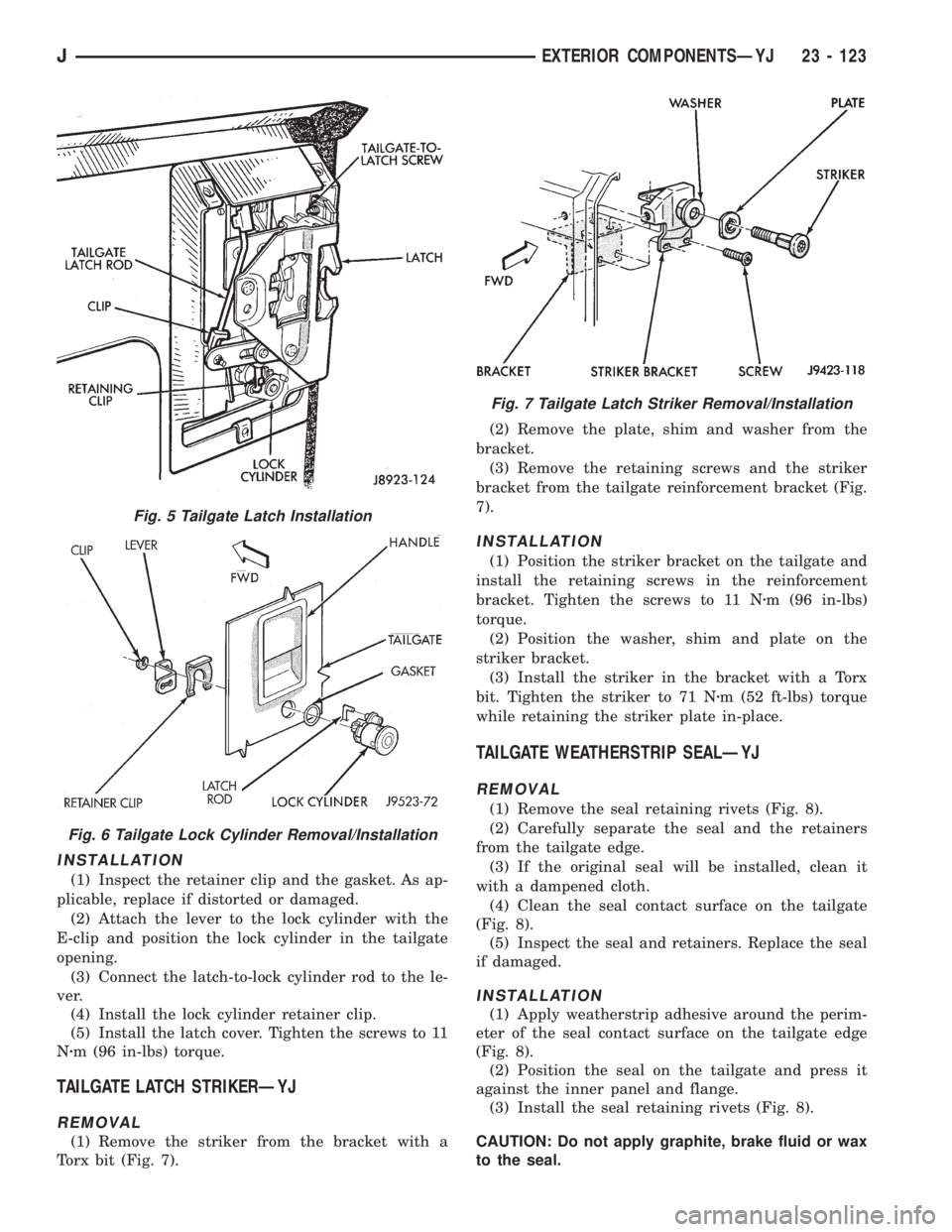

(4) Remove the retainer clip from the latch-to-lock

cylinder rod and disconnect the rod from the lock cyl-

inder (Fig. 4).(5) Remove the retainer clip from the latch-to-re-

lease handle rod and disconnect the rod from the re-

lease handle (Fig. 4).

(6) Remove the latch from the tailgate.

(7) Remove the latch release handle screws.

(8) Remove the release handle and seal from the

tailgate.

INSTALLATION

(1) Position seal latch release handle on the tail-

gate and install screws. Tighten the screws to 6 Nzm

(50 in-lbs) torque.

(2) Position the latch at the tailgate.

(3) Install the latch retaining screws and connect

the latch rods and rod retainers (Fig. 4 and 5).

Tighten the screws to 6 Nzm (50 in-lbs) torque.

(4) Install the latch cover. Tighten the screws to 11

Nzm (96 in-lbs) torque.

TAILGATE LOCK CYLINDERÐYJ

REMOVAL

(1) Open the tailgate.

(2) Remove the latch cover.

(3) Remove the lock cylinder retainer clip (Fig. 6).

(4) Disengage the lock cylinder lever (Fig. 6) from

the latch-to-lock cylinder rod.

(5) Remove the lock cylinder from the tailgate

opening.

(6) Remove the E-clip and separate the lever from

the lock cylinder (Fig. 6).

Fig. 3 Tailgate and Components

Fig. 4 Tailgate Latch and Rods

23 - 122 EXTERIOR COMPONENTSÐYJJ

Page 1856 of 2198

INSTALLATION

(1) Inspect the retainer clip and the gasket. As ap-

plicable, replace if distorted or damaged.

(2) Attach the lever to the lock cylinder with the

E-clip and position the lock cylinder in the tailgate

opening.

(3) Connect the latch-to-lock cylinder rod to the le-

ver.

(4) Install the lock cylinder retainer clip.

(5) Install the latch cover. Tighten the screws to 11

Nzm (96 in-lbs) torque.

TAILGATE LATCH STRIKERÐYJ

REMOVAL

(1) Remove the striker from the bracket with a

Torx bit (Fig. 7).(2) Remove the plate, shim and washer from the

bracket.

(3) Remove the retaining screws and the striker

bracket from the tailgate reinforcement bracket (Fig.

7).

INSTALLATION

(1) Position the striker bracket on the tailgate and

install the retaining screws in the reinforcement

bracket. Tighten the screws to 11 Nzm (96 in-lbs)

torque.

(2) Position the washer, shim and plate on the

striker bracket.

(3) Install the striker in the bracket with a Torx

bit. Tighten the striker to 71 Nzm (52 ft-lbs) torque

while retaining the striker plate in-place.

TAILGATE WEATHERSTRIP SEALÐYJ

REMOVAL

(1) Remove the seal retaining rivets (Fig. 8).

(2) Carefully separate the seal and the retainers

from the tailgate edge.

(3) If the original seal will be installed, clean it

with a dampened cloth.

(4) Clean the seal contact surface on the tailgate

(Fig. 8).

(5) Inspect the seal and retainers. Replace the seal

if damaged.

INSTALLATION

(1) Apply weatherstrip adhesive around the perim-

eter of the seal contact surface on the tailgate edge

(Fig. 8).

(2) Position the seal on the tailgate and press it

against the inner panel and flange.

(3) Install the seal retaining rivets (Fig. 8).

CAUTION: Do not apply graphite, brake fluid or wax

to the seal.

Fig. 5 Tailgate Latch Installation

Fig. 6 Tailgate Lock Cylinder Removal/Installation

Fig. 7 Tailgate Latch Striker Removal/Installation

JEXTERIOR COMPONENTSÐYJ 23 - 123

Page 1857 of 2198

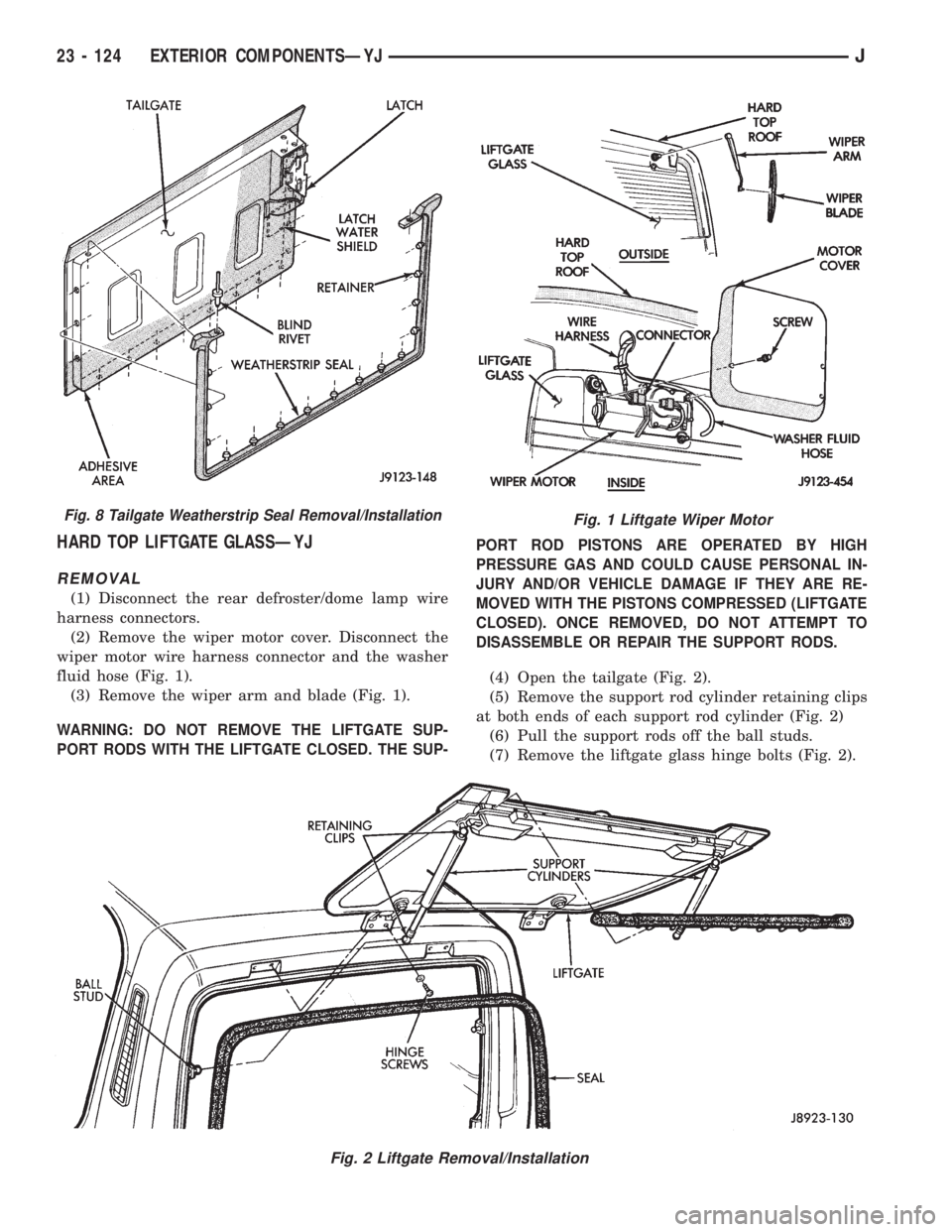

HARD TOP LIFTGATE GLASSÐYJ

REMOVAL

(1) Disconnect the rear defroster/dome lamp wire

harness connectors.

(2) Remove the wiper motor cover. Disconnect the

wiper motor wire harness connector and the washer

fluid hose (Fig. 1).

(3) Remove the wiper arm and blade (Fig. 1).

WARNING: DO NOT REMOVE THE LIFTGATE SUP-

PORT RODS WITH THE LIFTGATE CLOSED. THE SUP-PORT ROD PISTONS ARE OPERATED BY HIGH

PRESSURE GAS AND COULD CAUSE PERSONAL IN-

JURY AND/OR VEHICLE DAMAGE IF THEY ARE RE-

MOVED WITH THE PISTONS COMPRESSED (LIFTGATE

CLOSED). ONCE REMOVED, DO NOT ATTEMPT TO

DISASSEMBLE OR REPAIR THE SUPPORT RODS.

(4) Open the tailgate (Fig. 2).

(5) Remove the support rod cylinder retaining clips

at both ends of each support rod cylinder (Fig. 2)

(6) Pull the support rods off the ball studs.

(7) Remove the liftgate glass hinge bolts (Fig. 2).

Fig. 1 Liftgate Wiper Motor

Fig. 2 Liftgate Removal/Installation

Fig. 8 Tailgate Weatherstrip Seal Removal/Installation

23 - 124 EXTERIOR COMPONENTSÐYJJ

Page 1858 of 2198

(8) Separate the liftgate glass from the hard top.

(9) Remove the weatherstrip seal (Fig. 2), if neces-

sary.

INSTALLATION

(1) Assemble the liftgate components, if necessary

(2) Position the liftgate glass in the hard top open-

ing and install the hinge bolts. Do not tighten the

bolts.

(3) Adjust the liftgate glass to fit the hard top

opening.

(4) Tighten the hinge bolts to 11 Nzm (95 in-lbs)

torque.

(5) Position the support rod cylinders on the ball

studs.

(6) Install the support rod cylinder retainer clips.

(7) Connect the wiper motor wire harness connec-

tor and the washer fluid hose. Install the wiper mo-

tor cover (Fig. 1).

(8) Install the wiper arm and blade.

(9) Connect the rear window defroster/dome lamp

wire harness connectors.

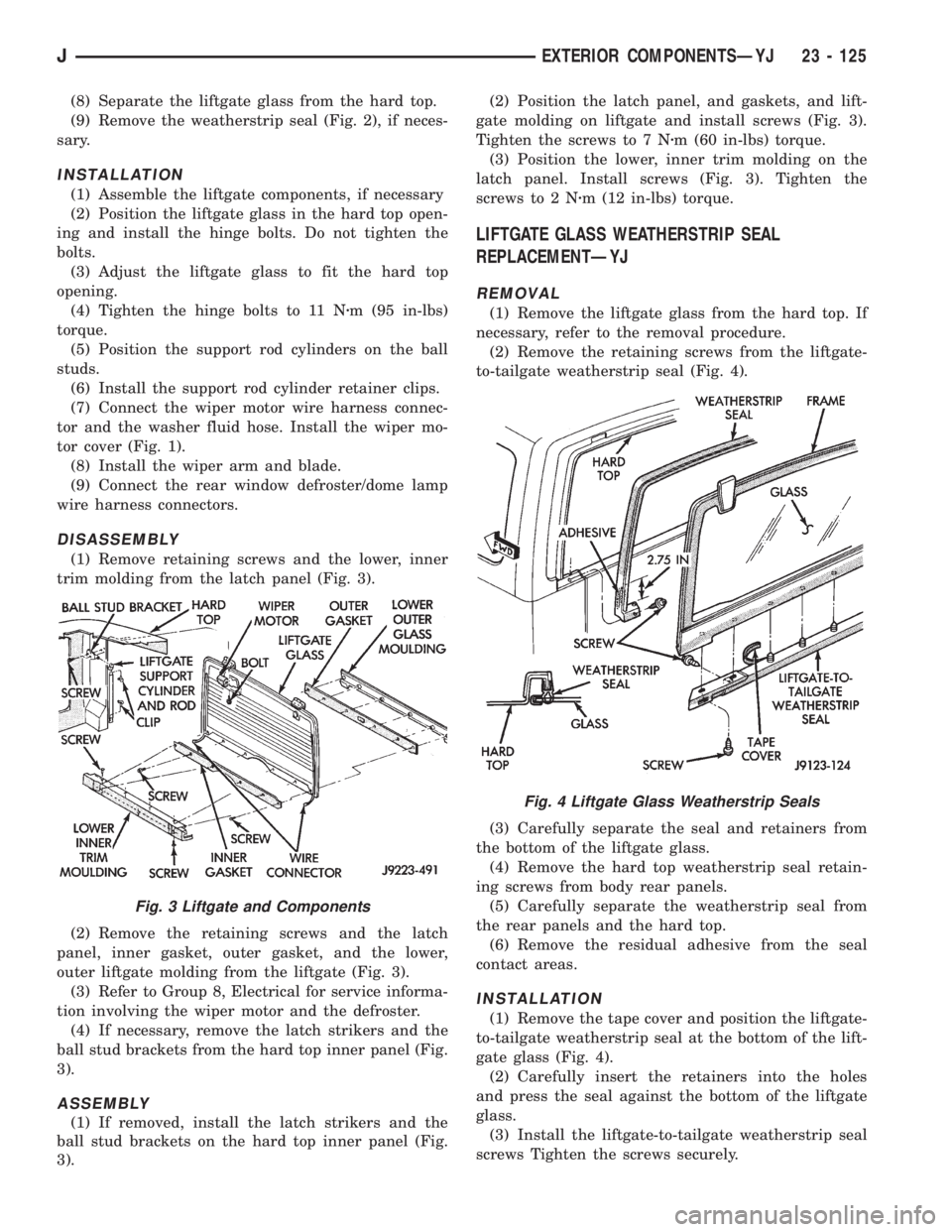

DISASSEMBLY

(1) Remove retaining screws and the lower, inner

trim molding from the latch panel (Fig. 3).

(2) Remove the retaining screws and the latch

panel, inner gasket, outer gasket, and the lower,

outer liftgate molding from the liftgate (Fig. 3).

(3) Refer to Group 8, Electrical for service informa-

tion involving the wiper motor and the defroster.

(4) If necessary, remove the latch strikers and the

ball stud brackets from the hard top inner panel (Fig.

3).

ASSEMBLY

(1) If removed, install the latch strikers and the

ball stud brackets on the hard top inner panel (Fig.

3).(2) Position the latch panel, and gaskets, and lift-

gate molding on liftgate and install screws (Fig. 3).

Tighten the screws to 7 Nzm (60 in-lbs) torque.

(3) Position the lower, inner trim molding on the

latch panel. Install screws (Fig. 3). Tighten the

screws to 2 Nzm (12 in-lbs) torque.

LIFTGATE GLASS WEATHERSTRIP SEAL

REPLACEMENTÐYJ

REMOVAL

(1) Remove the liftgate glass from the hard top. If

necessary, refer to the removal procedure.

(2) Remove the retaining screws from the liftgate-

to-tailgate weatherstrip seal (Fig. 4).

(3) Carefully separate the seal and retainers from

the bottom of the liftgate glass.

(4) Remove the hard top weatherstrip seal retain-

ing screws from body rear panels.

(5) Carefully separate the weatherstrip seal from

the rear panels and the hard top.

(6) Remove the residual adhesive from the seal

contact areas.

INSTALLATION

(1) Remove the tape cover and position the liftgate-

to-tailgate weatherstrip seal at the bottom of the lift-

gate glass (Fig. 4).

(2) Carefully insert the retainers into the holes

and press the seal against the bottom of the liftgate

glass.

(3) Install the liftgate-to-tailgate weatherstrip seal

screws Tighten the screws securely.

Fig. 3 Liftgate and Components

Fig. 4 Liftgate Glass Weatherstrip Seals

JEXTERIOR COMPONENTSÐYJ 23 - 125

Page 1859 of 2198

(4) Apply weatherstrip adhesive to the hard top

weatherstrip seal (Fig. 4).

(5) Carefully position the weatherstrip seal on the

rear panels and the hard top.

(6) Press the seal onto the hard top flange and en-

sure that it is correctly seated on the flange.

(7) Install the seal retaining screws in the rear

panels and tighten them securely.

HARD TOPÐYJ

The hard top is constructed of compressed molded

fiberglass and painted to a special spatter paint. The

hard top can be removed for service access or for

other purposes.

REMOVAL

CAUTION: When removing the hard top, avoid dam-

aging the foam sealant between the hard top and

body panels.

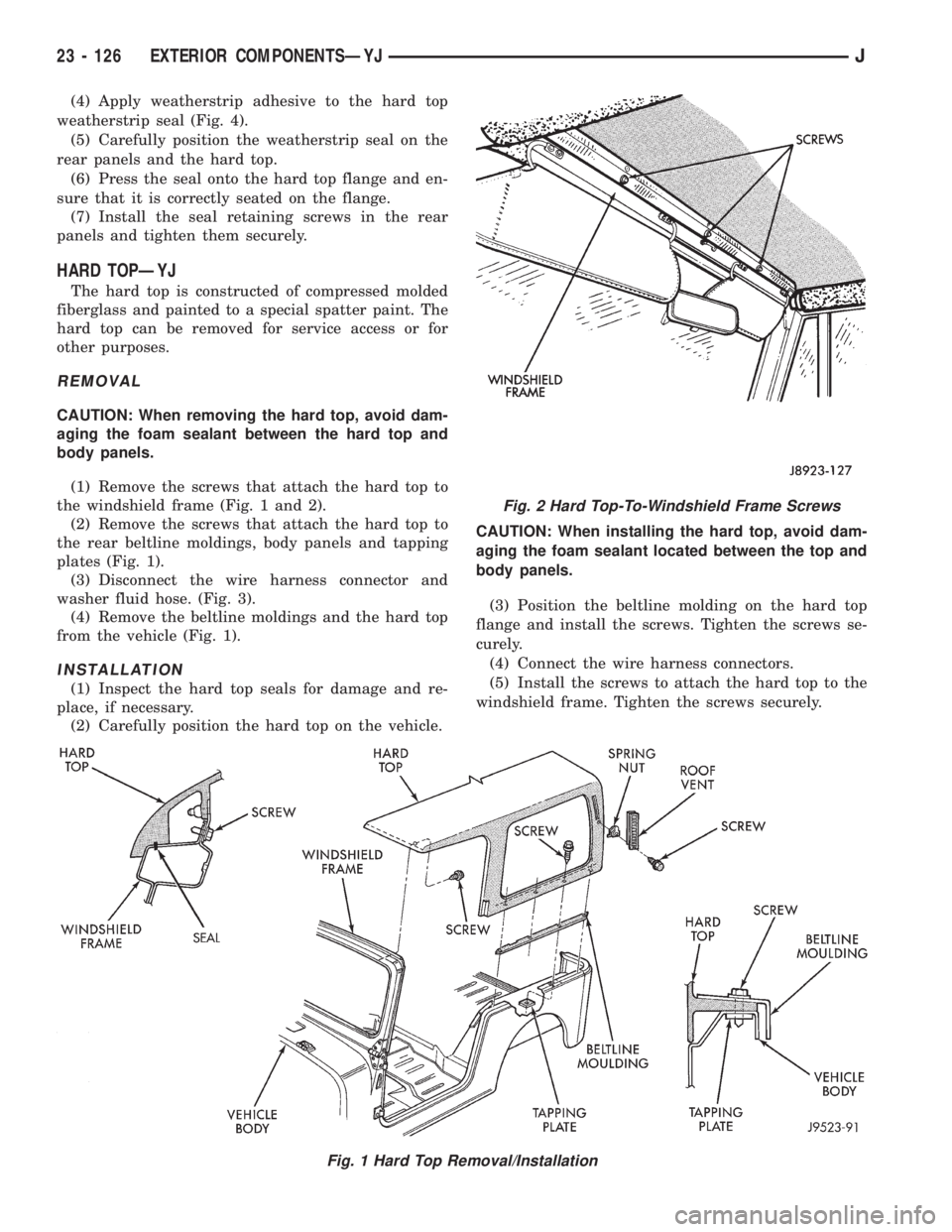

(1) Remove the screws that attach the hard top to

the windshield frame (Fig. 1 and 2).

(2) Remove the screws that attach the hard top to

the rear beltline moldings, body panels and tapping

plates (Fig. 1).

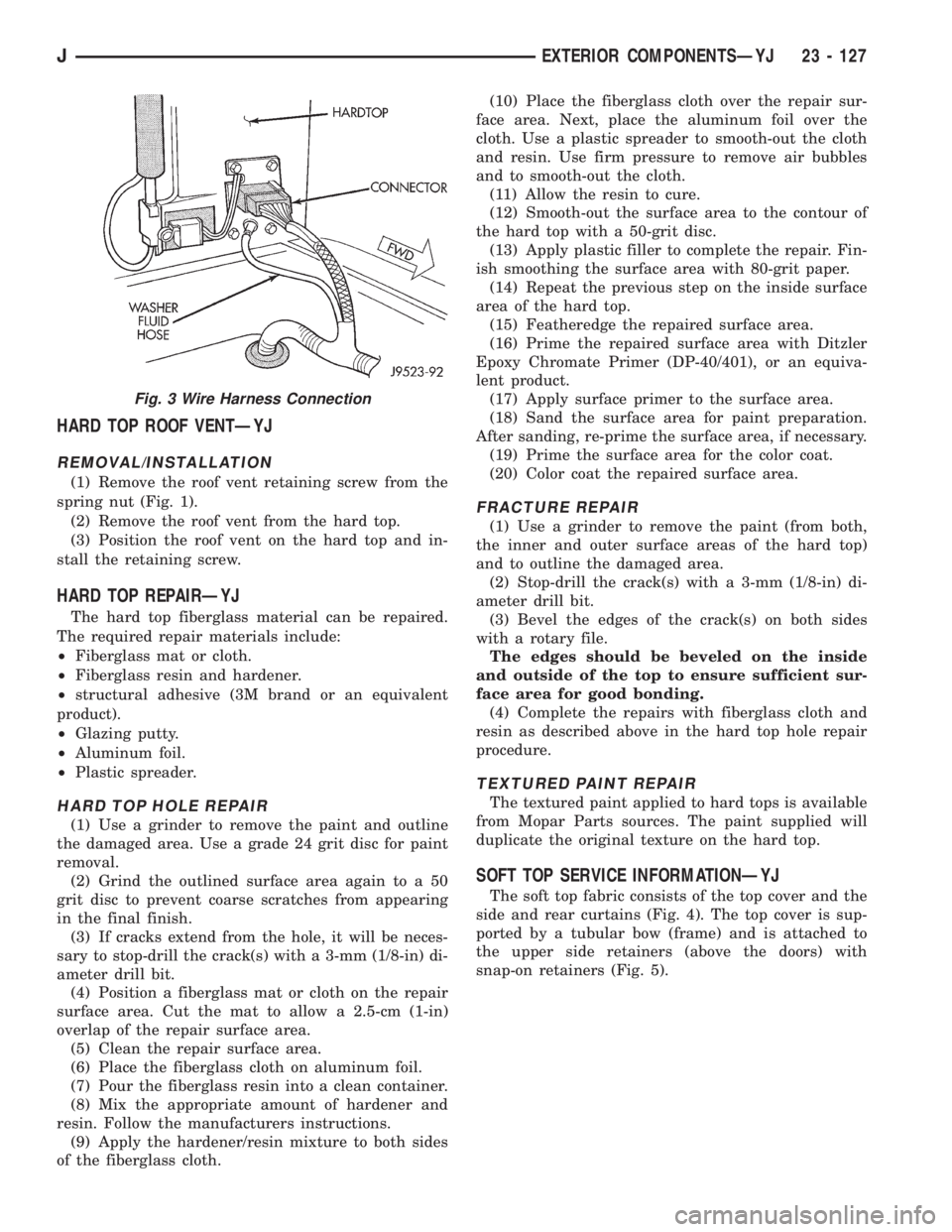

(3) Disconnect the wire harness connector and

washer fluid hose. (Fig. 3).

(4) Remove the beltline moldings and the hard top

from the vehicle (Fig. 1).

INSTALLATION

(1) Inspect the hard top seals for damage and re-

place, if necessary.

(2) Carefully position the hard top on the vehicle.CAUTION: When installing the hard top, avoid dam-

aging the foam sealant located between the top and

body panels.

(3) Position the beltline molding on the hard top

flange and install the screws. Tighten the screws se-

curely.

(4) Connect the wire harness connectors.

(5) Install the screws to attach the hard top to the

windshield frame. Tighten the screws securely.

Fig. 1 Hard Top Removal/Installation

Fig. 2 Hard Top-To-Windshield Frame Screws

23 - 126 EXTERIOR COMPONENTSÐYJJ

Page 1860 of 2198

HARD TOP ROOF VENTÐYJ

REMOVAL/INSTALLATION

(1) Remove the roof vent retaining screw from the

spring nut (Fig. 1).

(2) Remove the roof vent from the hard top.

(3) Position the roof vent on the hard top and in-

stall the retaining screw.

HARD TOP REPAIRÐYJ

The hard top fiberglass material can be repaired.

The required repair materials include:

²Fiberglass mat or cloth.

²Fiberglass resin and hardener.

²structural adhesive (3M brand or an equivalent

product).

²Glazing putty.

²Aluminum foil.

²Plastic spreader.

HARD TOP HOLE REPAIR

(1) Use a grinder to remove the paint and outline

the damaged area. Use a grade 24 grit disc for paint

removal.

(2) Grind the outlined surface area again to a 50

grit disc to prevent coarse scratches from appearing

in the final finish.

(3) If cracks extend from the hole, it will be neces-

sary to stop-drill the crack(s) with a 3-mm (1/8-in) di-

ameter drill bit.

(4) Position a fiberglass mat or cloth on the repair

surface area. Cut the mat to allow a 2.5-cm (1-in)

overlap of the repair surface area.

(5) Clean the repair surface area.

(6) Place the fiberglass cloth on aluminum foil.

(7) Pour the fiberglass resin into a clean container.

(8) Mix the appropriate amount of hardener and

resin. Follow the manufacturers instructions.

(9) Apply the hardener/resin mixture to both sides

of the fiberglass cloth.(10) Place the fiberglass cloth over the repair sur-

face area. Next, place the aluminum foil over the

cloth. Use a plastic spreader to smooth-out the cloth

and resin. Use firm pressure to remove air bubbles

and to smooth-out the cloth.

(11) Allow the resin to cure.

(12) Smooth-out the surface area to the contour of

the hard top with a 50-grit disc.

(13) Apply plastic filler to complete the repair. Fin-

ish smoothing the surface area with 80-grit paper.

(14) Repeat the previous step on the inside surface

area of the hard top.

(15) Featheredge the repaired surface area.

(16) Prime the repaired surface area with Ditzler

Epoxy Chromate Primer (DP-40/401), or an equiva-

lent product.

(17) Apply surface primer to the surface area.

(18) Sand the surface area for paint preparation.

After sanding, re-prime the surface area, if necessary.

(19) Prime the surface area for the color coat.

(20) Color coat the repaired surface area.

FRACTURE REPAIR

(1) Use a grinder to remove the paint (from both,

the inner and outer surface areas of the hard top)

and to outline the damaged area.

(2) Stop-drill the crack(s) with a 3-mm (1/8-in) di-

ameter drill bit.

(3) Bevel the edges of the crack(s) on both sides

with a rotary file.

The edges should be beveled on the inside

and outside of the top to ensure sufficient sur-

face area for good bonding.

(4) Complete the repairs with fiberglass cloth and

resin as described above in the hard top hole repair

procedure.

TEXTURED PAINT REPAIR

The textured paint applied to hard tops is available

from Mopar Parts sources. The paint supplied will

duplicate the original texture on the hard top.

SOFT TOP SERVICE INFORMATIONÐYJ

The soft top fabric consists of the top cover and the

side and rear curtains (Fig. 4). The top cover is sup-

ported by a tubular bow (frame) and is attached to

the upper side retainers (above the doors) with

snap-on retainers (Fig. 5).

Fig. 3 Wire Harness Connection

JEXTERIOR COMPONENTSÐYJ 23 - 127