JEEP CJ 1953 Service Manual

Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 111 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

E

FIG.

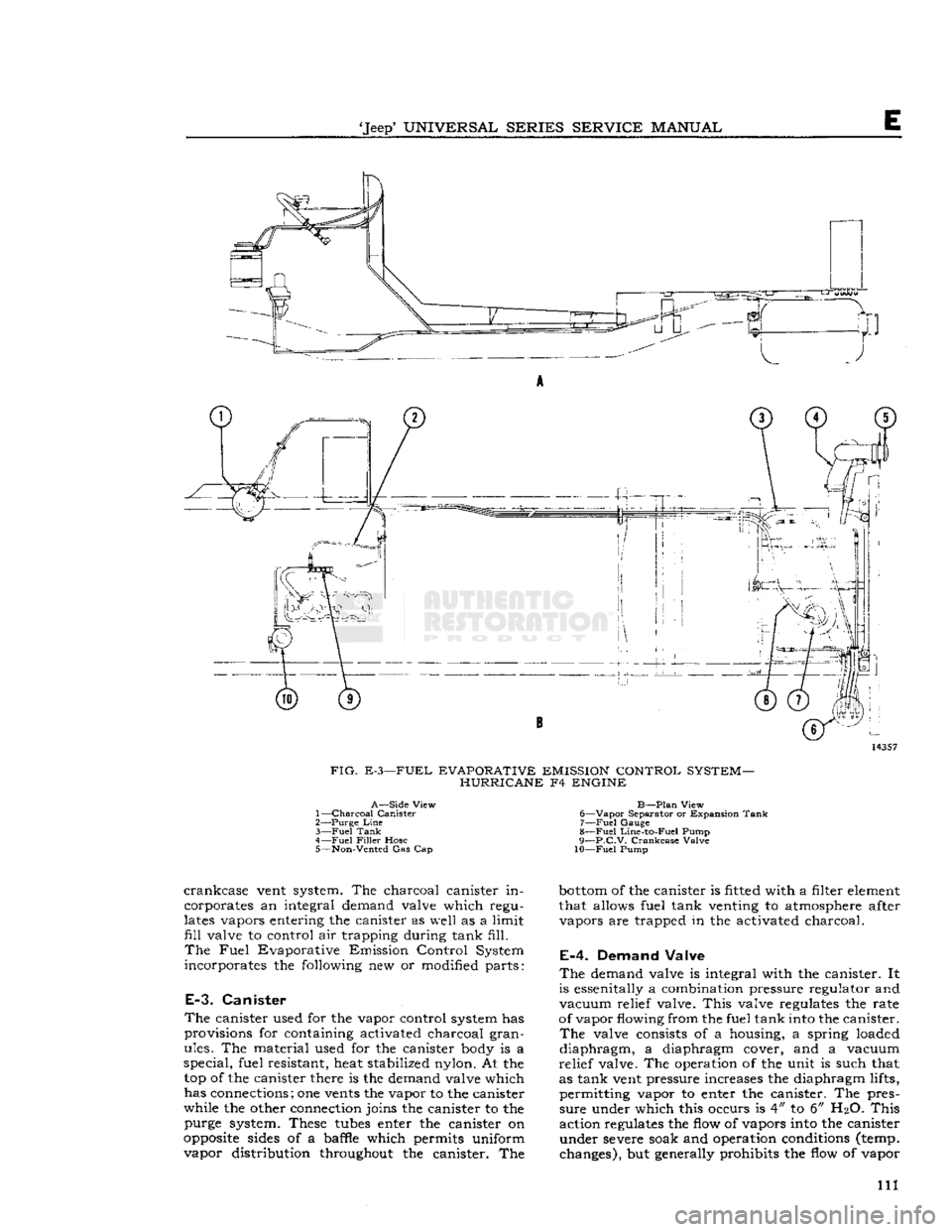

E-3—FUEL EVAPORATIVE EMISSION CONTROL SYSTEM- HURRICANE F4 ENGINE

A—Side

View

1—

Charcoal Canister

2— Purge

Line

3—

Fuel

Tank

4—

Fuel

Filler

Hose 5—

Non-Vented

Gas Cap

B—Plan

View

6—

Vapor

Separator

or Expansion Tank 7—

Fuel

Gauge

8—

Fuel

Line-to-Fuel Pump

9—

p.C.V.

Crankcase

Valve

10—Fuel

Pump

crankcase

vent system. The charcoal canister in

corporates an integral demand valve

which

regu

lates

vapors entering the canister as

well

as a

limit

fill

valve

to control air trapping during tank

fill.

The

Fuel

Evaporative Emission Control System

incorporates the following new or modified parts:

E-3.

Canister

The canister used for the vapor control system has

provisions for containing activated charcoal gran ules. The material used for the canister body is a

special,

fuel resistant, heat stabilized nylon. At the top of the canister there is the demand valve which

has connections; one vents the vapor to the canister

while the other connection joins the canister to the purge system. These

tubes

enter the canister on

opposite

sides of a baffle which permits uniform

vapor distribution throughout the canister. The

bottom

of the canister is fitted with a filter element

that allows fuel tank venting to atmosphere after vapors are trapped in the activated charcoal.

E-4.

Demand Valve

The

demand valve is integral with the canister. It

is essenitally a combination pressure regulator and

vacuum

relief valve.

This

valve regulates the rate

of vapor

flowing

from the fuel tank into the canister.

The

valve consists of a housing, a spring loaded

diaphragm,

a diaphragm cover, and a vacuum

relief

valve. The operation of the unit is such that

as tank vent pressure increases the diaphragm lifts,

permitting vapor to enter the canister. The pres

sure

under which this occurs is 4" to 6"

H2O.

This

action regulates the flow of vapors into the canister

under severe soak and operation conditions (temp, changes), but generally prohibits the flow of vapor 111

Page 112 of 376

E

FUEL

SYSTEM

9

©

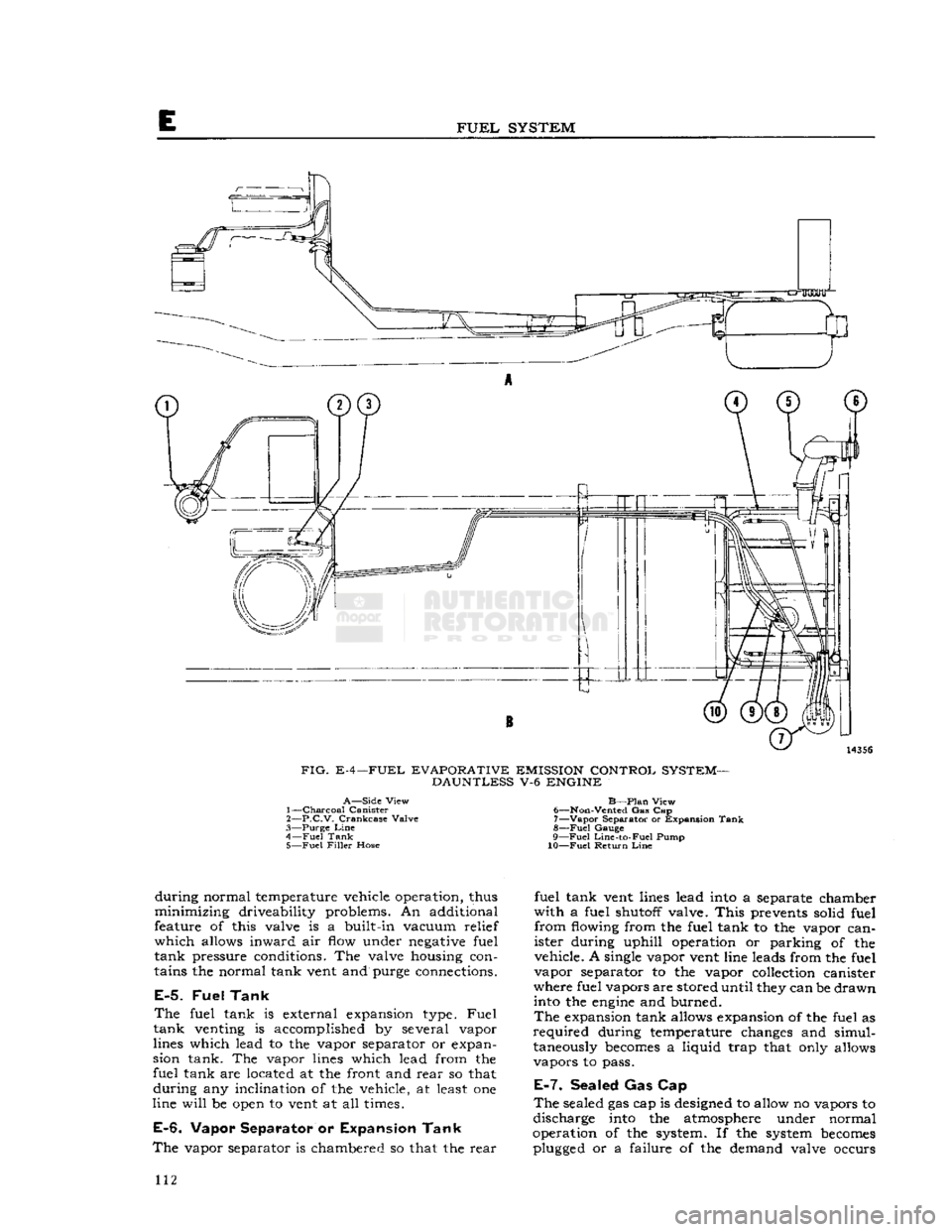

FIG.

E-4—FUEL

EVAPORATIVE

EMISSION

CONTROL

SYSTEM-

DAUNTLESS

V-6

ENGINE

A—Side

View

1—

Charcoal

Canister

2—

P.C.V.

Crankcase

Valve

3—

Purge

Line

4—

Fuel

Tank

5—

Fuel

Filler

Hose

B—Plan

View

6—

Non-Vented

Gas Cap 7—

Vapor

Separator or Expansion

Tank

g—Fuei

Gauge

9—Fuel

Line-to-Fuel

Pump

10—Fuei

Return

Line

during

normal temperature vehicle operation, thus

minimizing

driveability problems. An additional

feature of this valve is a built-in vacuum relief

which

allows inward air flow under negative fuel

tank

pressure conditions. The valve housing con

tains the normal tank vent and purge connections.

E-5.

Fuel Tank

The

fuel tank is external expansion type.

Fuel

tank

venting is accomplished by several vapor

lines which lead to the vapor separator or expan

sion tank. The vapor lines which lead from the

fuel tank are located at the front and

rear

so that

during

any inclination of the vehicle, at least one

line

will

be open to vent at all times.

E-6.

Vapor Separator

or

Expansion Tank

The

vapor separator is chambered so that the

rear

fuel tank vent lines lead into a separate chamber

with

a fuel shutofl valve.

This

prevents solid fuel

from

flowing from the fuel tank to the vapor can

ister during uphill operation or parking of the

vehicle. A single vapor vent line leads from the fuel

vapor separator to the vapor collection canister

where fuel vapors are stored until they can be drawn into the

engine

and burned.

The

expansion tank allows expansion of the fuel as

required

during temperature changes and simul taneously

becomes

a liquid trap that only allows

vapors to pass.

E-7.

Sealed

Gas Cap

The

sealed gas cap is designed to allow no vapors to

discharge into the atmosphere under normal

operation of the system. If the system

becomes

plugged or a failure of the demand valve occurs 112

Page 113 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

E

there is a relief valve that

opens

to reduce high

(dangerous) pressures in the fuel tank. In con

junction

with the pressure relief valve there is a

vacuum

relief valve to

stop

collapse of the fuel

tank

in case of a plugged system or failure of the demand valve. When replacing the gas cap, the

same type must be used as originally installed.

E-8.

System Inspection Test

The

fuel emission vent system should be checked

carefully

to ensure the absence of any leaks to the

atmosphere of either liquid or vapor which might

affect the accuracy, safety, or performance of the control system.

To

assure that the sealed system has been properly

installed,

the following

test

procedure has been

developed.

Disconnect the vent line from the fuel tank system

to the activated charcoal canister, induce l/i p.s.i.

air

pressure. If this pressure can be maintained for

a

few seconds the vent system is assured to be sealed. DO NOT add air pressure to the canister

because damage can occur to the demand valve if

care

is not taken.

E-9.

Servicing the System

Periodic

Maintenance — Replace carbon canister filter at

12,000

miles

[19,200

km.] or 12 month intervals (more

often

for operation in dusty areas).

This

is the only regular maintenance service

required.

Canister

Filter

Replacement — Disconnect

hoses

from

top of canister, remove canister from mount

-

t

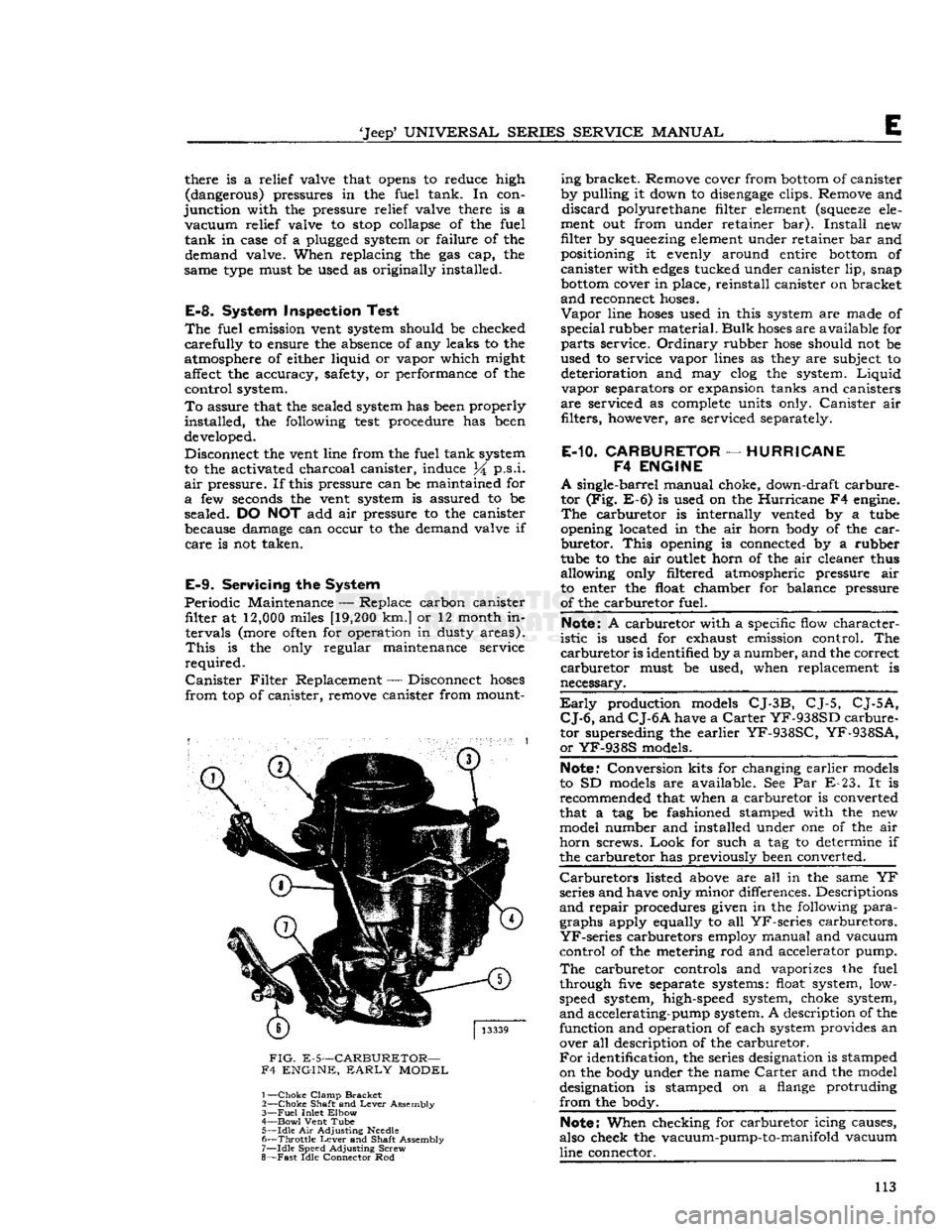

FIG.

E-5—CARBURETOR—

F4 ENGINE,

EARLY

MODEL

1—

Choke

Clamp

Bracket

2—

Choke

Shaft and

Lever

Assembly

3—

Fuel

Inlet

Elbow

4—

Bowl

Vent Tube 5—

Idle

Air Adjusting

Needle

6—

Throttle

Lever

and Shaft Assembly

7—

Idle

Speed Adjusting Screw

8—

Fast

Idle Connector Rod ing bracket. Remove cover from

bottom

of canister

by pulling it down to

disengage

clips. Remove and

discard

polyurethane filter element

(squeeze

ele

ment out from under retainer bar).

Install

new

filter by squeezing element under retainer bar and positioning it evenly around entire

bottom

of

canister with

edges

tucked under canister lip, snap

bottom

cover in place, reinstall canister on bracket

and

reconnect

hoses.

Vapor

line

hoses

used in this system are made of

special

rubber material.

Bulk

hoses

are available for

parts

service.

Ordinary

rubber

hose

should not be

used to service vapor lines as they are subject to deterioration and may clog the system.

Liquid

vapor separators or expansion tanks and canisters

are

serviced as complete units only.

Canister

air filters, however, are serviced separately.

E-10.

CARBURETOR

—

HURRICANE

F4

ENGINE

A

single-barrel manual choke, down-draft carbure

tor (Fig. E-6) is used on the

Hurricane

F4 engine.

The

carburetor is internally vented by a tube

opening located in the air horn body of the

car

buretor.

This

opening is connected by a rubber

tube to the air

outlet

horn of the air cleaner thus

allowing only filtered atmospheric pressure air

to enter the float chamber for balance pressure

of the carburetor fuel.

Note:

A carburetor with a specific flow character

istic

is used for exhaust emission control. The

carburetor

is identified by a number, and the correct

carburetor

must be used, when replacement is

necessary.

Early

production models

CJ-3B,

CJ-5,

CJ-5A,

CJ-6,

and

CJ-6A

have a

Carter

YF-938SD

carbure

tor superseding the earlier

YF-938SC,

YF-938SA,

or

YF-938S

models.

Note."

Conversion kits for changing earlier models

to SD models are available. See Par E-23. It is recommended that when a carburetor is converted

that a tag be fashioned stamped with the new model number and installed under one of the air

horn

screws.

Look

for such a tag to determine if

the carburetor has previously been converted.

Carburetors

listed above are all in the same YF

series and have only minor differences. Descriptions

and

repair procedures given in the following

para

graphs apply equally to all

YF-series

carburetors.

YF-series

carburetors employ manual and vacuum

control of the metering rod and accelerator pump.

The

carburetor controls and vaporizes the fuel

through five separate systems: float system, low-

speed system, high-speed system, choke system,

and

accelerating-pump system. A description of the function and operation of each system provides an over all description of the carburetor.

For

identification, the series designation is stamped

on the body under the name

Carter

and the model

designation is stamped on a flange protruding

from

the body.

Note:

When checking for carburetor icing causes,

also check the vacuum-pump-to-manifold vacuum

line connector. 113

Page 114 of 376

FUEL

SYSTEM

14261

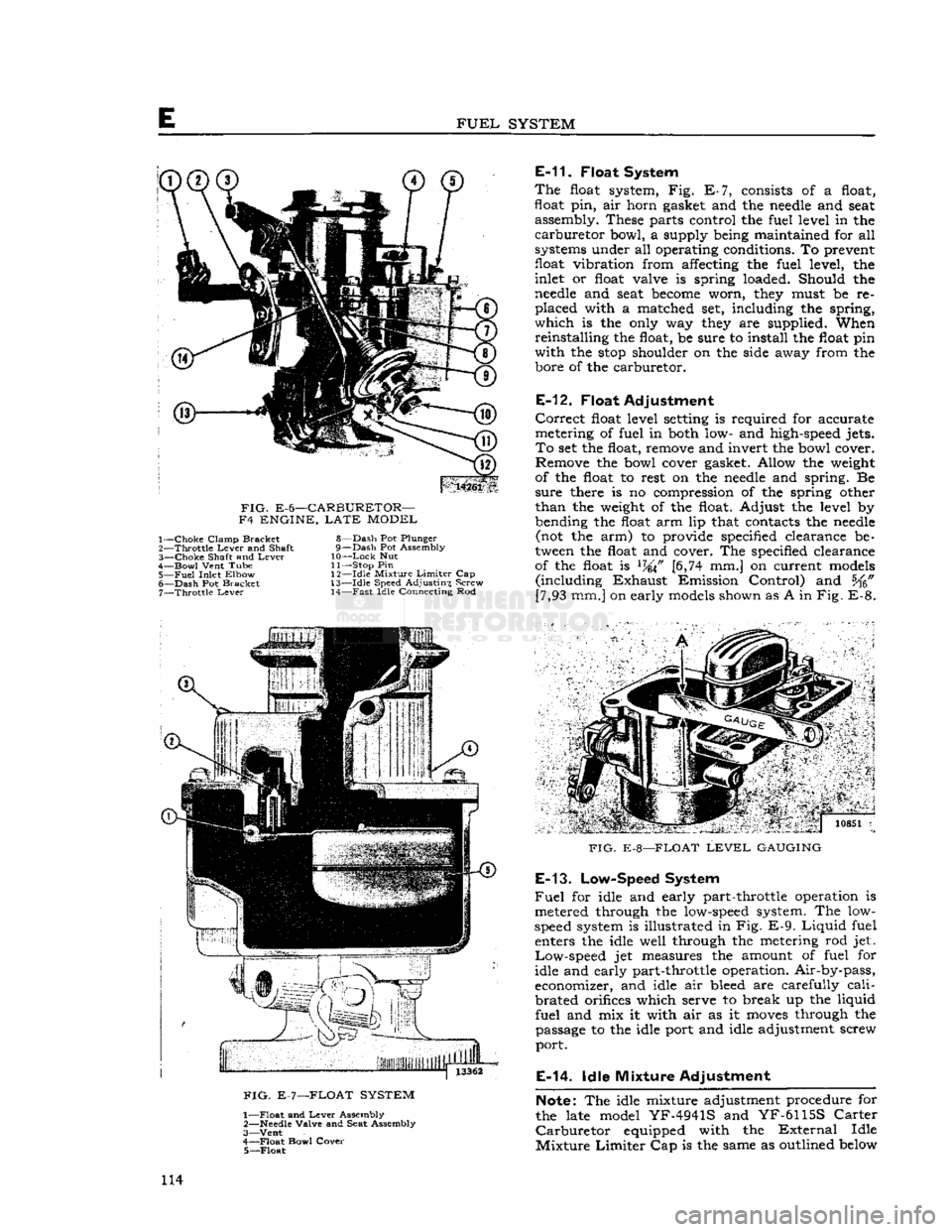

FIG.

E-6—CARBURETOR—

F4 ENGINE,

LATE

MODEL 1—

Choke

Clamp Bracket

2—

Throttle

Lever

and Shaft

3—

Choke

Shaft and

Lever

4—

Bowl

Vent Tube

5—

Fuel

Inlet Elbow

6—

Dash

Pot Bracket 7—

Throttle

Lever

8—

Dash

Pot Plunger

9—

Dash

Pot Assembly

10—

Lock

Nut

11— Stop Pin

1

2—Idle Mixture

Limiter

Cap

13—

Idle

Speed Adjusting Screw 14—

Fast

Idle Connecting Rod

E-11.

Float System

The

float system, Fig. E-7, consists of a float,

float

pin,

air horn gasket and the

needle

and seat assembly. These parts control the fuel level in the

carburetor

bowl, a supply being maintained for all

systems under all operating conditions. To prevent

float

vibration

from affecting the fuel level, the

inlet or float valve is spring loaded. Should the

needle

and seat

become

worn, they must be re

placed

with a matched set, including the spring,

which

is the only way they are supplied. When

reinstalling

the float, be sure to install the float pin

with

the

stop

shoulder on the side away from the bore of the carburetor.

E-12.

Float Adjustment

Correct

float level setting is required for accurate

metering of fuel in both low- and high-speed jets.

To

set the float, remove and invert the bowl cover. Remove the bowl cover gasket. Allow the weight

of the float to rest on the

needle

and spring. Be

sure

there is no compression of the spring other

than

the weight of the float. Adjust the level by

bending the float arm lip that contacts the

needle

(not the arm) to provide specified clearance be

tween the float and cover. The specified clearance of the float is

L74\F

[6,74 mm.] on current models

(including

Exhaust

Emission Control) and [7,93 mm.] on early models shown as A in

Fig.

E-8.

FIG.

E-7—FLOAT SYSTEM

1—

Float

and

Lever

Assembly

2—

Needle

Valve and Seat Assembly

3—

Vent

4—

Float

Bowl Cover 5—

Float

7 '.. j

io8Si

i

FIG.

E-8—FLOAT

LEVEL

GAUGING

E-13.

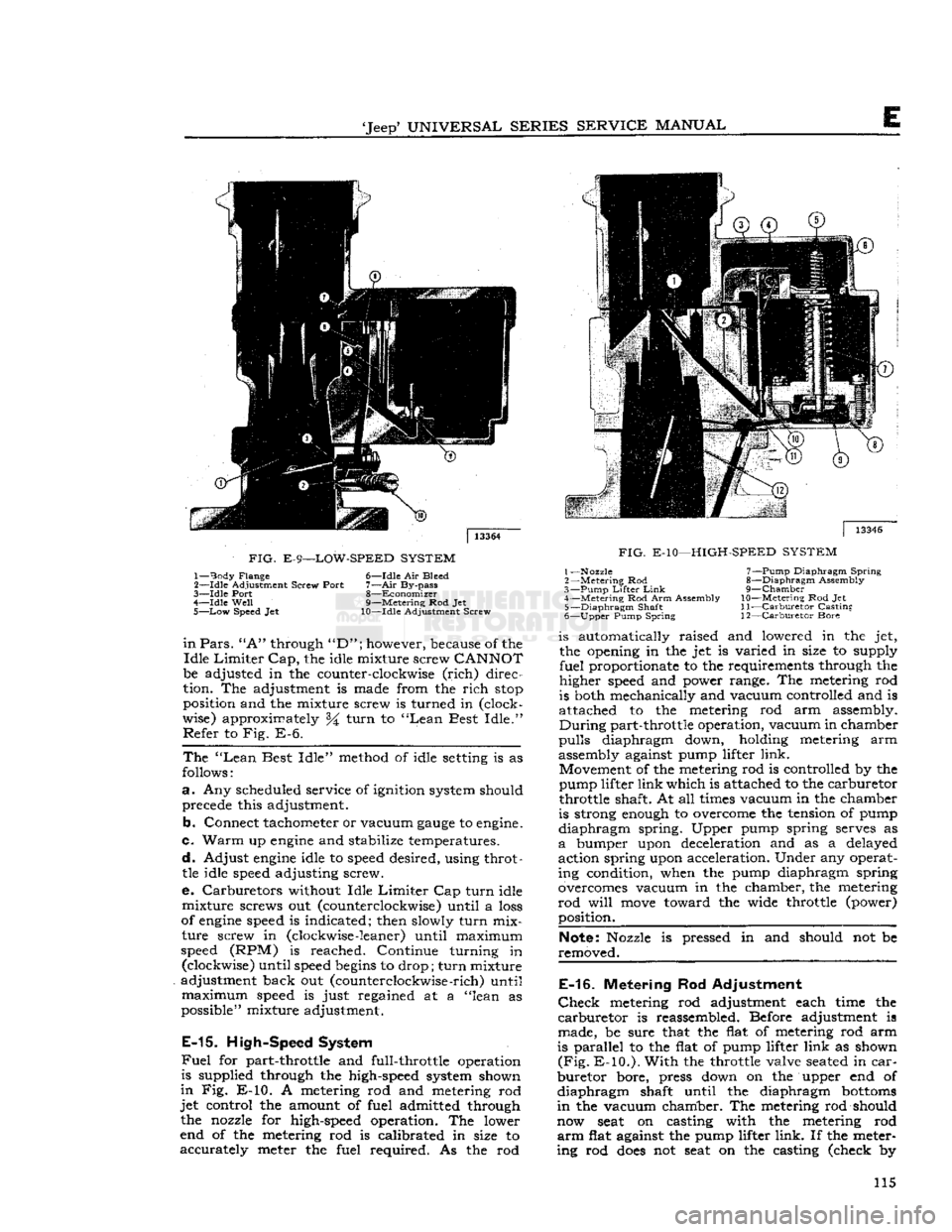

Low-Speed System

Fuel

for idle and early part-throttle operation is

metered through the low-speed system. The low-

speed system is illustrated in Fig.

E-9.

Liquid

fuel enters the idle well through the metering rod jet.

Low-speed

jet measures the amount of fuel for

idle and early part-throttle operation. Air-by-pass,

economizer, and idle air bleed are carefully

cali

brated

orifices which serve to break up the liquid

fuel

and mix it with air as it

moves

through the passage to the idle port and idle adjustment screw

port.

E-14.

Idle Mixture Adjustment

Note:

The idle mixture adjustment procedure for

the late model

YF-4941S

and

YF-6115S

Carter

Carburetor

equipped with the

External

Idle

Mixture

Limiter

Cap is the same as outlined below 114

Page 115 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

E

FIG.

E-9—LOW-SPEED

SYSTEM

1—

Body

Flange 6—Idle Air Bleed

2—

-Idle

Adjustment Screw Port

7—Air

By-pass

3—

Idle

Port 8—Economizer

4—

Idle

Well

9—Metering Rod Jet

5—

Low

Speed Jet 10—Idle Adjustment Screw

in

Pars.

"A"

through

"D";

however, because of the

Idle

Limiter

Cap,

the idle mixture screw

CANNOT

be adjusted in the counter-clockwise

(rich)

direc

tion. The adjustment is made from the

rich

stop

position and the mixture screw is turned in (clock

wise) approximately %

turn

to

"Lean

Best

Idle."

Refer

to Fig. E-6.

The

"Lean

Best

Idle"

method of idle

setting

is as

follows:

a.

Any scheduled service of ignition system should precede this adjustment.

b.

Connect tachometer or vacuum

gauge

to

engine.

c.

Warm

up

engine

and stabilize temperatures.

d.

Adjust

engine

idle to

speed

desired, using throttle idle

speed

adjusting screw.

e. Carburetors without Idle

Limiter

Cap

turn

idle

mixture

screws out (counterclockwise) until a

loss

of

engine

speed

is indicated; then slowly

turn

mix

ture

screw in (clockwise

-leaner)

until maximum

speed

(RPM) is reached. Continue turning in (clockwise) until

speed

begins

to drop;

turn

mixture

adjustment back out (counterclockwise

-rich)

until

maximum

speed

is just regained at a "lean as

possible" mixture adjustment.

E-15.

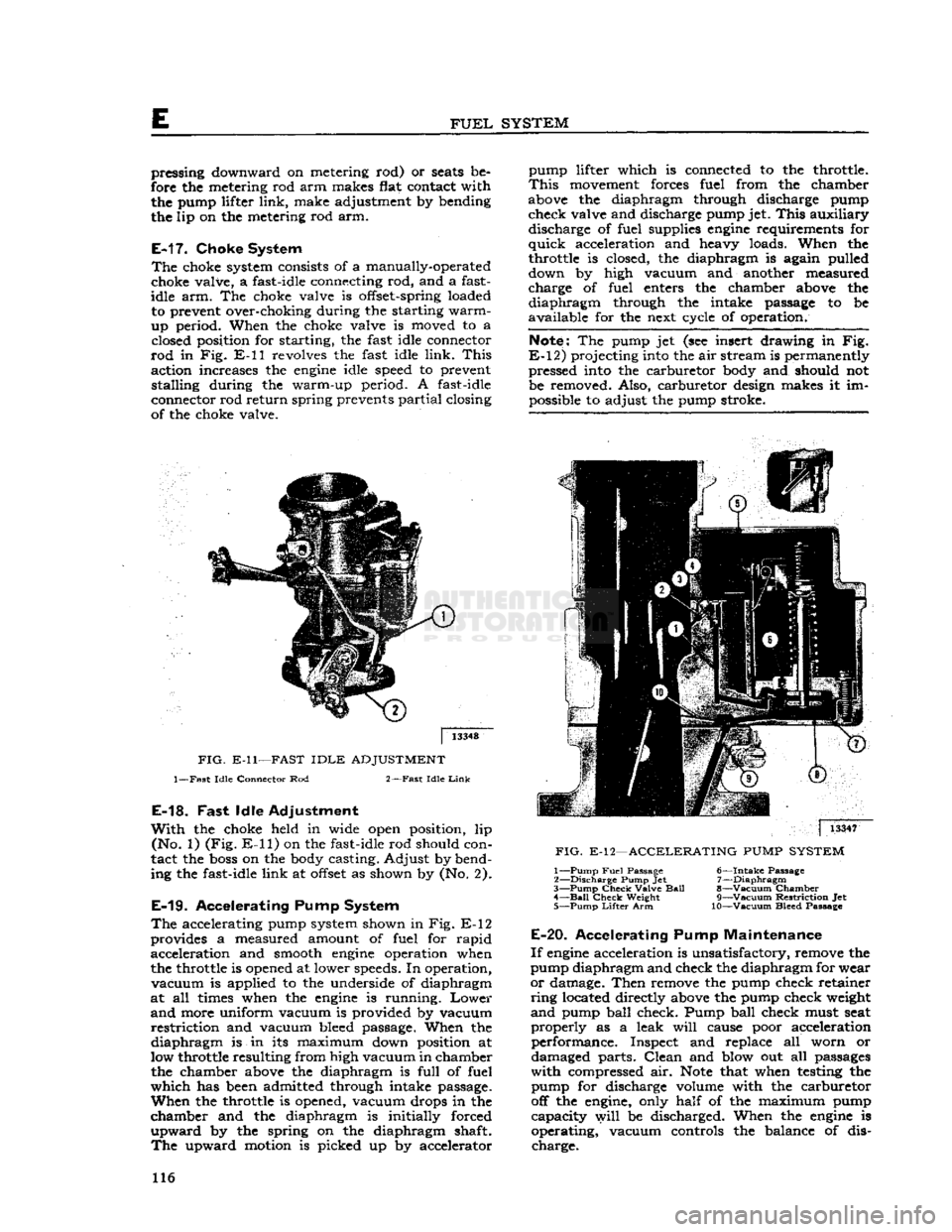

High-Speed System

Fuel

for part-throttle and full-throttle operation

is supplied through the high-speed system shown

in

Fig. E-10. A metering rod and metering rod

jet

control the amount of fuel admitted through the nozzle for high-speed operation. The lower

end of the metering rod is calibrated in size to

accurately

meter the fuel required. As the rod

|

13346

FIG.

E-10—HIGH-SPEED

SYSTEM

1—Nozzle 7—Pump Diaphragm

Spring

2

—Metering

Rod 8—Diaphragm Assembly

3—

Pump

Lifter

Link

9—Chamber

4—

Metering

Rod Arm Assembly

10—Metering

Rod Jet 5—

Diaphragm

Shaft

11—Carburetor

Casting

6—

Upper

Pump Spring 12—Carburetor Bore is automatically raised and lowered in the jet,

the opening in the jet is varied in size to supply

fuel

proportionate to the requirements through the

higher

speed

and power range. The metering rod

is both mechanically and vacuum controlled and is

attached to the metering rod arm assembly.

During

part-throttle operation, vacuum in chamber

pulls

diaphragm down, holding metering arm

assembly against pump lifter

link.

Movement of the metering rod is controlled by the

pump lifter

link

which is attached to the carburetor

throttle shaft. At all

times

vacuum in the chamber

is strong

enough

to overcome the tension of pump

diaphragm

spring. Upper pump spring serves as

a

bumper upon deceleration and as a delayed

action spring upon acceleration. Under any operat ing condition, when the pump diaphragm spring

overcomes vacuum in the chamber, the metering

rod

will

move

toward the wide throttle (power) position.

Note:

Nozzle is pressed in and should not be

removed.

E-16.

Metering Rod Adjustment

Check

metering rod adjustment each time the

carburetor

is reassembled. Before adjustment is

made, be sure that the flat of metering rod arm

is parallel to the flat of pump lifter

link

as shown

(Fig.

E-10.).

With

the throttle valve

seated

in

car

buretor

bore, press down on the upper end of

diaphragm

shaft until the diaphragm

bottoms

in

the vacuum chamber. The metering rod should

now

seat

on casting with the metering rod

arm

flat against the pump lifter

link.

If the meter

ing rod

does

not

seat

on the casting (check by 115

Page 116 of 376

E

FUEL

SYSTEM

pressing downward on metering rod) or

seats

be

fore the metering rod arm makes flat contact with the pump lifter link, make adjustment by bending

the lip on the metering rod arm.

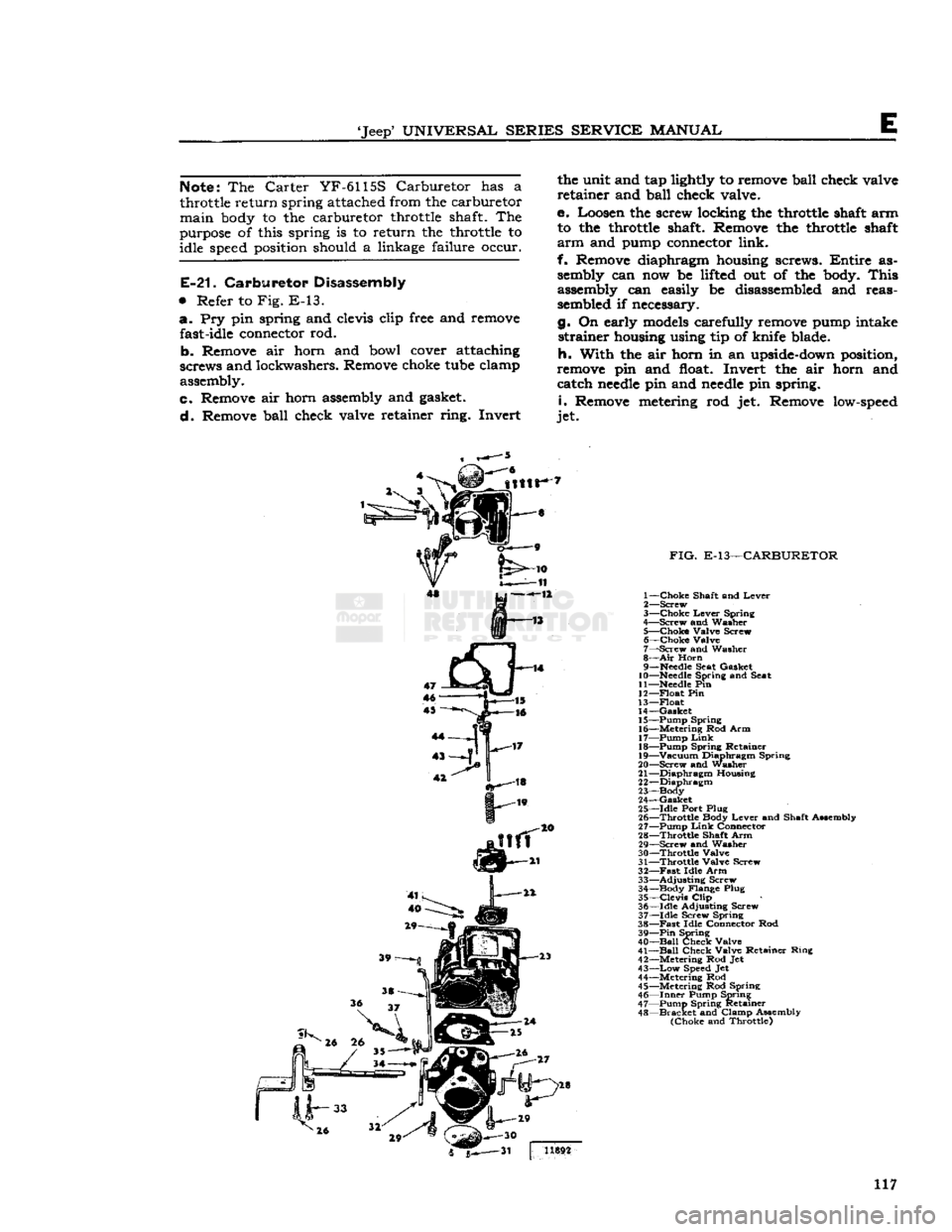

E-17.

Choke System

The

choke system consists of a manually-operated

choke valve, a fast-idle connecting rod, and a fast-

idle arm. The choke valve is offset-spring loaded to prevent over-choking during the starting warm-

up period. When the choke valve is moved to a closed position for starting, the fast idle connector

rod

in Fig. E-ll revolves the fast idle link.

This

action increases the

engine

idle speed to prevent stalling during the warm-up period. A fast-idle

connector rod return spring prevents partial closing

of the choke valve. pump lifter which is connected to the throttle.

This

movement forces fuel from the chamber

above the diaphragm through discharge pump check valve and discharge pump jet.

This

auxiliary discharge of fuel supplies

engine

requirements for

quick

acceleration and heavy loads. When the

throttle is closed, the diaphragm is again pulled

down by high vacuum and another measured

charge of fuel enters the chamber above the

diaphragm

through the intake passage to be

available for the next cycle of operation.

Note:

The pump jet (see insert drawing in Fig.

E-12)

projecting into the air stream is permanently pressed into the carburetor body and should not

be removed. Also, carburetor design makes it im possible to adjust the pump stroke.

FIG.

E-ll—FAST

IDLE

ADJUSTMENT

1—Fast

Idle

Connector Rod

2—Fast

Idle

Link

E-18.

Fast

Idle Adjustment

With

the choke held in wide open position, lip (No. 1) (Fig.

E-ll)

on the fast-idle rod should con

tact the

boss

on the body casting. Adjust by bend

ing the fast-idle link at

offset

as shown by (No. 2).

E-19.

Accelerating Pump System

The

accelerating pump system shown in Fig. E-12

provides a measured amount of fuel for rapid acceleration and smooth

engine

operation when

the throttle is opened at lower speeds. In operation,

vacuum

is applied to the underside of diaphragm

at all times when the

engine

is running.

Lower

and

more uniform vacuum is provided by vacuum

restriction

and vacuum bleed passage. When the

diaphragm

is in its maximum down position at

low throttle resulting from high vacuum in chamber the chamber above the diaphragm is full of fuel

which

has been admitted through intake passage.

When

the throttle is opened, vacuum drops in the

chamber and the diaphragm is initially forced

upward

by the spring on the diaphragm shaft.

The

upward motion is picked up by accelerator

|

13347

FIG.

E-12—ACCELERATING

PUMP

SYSTEM

1—

Pump

Fuel

Passage

6—Intake

Passage

2—

Discharge

Pump Jet 7—Diaphragm

3—

Pump

Check

Valve

Ball

8—Vacuum Chamber 4—

Bail

Check

Weight

9—Vacuum

Restriction

Jet

5—

Pump

Lifter

Arm 10—Vacuum Bleed Passage

E-20.

Accelerating Pump Maintenance

If

engine

acceleration is unsatisfactory, remove the

pump diaphragm and check the diaphragm for wear

or

damage. Then remove the pump check retainer

ring

located directly above the pump check weight

and

pump ball check. Pump ball check must seat

properly

as a leak

will

cause poor acceleration performance. Inspect and replace all worn or

damaged parts.

Clean

and blow out all passages

with

compressed air.

Note

that when testing the pump for discharge volume with the carburetor

off the engine, only half of the maximum pump capacity

will

be discharged. When the

engine

is

operating, vacuum controls the balance of dis charge. 116

Page 117 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

E

Note:

The

Carter

YF-6115S Carburetor has a

throttle

return spring

attached

from the carburetor

main

body

to the carburetor

throttle

shaft. The

purpose

of

this

spring is to return the

throttle

to

idle

speed

position

should a linkage failure occur.

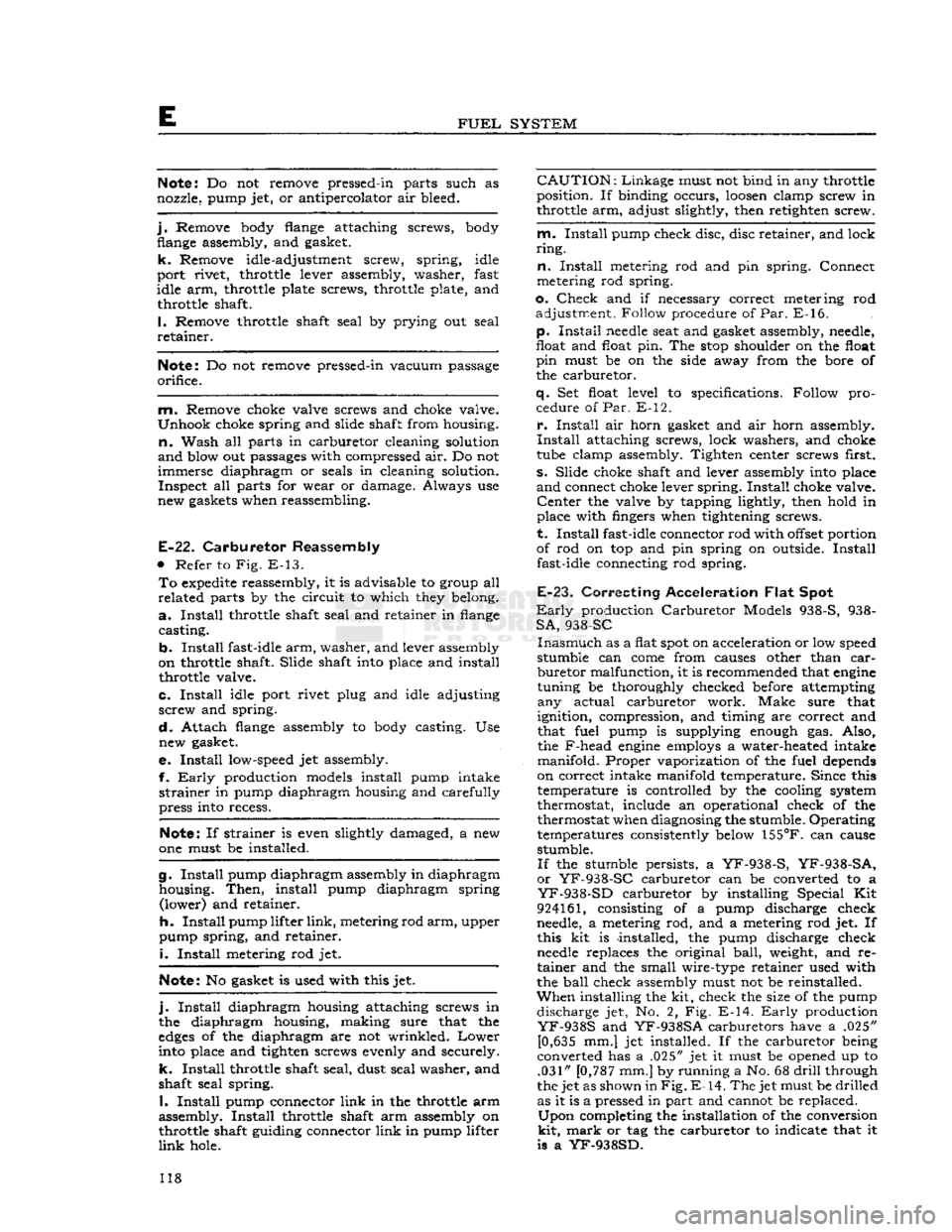

E-21.

Carburetor Disassembly

•

Refer to Fig. E-13. a. Pry pin spring and

clevis

clip

free

and

remove

fast-idle

connector

rod.

b- Remove air horn and bowl

cover

attaching

screws and lockwashers. Remove

choke

tube

clamp

assembly.

c. Remove air horn

assembly

and

gasket.

d. Remove ball check valve retainer ring. Invert the unit and tap

lightly

to

remove

ball check valve

retainer and ball check valve.

e. Loosen the screw locking the

throttle

shaft

arm to the

throttle

shaft. Remove the

throttle

shaft

arm

and

pump

connector

link.

f. Remove diaphragm

housing

screws.

Entire

as

sembly

can now be

lifted

out of the

body.

This

assembly

can easily be

disassembled

and reas

sembled

if necessary.

g. On early

models

carefully

remove

pump

intake strainer

housing

using tip of knife blade.

h. With the air horn in an

upside-down

position,

remove

pin and

float.

Invert the air horn and catch

needle

pin and

needle

pin spring.

i.

Remove

metering

rod jet. Remove

low-speed

jet.

FIG.

E-13—CARBURETOR

1— Choke Shaft and Lever

2— Screw

3— Choke Lever Spring

4— Screw and Washer

5— Choke Valve Screw 6— Choke Valve

7— Screw and Washer

8—

Air

Horn

9—

Needle

Seat Gasket

10—

Needle

Spring and Seat

11—Needle

Pin

12— Float Pin

13— Float

14— Gasket 15— Pump Spring

16— Metering Rod Arm

17— Pump

Link

18— Pump Spring Retainer

19— Vacuum Diaphragm Spring

20— Screw and washer

21— Diaphragm Housing

22— Diaphragm

23—Body

24— Gasket

25— Idle Port Plug

26— Throttle Body Lever and Shaft Assembly

27— Pump

Link

Connector

28— Throttle Shaft Arm 29— Screw and Washer

30— Throttle Valve

31— Throttle Valve Screw

32—

Fast

Idle Arm 33— Adjusting Screw

34— Body Flange Plug

35— Clevis

Clip

36— Idle Adjusting Screw

37— Idle Screw Spring

38—

Fast

Idle Connector Rod 39—

Pin

Spring

40—

Ball

Check Valve

41—

Ball

Check Valve Retainer Ring

42— Metering Rod Jet

43—

Low

Speed

Jet

44— Metering Rod

45— Metering Rod Spring 46—

Inner

Pump Spring

47— Pump Spring Retainer

48—

Bracket

and Clamp Assembly (Choke and Throttle) 5^—31 | 1X892

117

Page 118 of 376

E

FUEL

SYSTEM

Note:

Do not remove pressed-in parts such as

nozzle, pump jet, or antipercolator air bleed.

j.

Remove body flange attaching screws, body flange assembly, and gasket.

k.

Remove idle-adjustment screw, spring, idle

port

rivet, throttle lever assembly, washer, fast

idle arm, throttle plate screws, throttle plate, and throttle shaft.

1. Remove throttle shaft seal by prying out seal

retainer.

Note:

Do not remove pressed-in vacuum passage

orifice.

m.

Remove choke valve screws and choke valve.

Unhook

choke spring and slide shaft from housing,

n.

Wash all parts in carburetor cleaning solution

and

blow out passages with compressed air. Do not immerse diaphragm or seals in cleaning solution.

Inspect

all parts for wear or damage. Always use

new gaskets when reassembling.

E-22.

Carburetor

Reassembly

•

Refer to Fig. E-13.

To

expedite

reassembly, it is advisable to group all

related

parts by the circuit to which they belong.

a.

Install

throttle shaft seal and retainer in flange casting.

b.

Install

fast-idle

arm,

washer, and lever assembly

on throttle shaft. Slide shaft into place and install throttle valve.

c.

Install

idle port rivet plug and idle adjusting

screw

and spring.

d.

Attach flange assembly to body casting. Use new gasket.

e.

Install

low-speed jet assembly.

f.

Early

production models install pump intake

strainer

in pump diaphragm housing and carefully

press into recess.

Note:

If strainer is even slightly damaged, a new

one must be installed.

g.

Install

pump diaphragm assembly in diaphragm housing.

Then,

install pump diaphragm spring

(lower)

and retainer.

h.

Install

pump lifter

link,

metering rod

arm,

upper

pump spring, and retainer.

I.

Install

metering rod jet.

Note:

No gasket is used with this jet.

j.

Install

diaphragm housing attaching screws in

the diaphragm housing, making sure that the

edges

of the diaphragm are not wrinkled.

Lower

into place and tighten screws evenly and securely,

k.

Install

throttle shaft seal, dust seal washer, and

shaft seal spring.

I.

Install

pump connector

link

in the throttle arm

assembly.

Install

throttle shaft arm assembly on

throttle shaft guiding connector

link

in pump lifter

link

hole.

CAUTION:

Linkage

must not bind in any throttle

position. If binding occurs,

loosen

clamp screw in

throttle arm, adjust slightly, then retighten screw.

m.

Install

pump check disc, disc retainer, and lock

ring.

n.

Install

metering rod and pin spring. Connect

metering rod spring.

o.

Check

and if necessary correct meter ing rod adjustment. Follow procedure of

Par.

E-16.

p.

Install

needle

seat and gasket assembly, needle,

float

and

float pin. The

stop

shoulder on the float

pin

must be on the side away from the bore of

the carburetor.

q.

Set float level to specifications. Follow pro cedure of

Par.

E-12.

r.

Install

air horn gasket and air horn assembly.

Install

attaching screws, lock washers, and choke

tube clamp assembly. Tighten center screws first,

s. Slide choke shaft and lever assembly into place

and

connect choke lever

spring.

Install

choke valve.

Center

the valve by tapping lightly, then hold in

place with fingers when tightening screws,

t.

Install

fast-idle connector rod with

offset

portion

of rod on top and pin spring on outside.

Install

fast-idle connecting rod spring.

E-23.

Correcting Acceleration

Flat

Spot

Early

production

Carburetor

Models 938-S, 938-

SA,

938-SC

Inasmuch

as a flat

spot

on acceleration or low speed

stumble can

come

from causes other than

car

buretor

malfunction, it is recommended that

engine

tuning be thoroughly checked before attempting

any

actual carburetor work. Make sure that

ignition, compression, and timing are correct and

that fuel pump is supplying enough gas. Also, the F-head

engine

employs a water-heated intake

manifold.

Proper vaporization of the fuel depends

on correct intake manifold temperature. Since this

temperature is controlled by the cooling system

thermostat, include an operational check of the

thermostat when diagnosing the stumble. Operating

temperatures consistently below

155°F.

can cause stumble.

If

the stumble persists, a

YF-938-S,

YF-938-SA,

or

YF-938-SC

carburetor can be converted to a

YF-938-SD

carburetor by installing Special Kit

924161, consisting of a pump discharge check

needle, a metering rod, and a metering rod jet. If this kit is installed, the pump discharge check

needle

replaces the original

ball,

weight, and re

tainer

and the small wire-type retainer used with

the

ball

check assembly must not be reinstalled.

When

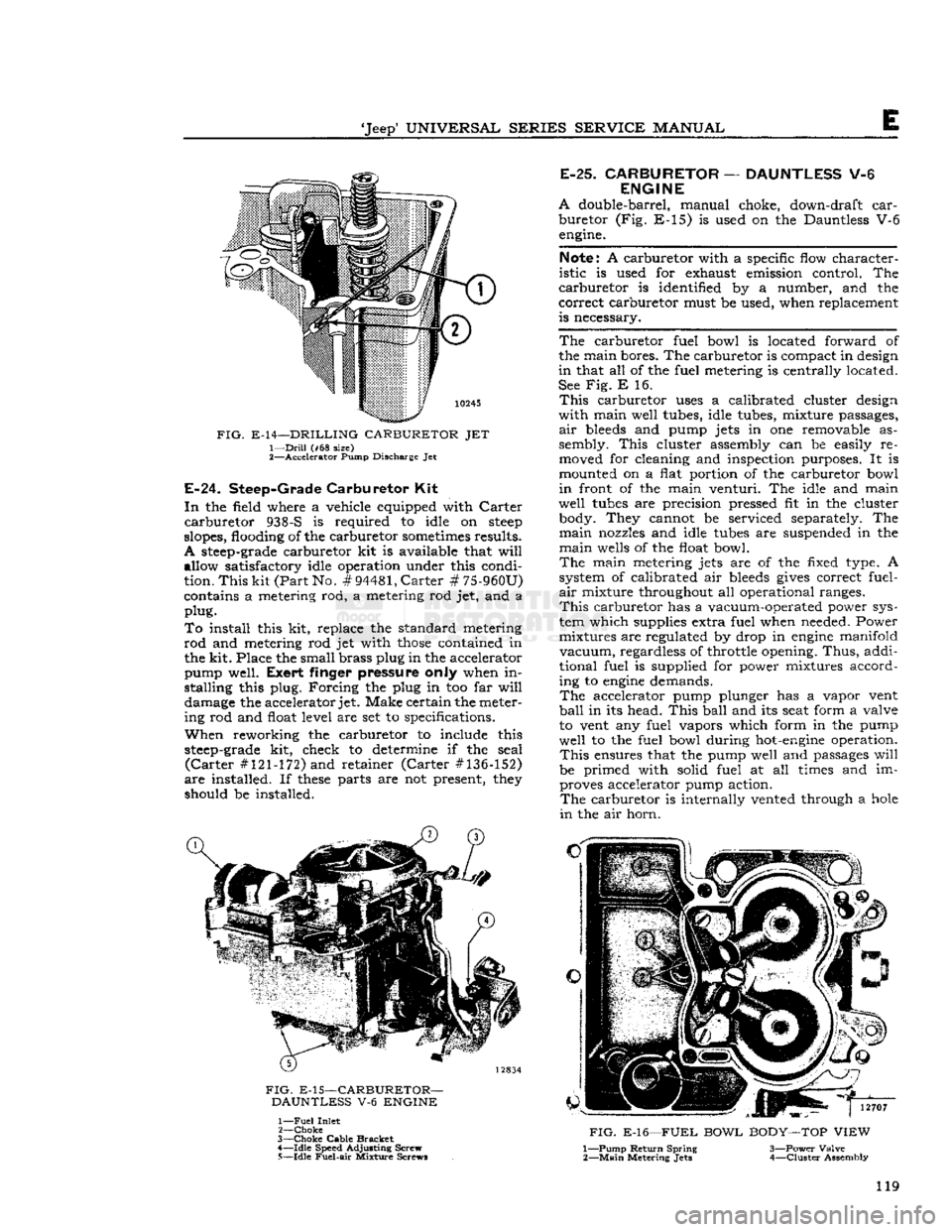

installing the kit, check the size of the pump discharge jet, No. 2, Fig. E-14.

Early

production

YF-938S

and

YF-938SA

carburetors have a .025" [0,635 mm.] jet installed. If the carburetor being

converted has a .025" jet it must be opened up to .031" [0,787 mm.] by running a No. 68

drill

through

the jet as shown in

Fig.

E-14.

The jet must be drilled

as it is a pressed in part and cannot be replaced.

Upon

completing the installation of the conversion

kit,

mark

or tag the carburetor to indicate that it

is a

YF-938SD.

118

Page 119 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

E

FIG.

E-14—DRILLING CARBURETOR JET 1—

Drill

(#68 size)

2—

Accelerator

Pump Discharge Jet

E-24.

Steep-Grade

Carburetor

Kit

In

the

field

where a vehicle equipped

with

Carter carburetor 938-S is required to

idle

on

steep

slopes,

flooding

of the carburetor sometimes results.

A

steep-grade

carburetor kit is available that

will

allow satisfactory

idle

operation under this condi

tion.

This kit (Part

No.

#94481,

Carter # 75-960U)

contains a metering rod, a metering rod jet, and a

plug.

To

install

this kit, replace the standard metering

rod

and metering rod jet

with

those

contained in the

kit.

Place the small

brass

plug

in the accelerator

pump

well.

Exert

finger pressure only when in

stalling

this

plug.

Forcing the

plug

in too far

will

damage

the accelerator

jet.

Make certain the meter

ing

rod and

float

level

are set to specifications.

When

reworking

the carburetor to include this

steep-grade

kit, check to determine if the seal (Carter #121-172) and retainer (Carter #136-152)

are installed. If

these

parts are not present, they

should

be installed.

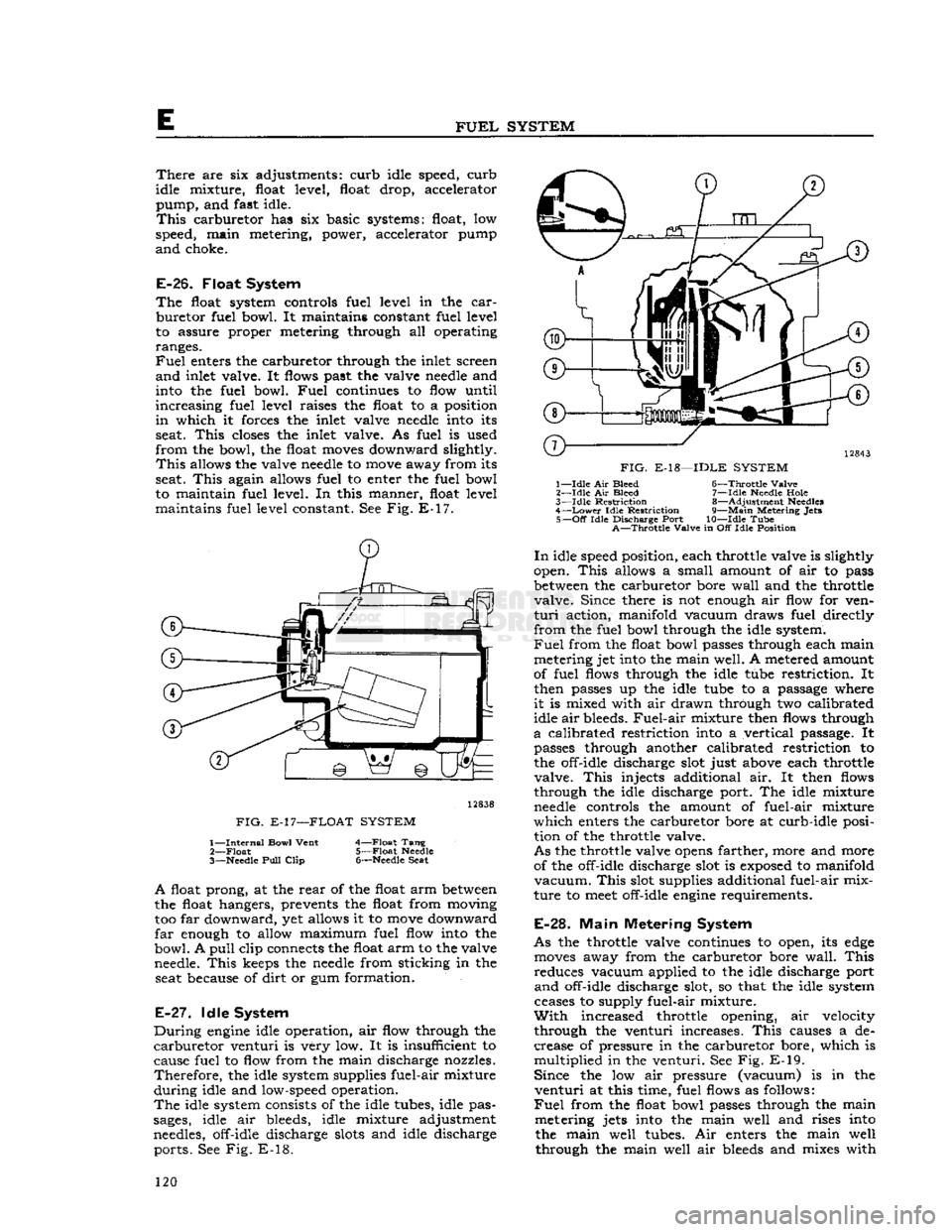

FIG.

E-15—CARBURETOR-

DAUNTLESS V-6 ENGINE 1—

Fuel

Inlet

2—

Choke

3—

Choke

Cable

Bracket

4—

Idle

Speed Adjusting Screw 5—

Idle

Fuel-air

Mixture Screws

E-25.

CARBURETOR

—

DAUNTLESS

V-6

ENGINE

A

double-barrel, manual choke, down-draft car

buretor (Fig. E-15) is used on the Dauntless V-6 engine.

Note: A carburetor

with

a specific

flow

character

istic

is used for exhaust emission

control.

The

carburetor is

identified

by a number, and the

correct carburetor must be used, when replacement

is

necessary.

The carburetor

fuel

bowl

is located

forward

of

the main bores. The carburetor is compact in design

in

that all of the

fuel

metering is centrally located.

See Fig. E 16.

This

carburetor

uses

a calibrated cluster design

with

main

well

tubes,

idle

tubes, mixture

passages,

air

bleeds and pump jets in one removable as

sembly.

This cluster assembly can be easily re

moved

for cleaning and inspection purposes. It is

mounted

on a

flat

portion

of the carburetor

bowl

in

front

of the main

venturi.

The

idle

and main

well

tubes

are precision

pressed

fit in the cluster

body.

They cannot be serviced separately. The

main

nozzles and

idle

tubes

are

suspended

in the

main

wells of the

float

bowl.

The main metering jets are of the

fixed

type. A

system of calibrated air bleeds gives correct

fuel-

air

mixture throughout all operational

ranges.

This

carburetor has a vacuum-operated power sys

tem

which

supplies extra

fuel

when needed. Power

mixtures

are regulated by drop in engine

manifold

vacuum,

regardless of throttle opening. Thus, addi

tional

fuel

is supplied for power mixtures accord

ing

to engine demands.

The accelerator pump plunger has a vapor vent

ball

in its head. This

ball

and its

seat

form

a valve

to

vent any

fuel

vapors

which

form

in the pump

well

to the

fuel

bowl

during hot-engine operation.

This

ensures

that the pump

well

and

passages

will

be primed

with

solid

fuel

at all times and im proves accelerator pump action. The carburetor is

internally

vented through a hole

in

the air horn.

FIG.

E-16—FUEL BOWL BODY—TOP VIEW

1— Pump Return Spring 3—Power

Valve

2—

Main

Metering

Jets

4—Cluster Assembly

119

Page 120 of 376

E

FUEL

SYSTEM

There

are six adjustments: curb idle speed, curb

idle mixture, float level, float drop, accelerator pump, and fast idle.

This

carburetor has six basic systems: float, low

speed, main metering, power, accelerator pump

and

choke.

E-26.

Float System

The

float system controls fuel level in the

car

buretor fuel bowl. It maintains constant fuel level

to assure proper metering through all operating

ranges.

Fuel

enters the carburetor through the inlet screen

and

inlet valve. It flows past the valve

needle

and into the fuel bowl.

Fuel

continues to flow until

increasing

fuel level raises the float to a position

in

which it forces the inlet valve

needle

into its seat.

This

closes

the inlet valve. As fuel is used

from

the bowl, the float

moves

downward slightly.

This

allows the valve

needle

to

move

away from its

seat.

This

again allows fuel to enter the fuel bowl

to maintain fuel level. In this manner, float level maintains fuel level constant. See Fig. E-17. 12838

FIG.

E-17—FLOAT

SYSTEM

1—

Internal

Bowl

Vent

4—Float Tang

2—

Float

5—Float Needle

3— Needle

Pull

Clip

6—Needle

Seat

A

float prong, at the

rear

of the float arm

between

the float hangers, prevents the float from moving too far downward, yet allows it to

move

downward

far

enough to allow maximum fuel flow into the

bowl. A

pull

clip connects the float arm to the valve needle.

This

keeps the

needle

from sticking in the seat because of

dirt

or gum formation.

E-27.

Idle System

During

engine

idle operation, air flow through the

carburetor

venturi is very low. It is insufficient to

cause fuel to flow from the main discharge nozzles.

Therefore,

the idle system supplies fuel-air mixture

during

idle and low-speed operation.

The

idle system consists of the idle tubes, idle pas

sages,

idle air bleeds, idle mixture adjustment

needles, off-idle discharge

slots

and idle discharge ports. See Fig. E-18.

FIG.

E-18—IDLE

SYSTEM

1—

Idle

Air Bleed 6—Throttle

Valve

2—

Idle

Air Bleed 7—Idle Needle

Hole

3—

Idle

Restriction

8—Adjustment Needles

4—

Lower

Idle

Restriction

9—Main

Metering

Jets

5—

Off

Idle

Discharge Port 10—Idle Tube

A—Throttle

Valve

in Off

Idle

Position

In

idle speed position, each throttle valve is slightly

open.

This

allows a small amount of air to pass

between

the carburetor bore

wall

and the throttle valve. Since there is not enough air flow for ven

turi

action, manifold vacuum draws fuel directly

from

the fuel bowl through the idle system.

Fuel

from the float bowl passes through each main metering jet into the main well. A metered amount

of fuel flows through the idle tube restriction. It

then passes up the idle tube to a passage where

it

is mixed with air drawn through two calibrated

idle air bleeds.

Fuel-air

mixture then flows through

a

calibrated restriction into a vertical passage. It passes through another calibrated restriction to the off-idle discharge slot just above each throttle

valve.

This

injects additional air. It then flows

through the idle discharge port. The idle mixture

needle

controls the amount of fuel-air mixture

which

enters the carburetor bore at curb-idle posi tion of the throttle valve.

As

the throttle valve

opens

farther, more and more of the off-idle discharge slot is

exposed

to manifold

vacuum.

This

slot supplies additional fuel-air mix

ture to

meet

off-idle

engine

requirements.

E-28.

Main

Metering System

As

the throttle valve continues to open, its

edge

moves

away from the carburetor bore

wall.

This

reduces vacuum applied to the idle discharge port

and

off-idle discharge slot, so that the idle system

ceases

to supply fuel-air mixture.

With

increased throttle opening, air velocity through the venturi increases.

This

causes a de

crease of pressure in the carburetor bore, which is multiplied in the venturi. See Fig. E-19.

Since

the low air pressure (vacuum) is in the

venturi

at this time, fuel flows as follows:

Fuel

from the float bowl passes through the main metering jets into the main well and rises into the main well tubes. Air enters the main well through the main well air

bleeds

and mixes with 120