LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 2611 of 3229

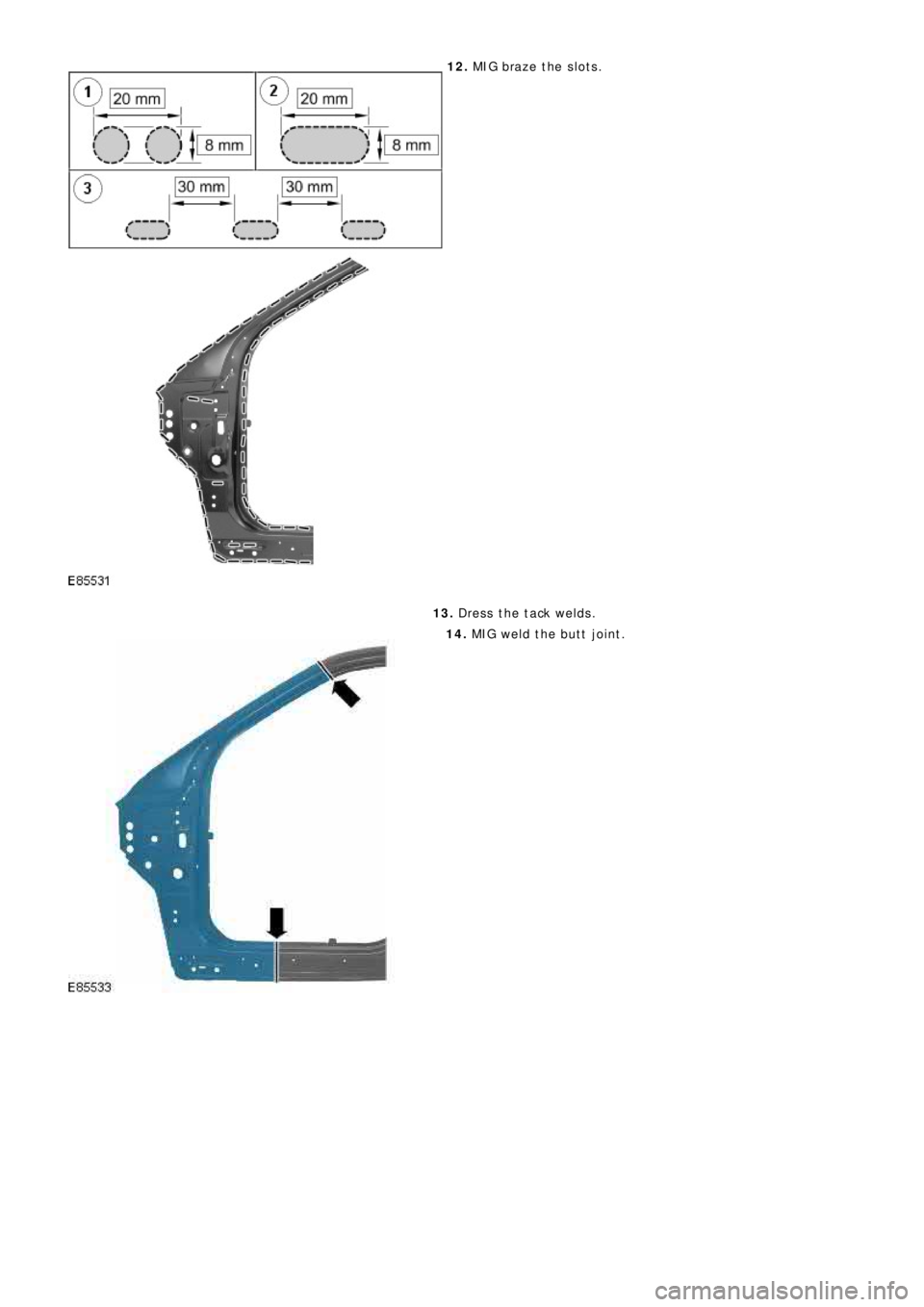

12. MIG braze the slots.

13. Dress the tack welds.

14. MIG weld the butt joint.

Page 2612 of 3229

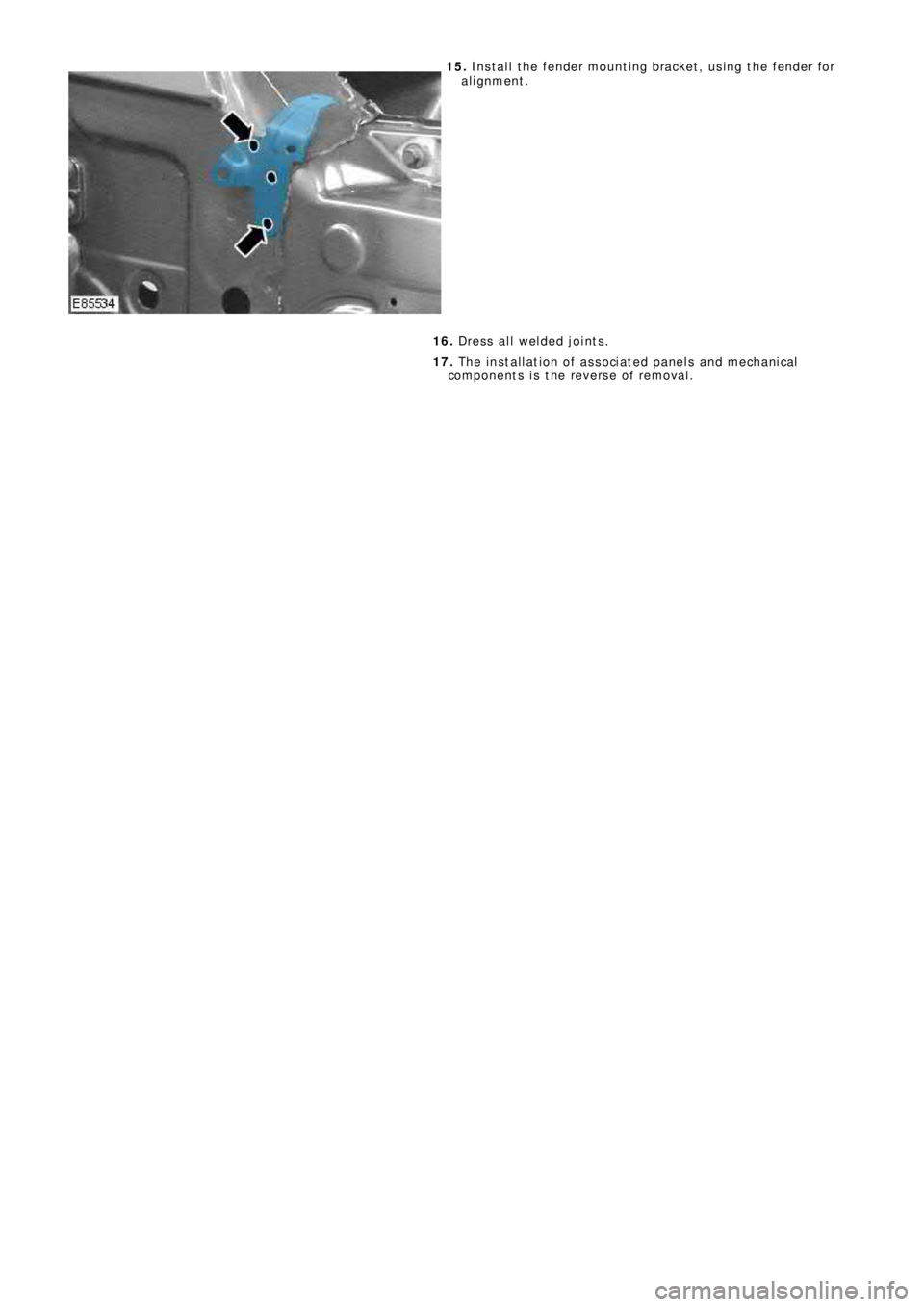

15. Install the fender mounting bracket, using the fender for

alignment.

16. Dress all welded joints.

17. The installation of associated panels and mechanical

components is the reverse of removal.

Page 2613 of 3229

Publ is hed: 11-May-2011

Side Panel Sheet Metal Repairs - A-Pillar Reinforcement

Removal and Installation

Removal

• CAUTIONS:

The A-Pillar reinforcement is DP600, (Dual Phase steel) and must be MIG plug welded to the inner. Spot we lds must

not be used.

Ensure that all welded joints are suitably sealed and waterproofed, particularly in the areas where the original panel

adhesive / sealer cannot be replicated. W here necessary, seal the joints prior to the fitment of outer panels.

• NOTE: The A-Pillar reinforcement is unpicked from the side panel reinforcement 'ring-frame', it is not serviced separately.

• NOTE: There are NVH elements attached inside this panel, they are not serviced on the new panel. If damaged, new

element/s will be required.

1. The A-Pillar reinforcement is replaced in conjunction with:

Front bumper cover

Front fender

Front door

Instrument panel

Windshield glass

A-Pillar outer panel

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Remove the A-Pillar outer panel.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : A -P i l l a r O ut e r P a ne l

(501-29 Side Panel Sheet Metal Repairs, Removal and

Installation).

Page 2614 of 3229

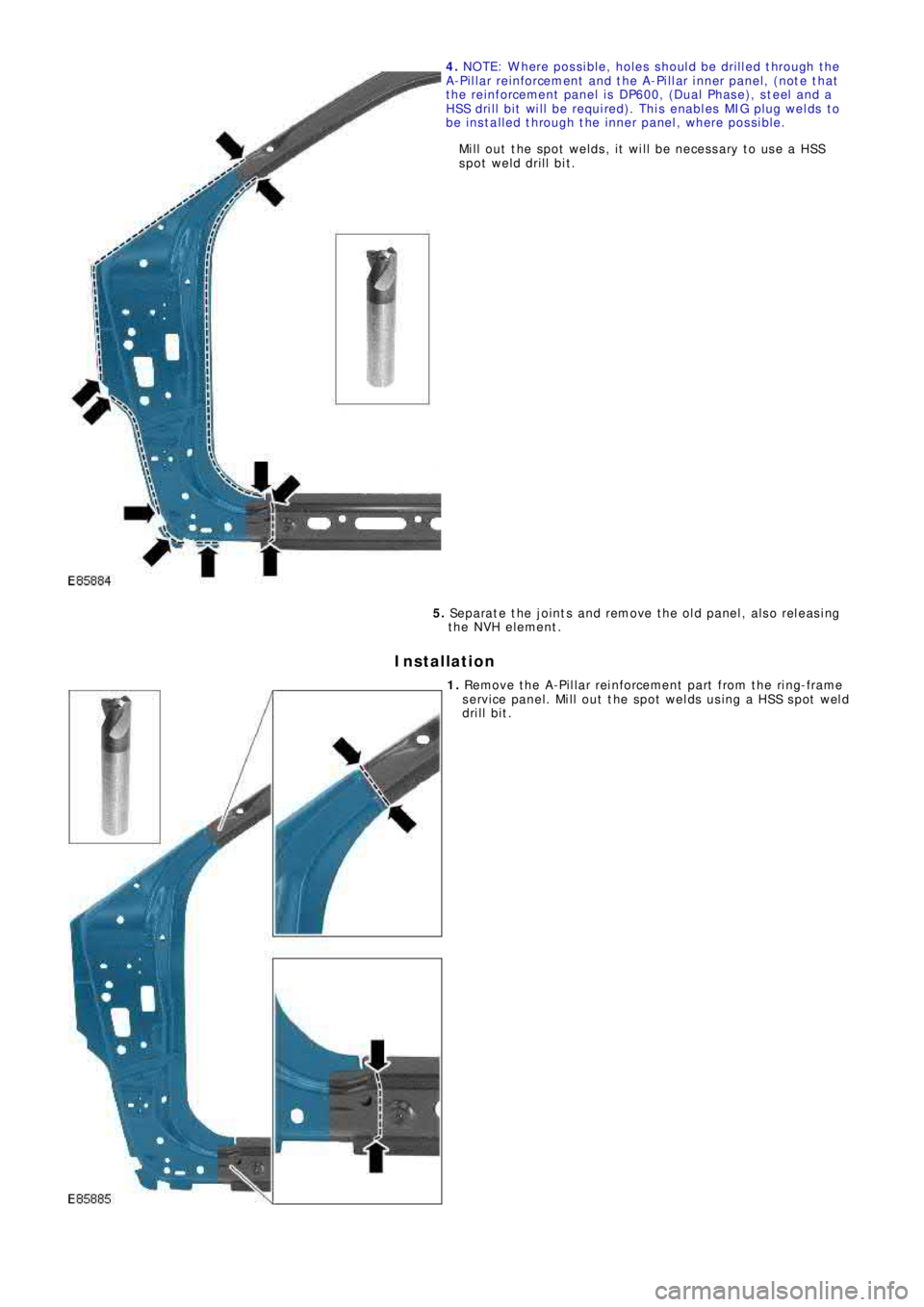

4. NOTE: W here possible, holes should be drilled through the

A-Pillar reinforcement and the A-Pillar inner panel, (note that

the reinforcement panel is DP600, (Dual Phase), steel and a

HSS drill bit will be required). This enables MIG plug welds to

be installed through the inner panel, where possible.

Mill out the spot welds, it will be necessary to use a HSS

spot weld drill bit.

5. Separate the joints and remove the old panel, also releasing

the NVH element.

Installation

1. Re mo ve t he A -P i l l a r re i nf o rce me nt p a rt f ro m t he ri ng -f ra me

service panel. Mill out the spot welds using a HSS spot weld

drill bit.

Page 2615 of 3229

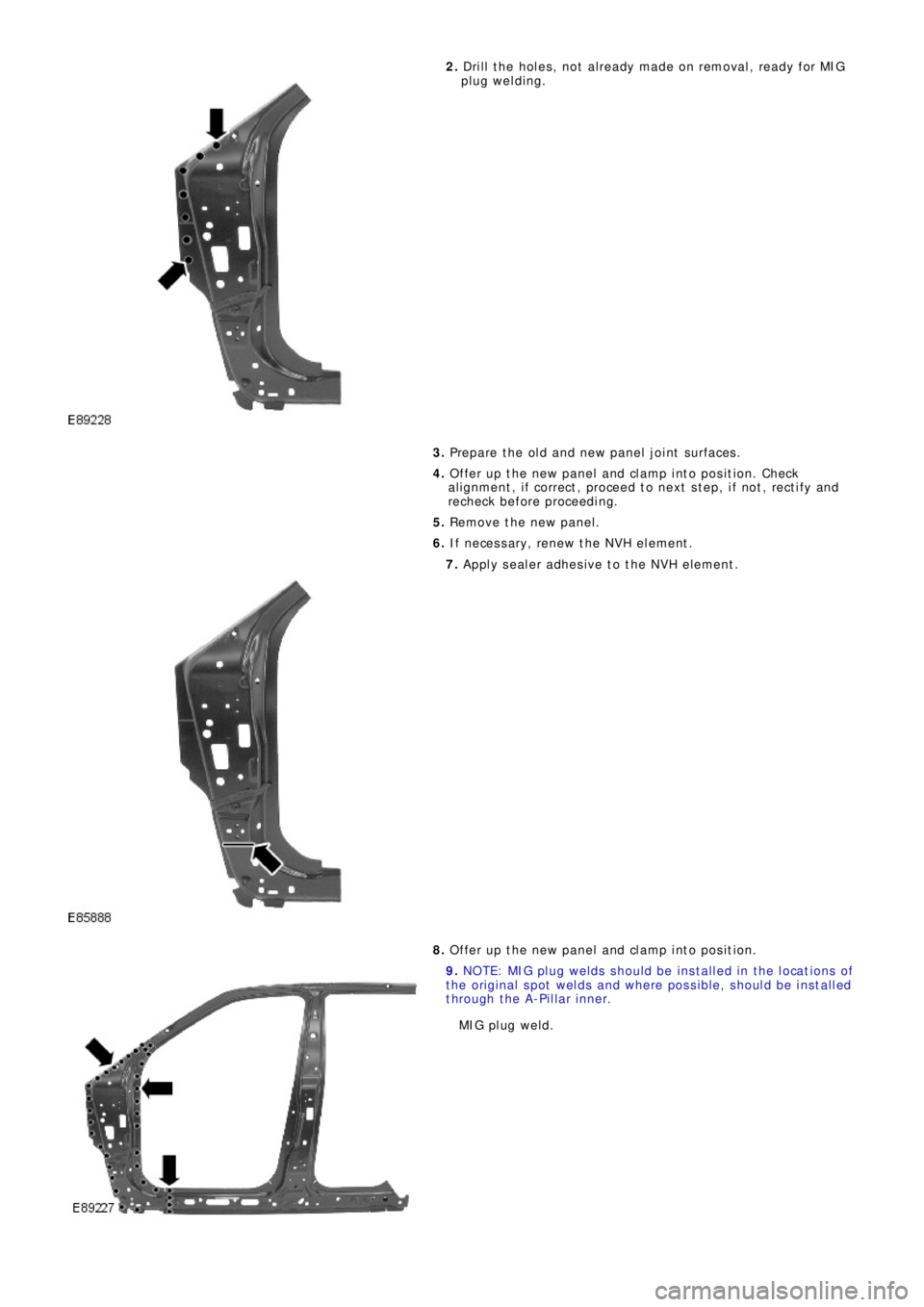

2. Dri l l t he ho l e s , no t a l re a d y ma d e o n re mo va l , re a d y f o r MI G

plug welding.

3. Prepare the old and new panel joint surfaces.

4. Offer up the new panel and clamp into position. Check

al ignment , i f correct , proceed t o next s t ep, i f not , rect i fy and

recheck before proceeding.

5. Remove the new panel.

6. If necessary, renew the NVH element.

7. Apply sealer adhesive to the NVH element.

8. Offer up the new panel and clamp into position.

9. NOTE: MIG plug welds should be installed in the locations of

the original spot welds and where possible, should be installed

t hro ug h t he A -P i l l a r i nne r.

MI G pl ug we l d.

Page 2616 of 3229

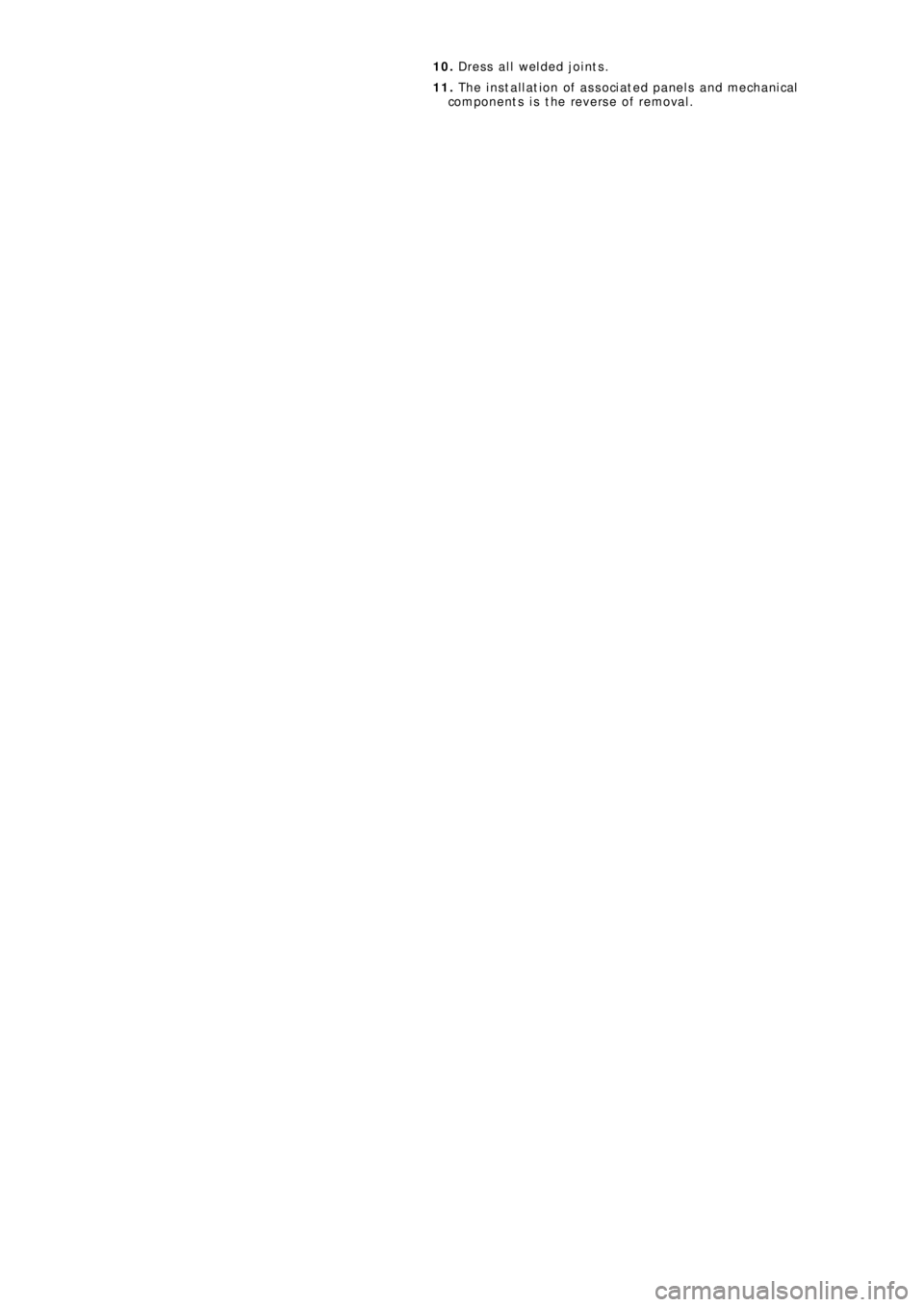

10. Dress all welded joints.

11. The installation of associated panels and mechanical

components is the reverse of removal.

Page 2617 of 3229

Publ is hed: 11-May-2011

Side Panel Sheet Metal Repairs - B-Pillar Outer Panel

Removal and Installation

Removal

CAUTION: The B-Pillar outer panel must be MIG slot brazed to the B-Pillar reinforcement, which is BH300, (Bake

Hardened steel) and the rocker panel inner reinforcement, which is DP600, (Dual Phase steel). MIG plug we lds / spot

we lds, must not be used.

• NOTE: The B-Pillar outer panel is serviced as a separate weld-on panel.

• NOTE: There is an NVH element attached inside this panel, it is not serviced on the new panel. If damaged, a new

element will be required.

• NOTE: If the B-Pillar outer is replaced without the B-Pillar reinforcement, the upper section butt joint can be made lower

down the pillar if required.

1. The B-Pillar out er panel is replaced in conjunct ion wit h:

Front door

Rear door

Headliner

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Remove the front door.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Front Door

(501-03 Body

Closures, Removal and Installation).

4. Remove the rear door.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Rear Door

(501-03 Body

Closures, Removal and Installation).

5. Remove t he upper and l ower door hi nges from t he B-Pi l lar, 4 x

bolts.

6. Remove the front door striker from the B-Pillar.

7. Remove the front seat.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Front Seat

(501-10

Seating, Removal and Installation).

8. Remove the rear seat cushion.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Rear Seat Cushion

(501-10

Seating, Removal and Installation).

9. Remove the front safety belt retractor.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Front Safety Belt Retractor

(501-20A Safe t y Bel t Sys t em, Removal and Ins t al l at i on).

10. Remove t he headli ner.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Headliner - Vehicles

Without: Tilting Roof Opening Panel (501-05 Int eri or Tri m and

Ornamentation, Removal and Installation) /

Headliner - Vehicles With: Tilting Roof Opening Panel

(501-05

Int erior Trim and Ornamentat ion, Removal and Installat ion).

11. Remove the RH & LH rocker panel inner trims.

12. Remove the B-Pillar side impact sensor.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : B-Pillar Side Impact Sensor

(501-20B Suppl ement al Res t rai nt Sys t em, Removal and

Installation).

13. Re mo ve t he s i d e a i r curt a i n mo d ul e .

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Si d e A i r Curt a i n Mo d ul e

(501-20B Suppl ement al Res t rai nt Sys t em, Removal and

Installation).

14. Remove the roof moulding, front and rear sections.

15. Remove the rocker panel outer moulding.

16. Release and lay aside the front carpet section.

17. Re mo ve t he re a r ca rp e t s e ct i o n.

18. Release and lay aside the wiring harness along the B-Pillar

i nne r a nd i nne r ro cke r p a ne l .

Page 2618 of 3229

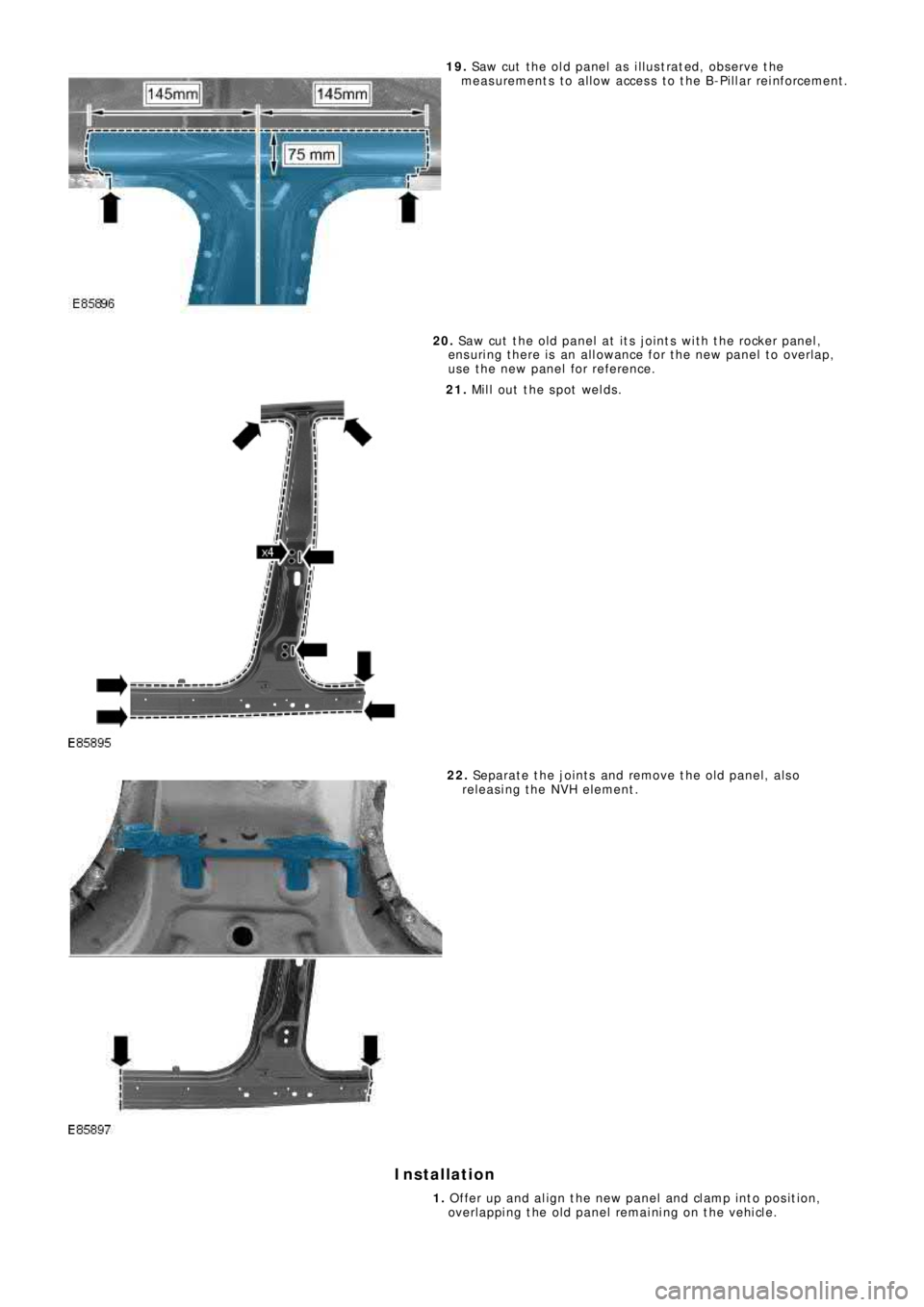

19. Saw cut the old panel as illustrated, observe the

measurements to allow access to the B-Pillar reinforcement.

20. Saw cut the old panel at its joints with the rocker panel,

ensuring there is an allowance for the new panel to overlap,

us e t he ne w p a ne l f o r re f e re nce .

21. Mill out the spot welds.

22. Separate the joints and remove the old panel, also

releasing the NVH element.

Installation

1. Offer up and align the new panel and clamp into position,

overlapping the old panel remaining on the vehicle.

Page 2619 of 3229

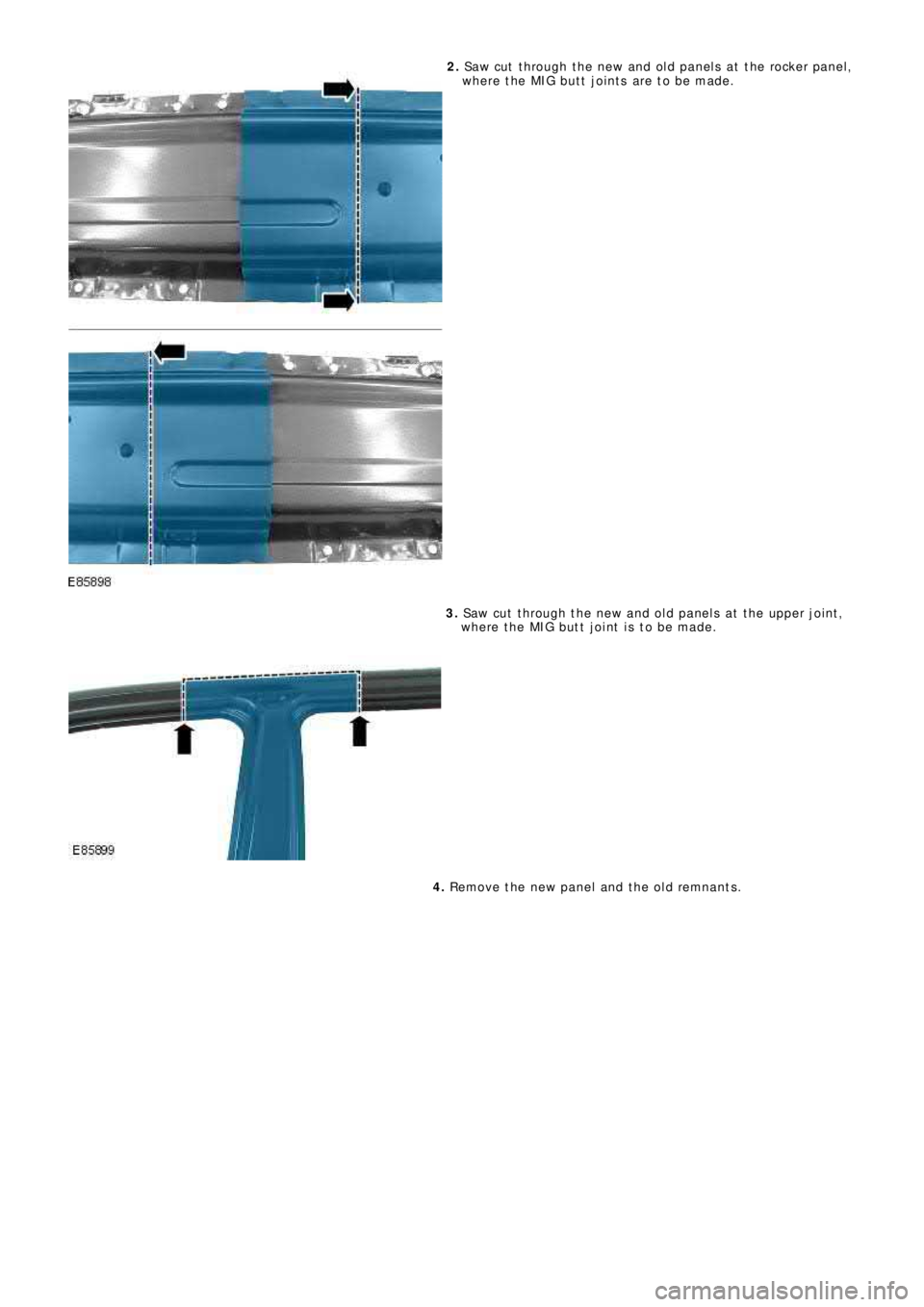

2. Saw cut t hrough t he new and old panels at t he rocker panel,

where the MIG butt joints are to be made.

3. Saw cut t hrough t he new and old panels at t he upper joint ,

where the MIG butt joint is to be made.

4. Remove the new panel and the old remnants.

Page 2620 of 3229

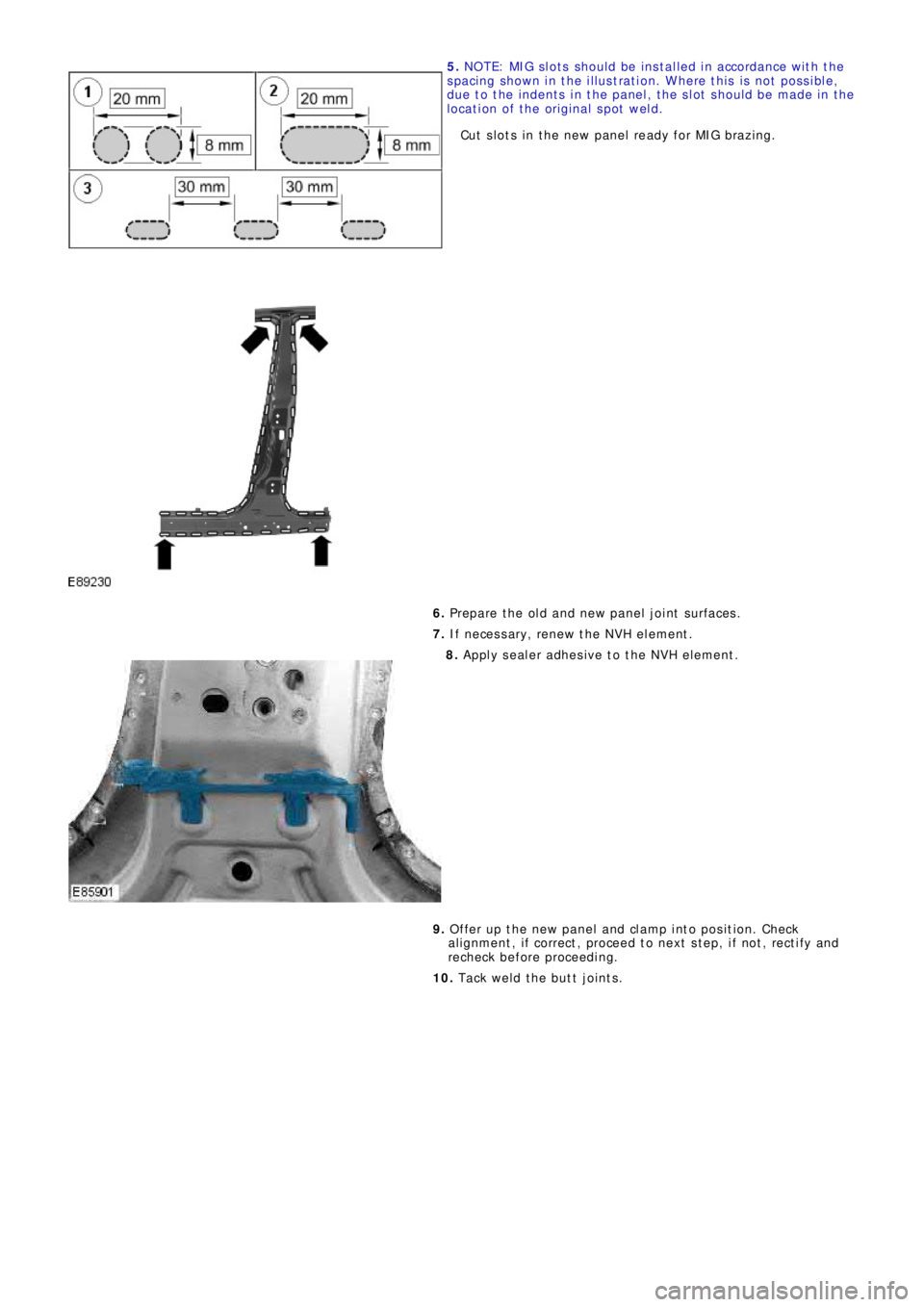

5. NOTE: MIG slots should be installed in accordance with the

spacing shown in the illustration. Where this is not possible,

due to the indents in the panel, the slot should be made in the

location of the original spot weld.

Cut slots in the new panel ready for MIG brazing.

6. Prepare the old and new panel joint surfaces.

7. If necessary, renew the NVH element.

8. Apply sealer adhesive to the NVH element.

9. Offer up the new panel and clamp into position. Check

al ignment , i f correct , proceed t o next s t ep, i f not , rect i fy and

recheck before proceeding.

10. Tack weld the butt joints.