LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1061 of 3229

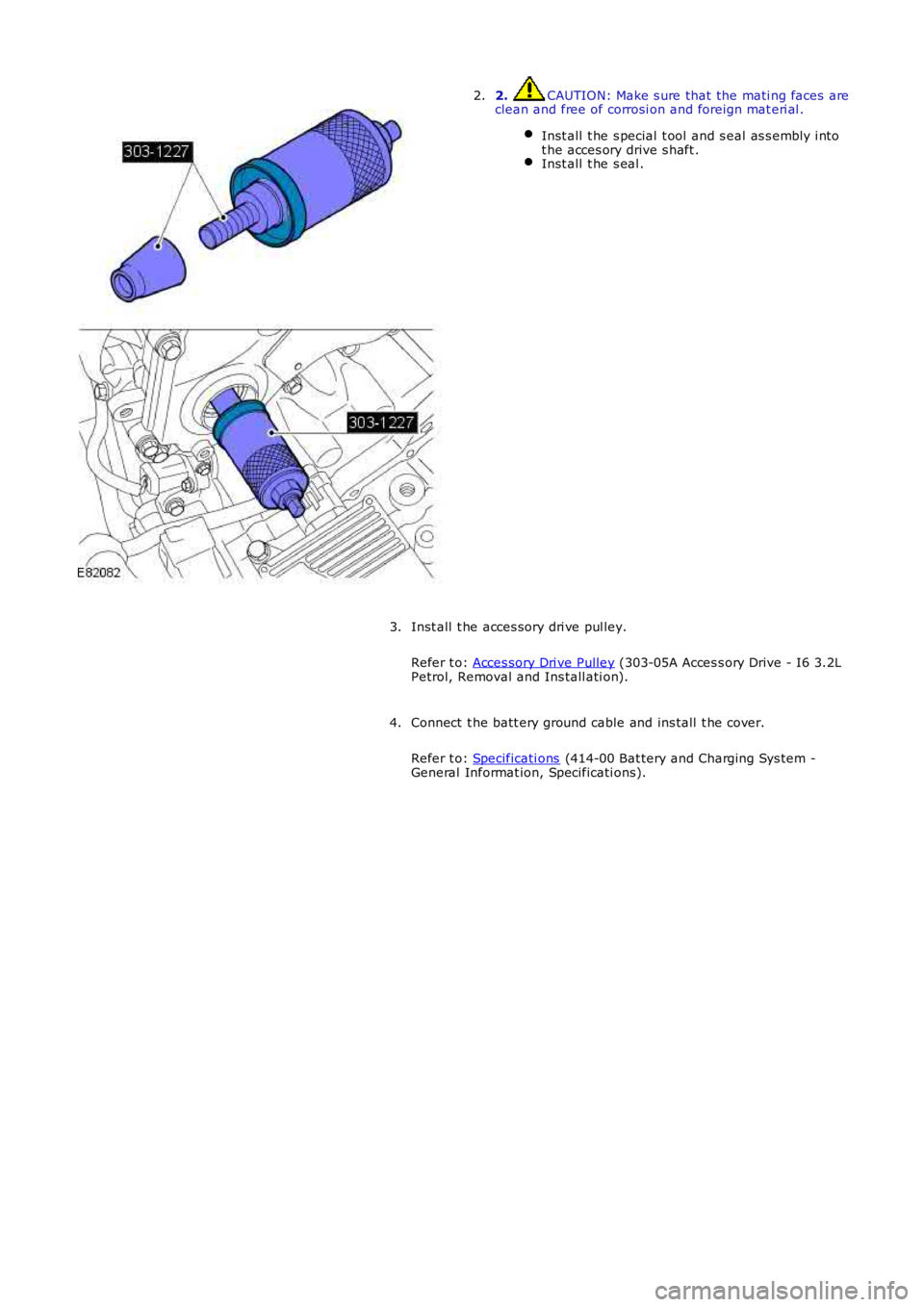

2. CAUTION: Make s ure that the mati ng faces areclean and free of corrosi on and foreign mat eri al .

Inst all t he s pecial t ool and s eal as s embly i ntot he acces ory drive s haft .Inst all t he s eal .

2.

Inst all t he acces sory dri ve pul ley.

Refer t o: Acces sory Dri ve Pulley (303-05A Acces s ory Drive - I6 3.2LPetrol, Removal and Ins tall ati on).

3.

Connect t he batt ery ground cable and ins tall t he cover.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

4.

Page 1062 of 3229

Publi s hed: 11-May-2011

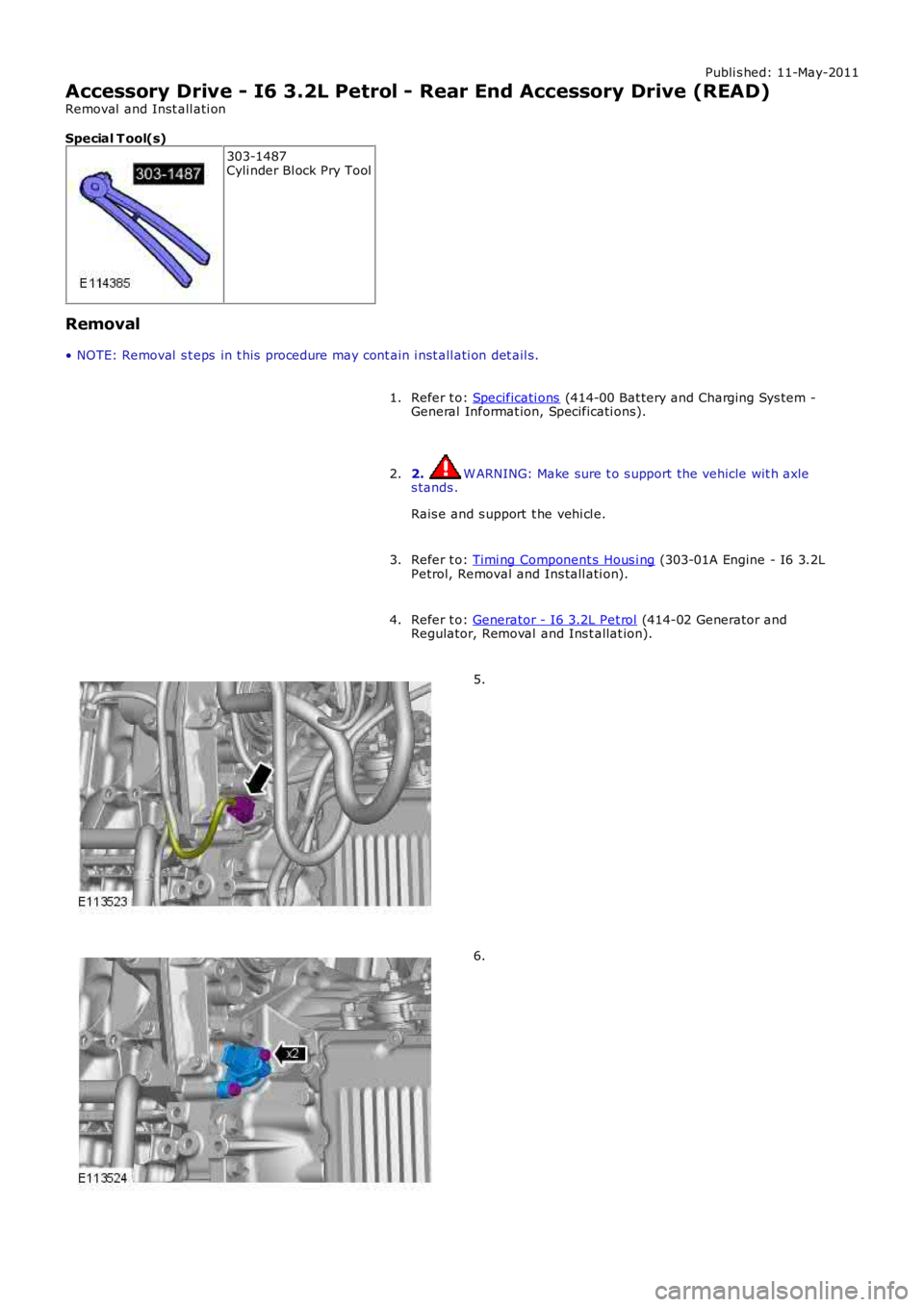

Accessory Drive - I6 3.2L Petrol - Rear End Accessory Drive (READ)

Removal and Inst all ati on

Special T ool(s)

303-1487Cyli nder Bl ock Pry Tool

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).1.

2. W ARNING: Make sure t o s upport the vehicle wit h axles tands .

Rais e and s upport t he vehi cl e.

2.

Refer t o: Timi ng Component s Hous i ng (303-01A Engine - I6 3.2LPetrol, Removal and Ins tall ati on).3.

Refer t o: Generator - I6 3.2L Pet rol (414-02 Generator andRegulator, Removal and Ins t allat ion).4.

5.

6.

Page 1063 of 3229

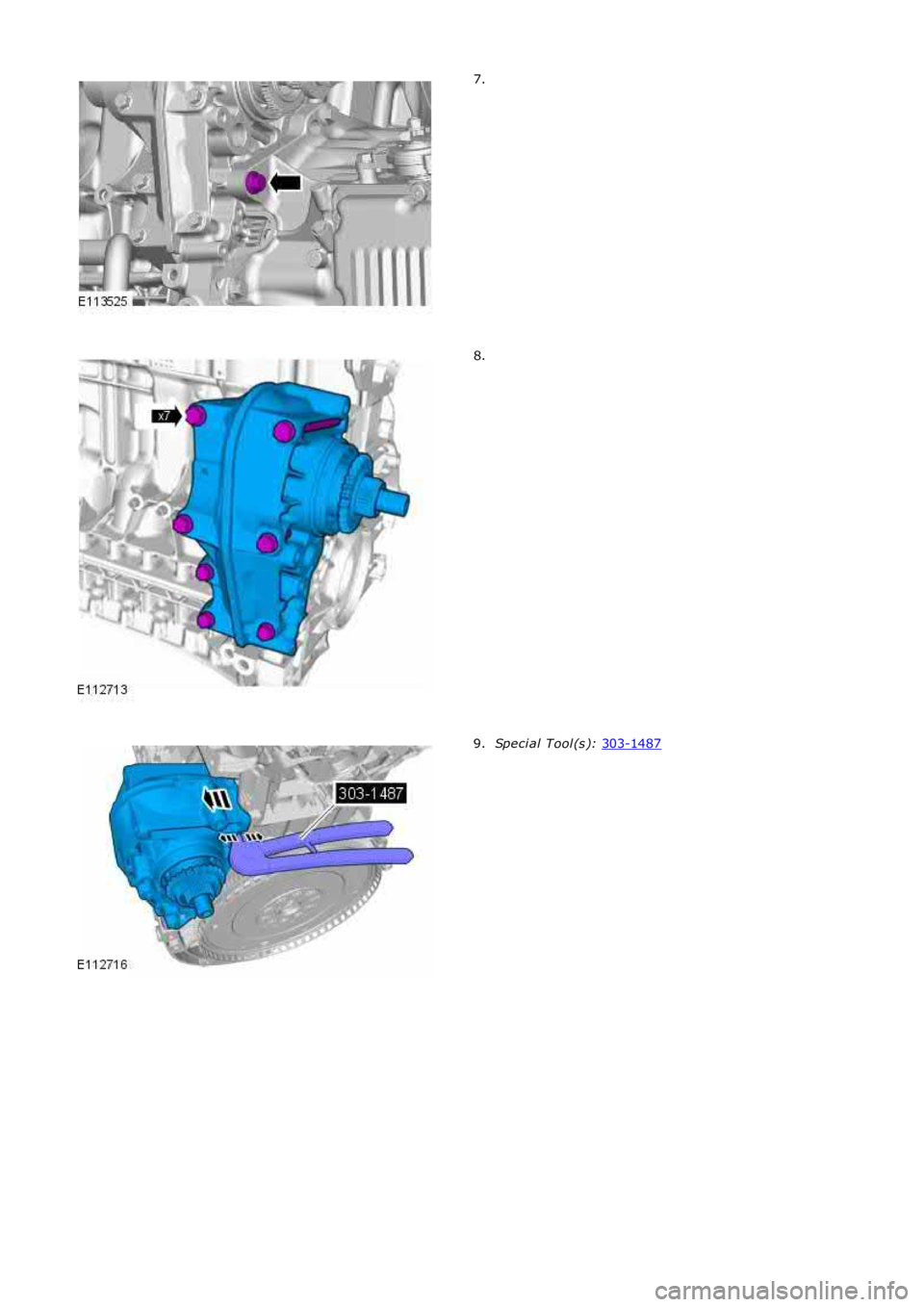

7.

8.

Speci al Tool (s ):

303-1487 9.

Page 1064 of 3229

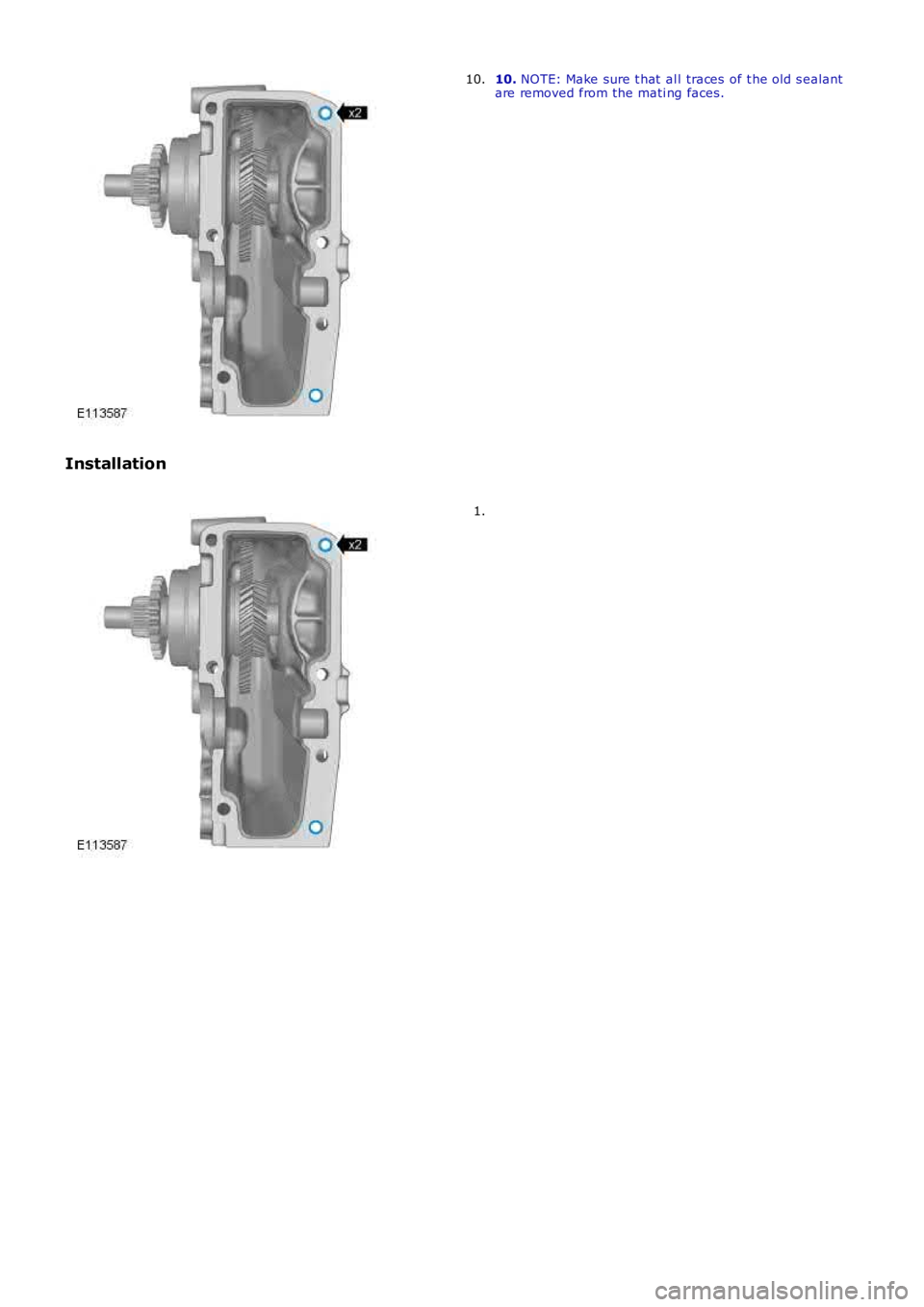

10. NOTE: Make sure t hat al l traces of t he old s ealantare removed from the mati ng faces.10.

Installation

1.

Page 1065 of 3229

Stage 1:

Stage 2:

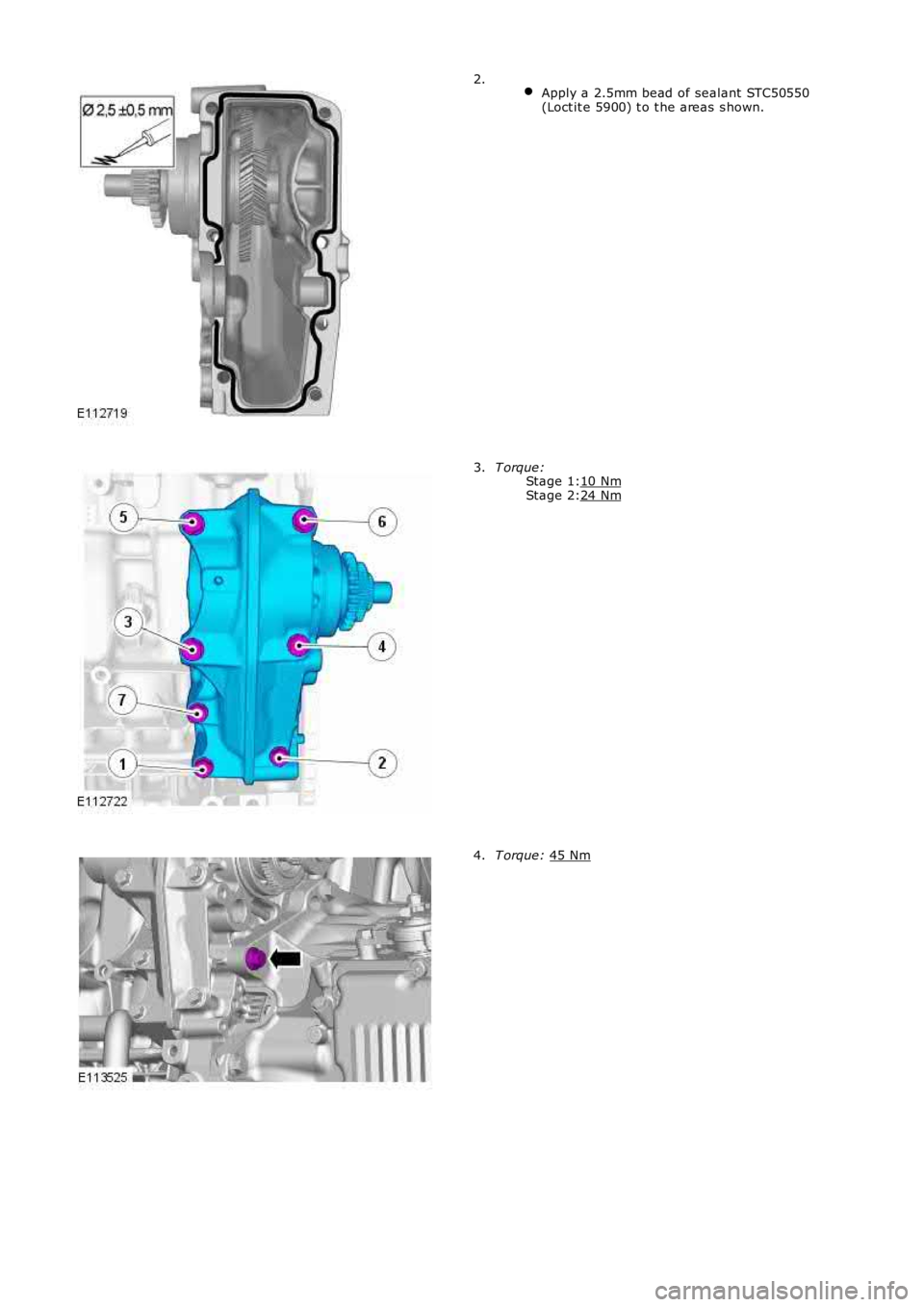

Apply a 2.5mm bead of sealant STC50550

(Loct it e 5900) t o t he areas s hown. 2.

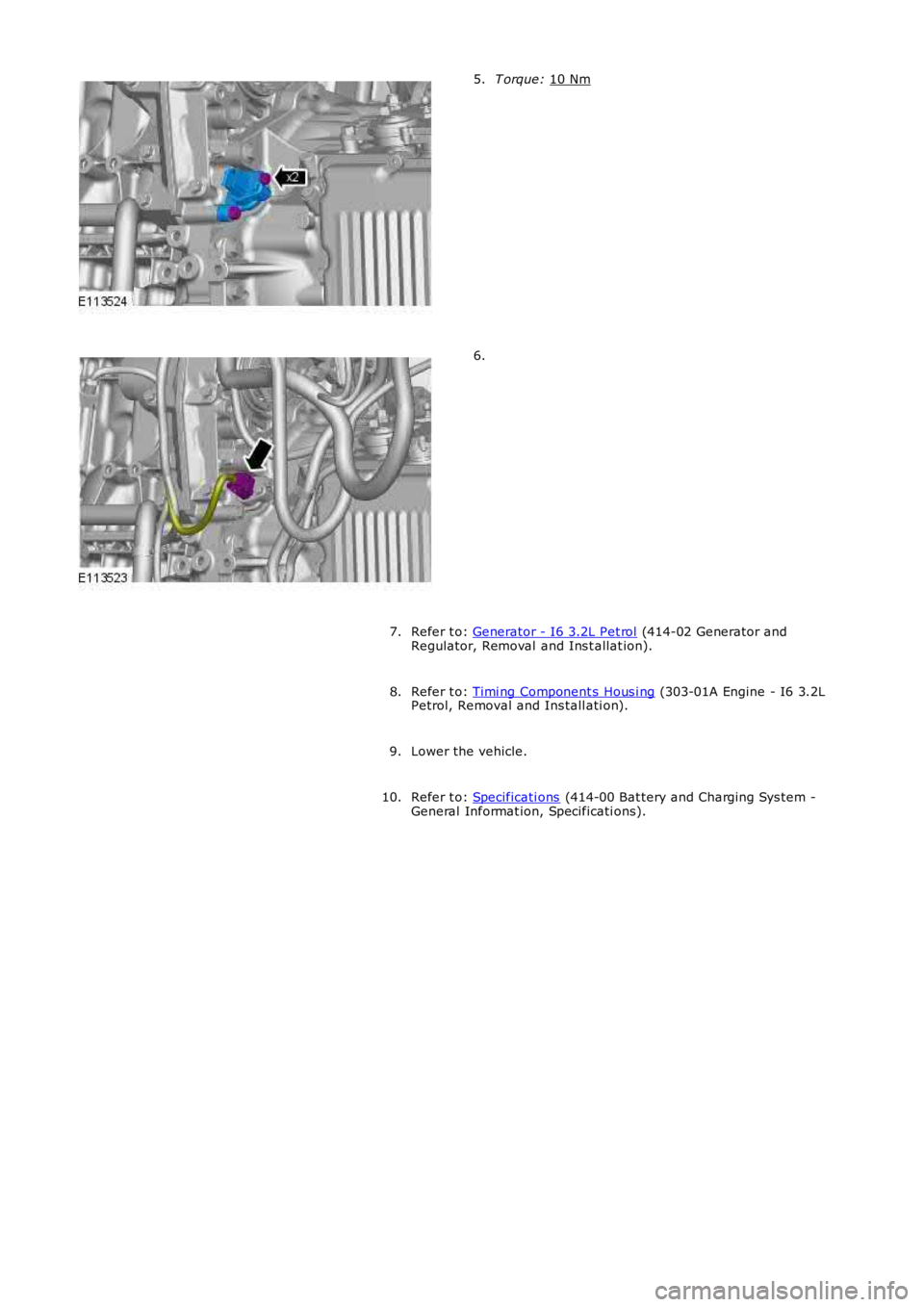

T orque:

10 Nm 24 Nm3.

T orque:

45 Nm 4.

Page 1066 of 3229

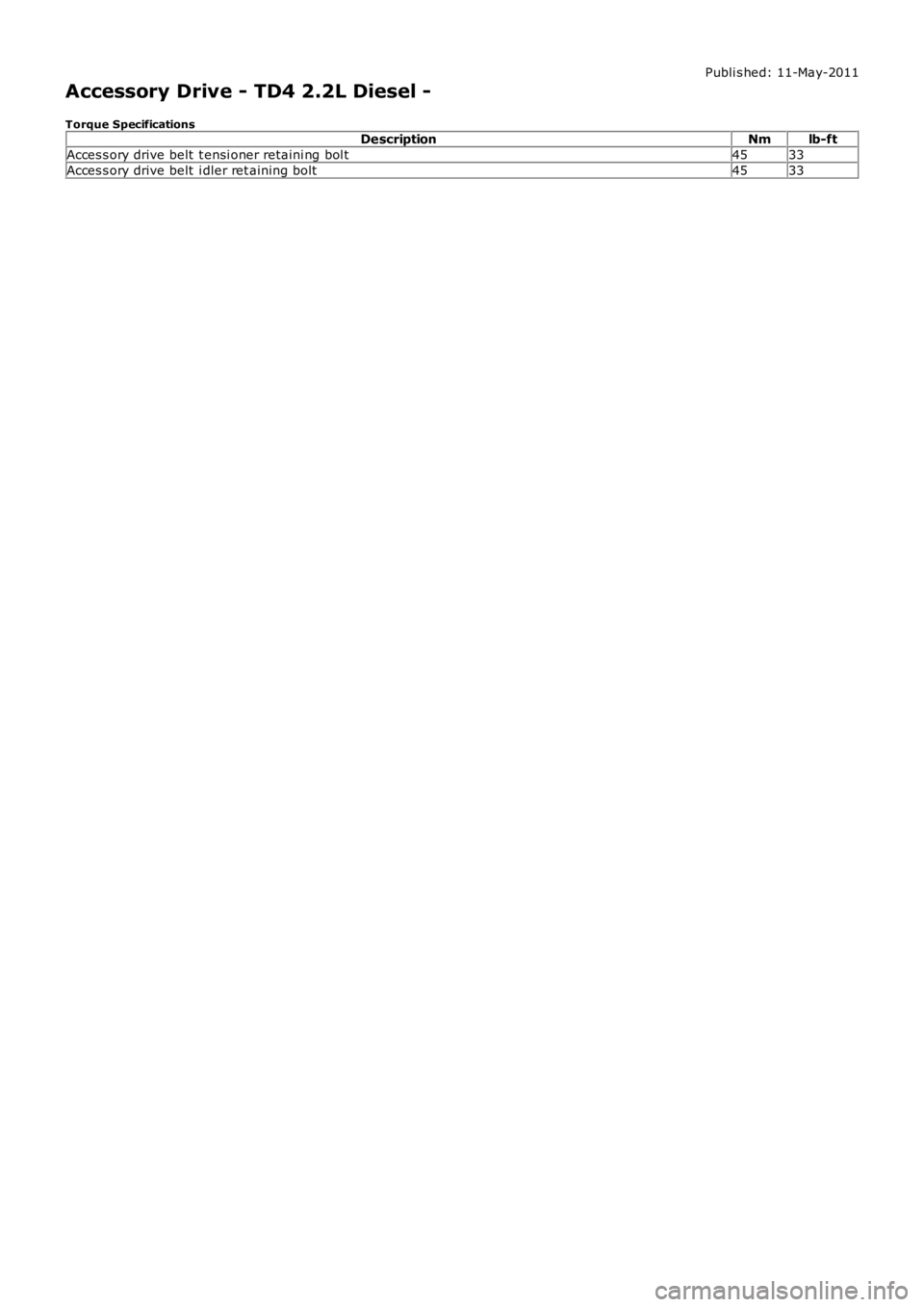

T orque:

10 Nm 5.

6.

Refer t o: Generator - I6 3.2L Pet rol (414-02 Generator and

Regulator, Removal and Ins t allat ion).

7.

Refer t o: Timi ng Component s Hous i ng (303-01A Engine - I6 3.2L

Petrol, Removal and Ins tall ati on).

8.

Lower the vehicle.

9.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -

General Informat ion, Specificati ons).

10.

Page 1067 of 3229

Publi s hed: 11-May-2011

Accessory Drive - TD4 2.2L Diesel -

Torque SpecificationsDescriptionNmlb-ft

Acces s ory drive belt t ensi oner retaini ng bol t4533

Acces s ory drive belt i dler ret aining bolt4533

Page 1068 of 3229

Publi s hed: 11-May-2011

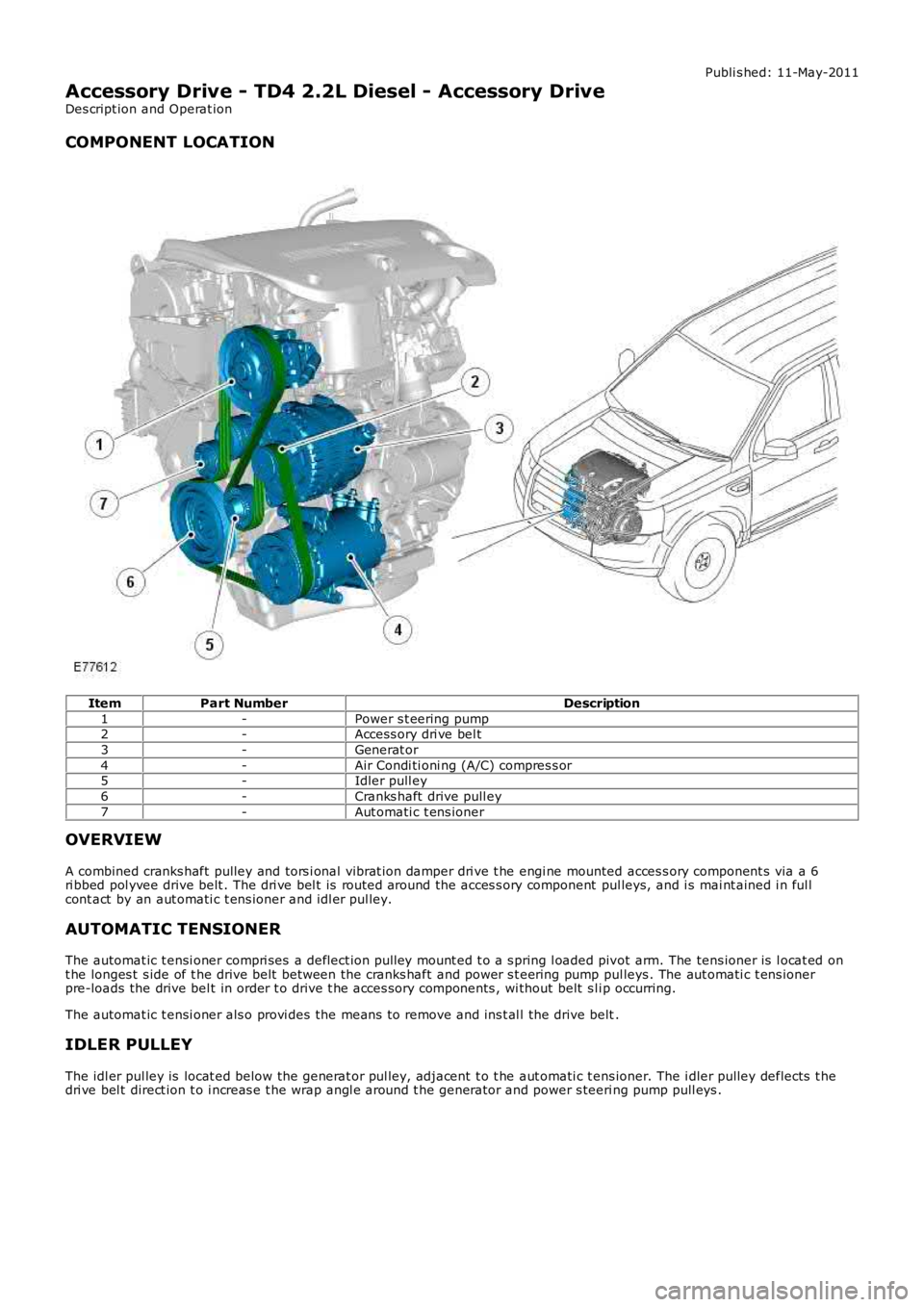

Accessory Drive - TD4 2.2L Diesel - Accessory Drive

Des cript ion and Operat ion

COMPONENT LOCATION

ItemPart NumberDescription

1-Power s t eering pump2-Access ory dri ve bel t

3-Generat or

4-Air Condi ti oni ng (A/C) compres s or5-Idler pull ey

6-Cranks haft drive pull ey

7-Aut omati c t ens ioner

OVERVIEW

A combined cranks haft pulley and tors i onal vibrat ion damper dri ve t he engi ne mounted acces s ory component s via a 6ri bbed pol yvee drive belt . The dri ve bel t is routed around the acces s ory component pul leys, and i s mai nt ained i n ful lcont act by an aut omati c t ens ioner and idl er pul ley.

AUTOMATIC TENSIONER

The automat ic t ensi oner compri ses a deflect ion pull ey mount ed t o a s pring l oaded pivot arm. The tens ioner is l ocat ed ont he longes t s ide of t he drive belt between the cranks haft and power s t eering pump pul leys . The aut omati c t ens ionerpre-loads the drive bel t in order t o drive t he acces sory components , wi thout belt s li p occurring.

The automat ic t ensi oner als o provi des the means to remove and ins t al l the drive belt.

IDLER PULLEY

The idl er pul ley is locat ed below the generat or pul ley, adjacent t o t he aut omati c t ens ioner. The i dler pulley deflects t hedri ve bel t direct ion t o i ncreas e t he wrap angl e around t he generator and power s teeri ng pump pull eys .

Page 1069 of 3229

Publi s hed: 11-May-2011

Accessory Drive - TD4 2.2L Diesel - Accessory Drive

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the Front End Access ory Dri ve (FEAD), refer t o t he relevant Descripti on and Operat ion s ect ionof the workshop manual.REFER to: Acces s ory Drive (303-05B Acces s ory Drive - TD4 2.2L Dies el, Des cript ion and Operat ion).

Inspection and Verification

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for s ys tem int egrit y and obvi ous s igns of damage.2.

Visual Inspection

Mechanical

FEAD beltFEAD belt t ensi onFEAD belt t ensi onerFEAD belt pull eysFEAD belt pull ey s eal s

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart.4.

Symptom Chart

SymptomPossible CauseAction

FEAD belt nois e ors quealFEAD belt pull ey(s )Lubricant or othercont ami nat ionFEAD belt

Check for pull ey alignment , freedom of rotat ion and damage. Repai ror i ns t all new part s as requi red.REFER t o: Access ory Dri ve Belt (303-05B Acces sory Dri ve - TD4 2.2LDi esel , Removal and Ins t allat ion) /Acces s ory Drive Bel t Tens ioner (303-05B Acces sory Dri ve - TD4 2.2LDi esel , Removal and Ins t allat ion) /Acces s ory Drive Bel t Idl er Pul ley (303-05B Acces sory Dri ve - TD42.2L Dies el, Removal and Ins tall ati on).Check FEAD belt for contami nat ion. If cont aminated, ins t al l a newbelt .REFER t o: Access ory Dri ve Belt (303-05B Acces sory Dri ve - TD4 2.2LDi esel , Removal and Ins t allat ion).Check FEAD belt for correct appli cat ionFEAD belt does nothold tens ionFEAD belt cracking ordamagedTensi oner worn ordamaged

Ins pect FEAD belt for cracking or damage. Ins tal l a new belt asrequi red.REFER t o: Access ory Dri ve Belt (303-05B Acces sory Dri ve - TD4 2.2LDi esel , Removal and Ins t allat ion).Check FEAD belt t ens ioner for damage and correct operat ion. Ins t al la new FEAD belt t ens i oner as requi red.REFER t o: Access ory Dri ve Belt Tensi oner (303-05B Acces s ory Drive -TD4 2.2L Dies el, Removal and Ins tal lati on).

Component Tests

FEAD belt tensioner

Stat ic

The only checks requi red for the FEAD bel t tens ioner are for st ick, grab or bind.

1. Remove the drive belt i n t he area of t he t ens ioner.1.

2. Us ing t he correct t ool , rot at e t he t ens ioner from it s rel axed pos it ion t hrough it s full s troke and back t o t herelaxed posi ti on to make s ure t here i s no s t ick, grab or bind, and to make s ure t hat there is t ensi on on t het ensi oner s pri ng.

2.

3. If t he t ens i oner meet s the above cri teria, proceed to the dynamic t es t. If the tens ioner does not meet t he abovecrit eria ins tall a new t ens ioner.REFER t o: Access ory Dri ve Belt Tensi oner (303-05B Acces s ory Drive - TD4 2.2L Dies el, Removal and Ins tall ati on).

3.

Dynamic

The FEAD belt t ens i oner can be checked dynami cal ly as foll ows:

W i th the engine running, obs erve drive belt t ensi oner movement , the FEAD belt t ensi oner s hould move (res pond) when theair condi ti oni ng clut ch cycles (if equipped), t he FEAD bel t tens ioner s hould move (res pond) when t he engi ne s peed isincreas ed rapi dl y. If t he dri ve bel t tens ioner movement i s errati c wit hout ai r condit ioni ng cl utch cycl ing or engineaccelerati on, a pul ley or s haft may be bent , or di st ort ed. Excess i ve drive bel t ri deout (uneven dept h of grooves in the drivebelt ) can al s o caus e exces s ive drive belt t ensi oner movement. Check condi ti on by instal ling a known good bel t.REFER to: Acces s ory Drive Bel t (303-05B Acces s ory Drive - TD4 2.2L Di es el, Removal and Ins t al lat ion).

Page 1070 of 3229

FEAD belt

1. W i th the engine off, check routi ng of the drive belt .REFER t o: Access ory Dri ve (303-05B Access ory Dri ve - TD4 2.2L Di esel , Des cri pti on and Operati on).1.

2. Ins pect t he dri ve belt t ens i oner wear indicator t o confirm the drive belt i s wi thin operati ng range. Ins tal l a newdrive belt as necess ary .REFER t o: Access ory Dri ve Belt (303-05B Acces sory Dri ve - TD4 2.2L Dies el , Removal and Inst all at ion).

2.