JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1841 of 2198

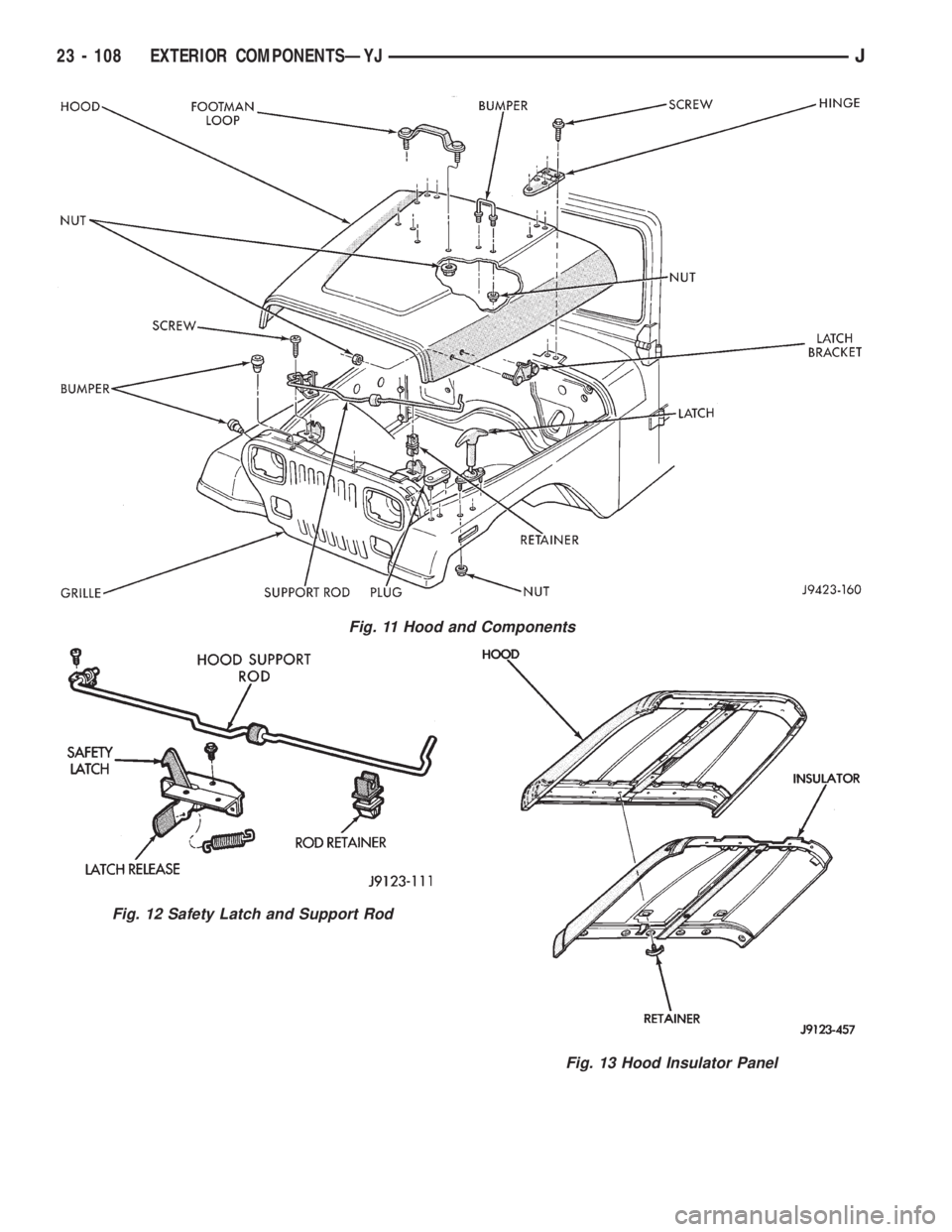

Fig. 11 Hood and Components

Fig. 12 Safety Latch and Support Rod

Fig. 13 Hood Insulator Panel

23 - 108 EXTERIOR COMPONENTSÐYJJ

Page 1842 of 2198

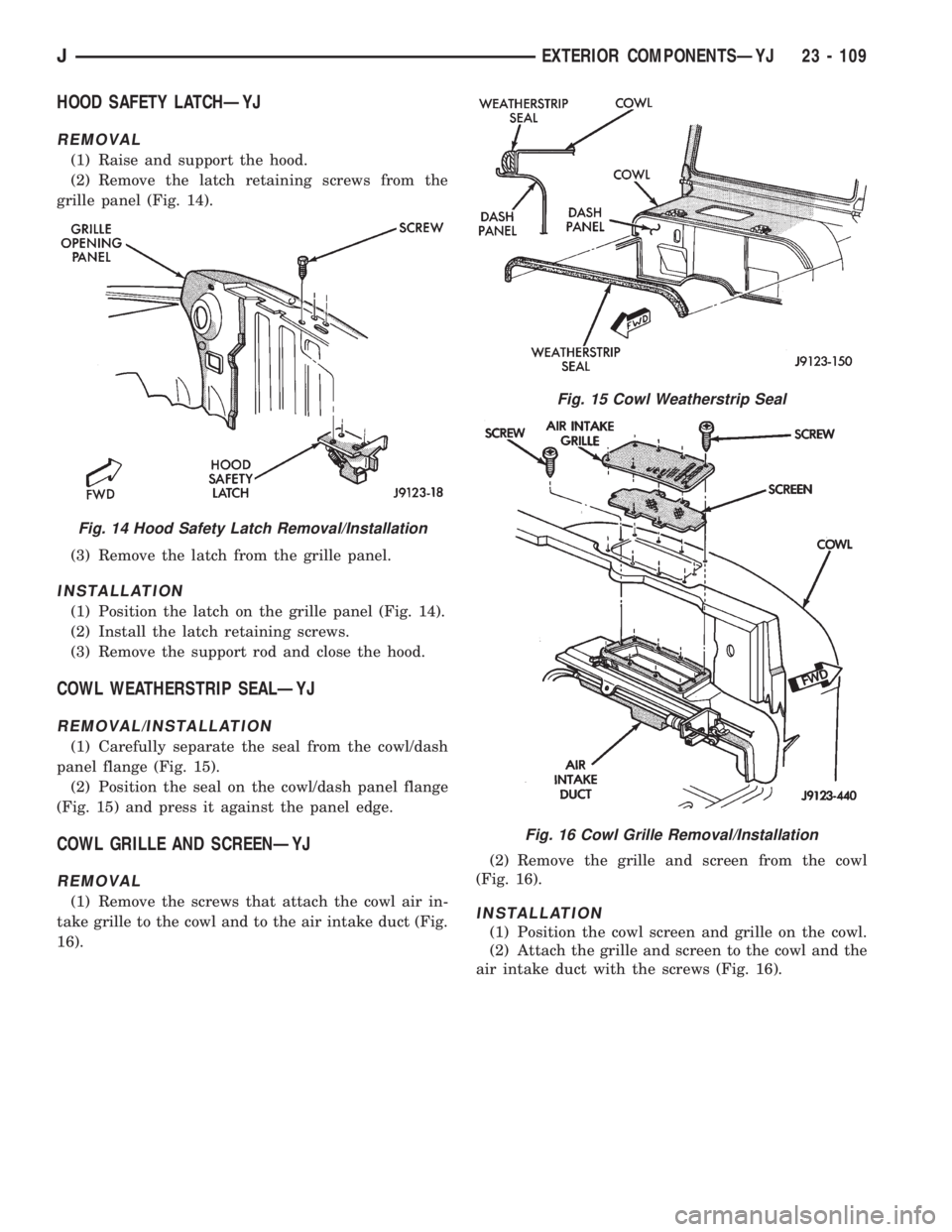

HOOD SAFETY LATCHÐYJ

REMOVAL

(1) Raise and support the hood.

(2) Remove the latch retaining screws from the

grille panel (Fig. 14).

(3) Remove the latch from the grille panel.

INSTALLATION

(1) Position the latch on the grille panel (Fig. 14).

(2) Install the latch retaining screws.

(3) Remove the support rod and close the hood.

COWL WEATHERSTRIP SEALÐYJ

REMOVAL/INSTALLATION

(1) Carefully separate the seal from the cowl/dash

panel flange (Fig. 15).

(2) Position the seal on the cowl/dash panel flange

(Fig. 15) and press it against the panel edge.

COWL GRILLE AND SCREENÐYJ

REMOVAL

(1) Remove the screws that attach the cowl air in-

take grille to the cowl and to the air intake duct (Fig.

16).(2) Remove the grille and screen from the cowl

(Fig. 16).INSTALLATION

(1) Position the cowl screen and grille on the cowl.

(2) Attach the grille and screen to the cowl and the

air intake duct with the screws (Fig. 16).

Fig. 14 Hood Safety Latch Removal/Installation

Fig. 15 Cowl Weatherstrip Seal

Fig. 16 Cowl Grille Removal/Installation

JEXTERIOR COMPONENTSÐYJ 23 - 109

Page 1843 of 2198

BATTERY TRAYÐYJ

REMOVAL

(1) Remove the cables from the battery and power

distribution center (Fig. 1).

(2) Remove the retaining nuts and the battery

holddown bracket from the holddown J-bolts (Fig. 2).

(3) Remove the battery from the tray.

(4) Remove the retaining screws, the support

bracket and the PDC from the battery tray (Fig. 3).

(5) Remove the nuts that attach the battery tray to

the cowl panel (Fig. 2).

(6) Remove the screws that attach the support

brackets to the fender inner panel.

(7) Remove the screw that attaches the brace to

the battery tray (Fig. 2).

(8) Remove the battery tray from the vehicle (Fig.

2).

INSTALLATION

(1) If removed, install the J-bolts on the battery

tray.

(2) Position the battery tray on the cowl panel with

the studs inserted in the holes.

(3) Attach the battery tray to the cowl panel studs

with the attaching nuts.Tighten the nuts on the

studs to 4 Nzm (35 in-lbs) torque.

(4) Install the screw that attaches the brace to the

battery tray. Tighten the screw to 18 Nzm (156 in-lbs)

torque.

(5) Install the screws that attach the support

brackets to the fender inner panel. Tighten the

screws to 18 Nzm (156 in-lbs) torque.(6) Install the support bracket and PDC on the

battery tray. Tighten the screws to 18 Nzm (156 in-

lbs) torque.

(7) Install the battery in the tray.

(8) Position the holddown bracket over the J-bolts.

(9) Install the retaining nuts on the J-bolts.

Tighten the nuts to 4 Nzm (35 in-lbs) torque.

(10) Remove the cables from the battery and power

distribution center.

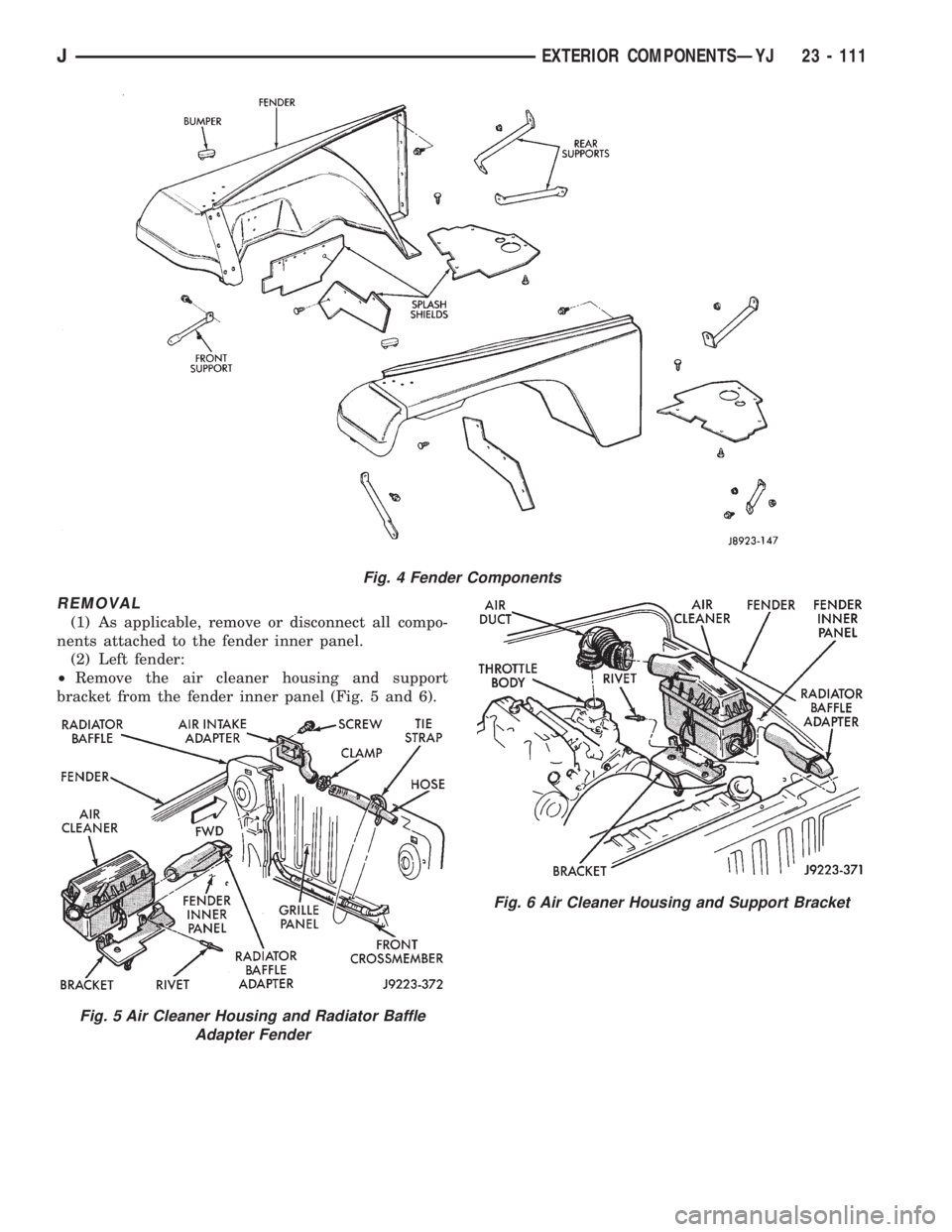

FENDERSÐYJ

SERVICE INFORMATION

YJ fenders are comprised of the fender outer panel,

the fender inner panel, the front and rear support

brackets, and the splash shields (Fig. 4).

Fig. 1 Battery and PDC Cables

Fig. 2 Battery Tray Removal/Installation

Fig. 3 PDC and Bracket Removal/Installation

23 - 110 EXTERIOR COMPONENTSÐYJJ

Page 1844 of 2198

REMOVAL

(1) As applicable, remove or disconnect all compo-

nents attached to the fender inner panel.

(2) Left fender:

²Remove the air cleaner housing and support

bracket from the fender inner panel (Fig. 5 and 6).

Fig. 4 Fender Components

Fig. 5 Air Cleaner Housing and Radiator Baffle

Adapter Fender

Fig. 6 Air Cleaner Housing and Support Bracket

JEXTERIOR COMPONENTSÐYJ 23 - 111

Page 1845 of 2198

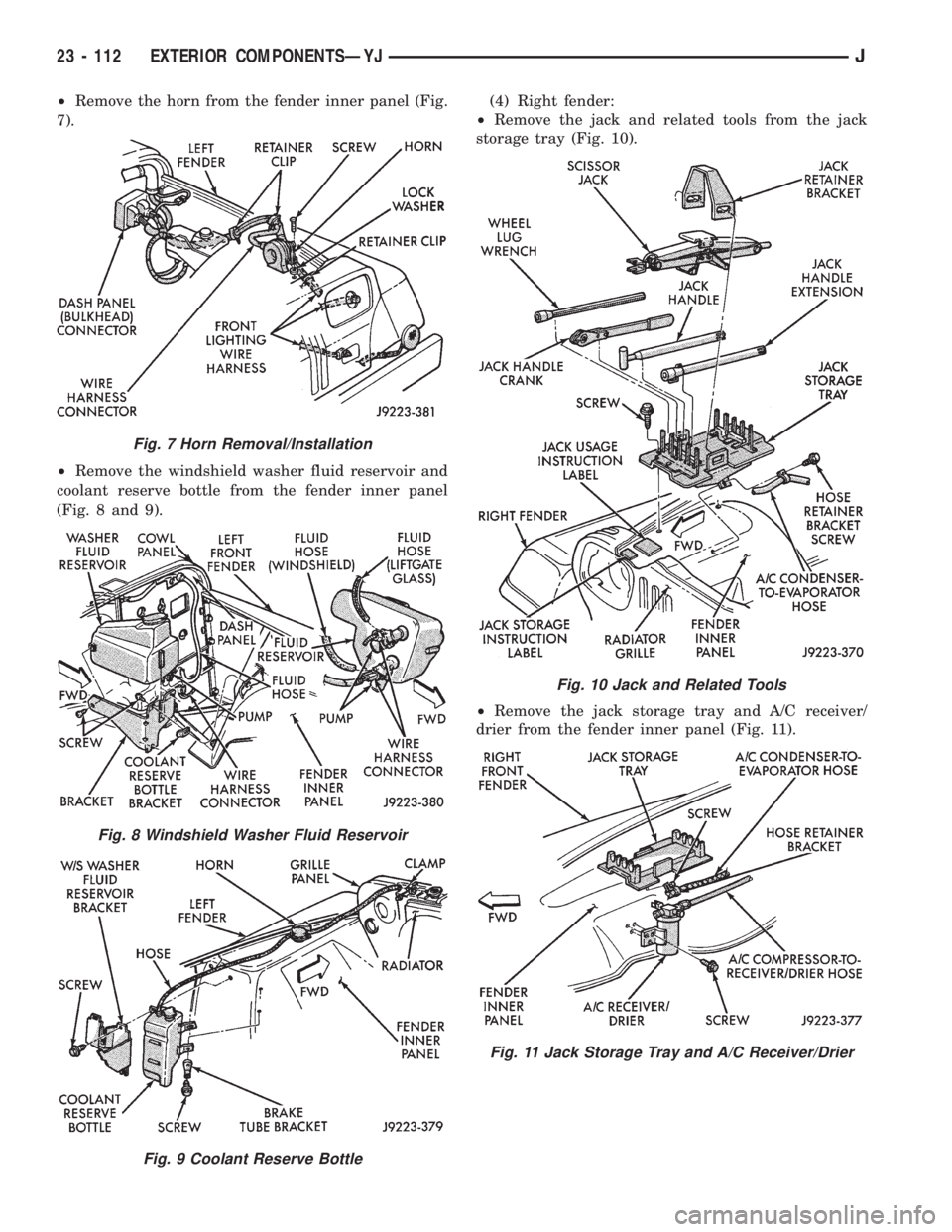

²Remove the horn from the fender inner panel (Fig.

7).

²Remove the windshield washer fluid reservoir and

coolant reserve bottle from the fender inner panel

(Fig. 8 and 9).(4) Right fender:

²Remove the jack and related tools from the jack

storage tray (Fig. 10).

²Remove the jack storage tray and A/C receiver/

drier from the fender inner panel (Fig. 11).

Fig. 7 Horn Removal/Installation

Fig. 8 Windshield Washer Fluid Reservoir

Fig. 9 Coolant Reserve Bottle

Fig. 10 Jack and Related Tools

Fig. 11 Jack Storage Tray and A/C Receiver/Drier

23 - 112 EXTERIOR COMPONENTSÐYJJ

Page 1846 of 2198

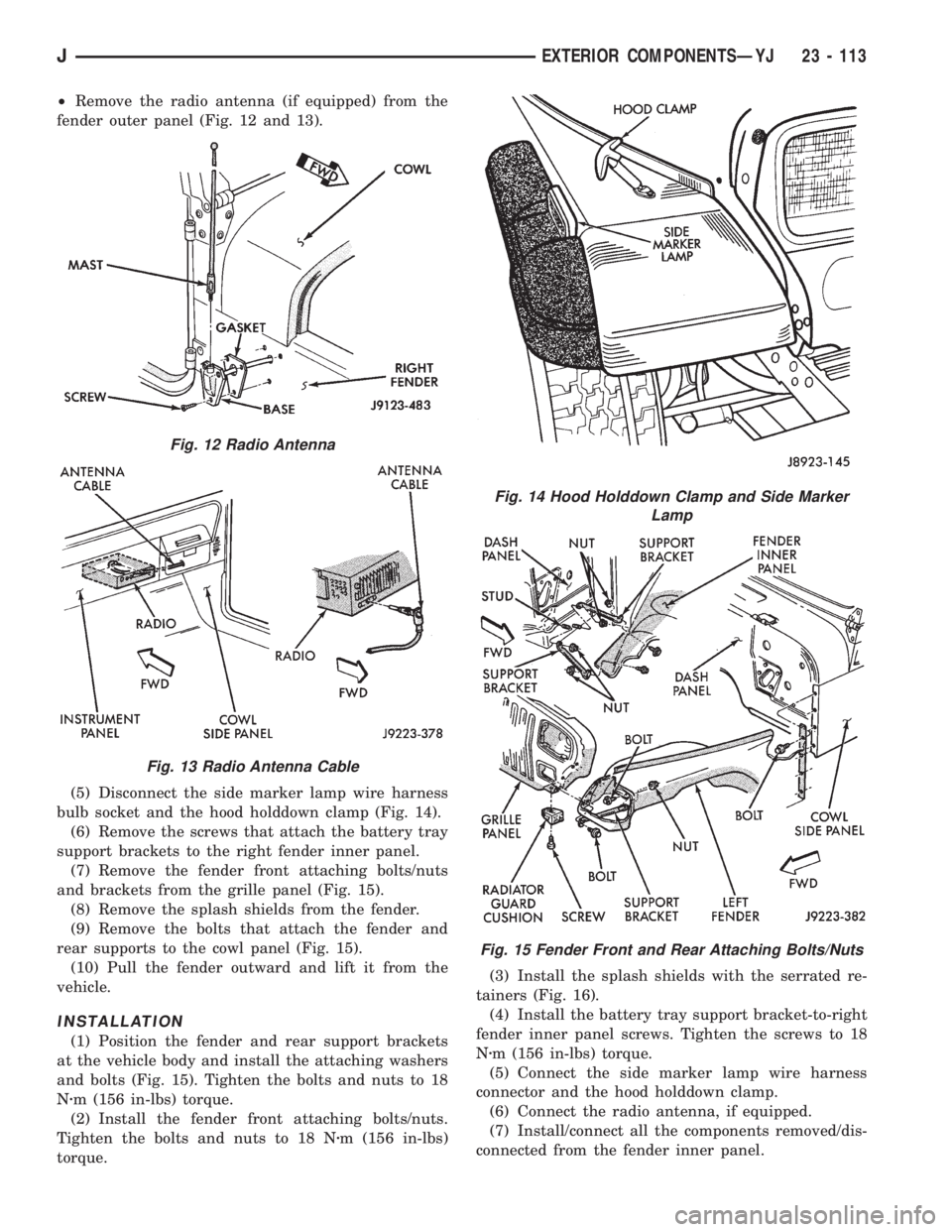

²Remove the radio antenna (if equipped) from the

fender outer panel (Fig. 12 and 13).

(5) Disconnect the side marker lamp wire harness

bulb socket and the hood holddown clamp (Fig. 14).

(6) Remove the screws that attach the battery tray

support brackets to the right fender inner panel.

(7) Remove the fender front attaching bolts/nuts

and brackets from the grille panel (Fig. 15).

(8) Remove the splash shields from the fender.

(9) Remove the bolts that attach the fender and

rear supports to the cowl panel (Fig. 15).

(10) Pull the fender outward and lift it from the

vehicle.

INSTALLATION

(1) Position the fender and rear support brackets

at the vehicle body and install the attaching washers

and bolts (Fig. 15). Tighten the bolts and nuts to 18

Nzm (156 in-lbs) torque.

(2) Install the fender front attaching bolts/nuts.

Tighten the bolts and nuts to 18 Nzm (156 in-lbs)

torque.(3) Install the splash shields with the serrated re-

tainers (Fig. 16).

(4) Install the battery tray support bracket-to-right

fender inner panel screws. Tighten the screws to 18

Nzm (156 in-lbs) torque.

(5) Connect the side marker lamp wire harness

connector and the hood holddown clamp.

(6) Connect the radio antenna, if equipped.

(7) Install/connect all the components removed/dis-

connected from the fender inner panel.

Fig. 12 Radio Antenna

Fig. 13 Radio Antenna Cable

Fig. 14 Hood Holddown Clamp and Side Marker

Lamp

Fig. 15 Fender Front and Rear Attaching Bolts/Nuts

JEXTERIOR COMPONENTSÐYJ 23 - 113

Page 1847 of 2198

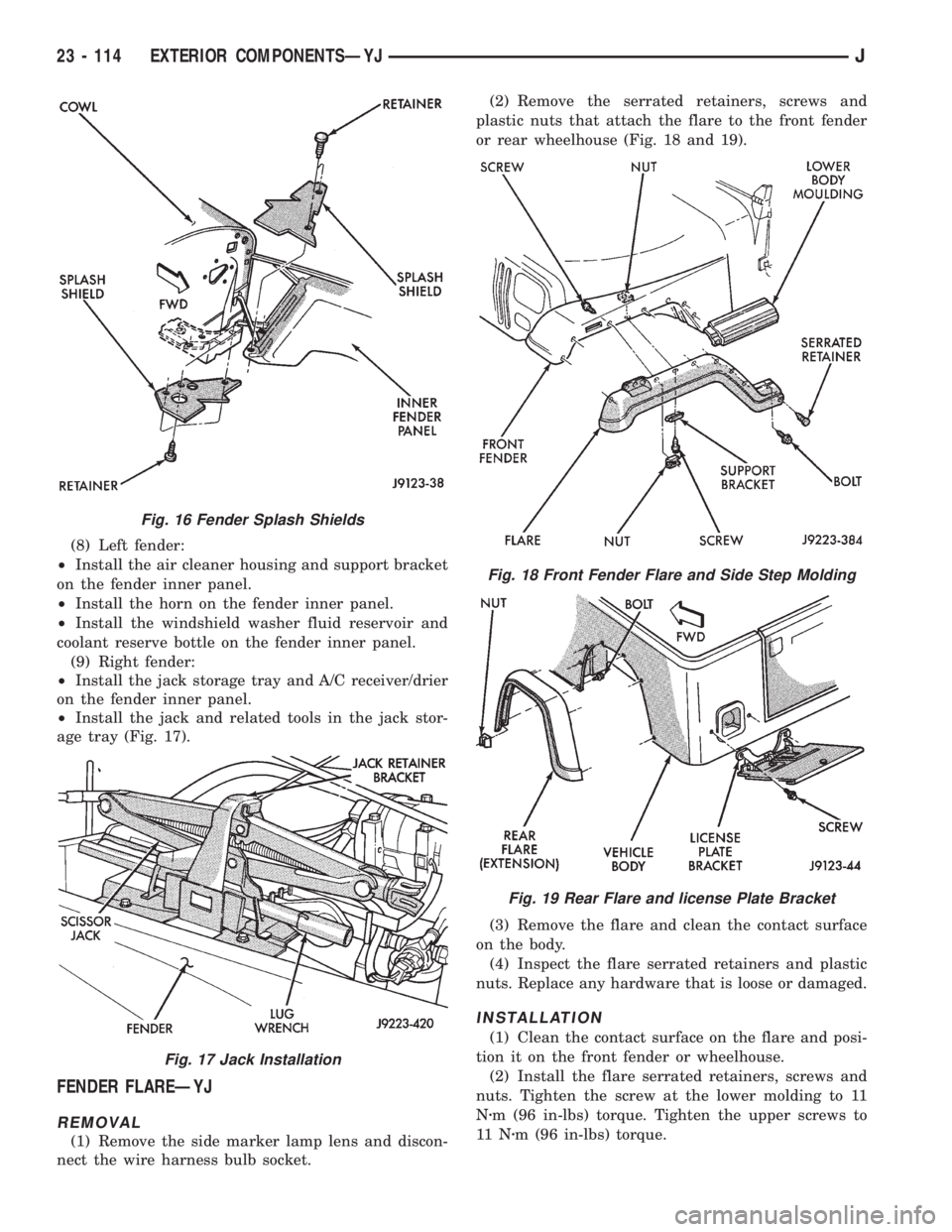

(8) Left fender:

²Install the air cleaner housing and support bracket

on the fender inner panel.

²Install the horn on the fender inner panel.

²Install the windshield washer fluid reservoir and

coolant reserve bottle on the fender inner panel.

(9) Right fender:

²Install the jack storage tray and A/C receiver/drier

on the fender inner panel.

²Install the jack and related tools in the jack stor-

age tray (Fig. 17).

FENDER FLAREÐYJ

REMOVAL

(1) Remove the side marker lamp lens and discon-

nect the wire harness bulb socket.(2) Remove the serrated retainers, screws and

plastic nuts that attach the flare to the front fender

or rear wheelhouse (Fig. 18 and 19).

(3) Remove the flare and clean the contact surface

on the body.

(4) Inspect the flare serrated retainers and plastic

nuts. Replace any hardware that is loose or damaged.

INSTALLATION

(1) Clean the contact surface on the flare and posi-

tion it on the front fender or wheelhouse.

(2) Install the flare serrated retainers, screws and

nuts. Tighten the screw at the lower molding to 11

Nzm (96 in-lbs) torque. Tighten the upper screws to

11 Nzm (96 in-lbs) torque.

Fig. 16 Fender Splash Shields

Fig. 17 Jack Installation

Fig. 18 Front Fender Flare and Side Step Molding

Fig. 19 Rear Flare and license Plate Bracket

23 - 114 EXTERIOR COMPONENTSÐYJJ

Page 1848 of 2198

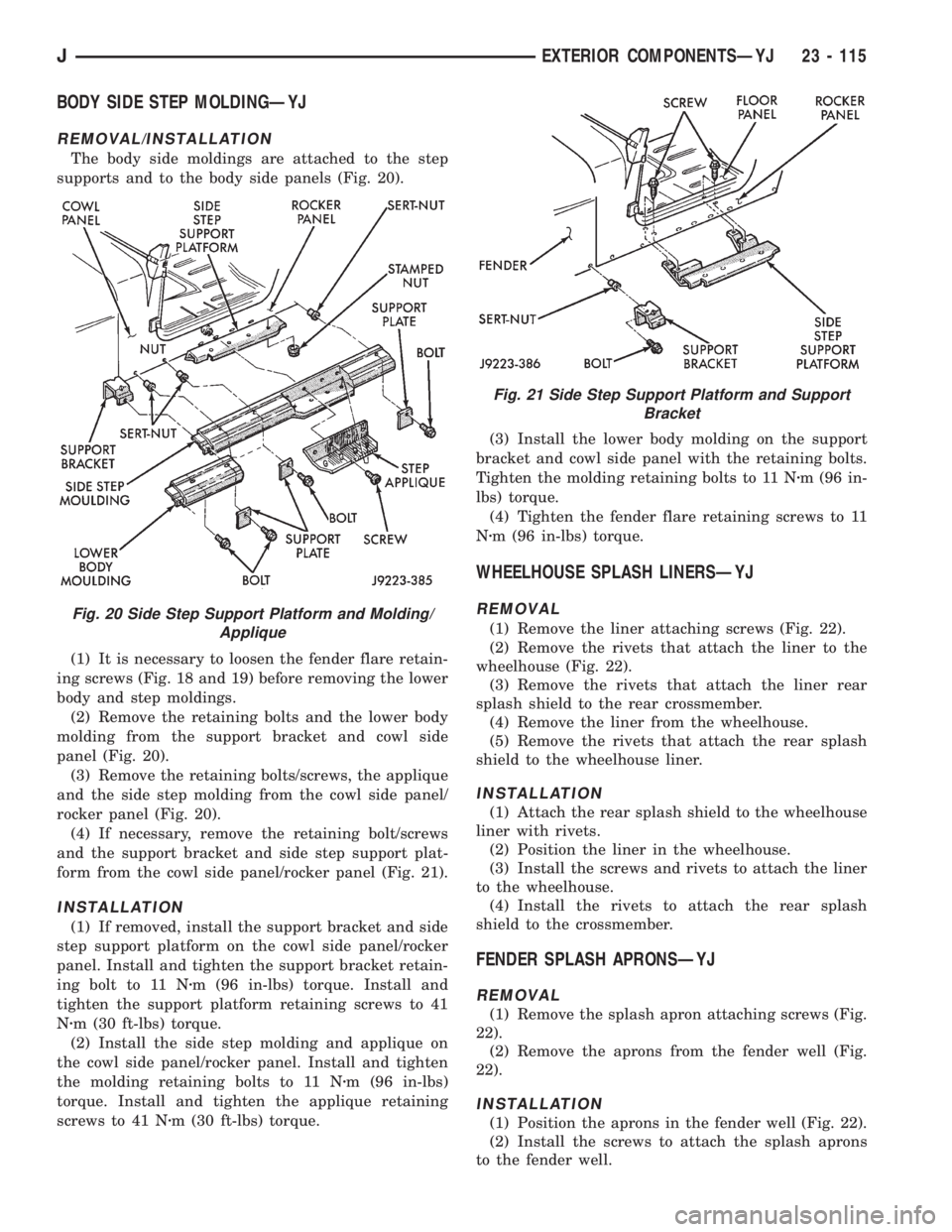

BODY SIDE STEP MOLDINGÐYJ

REMOVAL/INSTALLATION

The body side moldings are attached to the step

supports and to the body side panels (Fig. 20).

(1) It is necessary to loosen the fender flare retain-

ing screws (Fig. 18 and 19) before removing the lower

body and step moldings.

(2) Remove the retaining bolts and the lower body

molding from the support bracket and cowl side

panel (Fig. 20).

(3) Remove the retaining bolts/screws, the applique

and the side step molding from the cowl side panel/

rocker panel (Fig. 20).

(4) If necessary, remove the retaining bolt/screws

and the support bracket and side step support plat-

form from the cowl side panel/rocker panel (Fig. 21).

INSTALLATION

(1) If removed, install the support bracket and side

step support platform on the cowl side panel/rocker

panel. Install and tighten the support bracket retain-

ing bolt to 11 Nzm (96 in-lbs) torque. Install and

tighten the support platform retaining screws to 41

Nzm (30 ft-lbs) torque.

(2) Install the side step molding and applique on

the cowl side panel/rocker panel. Install and tighten

the molding retaining bolts to 11 Nzm (96 in-lbs)

torque. Install and tighten the applique retaining

screws to 41 Nzm (30 ft-lbs) torque.(3) Install the lower body molding on the support

bracket and cowl side panel with the retaining bolts.

Tighten the molding retaining bolts to 11 Nzm (96 in-

lbs) torque.

(4) Tighten the fender flare retaining screws to 11

Nzm (96 in-lbs) torque.

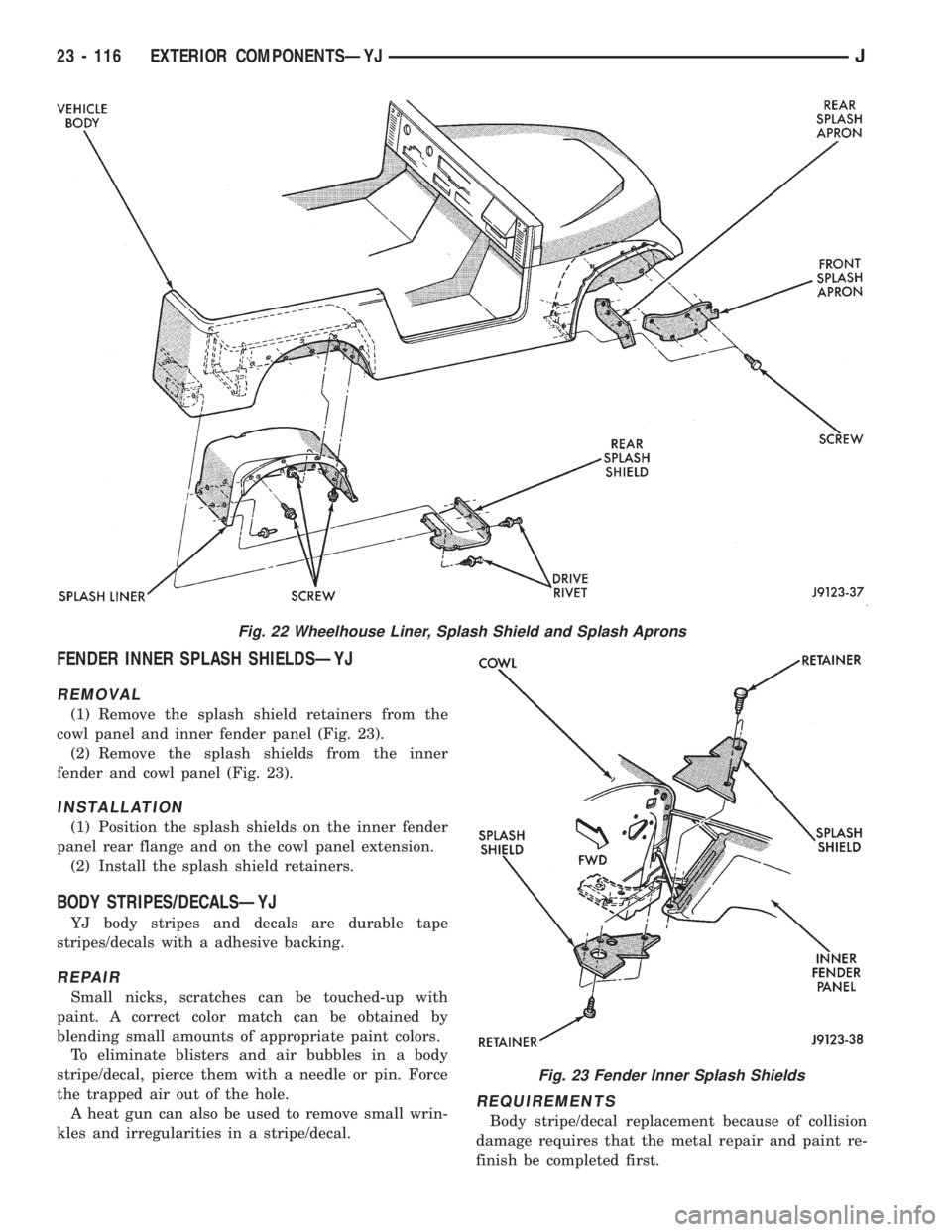

WHEELHOUSE SPLASH LINERSÐYJ

REMOVAL

(1) Remove the liner attaching screws (Fig. 22).

(2) Remove the rivets that attach the liner to the

wheelhouse (Fig. 22).

(3) Remove the rivets that attach the liner rear

splash shield to the rear crossmember.

(4) Remove the liner from the wheelhouse.

(5) Remove the rivets that attach the rear splash

shield to the wheelhouse liner.

INSTALLATION

(1) Attach the rear splash shield to the wheelhouse

liner with rivets.

(2) Position the liner in the wheelhouse.

(3) Install the screws and rivets to attach the liner

to the wheelhouse.

(4) Install the rivets to attach the rear splash

shield to the crossmember.

FENDER SPLASH APRONSÐYJ

REMOVAL

(1) Remove the splash apron attaching screws (Fig.

22).

(2) Remove the aprons from the fender well (Fig.

22).

INSTALLATION

(1) Position the aprons in the fender well (Fig. 22).

(2) Install the screws to attach the splash aprons

to the fender well.

Fig. 20 Side Step Support Platform and Molding/

Applique

Fig. 21 Side Step Support Platform and Support

Bracket

JEXTERIOR COMPONENTSÐYJ 23 - 115

Page 1849 of 2198

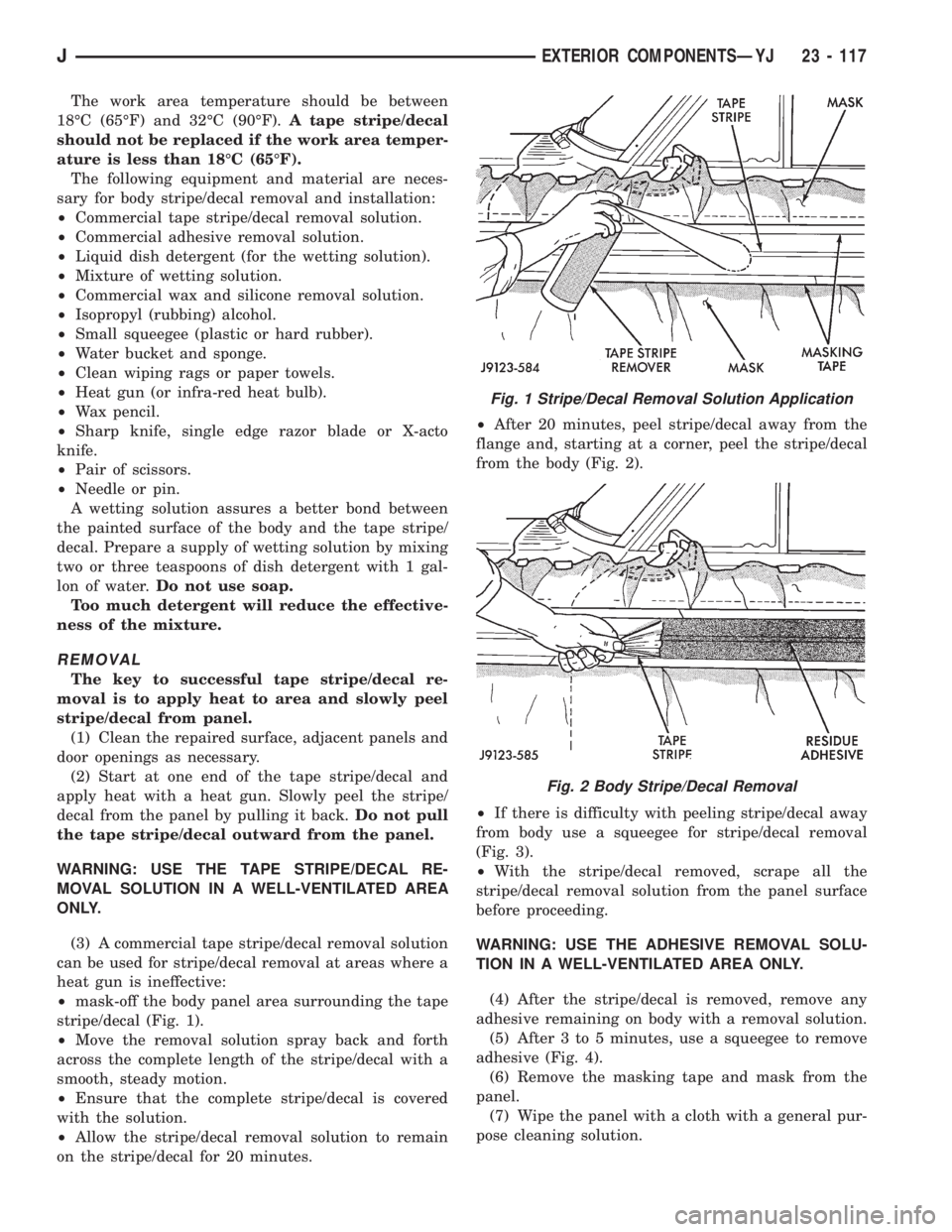

FENDER INNER SPLASH SHIELDSÐYJ

REMOVAL

(1) Remove the splash shield retainers from the

cowl panel and inner fender panel (Fig. 23).

(2) Remove the splash shields from the inner

fender and cowl panel (Fig. 23).

INSTALLATION

(1) Position the splash shields on the inner fender

panel rear flange and on the cowl panel extension.

(2) Install the splash shield retainers.

BODY STRIPES/DECALSÐYJ

YJ body stripes and decals are durable tape

stripes/decals with a adhesive backing.

REPAIR

Small nicks, scratches can be touched-up with

paint. A correct color match can be obtained by

blending small amounts of appropriate paint colors.

To eliminate blisters and air bubbles in a body

stripe/decal, pierce them with a needle or pin. Force

the trapped air out of the hole.

A heat gun can also be used to remove small wrin-

kles and irregularities in a stripe/decal.

REQUIREMENTS

Body stripe/decal replacement because of collision

damage requires that the metal repair and paint re-

finish be completed first.

Fig. 22 Wheelhouse Liner, Splash Shield and Splash Aprons

Fig. 23 Fender Inner Splash Shields

23 - 116 EXTERIOR COMPONENTSÐYJJ

Page 1850 of 2198

The work area temperature should be between

18ÉC (65ÉF) and 32ÉC (90ÉF).A tape stripe/decal

should not be replaced if the work area temper-

ature is less than 18ÉC (65ÉF).

The following equipment and material are neces-

sary for body stripe/decal removal and installation:

²Commercial tape stripe/decal removal solution.

²Commercial adhesive removal solution.

²Liquid dish detergent (for the wetting solution).

²Mixture of wetting solution.

²Commercial wax and silicone removal solution.

²Isopropyl (rubbing) alcohol.

²Small squeegee (plastic or hard rubber).

²Water bucket and sponge.

²Clean wiping rags or paper towels.

²Heat gun (or infra-red heat bulb).

²Wax pencil.

²Sharp knife, single edge razor blade or X-acto

knife.

²Pair of scissors.

²Needle or pin.

A wetting solution assures a better bond between

the painted surface of the body and the tape stripe/

decal. Prepare a supply of wetting solution by mixing

two or three teaspoons of dish detergent with 1 gal-

lon of water.Do not use soap.

Too much detergent will reduce the effective-

ness of the mixture.

REMOVAL

The key to successful tape stripe/decal re-

moval is to apply heat to area and slowly peel

stripe/decal from panel.

(1) Clean the repaired surface, adjacent panels and

door openings as necessary.

(2) Start at one end of the tape stripe/decal and

apply heat with a heat gun. Slowly peel the stripe/

decal from the panel by pulling it back.Do not pull

the tape stripe/decal outward from the panel.

WARNING: USE THE TAPE STRIPE/DECAL RE-

MOVAL SOLUTION IN A WELL-VENTILATED AREA

ONLY.

(3) A commercial tape stripe/decal removal solution

can be used for stripe/decal removal at areas where a

heat gun is ineffective:

²mask-off the body panel area surrounding the tape

stripe/decal (Fig. 1).

²Move the removal solution spray back and forth

across the complete length of the stripe/decal with a

smooth, steady motion.

²Ensure that the complete stripe/decal is covered

with the solution.

²Allow the stripe/decal removal solution to remain

on the stripe/decal for 20 minutes.²After 20 minutes, peel stripe/decal away from the

flange and, starting at a corner, peel the stripe/decal

from the body (Fig. 2).

²If there is difficulty with peeling stripe/decal away

from body use a squeegee for stripe/decal removal

(Fig. 3).

²With the stripe/decal removed, scrape all the

stripe/decal removal solution from the panel surface

before proceeding.

WARNING: USE THE ADHESIVE REMOVAL SOLU-

TION IN A WELL-VENTILATED AREA ONLY.

(4) After the stripe/decal is removed, remove any

adhesive remaining on body with a removal solution.

(5) After 3 to 5 minutes, use a squeegee to remove

adhesive (Fig. 4).

(6) Remove the masking tape and mask from the

panel.

(7) Wipe the panel with a cloth with a general pur-

pose cleaning solution.

Fig. 1 Stripe/Decal Removal Solution Application

Fig. 2 Body Stripe/Decal Removal

JEXTERIOR COMPONENTSÐYJ 23 - 117