tow LAND ROVER DISCOVERY 2002 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1176 of 1672

INTERIOR TRIM COMPONENTS

REPAIRS 76-3-23

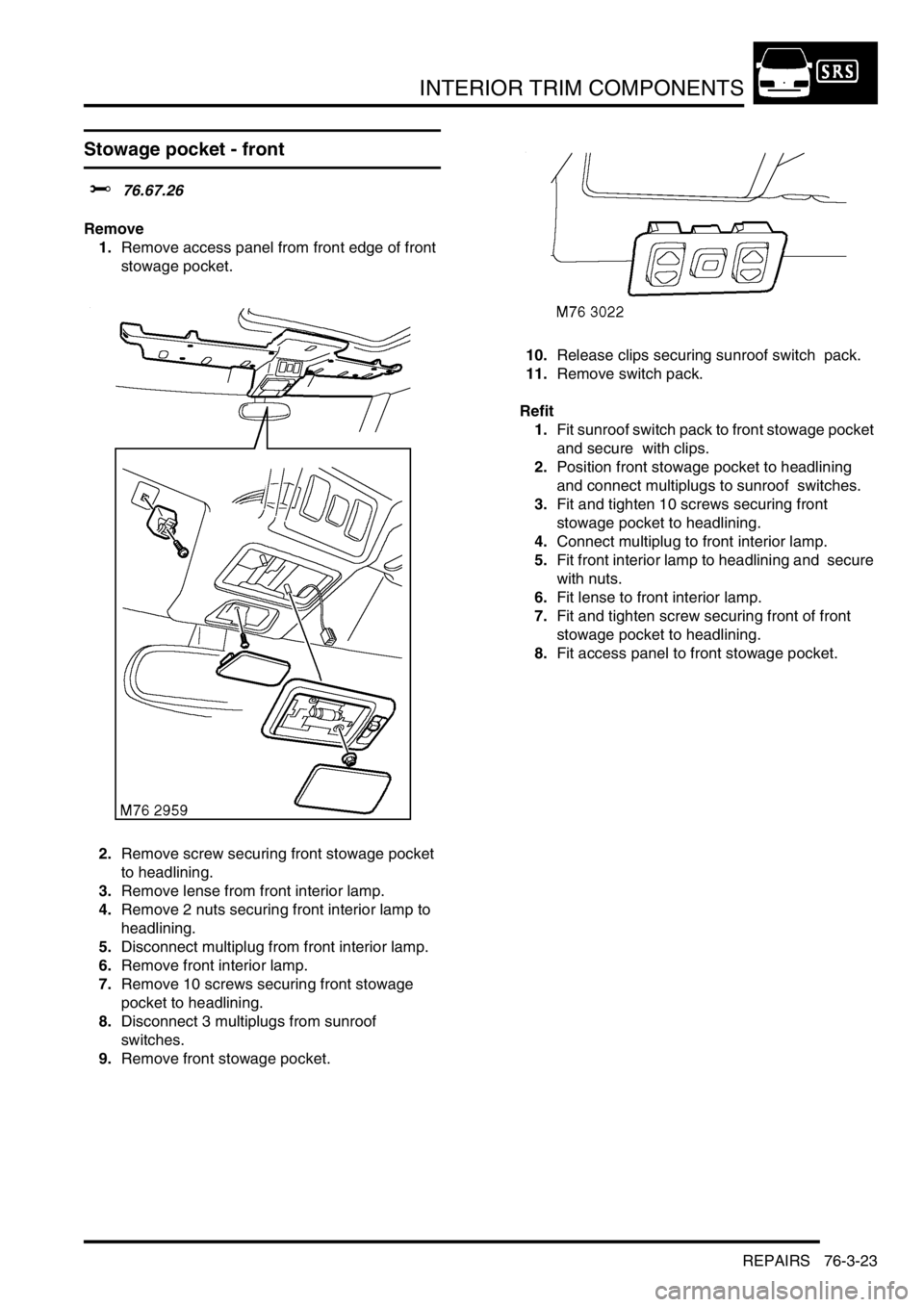

Stowage pocket - front

$% 76.67.26

Remove

1.Remove access panel from front edge of front

stowage pocket.

2.Remove screw securing front stowage pocket

to headlining.

3.Remove lense from front interior lamp.

4.Remove 2 nuts securing front interior lamp to

headlining.

5.Disconnect multiplug from front interior lamp.

6.Remove front interior lamp.

7.Remove 10 screws securing front stowage

pocket to headlining.

8.Disconnect 3 multiplugs from sunroof

switches.

9.Remove front stowage pocket. 10.Release clips securing sunroof switch pack.

11.Remove switch pack.

Refit

1.Fit sunroof switch pack to front stowage pocket

and secure with clips.

2.Position front stowage pocket to headlining

and connect multiplugs to sunroof switches.

3.Fit and tighten 10 screws securing front

stowage pocket to headlining.

4.Connect multiplug to front interior lamp.

5.Fit front interior lamp to headlining and secure

with nuts.

6.Fit lense to front interior lamp.

7.Fit and tighten screw securing front of front

stowage pocket to headlining.

8.Fit access panel to front stowage pocket.

Page 1202 of 1672

SEATS

REPAIRS 76-5-17

4.Remove saddle bracket cover from lower rear

quarter to allow access to third row seat

securing bolts and nuts.

5.Remove top 2 bolts securing seat to lower rear

quarter panel.

6.Position the locally manufactured retainer

bracket across the seat mounting. Ensure that

the lugs on the end of the retainer fit below the

seat mounting bar, then partially fold the seat

so that the retainer bracket is held in position.

7.Remove lower 2 nuts securing seat to lower

rear quarter panel. The action of the spring will

now hold the retainer bracket in place.

8.Remove seat.Refit

1.Ensuring that the retainer bracket is in position

on the spring, position third row seat to its

mounting studs.

2.Fit nuts securing third row seat to lower rear

quarter panel and tighten to 22 Nm (16 lbf.ft).

3.Remove the retainer bracket, fit bolts securing

third row seat to lower rear quarter panel and

tighten to 22 Nm (16 lbf.ft).

4.Fit saddle bracket cover to third row seat

securing bolts, fit the cup holder (where

applicable) and stow the seat.

Page 1211 of 1672

SEATS

76-5-26 REPAIRS

17.Release clip securing front of cover to squab

frame.

18.Release hooks from squab frame.

19.Fold cover upwards over squab until first row of

hog rings are visible.

20.Remove first row of hog rings. 21.Fold cover upwards over squab until second

row of hog rings are visible.

22.Remove second row of hog rings.

23.Push out centres of trim clips securing stowage

pocket elastic to seat frame.

24.Remove trim clip outers.

25.Release hooks from seat frame and feed

though to front of foam.

26.Fold cover upwards until third row of hog rings

are visible.

27.Remove third row of hog rings.

28.Remove hog rings securing rear of squab

cover to seat frame.

29.Release bar from seat frame.

Page 1212 of 1672

SEATS

REPAIRS 76-5-27

30.Remove headrest guides.

31.Fold cover fully upwards and remove. Refit

1.Fit squab cover to top of seat. Do not fold down

too far onto seat.

2.Fit headrest guides.

3.Fit grab handles to seat and secure with

screws.

4.Ensure top of cover fits correctly around grab

handles.

5.Fit bar securing rear of squab cover to seat

frame.

6.Fit hog rings securing rear of squab cover to

seat frame.

7.Pull cover down tight and align hog ring

location points.

8.Fit third row of hog rings.

9.Pull cover down tight and feed hooks though

foam.

10.Connect hooks to rear of squab frame.

11.Align stowage pocket elastic to seat frame and

secure with trim clips.

12.Pull cover down tight and align hog ring

location points.

13.Fit second row of hog rings.

14.Pull cover down tight and align hog ring

location points.

15.Fit first row of hog rings.

16.Pull cover down tight and connect hooks to

squab frame.

17.Feed front of cover through to rear.

18.Secure bottom of cover to frame with clip.

19.Fit clips securing ends of cover to frame.

20.Fit headrest to seat.

21.Turn seat upside down.

22.Secure rear edge of squab cover to frame with

clip.

23.Turn seat correct way up.

24.Fit inner edge trim casing to seat frame.

25.Fit outer edge trim casing and secure with

screws.

26.Position arm rest to seat, secure with screw and

loosen arm rest adjuster to the required

position.

27.Fit front seat.

+ SEATS, REPAIRS, Seat - front.

Page 1230 of 1672

SUNROOF

REPAIRS 76-6-15

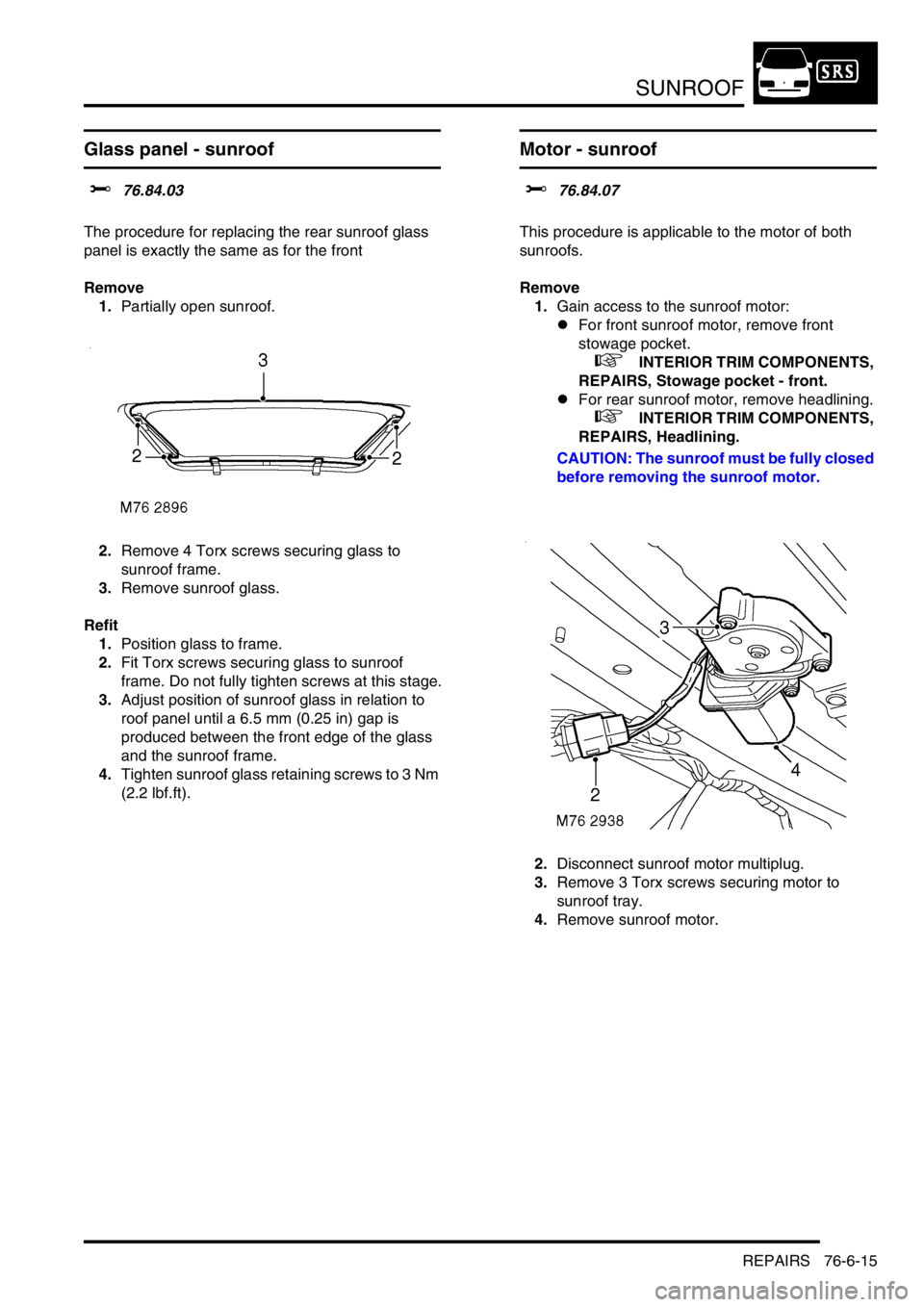

Glass panel - sunroof

$% 76.84.03

The procedure for replacing the rear sunroof glass

panel is exactly the same as for the front

Remove

1.Partially open sunroof.

2.Remove 4 Torx screws securing glass to

sunroof frame.

3.Remove sunroof glass.

Refit

1.Position glass to frame.

2.Fit Torx screws securing glass to sunroof

frame. Do not fully tighten screws at this stage.

3.Adjust position of sunroof glass in relation to

roof panel until a 6.5 mm (0.25 in) gap is

produced between the front edge of the glass

and the sunroof frame.

4.Tighten sunroof glass retaining screws to 3 Nm

(2.2 lbf.ft).

Motor - sunroof

$% 76.84.07

This procedure is applicable to the motor of both

sunroofs.

Remove

1.Gain access to the sunroof motor:

lFor front sunroof motor, remove front

stowage pocket.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Stowage pocket - front.

lFor rear sunroof motor, remove headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining.

CAUTION: The sunroof must be fully closed

before removing the sunroof motor.

2.Disconnect sunroof motor multiplug.

3.Remove 3 Torx screws securing motor to

sunroof tray.

4.Remove sunroof motor.

Page 1231 of 1672

SUNROOF

76-6-16 REPAIRS

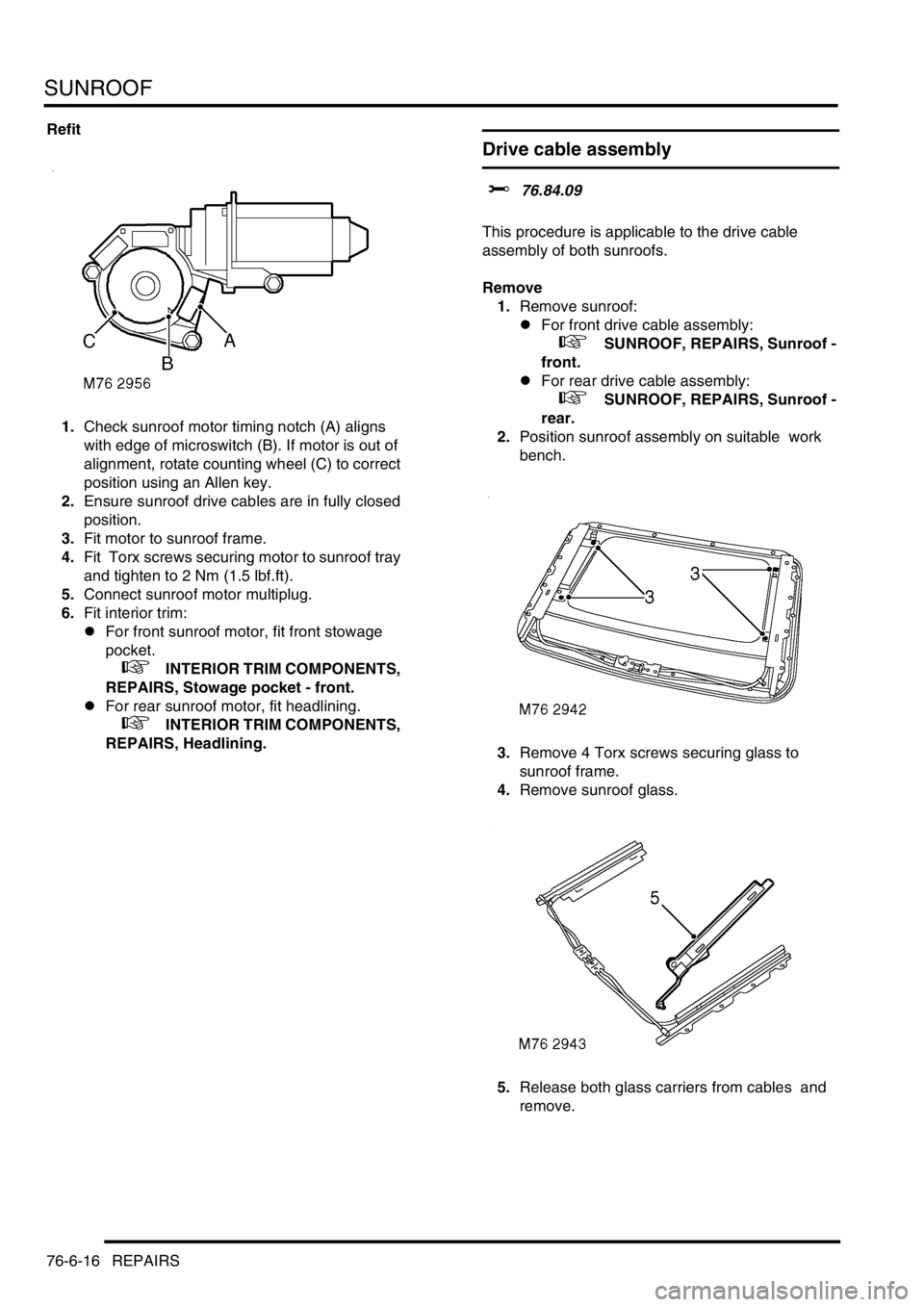

Refit

1.Check sunroof motor timing notch (A) aligns

with edge of microswitch (B). If motor is out of

alignment, rotate counting wheel (C) to correct

position using an Allen key.

2.Ensure sunroof drive cables are in fully closed

position.

3.Fit motor to sunroof frame.

4.Fit Torx screws securing motor to sunroof tray

and tighten to 2 Nm (1.5 lbf.ft).

5.Connect sunroof motor multiplug.

6.Fit interior trim:

lFor front sunroof motor, fit front stowage

pocket.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Stowage pocket - front.

lFor rear sunroof motor, fit headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining.

Drive cable assembly

$% 76.84.09

This procedure is applicable to the drive cable

assembly of both sunroofs.

Remove

1.Remove sunroof:

lFor front drive cable assembly:

+ SUNROOF, REPAIRS, Sunroof -

front.

lFor rear drive cable assembly:

+ SUNROOF, REPAIRS, Sunroof -

rear.

2.Position sunroof assembly on suitable work

bench.

3.Remove 4 Torx screws securing glass to

sunroof frame.

4.Remove sunroof glass.

5.Release both glass carriers from cables and

remove.

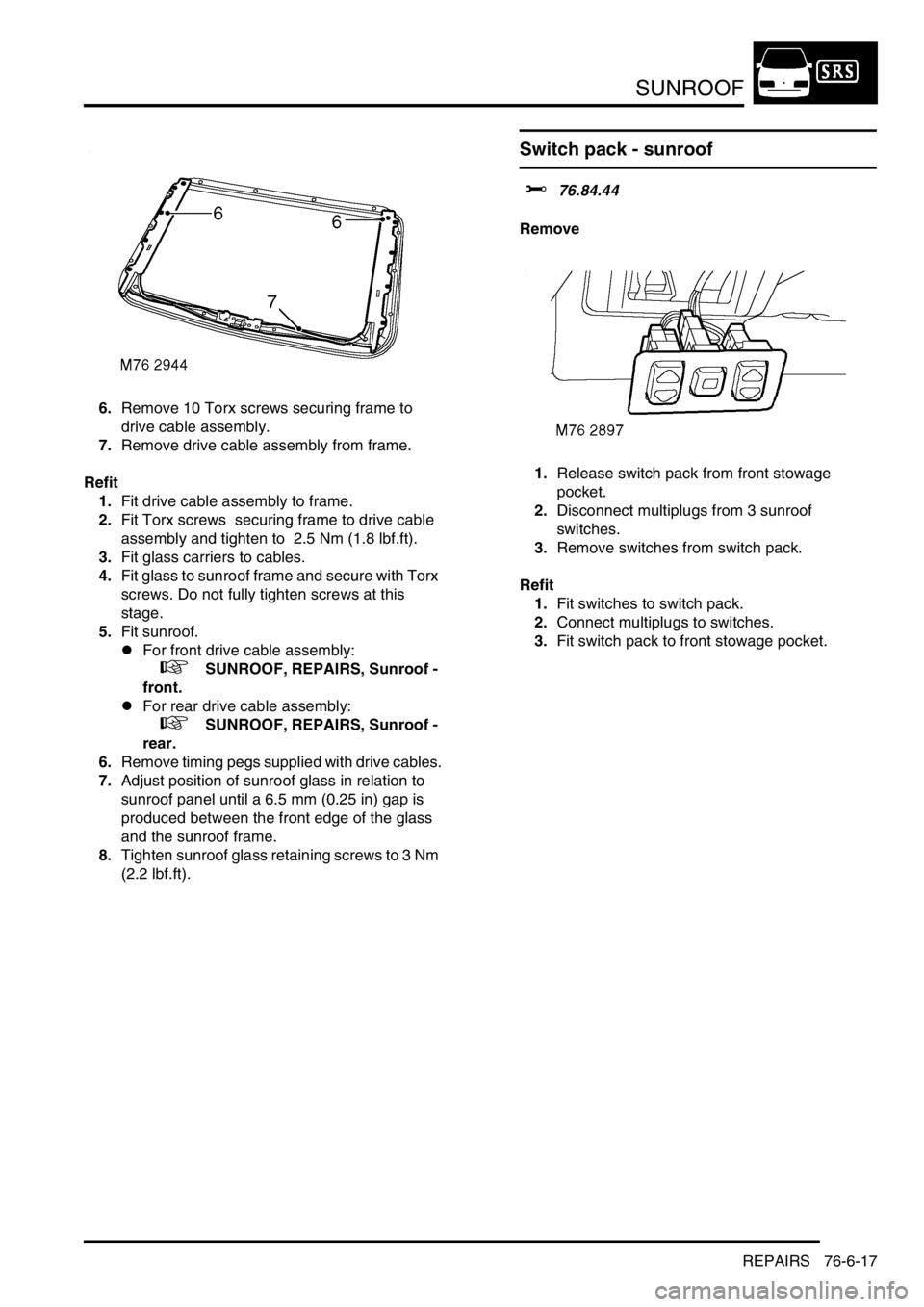

Page 1232 of 1672

SUNROOF

REPAIRS 76-6-17

6.Remove 10 Torx screws securing frame to

drive cable assembly.

7.Remove drive cable assembly from frame.

Refit

1.Fit drive cable assembly to frame.

2.Fit Torx screws securing frame to drive cable

assembly and tighten to 2.5 Nm (1.8 lbf.ft).

3.Fit glass carriers to cables.

4.Fit glass to sunroof frame and secure with Torx

screws. Do not fully tighten screws at this

stage.

5.Fit sunroof.

lFor front drive cable assembly:

+ SUNROOF, REPAIRS, Sunroof -

front.

lFor rear drive cable assembly:

+ SUNROOF, REPAIRS, Sunroof -

rear.

6.Remove timing pegs supplied with drive cables.

7.Adjust position of sunroof glass in relation to

sunroof panel until a 6.5 mm (0.25 in) gap is

produced between the front edge of the glass

and the sunroof frame.

8.Tighten sunroof glass retaining screws to 3 Nm

(2.2 lbf.ft).

Switch pack - sunroof

$% 76.84.44

Remove

1.Release switch pack from front stowage

pocket.

2.Disconnect multiplugs from 3 sunroof

switches.

3.Remove switches from switch pack.

Refit

1.Fit switches to switch pack.

2.Connect multiplugs to switches.

3.Fit switch pack to front stowage pocket.

Page 1233 of 1672

SUNROOF

76-6-18 REPAIRS

ECU - sunroof

$% 76.84.46

Remove

1.Remove front stowage pocket.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Stowage pocket - front.

2.Remove 2 screws securing ECU to roof.

3.Disconnect 2 multiplugs from ECU.

4.Remove sunroof ECU.

Refit

1.Position sunroof ECU and connect multiplugs.

2.Fit and tighten screws securing ECU to roof.

3.Fit front stowage pocket.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Stowage pocket - front.

Page 1321 of 1672

CORROSION PREVENTION AND SEALING

77-4-6 CORROSION PREVENTION

Corrosion prevention

Factory treatments

During production, vehicle bodies are treated with the following anti-corrosion materials:

lA PVC-based underbody sealer which is sprayed onto the underside of the main floor, rear floor, front and rear

wheelarches and the front valance assembly;

lAn application of cavity wax which is sprayed into the sill panels, 'A' post, 'B-C' post, fuel filler aperture, body rear

panel and the lower areas of the door panels;

lA coating of underbody wax which is applied to the entire underbody inboard of the sill vertical flanges, and

covers all moving and flexible components EXCEPT for wheels, tyres, brakes and exhaust;

lA coat of protective wax applied to the engine bay area.

Whenever body repairs are carried out, ensure the anti-corrosion materials in the affected area are repaired or

renewed as necessary using the approved materials.

+ BODY SEALING MATERIALS, MATERIALS AND APPLICATIONS, Approved materials.

Precautions during body repairs and handling

Take care when handling the vehicle in the workshop. Underbody sealers, seam sealers, underbody wax and body

panels may be damaged if the vehicle is carelessly lifted.

+ LIFTING AND TOWING, LIFTING.

Proprietary anti-corrosion treatments

The application of proprietary anti-corrosion treatments, in addition to the factory-applied treatment, could invalidate

the Corrosion Warranty and should be discouraged. This does not apply to Rover approved, compatible, preservative

waxes which may be applied on top of existing coatings.

Fitting approved accessories

When fitting accessories ensure that the vehicle's corrosion protection is not affected, either by breaking the protective

coating or by introducing a moisture trap.

Do not screw self-tapping screws directly into body panels. Fit suitable plastic inserts to the panel beforehand. Always

ensure that the edges of holes drilled into panels, chassis members and other body parts are protected with a suitable

zinc rich or acid etch primer, and follow with a protective wax coating brushed onto the surrounding area.

Do not attach painted metal surfaces of any accessory directly to the vehicle's bodywork unless suitably protected.

Where metal faces are bolted together always interpose a suitable interface material such as weldable zinc rich

primer, extruded strip, or zinc tape.

Steam cleaning and dewaxing

Due to the high temperatures generated by steam cleaning equipment, there is a risk that certain trim components

could be damaged and some adhesives and corrosion prevention materials softened or liquified.

Adjust the equipment so that the nozzle temperature does not exceed 90

° C (194° F). Take care not to allow the steam

jet to dwell on one area, and keep the nozzle at least 300 mm (11.811 in) from panel surfaces.

DO NOT remove wax or lacquer from underbody or underbonnet areas during repairs. Should it be necessary to

steam clean these areas, apply a new coating of wax or underbody protection as soon as possible.

Inspections during maintenance servicing

It is a requirement of the Corrosion Warranty that the vehicle body is checked for corrosion by an authorised Land

Rover Dealer at least once a year, to ensure that the factory-applied protection remains effective.

Service Job Sheets include the following operations to check bodywork for corrosion:

lWith the vehicle on a lift, carry out visual check of underbody sealer for damage;

lWith the vehicle lowered, inspect exterior paintwork for damage and body panels for corrosion.

It will be necessary for the vehicle to be washed by the Dealer prior to inspection of bodywork if the customer has

offered the vehicle in a dirty condition.

Page 1350 of 1672

HEATING AND VENTILATION

DESCRIPTION AND OPERATION 80-9

FBH fuel pump

The FBH fuel pump regulates the fuel supply to the FBH unit. The FBH fuel pump is installed in a rubber mounting on

the chassis crossmember immediately in front of the fuel tank. The pump is a self priming, solenoid operated plunger

pump, with a fixed displacement of 0.063 ml/Hz. The ECU in the FBH unit outputs a pulse width modulated signal to

control the operation of the pump. When the pump is de-energised, it provides a positive shut-off of the fuel supply to

the FBH unit.

FBH fuel pump nominal operating speeds/outputs

Sectioned view of FBH fuel pump

1Solenoid coil

2Plunger

3Filter insert

4Fuel line connector

5'O' ring seal6Spring

7Piston

8Bush

9Fuel line connector

10Non return valve

The solenoid coil of the FBH fuel pump is installed around a housing which contains a plunger and piston. The piston

locates in a bush, and a spring is installed on the piston between the bush and the plunger. A filter insert and a fuel

line connector are installed in the inlet end of the housing. A non return valve and a fuel line connector are installed

in the fuel outlet end of the housing.

While the solenoid coil is de-energised, the spring holds the piston and plunger in the 'closed' position at the inlet end

of the housing. An 'O' ring seal on the plunger provides a fuel tight seal between the plunger and the filter insert,

preventing any flow through the pump. When the solenoid coil is energised, the piston and plunger move towards the

outlet end of the housing, until the plunger contacts the bush, and draw fuel in through the inlet connection and filter.

The initial movement of the piston also closes transverse drillings in the bush and isolates the pumping chamber at

the outlet end of the housing. Subsequent movement of the piston then forces fuel from the pumping chamber through

the non return valve and into the line to the FBH unit. When the solenoid coil de-energises, the spring moves the piston

and plunger back towards the closed position. As the piston and plunger move towards the closed position, fuel flows

passed the plunger and through the annular gaps and transverse holes in the bush to replenish the pumping chamber.

Operating phase Speed, Hz Output, l/h (US galls/h)

Start sequence 0.70 0.159 (0.042)

Part load 1.35 0.306 (0.081)

Full load 2.70 0.612 (0.163)