LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 801 of 3229

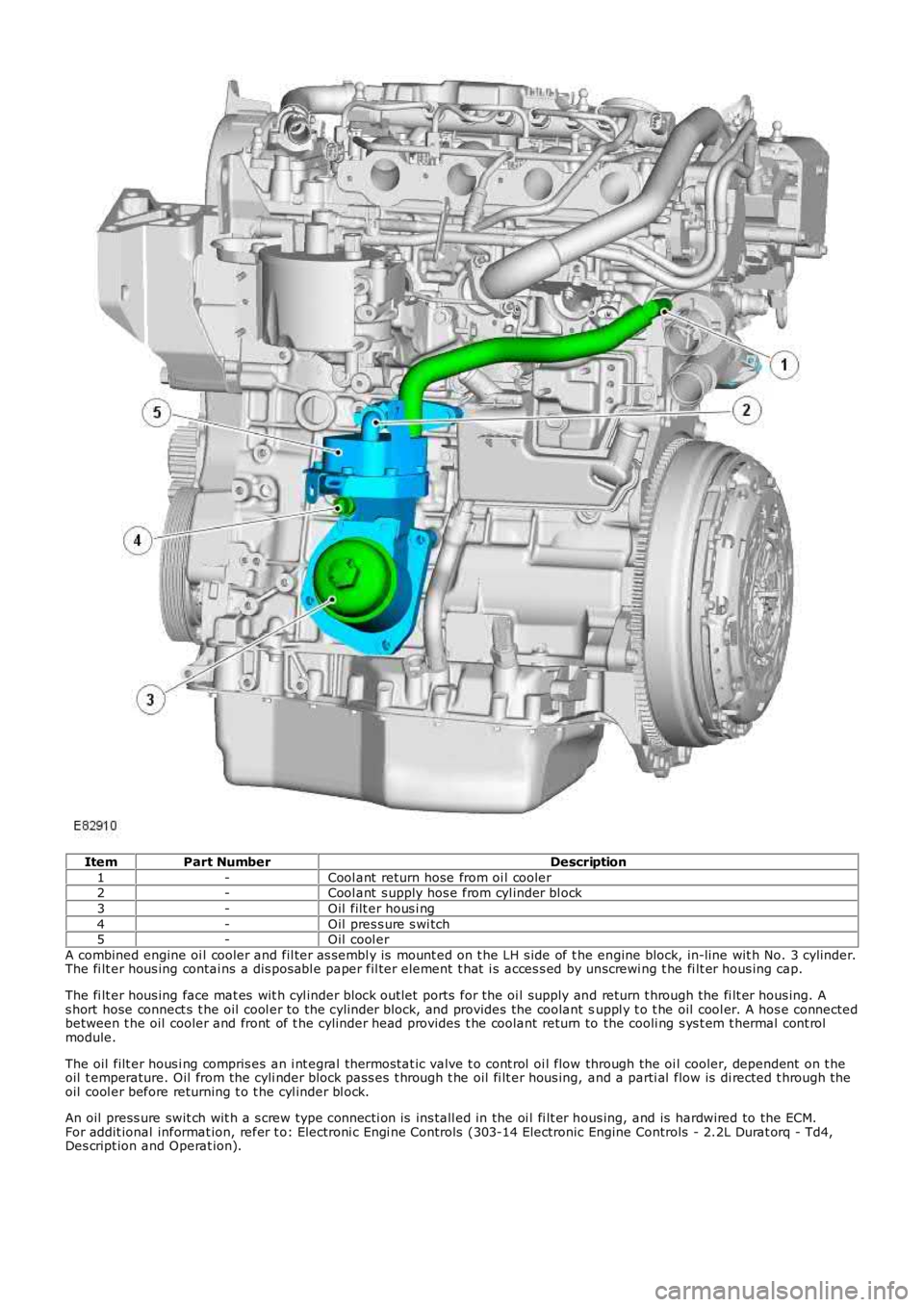

ItemPart NumberDescription

1-Cool ant return hose from oi l cooler2-Cool ant s upply hos e from cyl inder bl ock

3-Oil filt er hous i ng

4-Oil pres s ure s wi tch5-Oil cool er

A combined engine oi l cooler and fil ter as sembl y is mount ed on t he LH s ide of t he engine block, in-line wit h No. 3 cylinder.The fi lt er hous ing contai ns a dis pos abl e paper fil ter element t hat i s acces s ed by unscrewi ng t he fi lt er hous ing cap.

The fi lt er hous ing face mat es wit h cyl inder block out let ports for the oi l supply and return t hrough the fi lt er hous ing. As hort hose connect s t he oil cool er to the cyli nder block, and provides the coolant suppl y t o t he oil cool er. A hos e connectedbetween t he oil cooler and front of t he cylinder head provides t he coolant return to the cooli ng s ys t em t hermal cont rolmodule.

The oil filt er hous i ng compris es an i nt egral t hermos tat ic valve t o cont rol oi l flow through the oi l cooler, dependent on t heoil t emperature. Oil from the cyli nder block pass es t hrough t he oil fi lt er hous ing, and a parti al flow is di rected t hrough t heoil cool er before returning t o t he cyl inder bl ock.

An oil press ure swit ch wit h a s crew type connecti on is ins tall ed in the oi l fi lt er hous ing, and is hardwired to the ECM.For addit ional informat ion, refer t o: Electroni c Engi ne Controls (303-14 Electronic Engine Controls - 2.2L Durat orq - Td4,Des cript ion and Operat ion).

Page 802 of 3229

Publi s hed: 11-May-2011

Engine - TD4 2.2L Diesel - Engine

Diagnosi s and Tes ti ng

Principle of Operation

For a detail ed descripti on of the 2.2L Dies el engi ne, refer t o the relevant Descri pti on and Operat ion s ect ion in t heworks hop manual .REFER to: Engine (303-01B Engine - TD4 2.2L Dies el, Des cript ion and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

1. Verify t he cus t omer concern. Concerns have been s eparated i nto Leaks and Noise Vibration and Harshness(NVH) for ease of us e.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual Inspection

MechanicalIntake air s ys tem leaks/damageFuel l eaksCoolant levelCoolant leaks.REFER to: Engine Cooli ng (303-03B Engi ne Cool ing - TD4 2.2L Di es el, Di agnos is and Tes t ing).Oi l levelOi l leaksVis i bl y damaged or worn partsLoose or mis s ing nuts or bol ts

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he concern is not vis uall y evi dent , verify t he s ymptom and refer t o t he Symptom Chart .4.

Symptom Charts

Symptom C hart, LeaksSymptomPossible CauseAction

External coolant leaksDamaged hos e(s )Damaged expans iont ankDamaged radi atorLeaki ngs eals /gas ket sCracked/damagedcas ings

For cool ing s ys tem checks.REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).

Internal cool ant leaks . Note: T hismay be indicated by theproduction of w hite smoke fromthe exhaust

Leaki ngs eals /gas ket sCracked/damagedcas ings

Check for cros s contami nat ion of cooli ng sys t em andengine oi l. Check for exhaus t gases bei ng emit tedt hrough header t ank. For addi ti onal cooling sys temchecks .REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).

Engine overheatsInsuffi ci ent coolantInsuffi ci ent engineoi lCooli ng s ys t empres s ure cap faultThermos t at notopeningCoolant pump failureCooli ng fan fail ure

Check for correct coolant/engi ne oil l evels . For cool ings ys tem checks.REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).

Engine t akes t oo l ong to reachoperat ing t emperatureThermos t at st uckopenFor cool ing s ys tem checks.REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).External oil l eaksGas ket sSealsHos esOi l fi lt erOi l coolerDamaged/Cracked

Cl ean and confirm t he area of t he l eak. Vis uall y check t hecondit ion of oil carryi ng component s. Check the crankcaseventi lat ion s ys tem.REFER t o: Engi ne Emis s ion Cont rol (303-08B EngineEmis si on Control - TD4 2.2L Di es el, Di agnos is andTes ti ng).

Page 803 of 3229

SymptomPossible CauseAction

cas ingsCrankcaseventi lat ion s yst emPi st on ring blow-by

Carry out a compres s ion tes t, GO to Pinpoint Test A.

Internal oil l eaks (leaks int o cool antor combus t ion chamber) Note: T hismay be indicated by theproduction of blue smoke from theexhaust

Gas ket sSealsHos esDamaged/Crackedcas ingsW orn valve gui desW orn cyli nderbores /pi s tonsBroken pi st on rings

Check for t races of oil in the coolant. Check for evidenceof oi l i n t he combus t ion chambers (depos it s on t he glowpl ugs , et c). Confirm oi l cons umpti on and vehi cl e us agewit h the owner/driver. Carry out an oil consumpt ion t es t,GO t o Pinpoint Test B.

• NOTE: As t he checks s ugges ted here are open to i nterpretat ion, they s hould be us ed as a gui de only. Descripti ons ofnois es, et c, are i n general t erms, s o depend on a degree of experi ence on t he part of t he t echnician.

Symptom C hart, NVHSymptomPossible CauseAction

Ratt le/ti cki ng from t op ofengineVal ve gear noi seCamshaft bearing nois eCamshaft chain noi s eTens ioner nois eVacuum pump noi s eHigh pres s ure fuel pumpnoi s eInject or leaki ng

Check t he engi ne oil l evel and pres s ure, GO t o Pi npoint Tes tC. . Check t he functi on of the hydrauli c t appet s and condit ionof cams haft l obes and beari ngs. Check the cams haft chainsand tens ioners , vacuum pump and high pres s ure fuel pump.Carry out i njector l eak t es t

Squeaking/Creaking/Squealfrom front of engineAcces sory dri ve bel tAcces sory dri ve bel ttens ionerDri ven component s onaccess ory dri ve bel t

Check t he acces sory dri ve belt and dri ven components .REFER t o: Acces s ory Drive (303-05B Acces sory Drive - TD42.2L Di es el, Di agnos is and Tes t ing).

W hi ne/Slap/Growl fromfront of engi neAcces sory dri ve bel tAcces sory dri ve bel ttens ionerDri ven component s onaccess ory dri ve bel tTimi ng bel t nois eTimi ng bel t t ens ionernoi s e

Check t he acces sory dri ve belt and dri ven components .REFER t o: Acces s ory Drive (303-05B Acces sory Drive - TD42.2L Di es el, Di agnos is and Tes t ing).Check t he t imi ng bel t and t ens ioners for nois e/damage

Knock from l ower half ofengine (oft en wors e wi th acold engine)

Engi ne oil level/pres surelowPis ton s l apPis ton pi n nois eConnecti ng rod beari ngnoi s e

Check t he engi ne oil l evel and pres s ure, GO t o Pi npoint Tes tC. . Check for debri s i n the engi ne oil, check condit ion ofengi ne components

Knock/Rumble from lowerhalf of engine (oft en wors eon overrun)

Engi ne oil level/pres surelowMain beari ng nois e

Check t he engi ne oil l evel and pres s ure, GO t o Pi npoint Tes tC. . Check for debri s i n the engi ne oil, check condit ion ofengi ne components

W hi ne/W hi st leInt ake ai r s ys t em l eaksDamaged turbocharger(when nois e emanat ingfrom rear of engine)

Check for loose/damaged intake ai r sys tem components .Check for excess i ve turbocharger shaft fl oat Note: a smallamount of turbocharger shaft float is normal/acceptable.Check for general damage t o t urbocharger

Mi sfire/Rough runningElect roni c engi ne cont rol sFuel charging andcont rolsInt ake ai r s ys t em l eaksExhaus t gas recirculat ion(EGR) s yst emBurnt/s ti cki ng val vesW orn val ve guidesW orn cyl inderbores/pis t onsBroken pis ton ri ngsDamaged/Cracked cas ings

For el ect ronic engine controls .REFER t o: Electroni c Engine Controls (303-14B ElectronicEngi ne Cont rol s - TD4 2.2L Dies el , Diagnosi s and Test ing).For fuel charging and cont rols sys tems tes ts .REFER t o: Fuel Chargi ng and Cont rol s (303-04B Fuel Chargingand Cont rol s - TD4 2.2L Dies el , Diagnosi s and Test ing).Check i nt ake air s yst em for damage/leaks . For EGR s ys temtes ts .REFER t o: Engi ne Emi ss ion Cont rol (303-08B Engi ne Emis s ionCont rol - TD4 2.2L Dies el, Diagnos is and Tes ti ng).Check for damaged engine component s . Carry out acompress i on tes t, GO t o Pinpoint Test A.

Pinpoint Tests

• NOTE: W here reference is made to 's uit abl e equi pment', this refers t o s tandard workshop equipment . Refer to theoperati ng ins t ructi ons for your own equipment when performing any t es t s .

PINPOINT TEST A : CHECK THE CYLINDER COMPRESSIONS

W ARNING: Only compres s ion t es ters abl e t o read the hi gher compres si on pres s ures found i n dies el engi nes shouldbe us ed. Fai lure to foll ow t his i ns t ructi on may resul t in personal injury.

Page 804 of 3229

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

1

2

3

4

5

6

7

8

9

• NOTE: W here pos si ble, compress i on tes t ing s houl d be carried out on an engine at normal operat ing temperat ure.

T ESTCONDIT IONSDET AILS/RESULT S/ACT IONS

A1: CARRY OUT A DRY CYLINDER COMPRESSION T EST

Make s ure t he parki ng brake is appl ied and t hat t he s elector l ever is in neutral (or park for vehi cl eswi th aut omati c transmis si on).

Set the ignit ion s t at us t o OFF.

Remove t he st art er rel ay.

Dis connect t he st art er motor s olenoid connect or.

Connect a s uit able remote st art er devi ce to the s t art er mot or s ol enoi d.

Remove t he glow pl ugs .REFER to: Gl ow Plugs (303-07B Glow Plug Sys tem, Removal and Ins tal lati on).

Ins t all s uit abl e adapt or in pl ace of t he glow plug i n t he fi rs t cyl inder to be tes t ed.

Connect a s uit able compres s ion t es ter t o the adapt or. See warni ng above.

Us ing t he remote s t art er device, crank t he engi ne a mi nimum of fi ve revoluti ons.

Record t he compres si on fi gure and t he number of revol uti ons taken to reach it .

Repeat s t eps 7 - 10 above for t he remai ning cylinders , cranking t he engine for a s imi lar number ofrevolut ions each ti me.

Compare the compres s ion figures acros s al l t he cylinders .

Are the compres s ion figures wit hi n 10% of each ot her?YesUnles s t he compres si on fi gures are uni vers al ly very low (experience wi ll indicat e thi s), check forother caus es for the cus tomer complaint .NoGO to A2.

A2: CARRY OUT A WET CYLINDER COMPRESSIO N T EST

CAUTION: If engi ne oil i s int roduced i nto the cyli nders, run t he engi ne at 2,000 rpm for a mi ni mum of t en mi nutesaft er compl eti ng tes t ing t o prevent damage to the catal yt ic convert ers . Fai lure to foll ow t his i nst ruct ion may res ul t indamage t o t he vehi cl e.

• NOTE: There is a combus ti on chamber i n the top of each pis ton. Make s ure that the oi l is not all owed t o run into thi schamber.Us ing a sui table oil can wit h a flexibl e s pout , int roduce a s mall amount of cl ean engi ne oil int o t hecyl inder jus t before tes t ing, such t hat the oi l i s able to run between t he pis t on and t he cyl inder bore.Repeat s t eps 7 - 10 from the tes t above, int roduci ng oil i nt o each cyl inder jus t before tes ti ng.

Compare the compres s ion figures acros s al l t he cylinders .

Is the compres s ion figure higher than t he dry tes t?YesA hi gher figure foll owing t he int roducti on of oi l may indi cat e a worn or damaged cyli nder bore, pi st onand/or pis t on ri ngs . Dis as s embl y would be required to confirm t his .NoIf the compres s ion figure is unaffect ed by t he int roducti on of oi l, but t he fi gure is s ti ll les s t han 90%of the ot her cyl inders , thi s may i ndi cat e a burnt and/or s t icking valve, leaking head gasket , et c.Dis as s embl y would be required to confirm t his .Clear any DTCs which may have been i nduced by t he tes t .

PINPOINT TEST B : OIL CONSUMPTION TEST

• NOTE: Oi l cons umpti on wil l vary, dependi ng on a number of fact ors . New engines will normall y us e more oil t han 'run-in'engines, once a cons umpt ion fi gure has been det ermined cont act Deal er Techni cal Support for furt her as s is t ance.T ESTCO NDIT IONSDET AILS/RESULT S/ACT IONS

B1: CHECK FOR EXCESSIVE OIL CONSUMPT IONStart the engine and al low it t o run unt il i t reaches normal operat ing temperat ure.

Make s ure t he vehi cl e i s parked on a l evel s urface and swi tch off.

All ow t o s et t le for at least five minutes .

Check t he oil l evel.

Correct t he level, i f necess ary, and record t he reading and mileage i n t he vehi cl e his t ory.

Make s ure t hat the owner/dri ver i s aware that a t est i s being carried out , and that t hey should nottop-up their oi l level for the durat ion of t he t est , but should check t he level every 160-240 Km(100-150 mil es ).

W hen t he oil l evel reaches the ADD mark, t he cust omer s houl d bri ng the vehicle in to be checked.

Top-up t he oil t o the level at t he beginning of t he tes t and record the amount of oil needed to dos o, and t he mi leage covered in the cours e of t he tes t .

From this , t he cons umpt ion can be calculated, and a decis ion made as to whet her or not t hecons umpti on is cons idered excess ive.Is the consumpt ion excess ive for the mil eage and/or us e? Contact Dealer Technical Support for furtherass is t ance.YesDis as sembl y wil l be required t o check t he components indicated i n t he s ympt om chart .NoNo furt her acti on is necess ary.

PINPOINT TEST C : CHECK THE ENGINE OIL PRESSU RE

• NOTE: The vehicle must be driven a minimum of 6 mil es (10 ki lometers ) prior t o t est ing t he oil press ure. Do not at temptt o att ain normal engi ne operati ng temperature by all owi ng t he engi ne to idle.

• NOTE: Check and, i f neces sary, t op-up t he engine oil l evel before begi nning t his test .

T EST CO NDIT IONSDET AILS/RESULT S/ACT IONSC1: CHECK FOR LOW ENGINE OIL PRESSURE

Page 805 of 3229

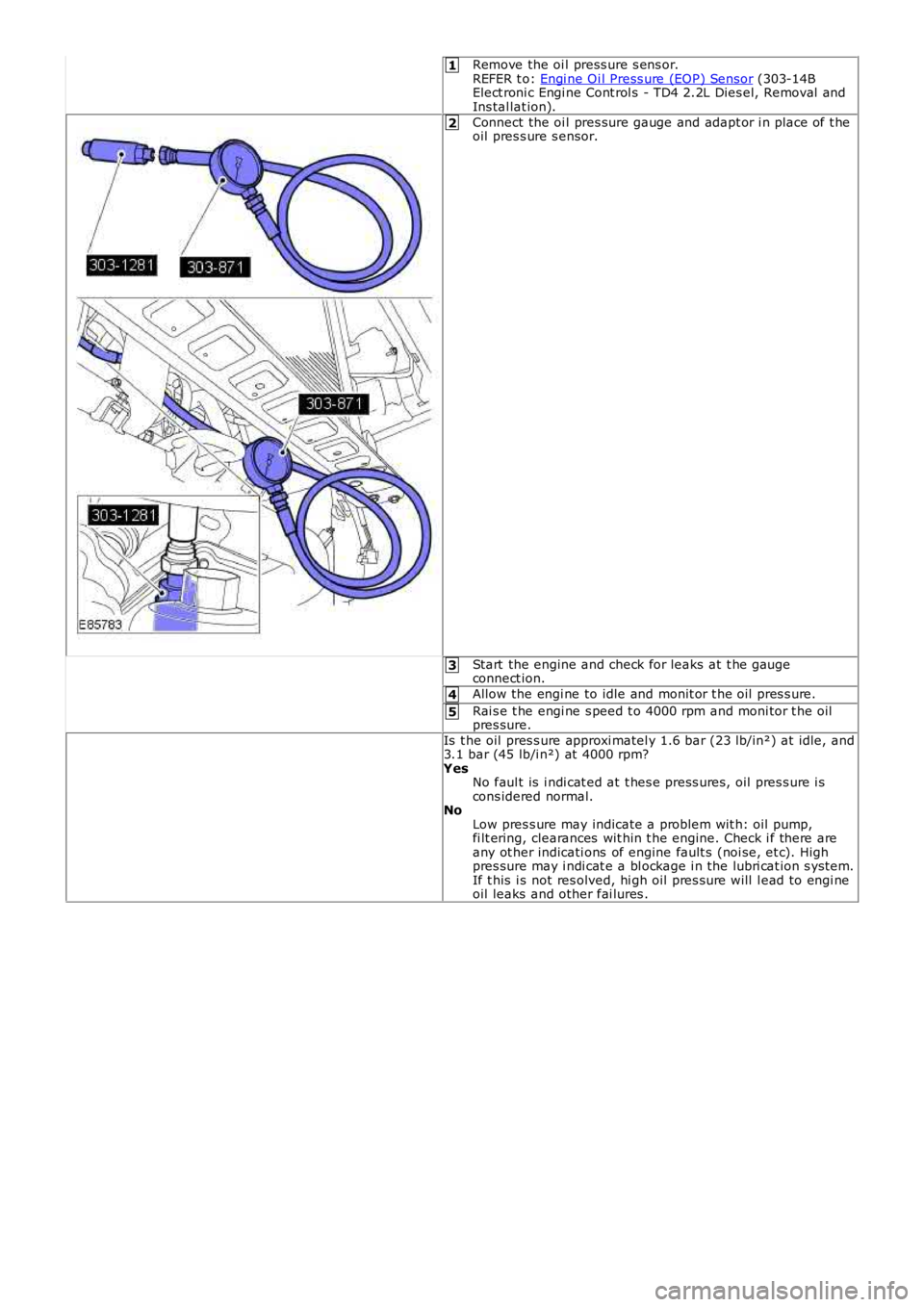

1

2

3

4

5

Remove the oi l press ure s ens or.REFER t o: Engi ne Oi l Press ure (EOP) Sensor (303-14BElect roni c Engi ne Cont rol s - TD4 2.2L Dies el, Removal andIns tal lat ion).

Connect the oi l pres sure gauge and adapt or i n place of t heoil pres s ure s ensor.

Start the engine and check for leaks at t he gaugeconnect ion.

Allow the engi ne to idle and monit or t he oil pres s ure.

Rai s e t he engi ne s peed t o 4000 rpm and moni tor t he oilpres sure.

Is t he oil pres s ure approxi matel y 1.6 bar (23 lb/in²) at idle, and3.1 bar (45 lb/i n²) at 4000 rpm?YesNo faul t is i ndi cat ed at t hes e press ures , oil pres s ure i scons idered normal.NoLow pres s ure may indicate a problem wit h: oil pump,fi lt ering, clearances wit hin t he engine. Check i f there areany ot her indicati ons of engine fault s (noi se, et c). Highpres sure may i ndi cat e a bl ockage i n the lubri cat ion s ys tem.If t his i s not res olved, hi gh oil pres s ure will l ead to engi neoil leaks and other fai lures .

Page 806 of 3229

Publi s hed: 11-May-2011

Engine - TD4 2.2L Diesel - Engine Oil Draining and Filling

General Procedures

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

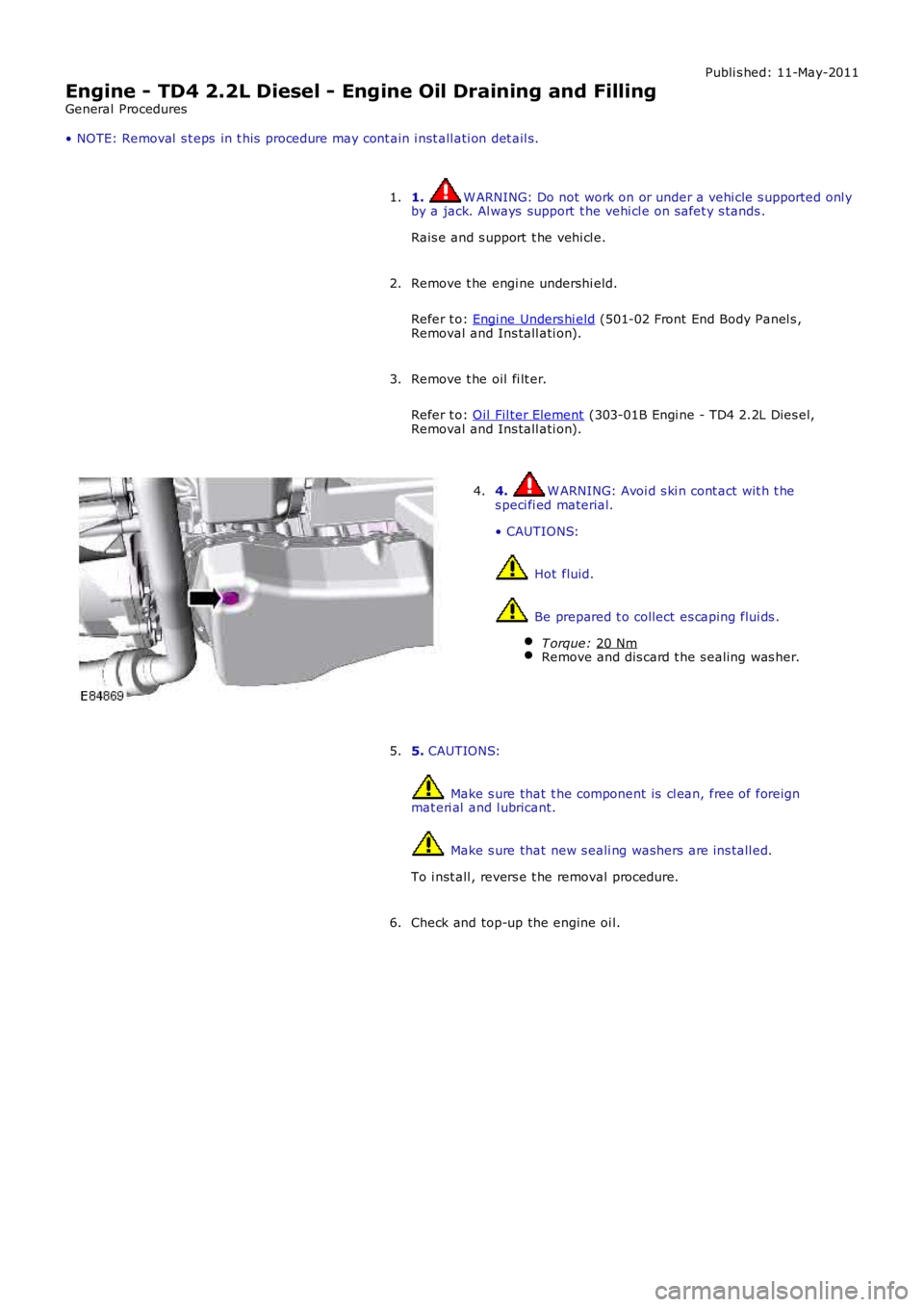

1. W ARNING: Do not work on or under a vehi cle s upported onl y

by a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he engi ne undershi eld.

Refer t o: Engi ne Unders hi eld (501-02 Front End Body Panel s ,

Removal and Ins tall ati on).

2.

Remove t he oil fi lt er.

Refer t o: Oil Fil ter Element (303-01B Engi ne - TD4 2.2L Dies el,

Removal and Ins tall ati on).

3. 4. W ARNING: Avoi d s ki n cont act wit h t he

s peci fi ed material.

• CAUTIONS: Hot fluid.

Be prepared t o collect es caping flui ds .

T orque: 20 Nm Remove and dis card t he s ealing was her.4.

5. CAUTIONS: Make s ure that t he component is cl ean, free of foreign

mat eri al and l ubricant. Make s ure that new s eali ng washers are ins tall ed.

To i nst all , revers e t he removal procedure.

5.

Check and top-up the engine oi l.

6.

Page 807 of 3229

Publi s hed: 11-May-2011

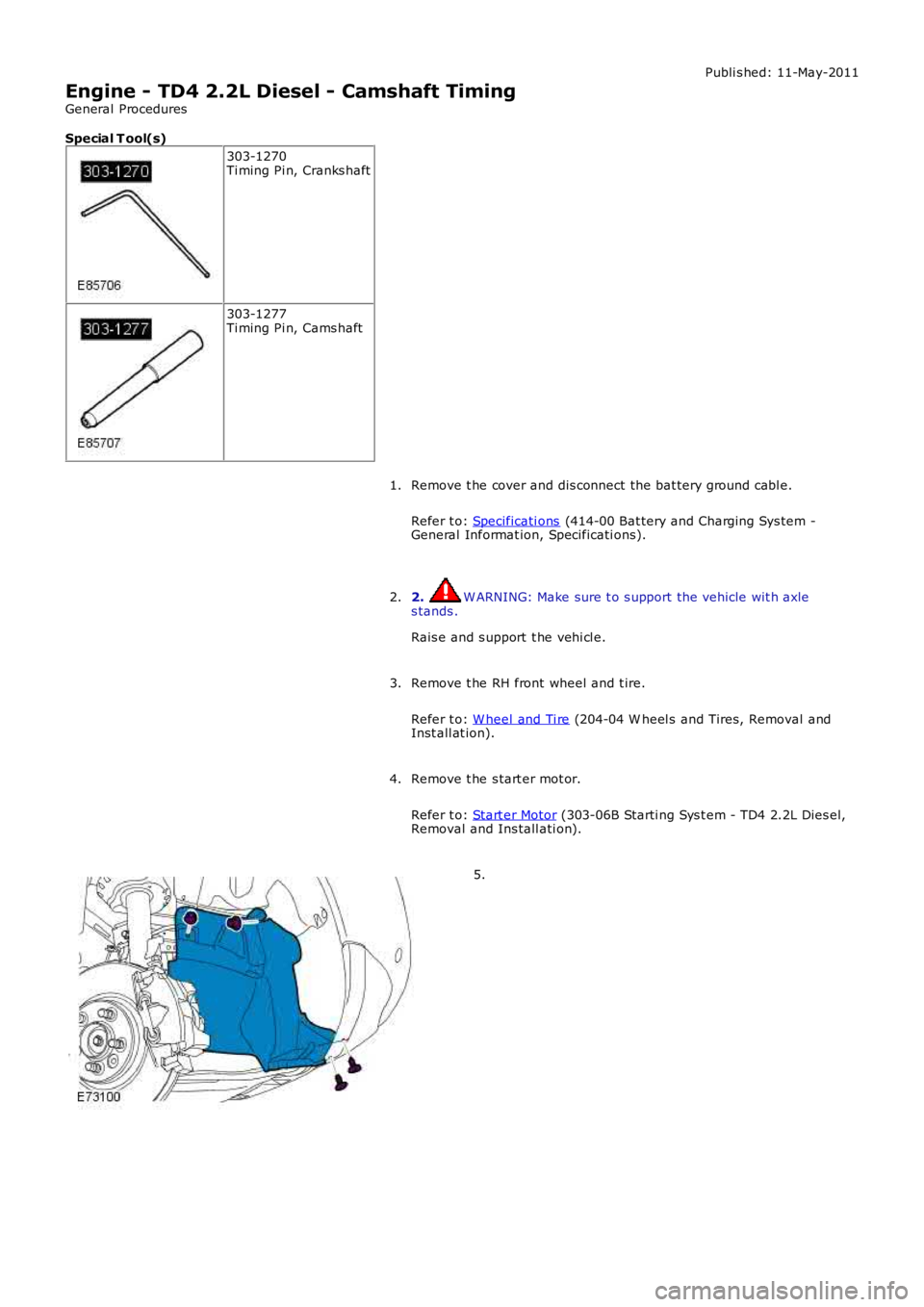

Engine - TD4 2.2L Diesel - Camshaft Timing

General Procedures

Special T ool(s)

303-1270Ti ming Pi n, Cranks haft

303-1277Ti ming Pi n, Cams haft

Remove t he cover and dis connect the bat tery ground cabl e.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

1.

2. W ARNING: Make sure t o s upport the vehicle wit h axles tands .

Rais e and s upport t he vehi cl e.

2.

Remove t he RH front wheel and t ire.

Refer t o: W heel and Ti re (204-04 W heel s and Tires, Removal andInst all at ion).

3.

Remove t he s tart er mot or.

Refer t o: Start er Motor (303-06B Starti ng Sys t em - TD4 2.2L Dies el,Removal and Ins tall ati on).

4.

5.

Page 808 of 3229

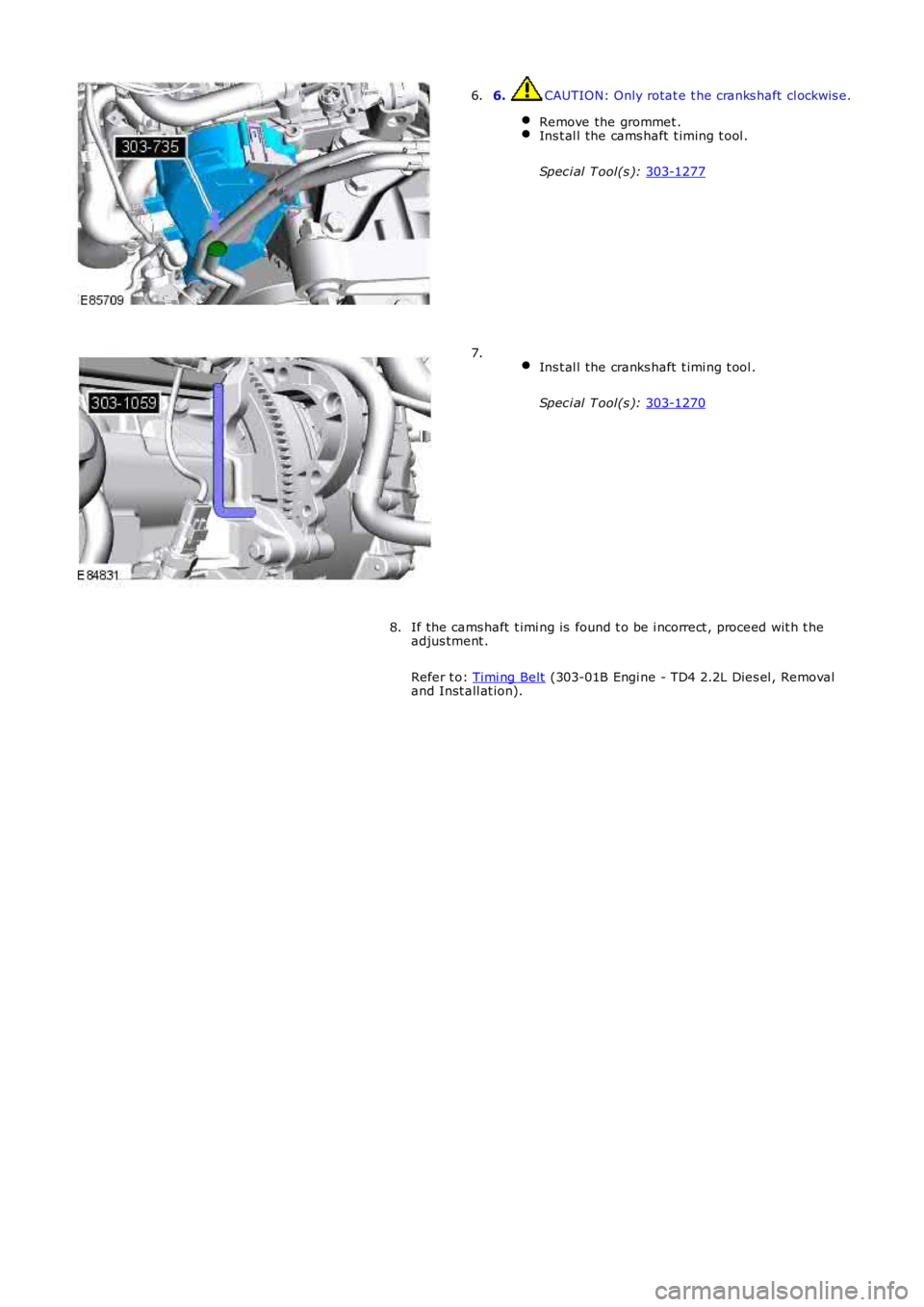

6. CAUTION: Only rotat e t he cranks haft cl ockwis e.

Remove the grommet . Ins t al l the cams haft t iming t ool .

Spec i al T ool(s ): 303-1277 6.

Ins t al l the cranks haft t imi ng t ool .

Spec i al T ool(s ): 303-1270 7.

If the cams haft t imi ng is found t o be i ncorrect , proceed wit h t he

adjus tment .

Refer t o: Timi ng Belt (303-01B Engi ne - TD4 2.2L Dies el , Removal

and Inst all at ion).

8.

Page 809 of 3229

Publi s hed: 11-May-2011

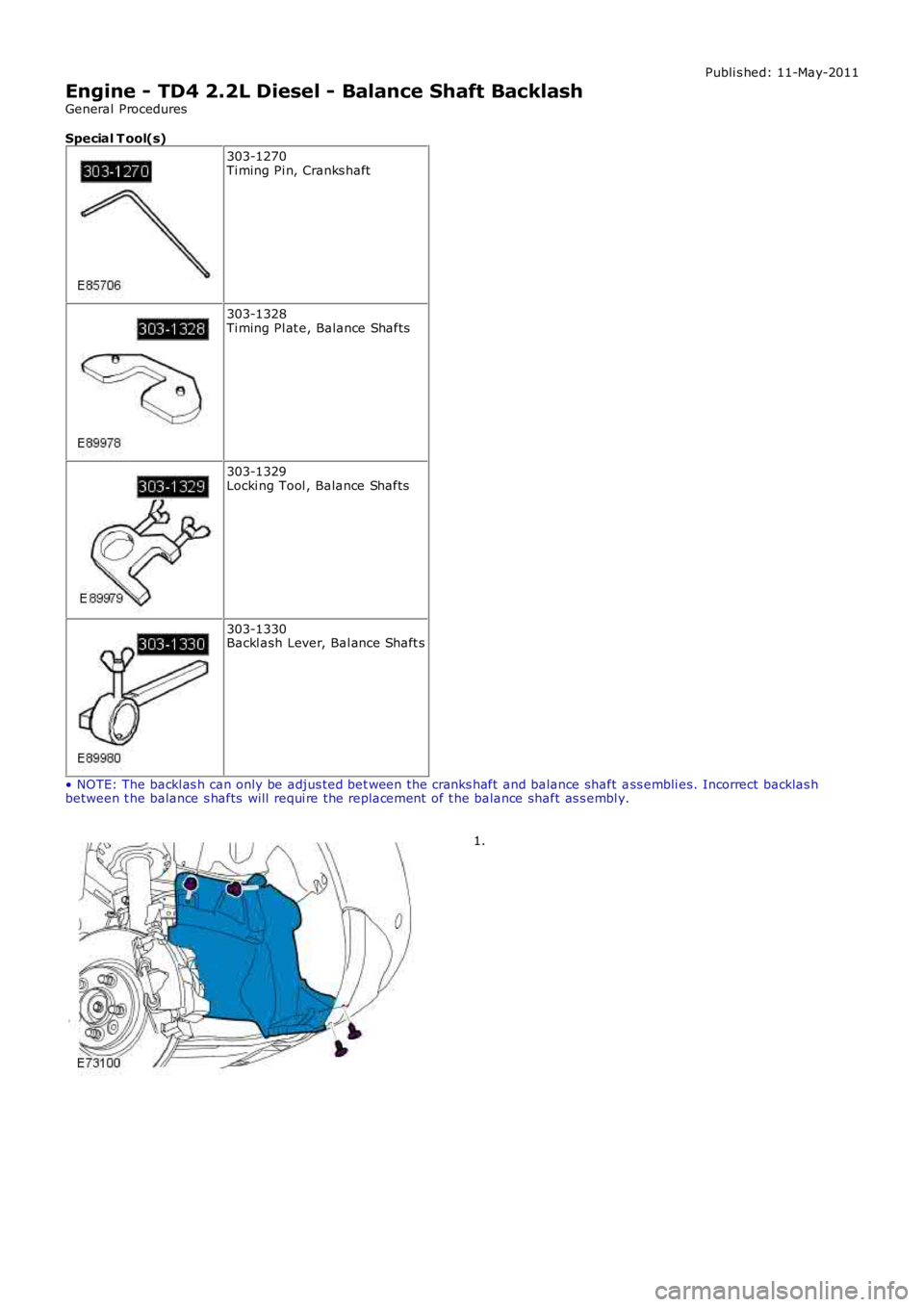

Engine - TD4 2.2L Diesel - Balance Shaft Backlash

General Procedures

Special T ool(s)

303-1270Ti ming Pi n, Cranks haft

303-1328Ti ming Pl at e, Balance Shafts

303-1329Locki ng Tool , Balance Shafts

303-1330Backl ash Lever, Bal ance Shaft s

• NOTE: The backl as h can only be adjus ted bet ween the cranks haft and balance shaft ass embli es. Incorrect backlas hbetween t he balance s hafts will requi re the replacement of t he balance shaft as s embly.

1.

Page 810 of 3229

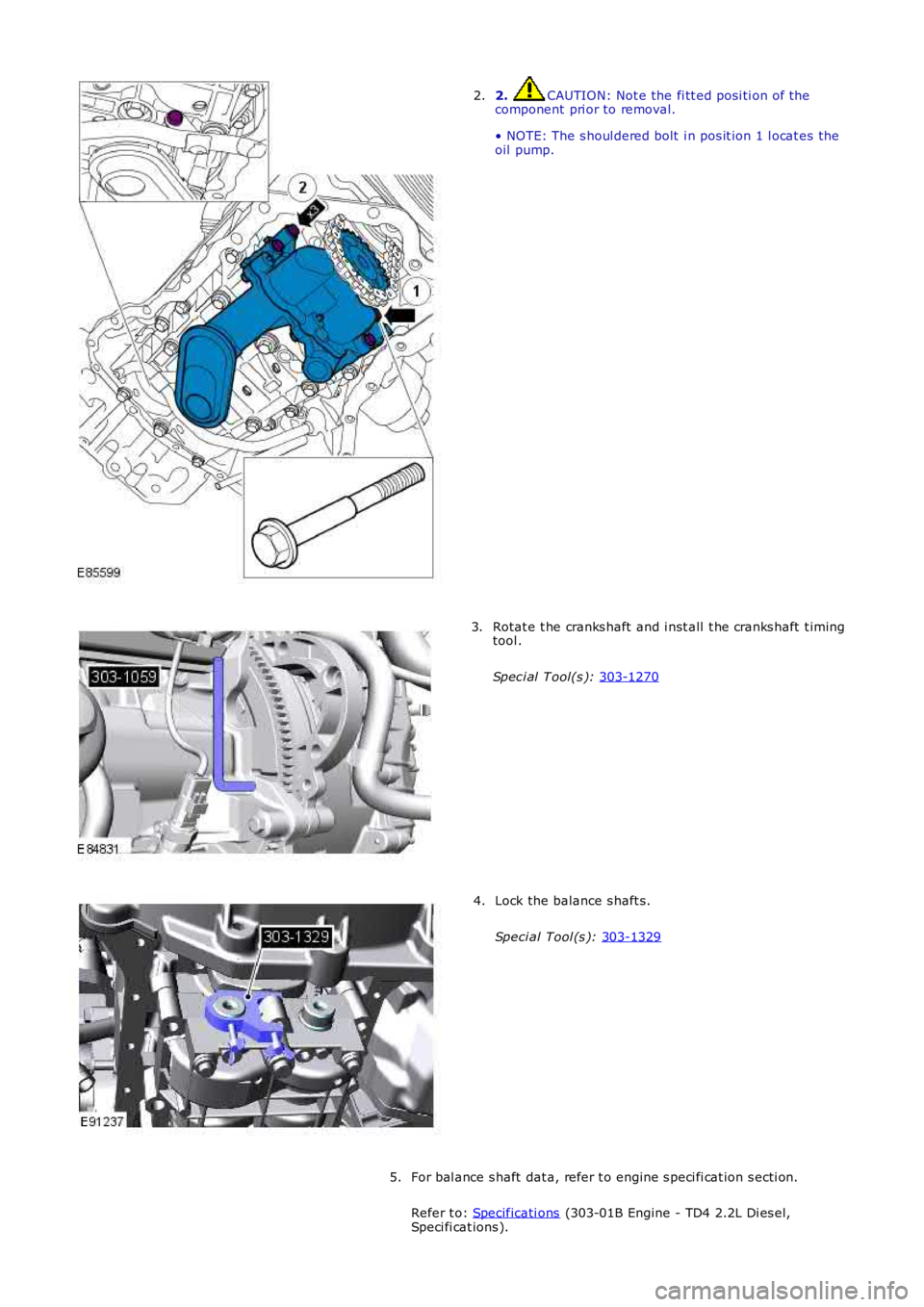

2. CAUTION: Not e the fi tt ed posi ti on of the

component pri or to removal.

• NOTE: The s houl dered bolt i n pos it ion 1 l ocat es the

oil pump.

2. Rotat e t he cranks haft and i nst all t he cranks haft t iming

tool .

Spec i al T ool(s ): 303-1270 3.

Lock the balance s haft s.

Speci al Tool (s ): 303-1329 4.

For bal ance s haft dat a, refer t o engine s peci fi cat ion s ecti on.

Refer t o: Specificati ons (303-01B Engine - TD4 2.2L Di es el,

Speci fi cat ions ).

5.