LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1071 of 3229

Publi s hed: 11-May-2011

Accessory Drive - TD4 2.2L Diesel - Accessory Drive Belt

Removal and Inst all ati on

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

1. W ARNING: Make sure t o s upport the vehicle wit h axles tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he cover and dis connect the bat tery ground cabl e.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

2.

Remove t he RH front wheel and t ire.

Refer t o: W heel and Ti re (204-04 W heel s and Tires, Removal andInst all at ion).

3.

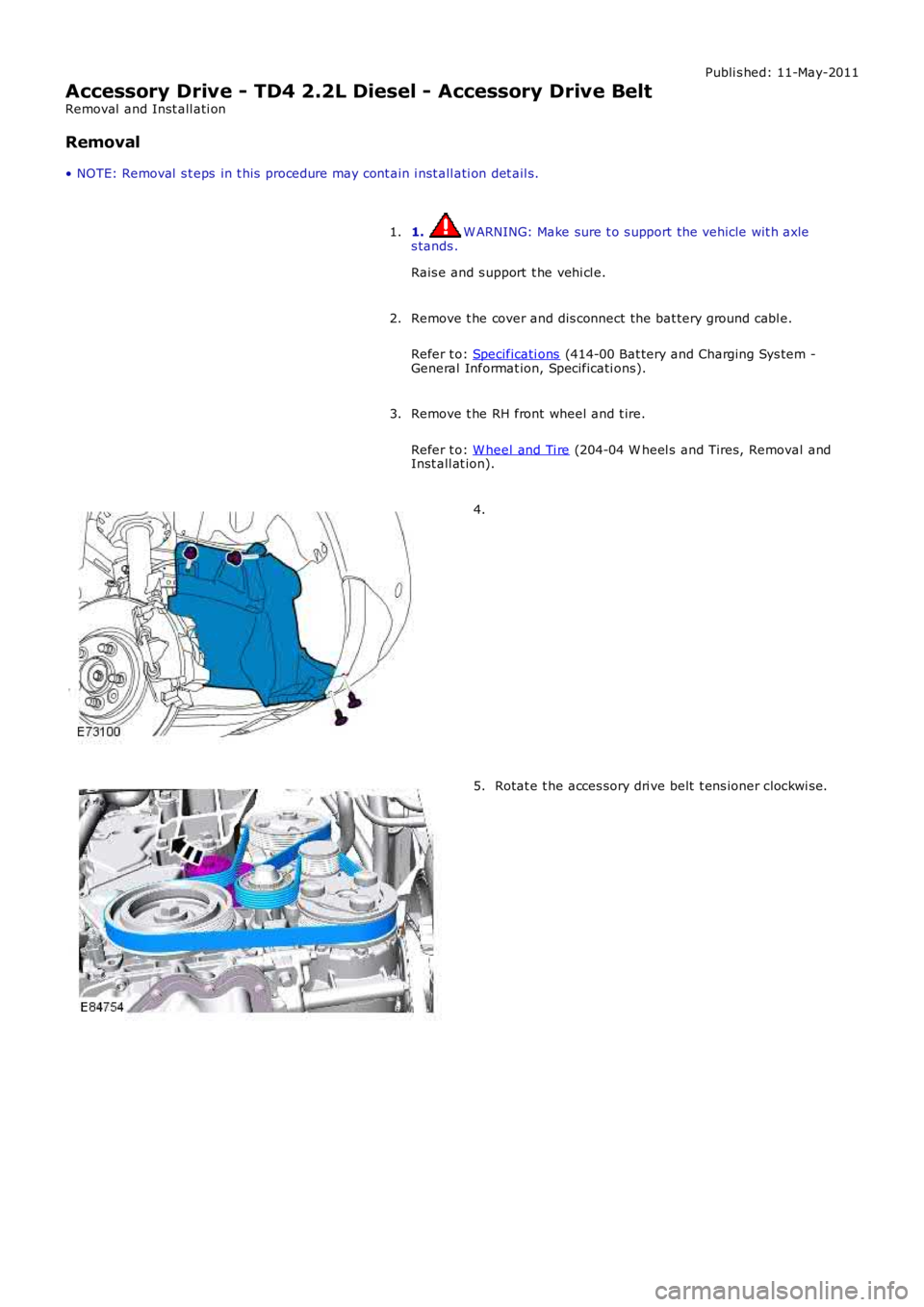

4.

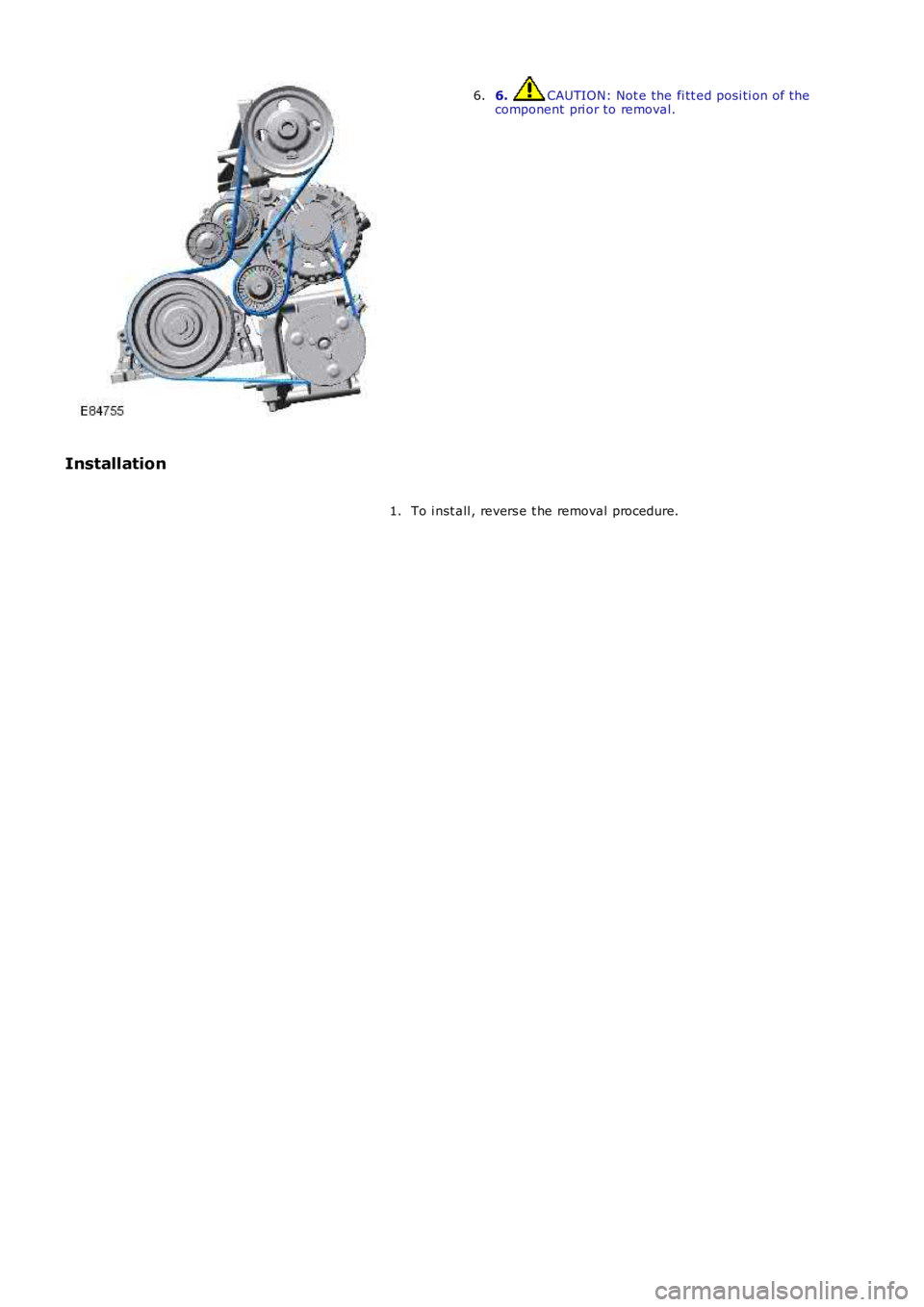

Rotat e t he acces sory dri ve belt t ens ioner clockwi s e.5.

Page 1072 of 3229

6. CAUTION: Not e the fi tt ed posi ti on of thecomponent pri or to removal.6.

Installation

To i nst all , revers e t he removal procedure.1.

Page 1073 of 3229

Publi s hed: 11-May-2011

Accessory Drive - TD4 2.2L Diesel - Accessory Drive Belt Tensioner

Removal and Inst all ati on

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

Remove t he cover and dis connect the bat tery ground cabl e.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -

General Informat ion, Specificati ons).

1.

Remove t he auxi liary dri ve belt .

Refer t o: Acces sory Dri ve Belt (303-05B Acces sory Drive - TD4 2.2L

Di es el, Removal and Ins tal lat ion).

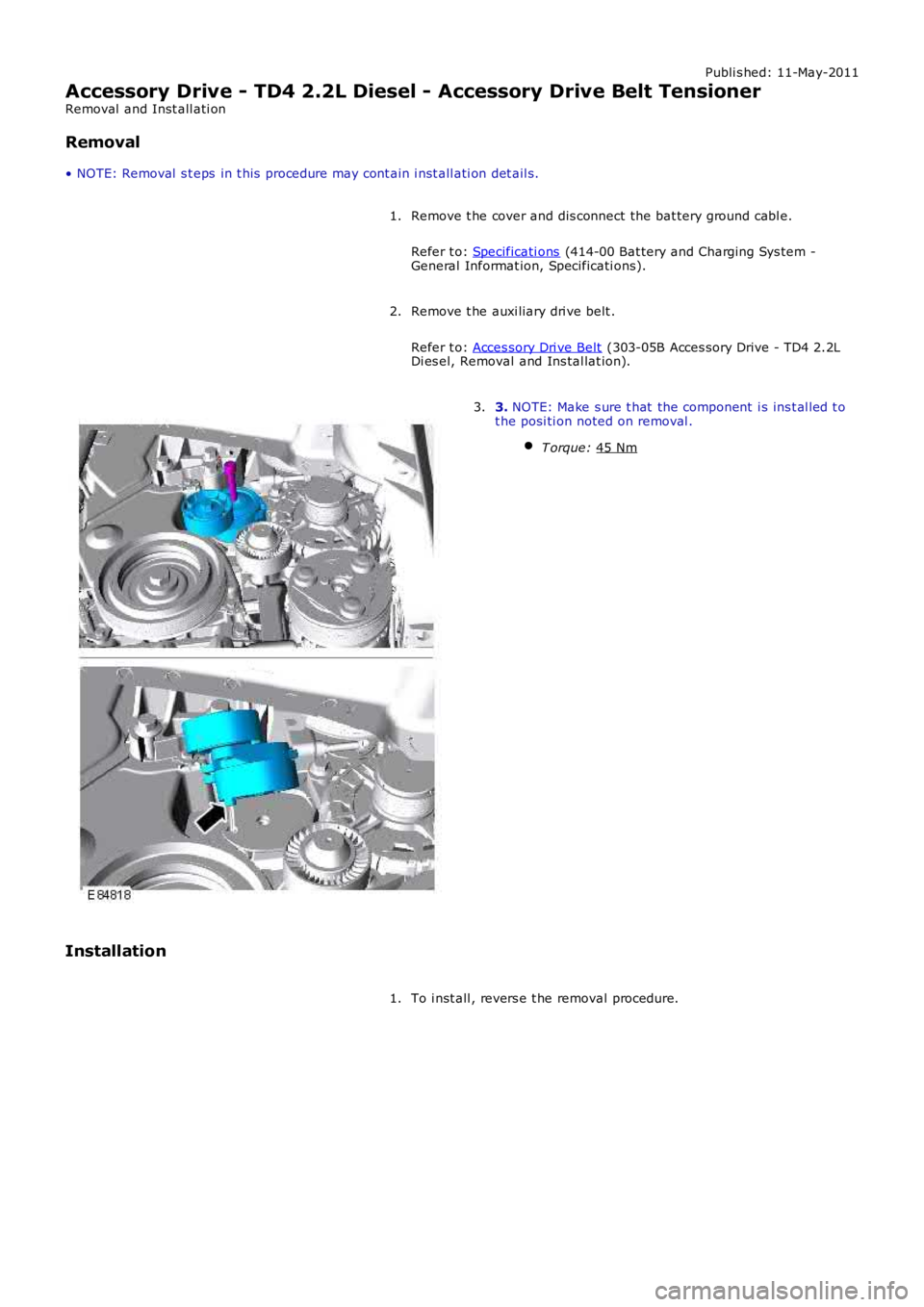

2. 3.

NOTE: Make s ure t hat the component i s ins t al led t o

t he posi ti on noted on removal .

T orque: 45 Nm 3.

Installation To i nst all , revers e t he removal procedure.

1.

Page 1074 of 3229

Publi s hed: 11-May-2011

Accessory Drive - TD4 2.2L Diesel - Accessory Drive Belt Idler Pulley

Removal and Inst all ati on

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

Di sconnect t he bat t ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -

General Informat ion, Specificati ons).

1.

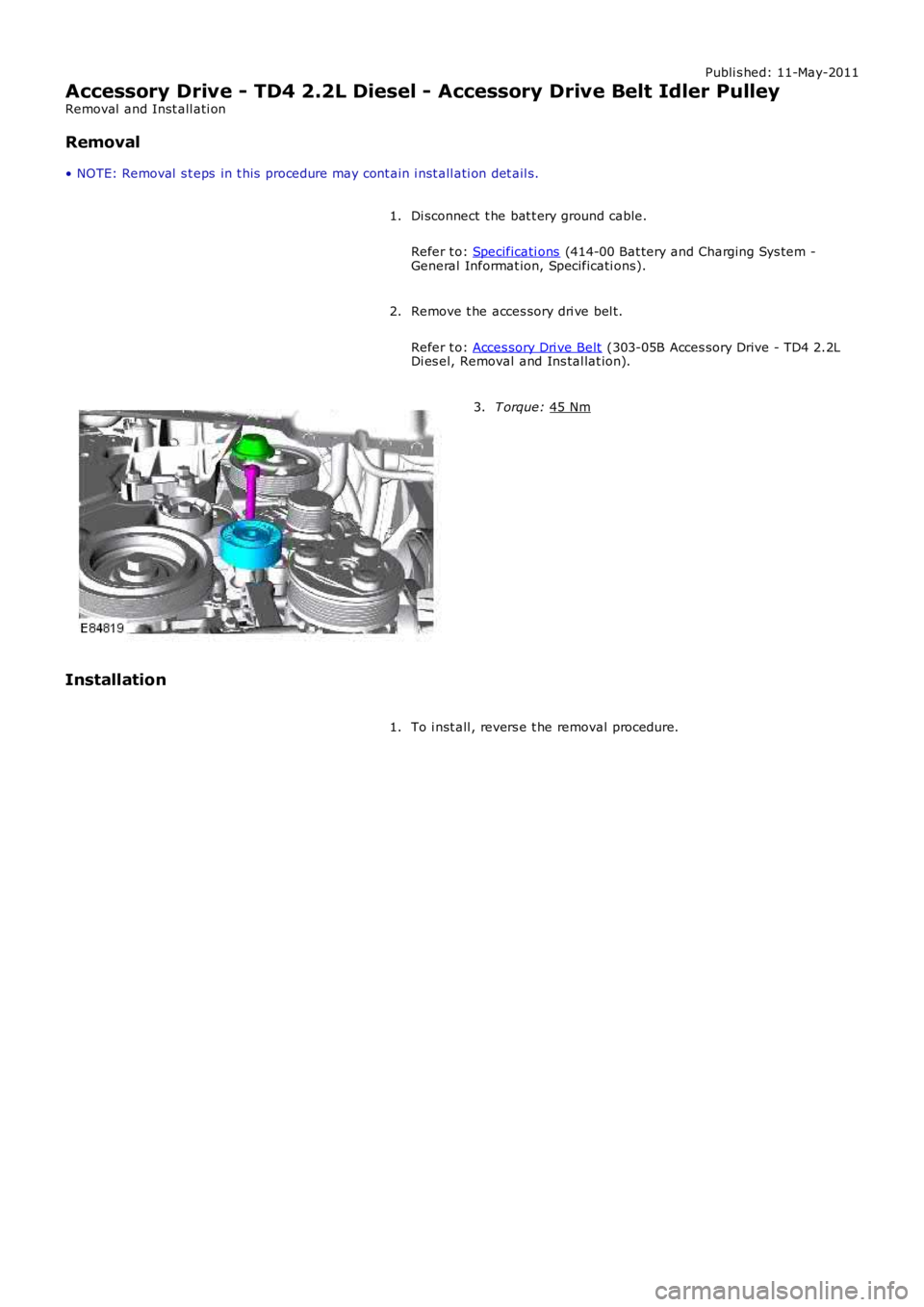

Remove t he acces sory dri ve bel t.

Refer t o: Acces sory Dri ve Belt (303-05B Acces sory Drive - TD4 2.2L

Di es el, Removal and Ins tal lat ion).

2. T orque:

45 Nm 3.

Installation To i nst all , revers e t he removal procedure.

1.

Page 1075 of 3229

Publi s hed: 11-May-2011

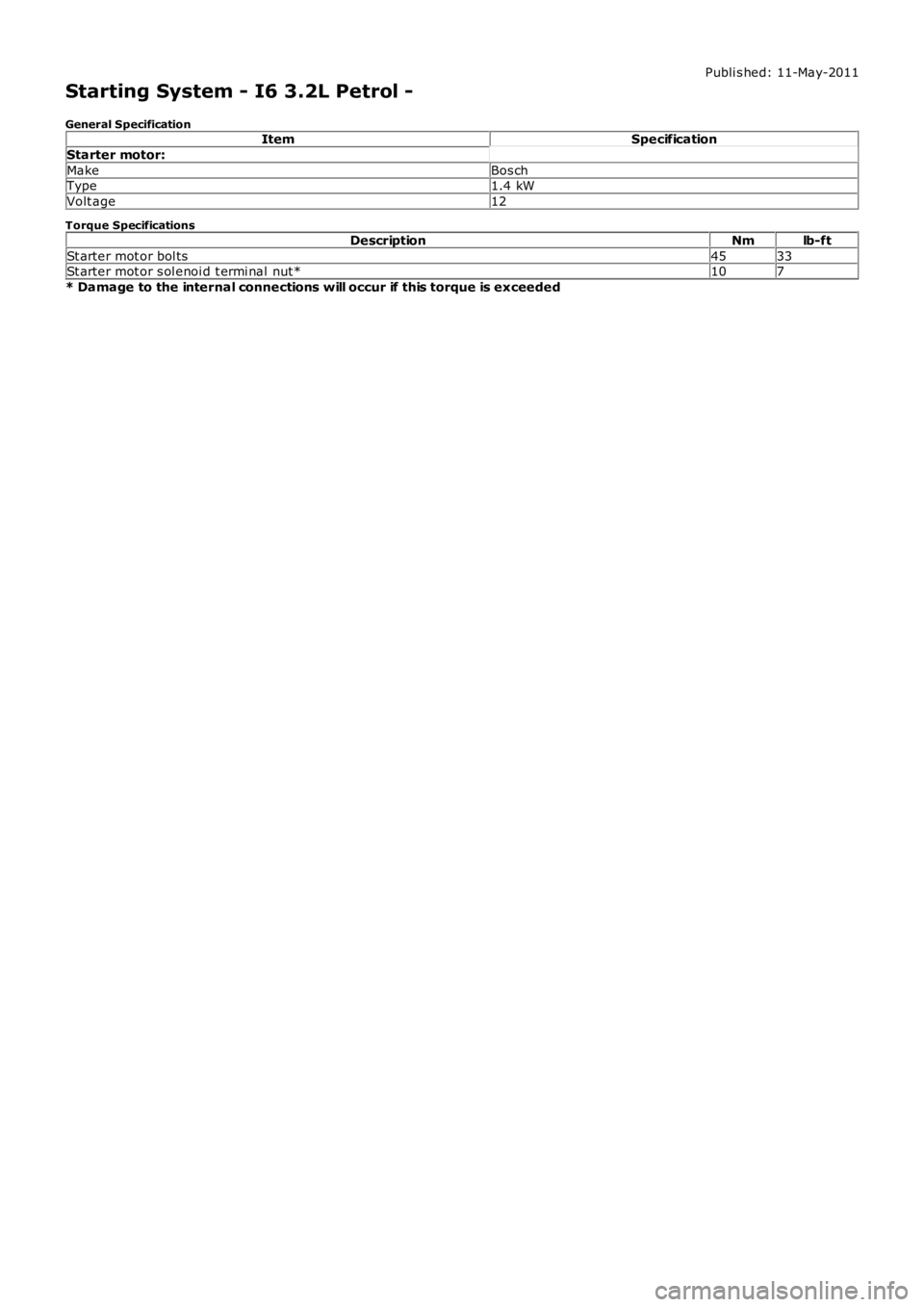

Starting System - I6 3.2L Petrol -

General SpecificationItemSpecification

Starter motor:

MakeBos chType1.4 kW

Volt age12

Torque Specifications

DescriptionNmlb-ft

St arter mot or bol ts4533St arter mot or s ol enoi d t ermi nal nut*107

* Damage to the internal connections will occur if this torque is exceeded

Page 1076 of 3229

Publi s hed: 11-May-2011

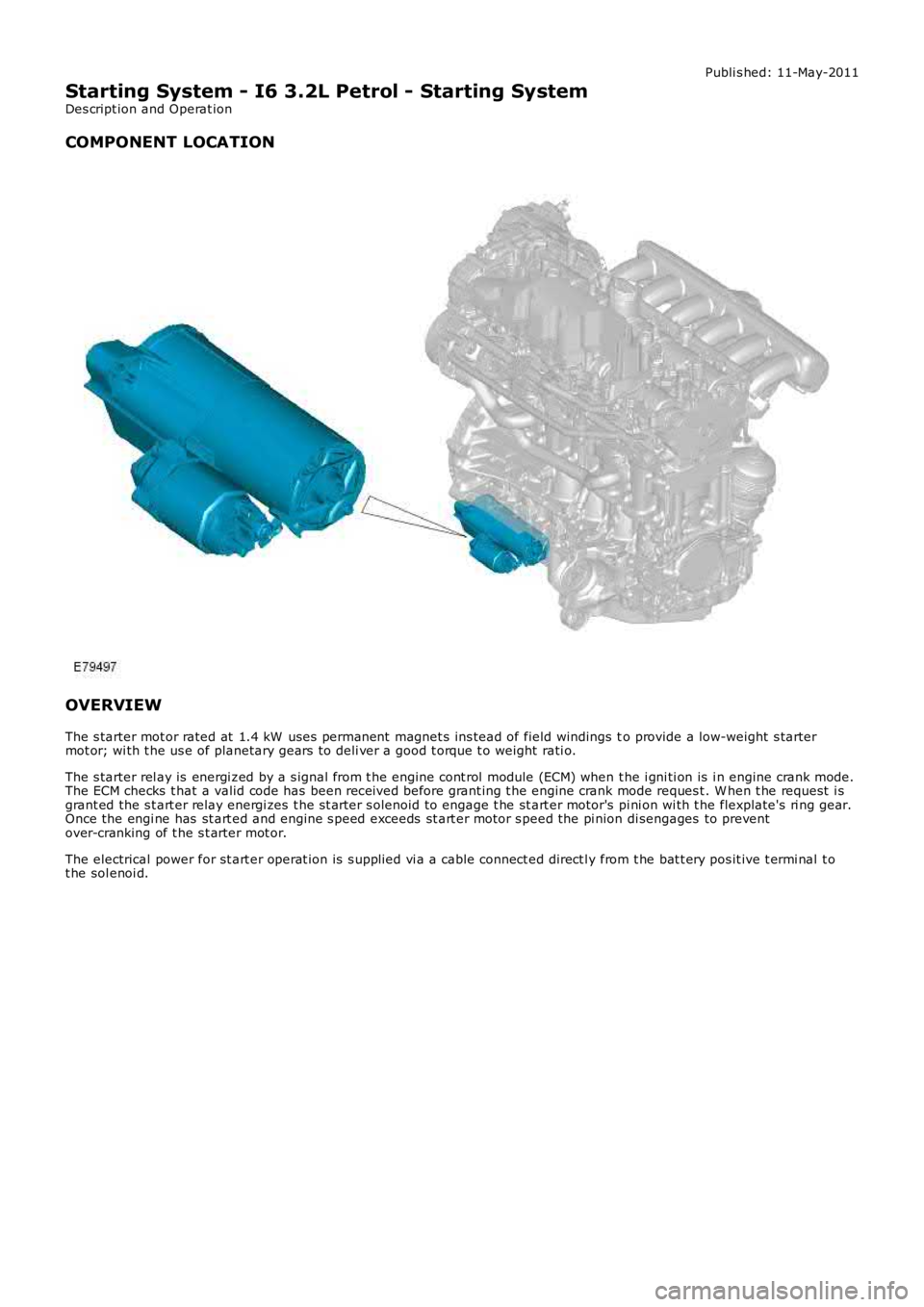

Starting System - I6 3.2L Petrol - Starting System

Des cript ion and Operat ion

COMPONENT LOCATION

OVERVIEW

The s tarter mot or rated at 1.4 kW uses permanent magnet s ins tead of field windings to provide a low-weight s tartermot or; wi th t he us e of planetary gears t o deli ver a good t orque t o weight rati o.

The s tarter rel ay is energi zed by a s ignal from t he engine cont rol module (ECM) when t he i gni ti on is i n engine crank mode.The ECM checks t hat a valid code has been received before grant ing t he engine crank mode reques t . W hen t he request i sgrant ed the s t art er relay energi zes t he s t arter s olenoid to engage t he st art er motor's pi ni on wi th t he flexplate's ri ng gear.Once the engi ne has st art ed and engine s peed exceeds st art er motor s peed the pi nion di sengages to preventover-cranking of t he s t arter mot or.

The electrical power for st art er operat ion is s upplied vi a a cable connect ed direct ly from t he bat t ery pos it ive t ermi nal t ot he sol enoi d.

Page 1077 of 3229

Publi s hed: 11-May-2011

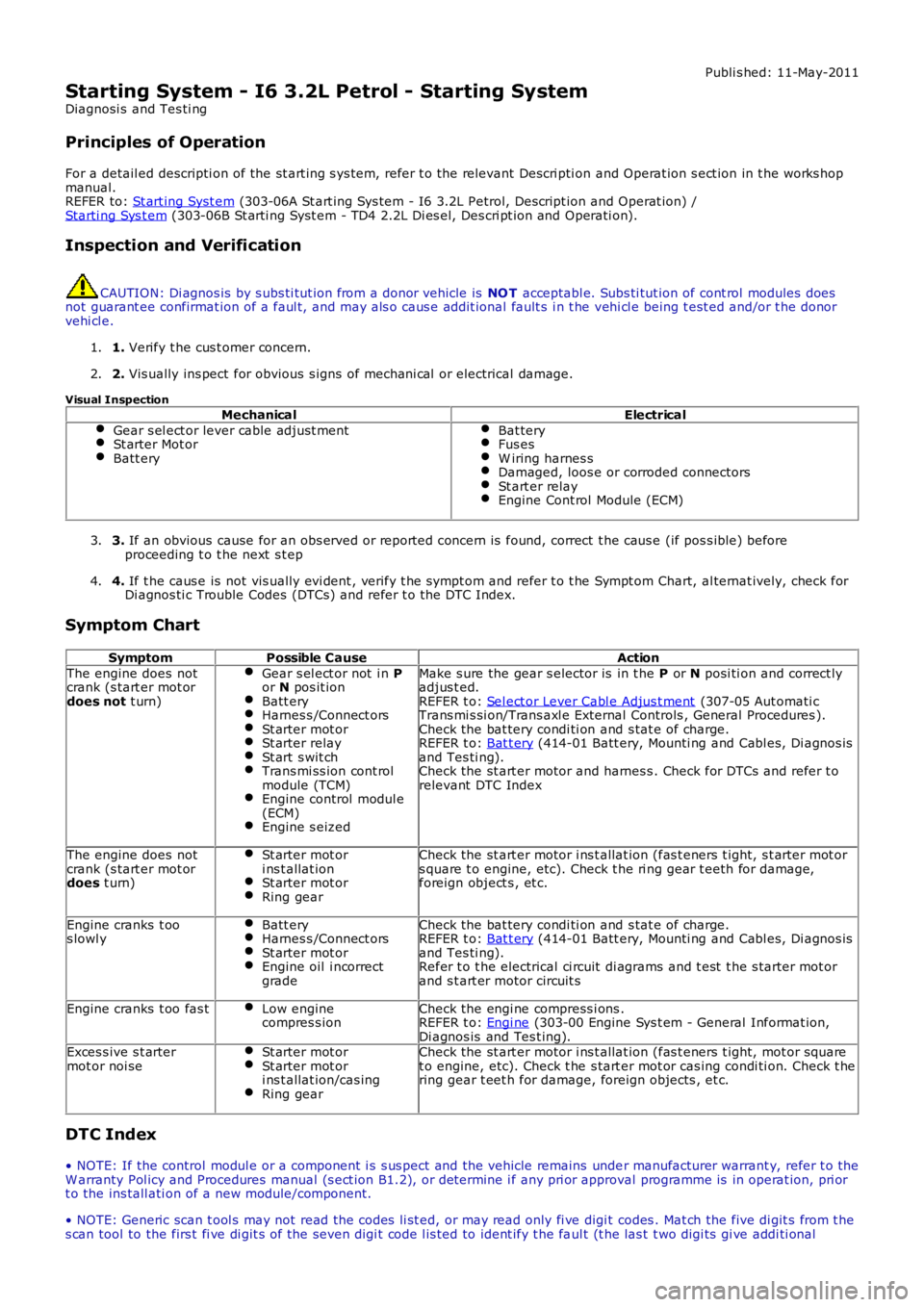

Starting System - I6 3.2L Petrol - Starting System

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the st art ing s ys tem, refer t o the relevant Descri pti on and Operat ion s ect ion in t he works hopmanual.REFER to: St art ing Syst em (303-06A St art ing Sys tem - I6 3.2L Petrol, Des cript ion and Operat ion) /Starti ng Sys t em (303-06B St arti ng Syst em - TD4 2.2L Di es el, Des cri pt ion and Operati on).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual Inspection

MechanicalElectrical

Gear s el ect or lever cable adjust mentSt arter Mot orBatt ery

Bat teryFus esW iring harnes sDamaged, loos e or corroded connectorsSt art er relayEngine Cont rol Module (ECM)

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

Symptom Chart

SymptomPossible CauseAction

The engine does notcrank (s tart er mot ordoes not t urn)

Gear s el ect or not i n Por N pos it ionBatt eryHarnes s /Connect orsSt arter mot orSt arter relaySt art s wit chTrans mi ss ion cont rolmodule (TCM)Engine control modul e(ECM)Engine s eized

Make s ure the gear s elector is in t he P or N posi ti on and correct lyadjus t ed.REFER t o: Sel ect or Lever Cabl e Adjus t ment (307-05 Aut omati cTrans mi s si on/Trans axl e External Controls , General Procedures ).Check the bat tery condi ti on and s tat e of charge.REFER t o: Bat t ery (414-01 Batt ery, Mounti ng and Cabl es, Di agnos isand Tes ti ng).Check the st art er motor and harnes s . Check for DTCs and refer t orelevant DTC Index

The engine does notcrank (s tart er mot ordoes t urn)

St arter mot ori ns t allat ionSt arter mot orRing gear

Check the st art er motor i ns t allat ion (fas t eners t ight, s t arter mot ors quare t o engine, etc). Check t he ri ng gear t eeth for damage,foreign object s , et c.

Engine cranks t oos lowl yBatt eryHarnes s /Connect orsSt arter mot orEngine oil i ncorrectgrade

Check the bat tery condi ti on and s tat e of charge.REFER t o: Bat t ery (414-01 Batt ery, Mounti ng and Cabl es, Di agnos isand Tes ti ng).Refer t o t he electrical ci rcuit di agrams and t est t he s tarter mot orand s t art er motor circuit s

Engine cranks t oo fas tLow enginecompres s ionCheck the engi ne compress i ons .REFER t o: Engi ne (303-00 Engine Sys t em - General Informat ion,Di agnos is and Tes t ing).Exces s ive s t artermot or noi seSt arter mot orSt arter mot ori ns t allat ion/cas ingRing gear

Check the st art er motor i ns t allat ion (fas t eners t ight, mot or squaret o engine, etc). Check t he s tart er mot or cas ing condi ti on. Check t hering gear t eet h for damage, foreign objects , et c.

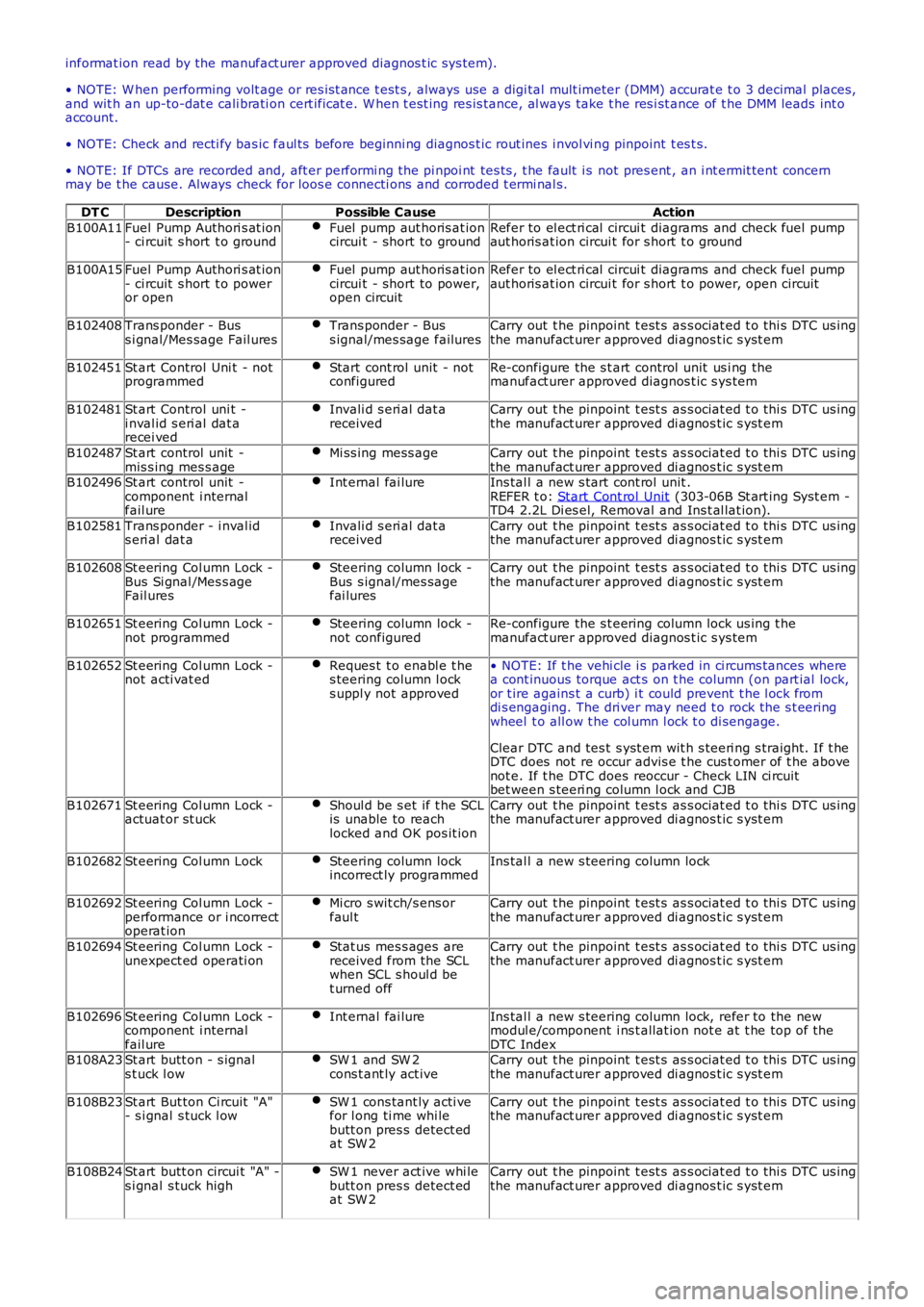

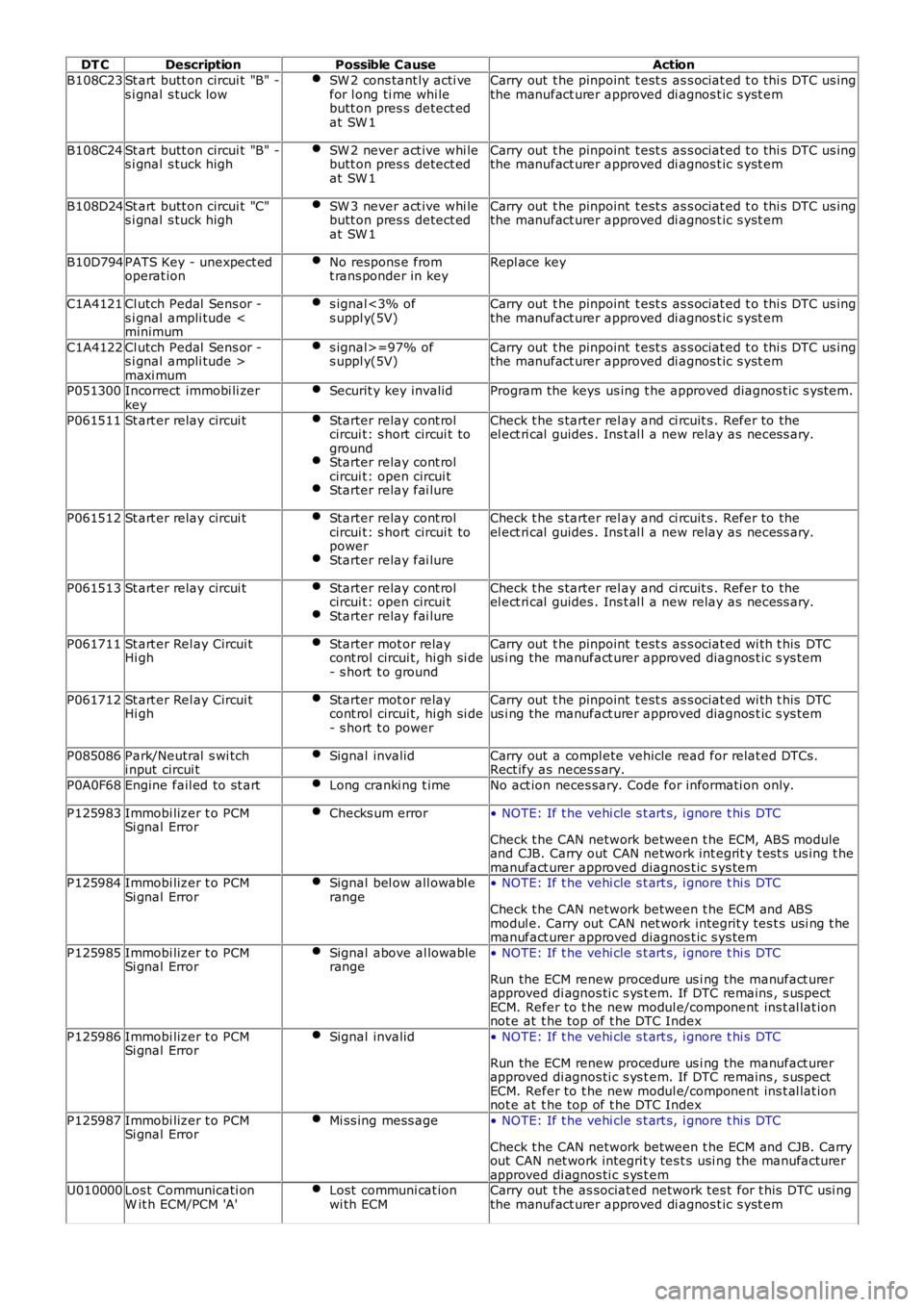

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onal

Page 1078 of 3229

informat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o 3 decimal places,and wit h an up-to-dat e cali brati on cert ificat e. W hen t est ing res is tance, al ways take t he res i st ance of t he DMM leads int oaccount.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , t he fault i s not pres ent , an i nt ermit tent concernmay be t he cause. Always check for loos e connecti ons and corroded t ermi nal s.

DT CDescriptionPossible CauseAction

B100A11Fuel Pump Authori s at ion- ci rcuit s hort t o groundFuel pump aut horis at ioncircui t - short to groundRefer to el ect ri cal circui t diagrams and check fuel pumpaut horis at ion circui t for s hort t o ground

B100A15Fuel Pump Authori s at ion- ci rcuit s hort t o poweror open

Fuel pump aut horis at ioncircui t - short to power,open circuit

Refer to el ect ri cal circui t diagrams and check fuel pumpaut horis at ion circui t for s hort t o power, open circuit

B102408Trans ponder - Buss i gnal/Mes sage Fail uresTrans ponder - Buss ignal/mes sage failuresCarry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B102451St art Control Uni t - notprogrammedStart cont rol unit - notconfiguredRe-configure the s t art control unit us i ng themanufact urer approved diagnos t ic s ys tem

B102481St art Control uni t -i nval id s eri al dat arecei ved

Invali d s eri al dat areceivedCarry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B102487St art control unit -mis s ing mes s ageMi ss ing mess ageCarry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst emB102496St art control unit -component i nternalfail ure

Int ernal fai lureIns tal l a new s tart cont rol unit .REFER t o: Start Cont rol Unit (303-06B St art ing Syst em -TD4 2.2L Di es el, Removal and Ins t al lat ion).

B102581Trans ponder - i nval ids eri al dat aInvali d s eri al dat areceivedCarry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B102608St eering Col umn Lock -Bus Si gnal /Mes s ageFail ures

Steering column lock -Bus s ignal/mes sagefai lures

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B102651St eering Col umn Lock -not programmedSteering column lock -not configuredRe-configure the s t eering column lock us ing t hemanufact urer approved diagnos t ic s ys tem

B102652St eering Col umn Lock -not acti vat edReques t t o enabl e t hes teering column l ocks uppl y not approved

• NOTE: If t he vehi cle i s parked in ci rcums tances wherea cont inuous torque act s on t he column (on part ial lock,or t ire agains t a curb) i t could prevent t he l ock fromdi s engaging. The dri ver may need t o rock the s t eeringwheel t o all ow t he col umn l ock t o di sengage.

Clear DTC and tes t s yst em wit h s teeri ng s traight. If t heDTC does not re occur advis e t he cus t omer of t he abovenot e. If t he DTC does reoccur - Check LIN ci rcuitbet ween s teeri ng column l ock and CJB

B102671St eering Col umn Lock -actuat or st uckShoul d be s et if t he SCLis unable to reachlocked and OK pos it ion

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B102682St eering Col umn LockSteering column lockincorrect ly programmedIns tal l a new s teering column lock

B102692St eering Col umn Lock -performance or i ncorrectoperat ion

Mi cro s wit ch/s ens orfaul tCarry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B102694St eering Col umn Lock -unexpect ed operati onStat us mes s ages arereceived from the SCLwhen SCL s houl d bet urned off

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B102696St eering Col umn Lock -component i nternalfail ure

Int ernal fai lureIns tal l a new s teering column lock, refer to the newmodul e/component i ns t allat ion not e at t he top of t heDTC IndexB108A23St art butt on - s ignals t uck l owSW 1 and SW 2cons t ant ly act iveCarry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B108B23St art But ton Ci rcuit "A"- s i gnal s tuck l owSW 1 cons tant ly acti vefor l ong ti me whi lebutt on pres s detect edat SW 2

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B108B24St art butt on circui t "A" -s i gnal s tuck highSW 1 never act ive whi lebutt on pres s detect edat SW 2

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

Page 1079 of 3229

DT CDescriptionPossible CauseAction

B108C23St art butt on circui t "B" -s i gnal s tuck lowSW 2 cons tant ly acti vefor l ong ti me whi lebutt on pres s detect edat SW 1

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B108C24St art butt on circui t "B" -s i gnal s tuck highSW 2 never act ive whi lebutt on pres s detect edat SW 1

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B108D24St art butt on circui t "C"s i gnal s tuck highSW 3 never act ive whi lebutt on pres s detect edat SW 1

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B10D794PATS Key - unexpect edoperat ionNo respons e fromt rans ponder in keyRepl ace key

C1A4121Cl utch Pedal Sens or -s i gnal ampli tude

C1A4122Cl utch Pedal Sens or -s i gnal ampli tude >maxi mum

s ignal>=97% ofs uppl y(5V)Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

P051300Incorrect immobi li zerkeySecurit y key invalidProgram the keys us ing t he approved diagnos t ic s yst em.

P061511St art er relay circui tStarter relay cont rolcircui t: s hort circui t togroundStarter relay cont rolcircui t: open circui tStarter relay fai lure

Check t he s tarter rel ay and ci rcuit s . Refer to theel ect ri cal guides . Ins t al l a new relay as neces s ary.

P061512St art er relay circui tStarter relay cont rolcircui t: s hort circui t topowerStarter relay fai lure

Check t he s tarter rel ay and ci rcuit s . Refer to theel ect ri cal guides . Ins t al l a new relay as neces s ary.

P061513St art er relay circui tStarter relay cont rolcircui t: open circui tStarter relay fai lure

Check t he s tarter rel ay and ci rcuit s . Refer to theel ect ri cal guides . Ins t al l a new relay as neces s ary.

P061711St art er Rel ay Circui tHi ghStarter mot or relaycont rol circui t, hi gh si de- s hort t o ground

Carry out t he pinpoint t est s as s ociat ed wi th t his DTCus i ng the manufact urer approved diagnos t ic s ys tem

P061712St art er Rel ay Circui tHi ghStarter mot or relaycont rol circui t, hi gh si de- s hort t o power

Carry out t he pinpoint t est s as s ociat ed wi th t his DTCus i ng the manufact urer approved diagnos t ic s ys tem

P085086Park/Neutral s wi tchi nput circui tSignal invalidCarry out a compl ete vehicle read for relat ed DTCs.Rect ify as neces s ary.

P0A0F68Engine fail ed to st artLong cranki ng t imeNo act ion neces sary. Code for informati on only.

P125983Immobi lizer t o PCMSi gnal ErrorChecks um error• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Check t he CAN network between t he ECM, ABS moduleand CJB. Carry out CAN network int egrit y t est s us ing t hemanufact urer approved diagnos t ic s ys temP125984Immobi lizer t o PCMSi gnal ErrorSignal bel ow all owabl erange• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Check t he CAN network between t he ECM and ABSmodul e. Carry out CAN net work integrit y tes t s usi ng t hemanufact urer approved diagnos t ic s ys tem

P125985Immobi lizer t o PCMSi gnal ErrorSignal above al lowablerange• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Run the ECM renew procedure us i ng the manufact urerapproved di agnos ti c s ys t em. If DTC remains , s uspectECM. Refer to t he new modul e/component ins t al lat ionnot e at t he top of t he DTC Index

P125986Immobi lizer t o PCMSi gnal ErrorSignal invalid• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Run the ECM renew procedure us i ng the manufact urerapproved di agnos ti c s ys t em. If DTC remains , s uspectECM. Refer to t he new modul e/component ins t al lat ionnot e at t he top of t he DTC Index

P125987Immobi lizer t o PCMSi gnal ErrorMi ss ing mess age• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Check t he CAN network between t he ECM and CJB. Carryout CAN net work integrit y tes t s usi ng t he manufacturerapproved di agnos ti c s ys t emU010000Los t Communicati onW it h ECM/PCM 'A'Lost communi cat ionwi th ECMCarry out t he as sociat ed network tes t for t his DTC usi ngthe manufact urer approved di agnos t ic s yst em

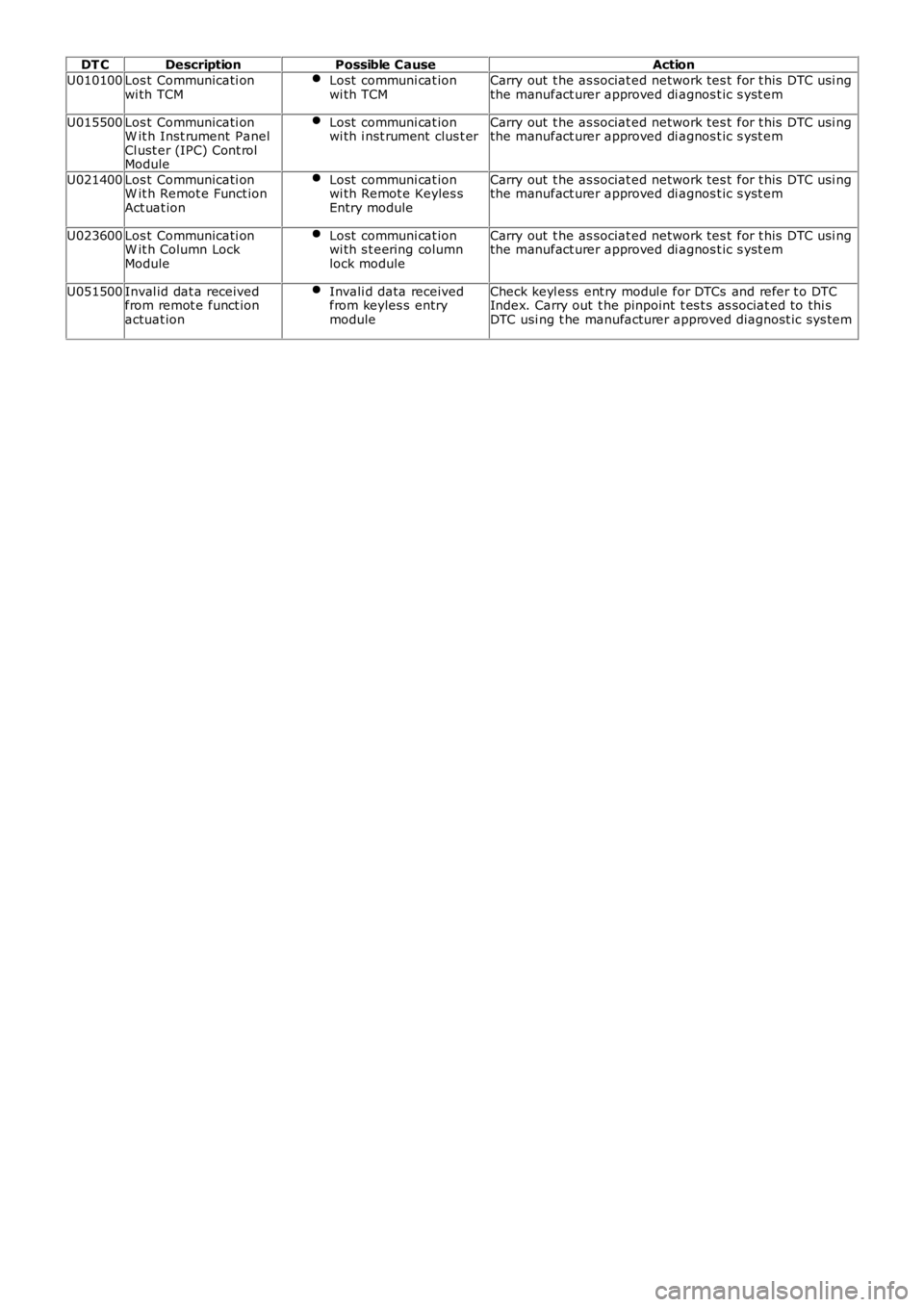

Page 1080 of 3229

DT CDescriptionPossible CauseAction

U010100Los t Communicati onwi th TCMLost communi cat ionwi th TCMCarry out t he as sociat ed network tes t for t his DTC usi ngthe manufact urer approved di agnos t ic s yst em

U015500Los t Communicati onW it h Inst rument PanelCl ust er (IPC) Cont rolModule

Lost communi cat ionwi th i nst rument clus t erCarry out t he as sociat ed network tes t for t his DTC usi ngthe manufact urer approved di agnos t ic s yst em

U021400Los t Communicati onW it h Remot e Funct ionAct uat ion

Lost communi cat ionwi th Remot e Keyles sEntry module

Carry out t he as sociat ed network tes t for t his DTC usi ngthe manufact urer approved di agnos t ic s yst em

U023600Los t Communicati onW it h Column LockModule

Lost communi cat ionwi th s t eering columnlock module

Carry out t he as sociat ed network tes t for t his DTC usi ngthe manufact urer approved di agnos t ic s yst em

U051500Inval id dat a receivedfrom remot e funct ionactuat ion

Invali d data receivedfrom keyles s entrymodule

Check keyl ess ent ry modul e for DTCs and refer t o DTCIndex. Carry out t he pinpoint t es t s as sociat ed to thi sDTC usi ng t he manufacturer approved diagnost ic sys tem