LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 981 of 3229

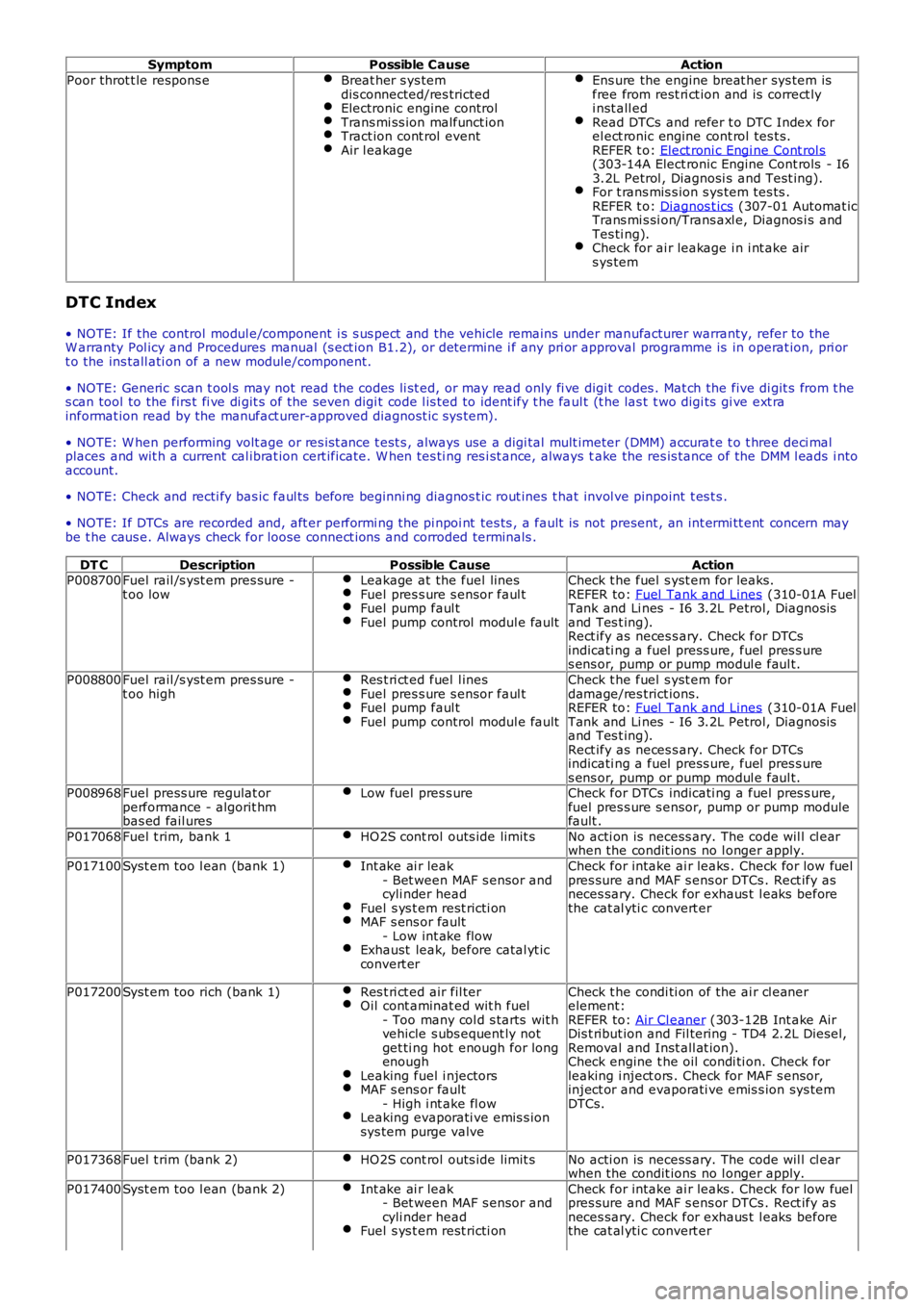

SymptomPossible CauseAction

Poor throt t le respons eBreat her s ys temdis connected/res trictedElectronic engine controlTrans mi ss ion malfunct ionTract ion cont rol eventAir l eakage

Ens ure the engine breat her sys tem isfree from rest ri ct ion and is correct lyi nst all edRead DTCs and refer t o DTC Index forel ect ronic engine cont rol tes t s.REFER t o: Elect roni c Engi ne Cont rol s(303-14A Elect ronic Engine Cont rols - I63.2L Petrol , Diagnosi s and Test ing).For t rans mis s ion s ys tem tes ts .REFER t o: Diagnos t ics (307-01 Automat icTrans mi s si on/Trans axl e, Diagnos i s andTes ti ng).Check for ai r leakage i n i nt ake airs ys tem

DTC Index

• NOTE: If the control modul e/component i s s us pect and the vehicle remains under manufacturer warranty, refer to theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve ext rainformat ion read by the manufact urer-approved diagnost ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces and wit h a current cal ibrat ion cert ificate. W hen tes ti ng res i st ance, always take the res is tance of the DMM l eads i ntoaccount.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines t hat invol ve pinpoint t es t s .

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

DT CDescriptionPossible CauseActionP008700Fuel rail /s yst em pres sure -t oo lowLeakage at the fuel linesFuel pres s ure s ensor faul tFuel pump faul tFuel pump control modul e fault

Check t he fuel s yst em for leaks.REFER to: Fuel Tank and Lines (310-01A FuelTank and Li nes - I6 3.2L Petrol, Diagnos isand Tes t ing).Rect ify as neces s ary. Check for DTCsindicati ng a fuel press ure, fuel pres s ures ens or, pump or pump modul e faul t.

P008800Fuel rail /s yst em pres sure -t oo highRes t ri ct ed fuel l inesFuel pres s ure s ensor faul tFuel pump faul tFuel pump control modul e fault

Check t he fuel s yst em fordamage/res trict ions.REFER to: Fuel Tank and Lines (310-01A FuelTank and Li nes - I6 3.2L Petrol, Diagnos isand Tes t ing).Rect ify as neces s ary. Check for DTCsindicati ng a fuel press ure, fuel pres s ures ens or, pump or pump modul e faul t.P008968Fuel press ure regulat orperformance - algorit hmbas ed fail ures

Low fuel pres s ureCheck for DTCs indicati ng a fuel pres s ure,fuel pres s ure s ensor, pump or pump modulefault .

P017068Fuel t rim, bank 1HO2S cont rol outs ide limit sNo acti on is necess ary. The code wil l cl earwhen the condit ions no l onger apply.

P017100Syst em too l ean (bank 1)Int ake ai r leak- Bet ween MAF s ensor andcyli nder headFuel s ys t em rest ricti onMAF s ens or fault- Low int ake flowExhaust leak, before catal yt icconvert er

Check for intake ai r leaks . Check for low fuelpres sure and MAF s ens or DTCs . Rect ify asneces sary. Check for exhaus t l eaks beforethe cat al yti c convert er

P017200Syst em too rich (bank 1)Res t ri ct ed air fil terOil cont aminat ed wit h fuel- Too many col d s tarts wit hvehicle s ubs equent ly notget ti ng hot enough for longenoughLeaking fuel i njectorsMAF s ens or fault- High i nt ake fl owLeaking evaporati ve emis s ionsys tem purge valve

Check t he condi ti on of the ai r cl eanerelement:REFER to: Air Cl eaner (303-12B Int ake AirDis t ribut ion and Fil tering - TD4 2.2L Dies el,Removal and Inst all at ion).Check engine t he oil condi ti on. Check forleaking i nject ors . Check for MAF s ensor,inject or and evaporati ve emis s ion sys temDTCs.

P017368Fuel t rim (bank 2)HO2S cont rol outs ide limit sNo acti on is necess ary. The code wil l cl earwhen the condit ions no l onger apply.

P017400Syst em too l ean (bank 2)Int ake ai r leak- Bet ween MAF s ensor andcyli nder headFuel s ys t em rest ricti on

Check for intake ai r leaks . Check for low fuelpres sure and MAF s ens or DTCs . Rect ify asneces sary. Check for exhaus t l eaks beforethe cat al yti c convert er

Page 982 of 3229

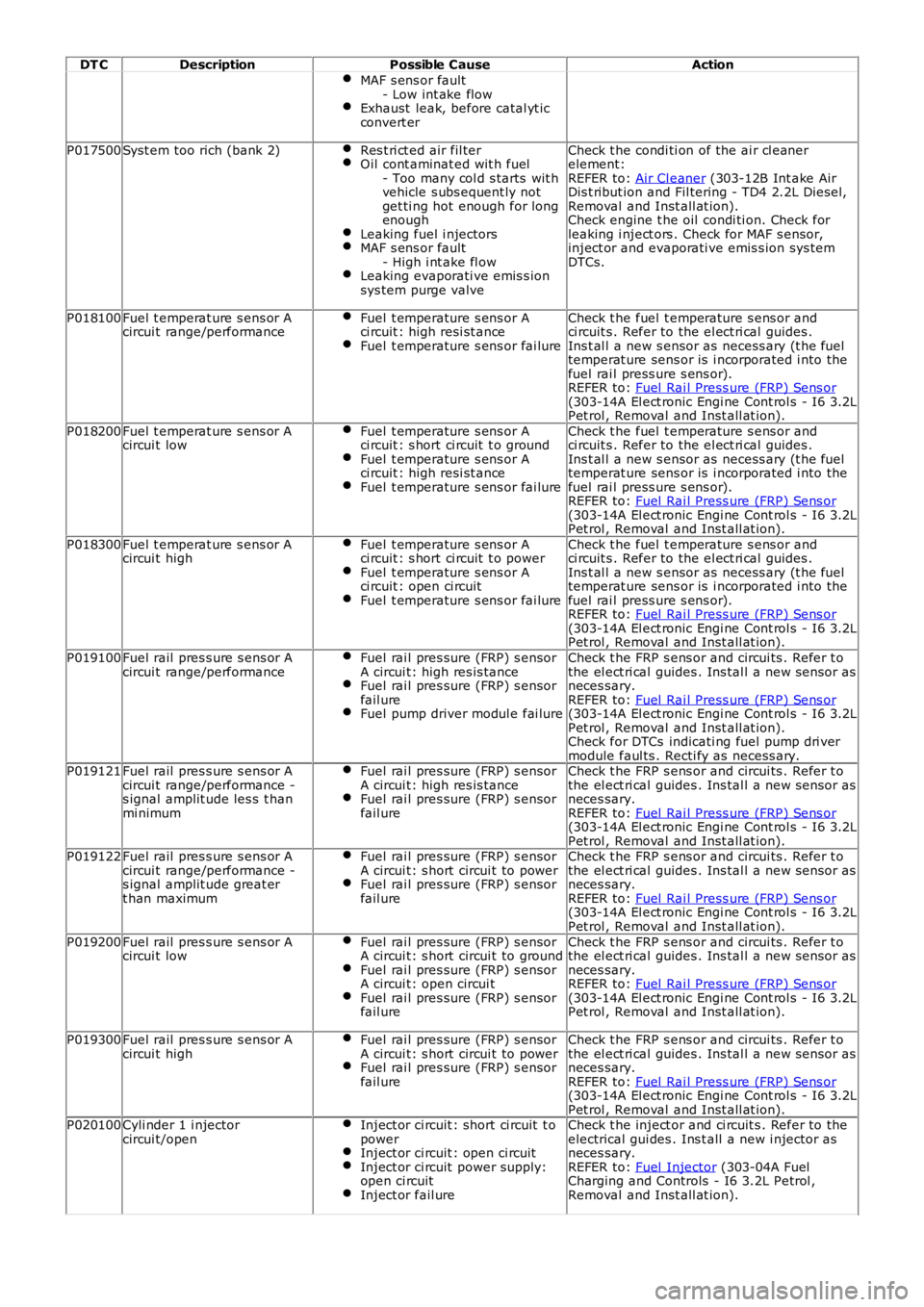

DT CDescriptionPossible CauseAction

MAF s ens or fault- Low int ake flowExhaust leak, before catal yt icconvert er

P017500Syst em too rich (bank 2)Res t ri ct ed air fil terOil cont aminat ed wit h fuel- Too many col d s tarts wit hvehicle s ubs equent ly notget ti ng hot enough for longenoughLeaking fuel i njectorsMAF s ens or fault- High i nt ake fl owLeaking evaporati ve emis s ionsys tem purge valve

Check t he condi ti on of the ai r cl eanerelement:REFER to: Air Cl eaner (303-12B Int ake AirDis t ribut ion and Fil tering - TD4 2.2L Dies el,Removal and Inst all at ion).Check engine t he oil condi ti on. Check forleaking i nject ors . Check for MAF s ensor,inject or and evaporati ve emis s ion sys temDTCs.

P018100Fuel t emperat ure s ens or Acircui t range/performanceFuel t emperature s ens or Aci rcuit : high resi st anceFuel t emperature s ens or fai lure

Check t he fuel t emperature s ens or andci rcuit s . Refer to the el ect ri cal guides .Ins t al l a new s ensor as necess ary (t he fueltemperat ure sens or is i ncorporated i nto thefuel rai l press ure s ens or).REFER to: Fuel Rai l Press ure (FRP) Sens or(303-14A El ect ronic Engi ne Cont rol s - I6 3.2LPet rol , Removal and Inst all at ion).

P018200Fuel t emperat ure s ens or Acircui t lowFuel t emperature s ens or Aci rcuit : s hort ci rcuit t o groundFuel t emperature s ens or Aci rcuit : high resi st anceFuel t emperature s ens or fai lure

Check t he fuel t emperature s ens or andci rcuit s . Refer to the el ect ri cal guides .Ins t al l a new s ensor as necess ary (t he fueltemperat ure sens or is i ncorporated i nto thefuel rai l press ure s ens or).REFER to: Fuel Rai l Press ure (FRP) Sens or(303-14A El ect ronic Engi ne Cont rol s - I6 3.2LPet rol , Removal and Inst all at ion).

P018300Fuel t emperat ure s ens or Acircui t highFuel t emperature s ens or Aci rcuit : s hort ci rcuit t o powerFuel t emperature s ens or Aci rcuit : open ci rcuitFuel t emperature s ens or fai lure

Check t he fuel t emperature s ens or andci rcuit s . Refer to the el ect ri cal guides .Ins t al l a new s ensor as necess ary (t he fueltemperat ure sens or is i ncorporated i nto thefuel rai l press ure s ens or).REFER to: Fuel Rai l Press ure (FRP) Sens or(303-14A El ect ronic Engi ne Cont rol s - I6 3.2LPet rol , Removal and Inst all at ion).

P019100Fuel rail pres s ure s ens or Acircui t range/performanceFuel rai l pres sure (FRP) s ensorA circui t: high res is tanceFuel rai l pres sure (FRP) s ensorfail ureFuel pump driver modul e fai lure

Check t he FRP s ens or and circui ts . Refer t othe el ect ri cal guides . Ins tal l a new s ensor asneces sary.REFER to: Fuel Rai l Press ure (FRP) Sens or(303-14A El ect ronic Engi ne Cont rol s - I6 3.2LPet rol , Removal and Inst all at ion).Check for DTCs indicati ng fuel pump dri vermodule faul ts . Recti fy as necess ary.P019121Fuel rail pres s ure s ens or Acircui t range/performance -s ignal amplit ude les s t hanmi nimum

Fuel rai l pres sure (FRP) s ensorA circui t: high res is tanceFuel rai l pres sure (FRP) s ensorfail ure

Check t he FRP s ens or and circui ts . Refer t othe el ect ri cal guides . Ins tal l a new s ensor asneces sary.REFER to: Fuel Rai l Press ure (FRP) Sens or(303-14A El ect ronic Engi ne Cont rol s - I6 3.2LPet rol , Removal and Inst all at ion).P019122Fuel rail pres s ure s ens or Acircui t range/performance -s ignal amplit ude great ert han maximum

Fuel rai l pres sure (FRP) s ensorA circui t: s hort circui t to powerFuel rai l pres sure (FRP) s ensorfail ure

Check t he FRP s ens or and circui ts . Refer t othe el ect ri cal guides . Ins tal l a new s ensor asneces sary.REFER to: Fuel Rai l Press ure (FRP) Sens or(303-14A El ect ronic Engi ne Cont rol s - I6 3.2LPet rol , Removal and Inst all at ion).

P019200Fuel rail pres s ure s ens or Acircui t lowFuel rai l pres sure (FRP) s ensorA circui t: s hort circui t to groundFuel rai l pres sure (FRP) s ensorA circui t: open circui tFuel rai l pres sure (FRP) s ensorfail ure

Check t he FRP s ens or and circui ts . Refer t othe el ect ri cal guides . Ins tal l a new s ensor asneces sary.REFER to: Fuel Rai l Press ure (FRP) Sens or(303-14A El ect ronic Engi ne Cont rol s - I6 3.2LPet rol , Removal and Inst all at ion).

P019300Fuel rail pres s ure s ens or Acircui t highFuel rai l pres sure (FRP) s ensorA circui t: s hort circui t to powerFuel rai l pres sure (FRP) s ensorfail ure

Check t he FRP s ens or and circui ts . Refer t othe el ect ri cal guides . Ins tal l a new s ensor asneces sary.REFER to: Fuel Rai l Press ure (FRP) Sens or(303-14A El ect ronic Engi ne Cont rol s - I6 3.2LPet rol , Removal and Inst all at ion).P020100Cyli nder 1 i njectorcircui t/openInject or ci rcuit : short ci rcuit t opowerInject or ci rcuit : open ci rcuitInject or ci rcuit power supply:open ci rcuitInject or fail ure

Check t he inject or and ci rcuit s . Refer to theelectrical gui des . Ins t all a new i njector asneces sary.REFER to: Fuel Injector (303-04A FuelCharging and Controls - I6 3.2L Petrol ,Removal and Inst all at ion).

Page 983 of 3229

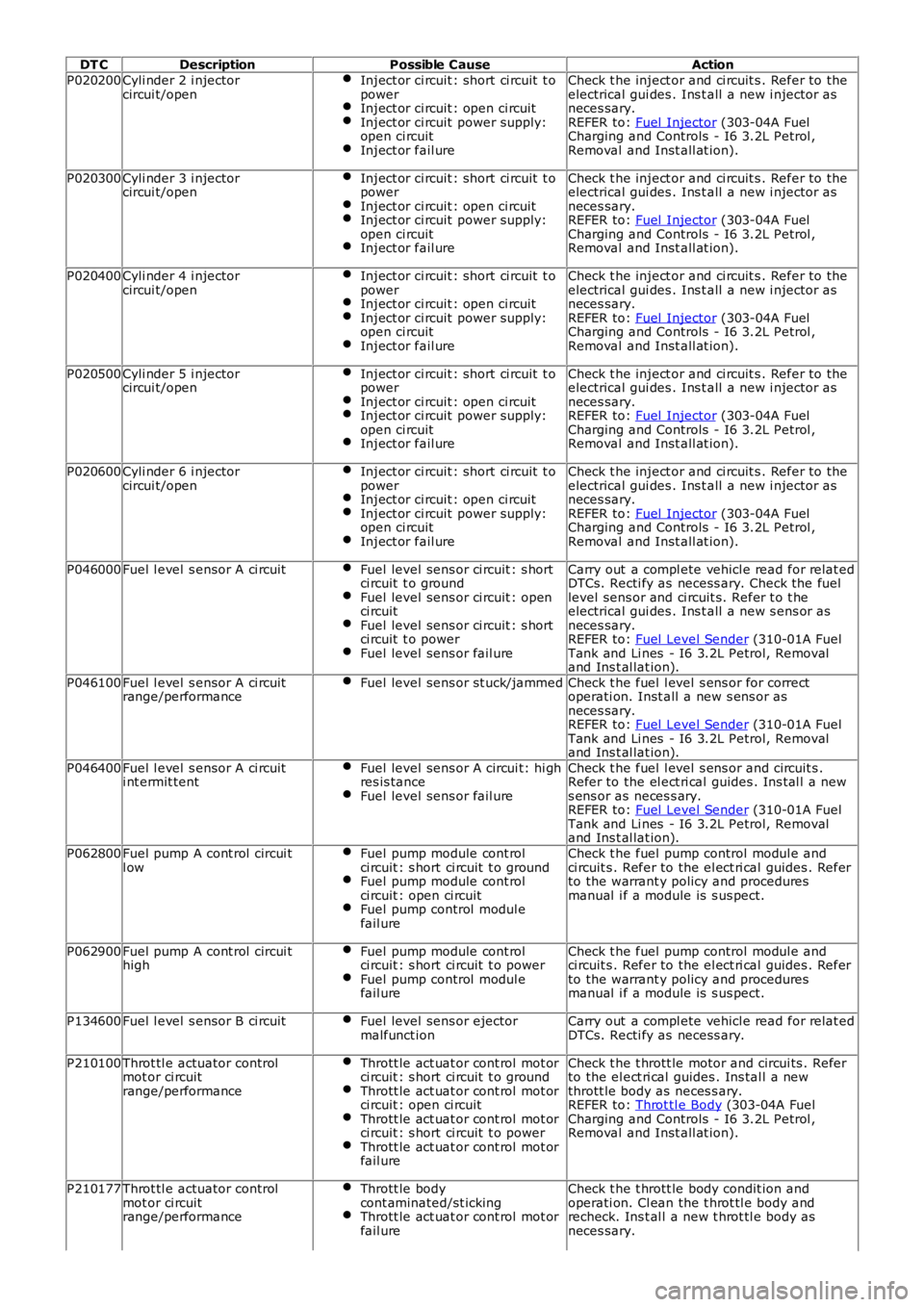

DT CDescriptionPossible CauseAction

P020200Cyli nder 2 i njectorcircui t/openInject or ci rcuit : short ci rcuit t opowerInject or ci rcuit : open ci rcuitInject or ci rcuit power supply:open ci rcuitInject or fail ure

Check t he inject or and ci rcuit s . Refer to theelectrical gui des . Ins t all a new i njector asneces sary.REFER to: Fuel Injector (303-04A FuelCharging and Controls - I6 3.2L Petrol ,Removal and Inst all at ion).

P020300Cyli nder 3 i njectorcircui t/openInject or ci rcuit : short ci rcuit t opowerInject or ci rcuit : open ci rcuitInject or ci rcuit power supply:open ci rcuitInject or fail ure

Check t he inject or and ci rcuit s . Refer to theelectrical gui des . Ins t all a new i njector asneces sary.REFER to: Fuel Injector (303-04A FuelCharging and Controls - I6 3.2L Petrol ,Removal and Inst all at ion).

P020400Cyli nder 4 i njectorcircui t/openInject or ci rcuit : short ci rcuit t opowerInject or ci rcuit : open ci rcuitInject or ci rcuit power supply:open ci rcuitInject or fail ure

Check t he inject or and ci rcuit s . Refer to theelectrical gui des . Ins t all a new i njector asneces sary.REFER to: Fuel Injector (303-04A FuelCharging and Controls - I6 3.2L Petrol ,Removal and Inst all at ion).

P020500Cyli nder 5 i njectorcircui t/openInject or ci rcuit : short ci rcuit t opowerInject or ci rcuit : open ci rcuitInject or ci rcuit power supply:open ci rcuitInject or fail ure

Check t he inject or and ci rcuit s . Refer to theelectrical gui des . Ins t all a new i njector asneces sary.REFER to: Fuel Injector (303-04A FuelCharging and Controls - I6 3.2L Petrol ,Removal and Inst all at ion).

P020600Cyli nder 6 i njectorcircui t/openInject or ci rcuit : short ci rcuit t opowerInject or ci rcuit : open ci rcuitInject or ci rcuit power supply:open ci rcuitInject or fail ure

Check t he inject or and ci rcuit s . Refer to theelectrical gui des . Ins t all a new i njector asneces sary.REFER to: Fuel Injector (303-04A FuelCharging and Controls - I6 3.2L Petrol ,Removal and Inst all at ion).

P046000Fuel l evel s ensor A ci rcuitFuel level sens or ci rcuit : s hortci rcuit t o groundFuel level sens or ci rcuit : openci rcuitFuel level sens or ci rcuit : s hortci rcuit t o powerFuel level sens or fail ure

Carry out a compl ete vehicl e read for relat edDTCs. Recti fy as necess ary. Check the fuellevel sens or and ci rcuit s. Refer t o t heelectrical gui des . Ins t all a new s ens or asneces sary.REFER to: Fuel Level Sender (310-01A FuelTank and Li nes - I6 3.2L Petrol, Removaland Ins t al lat ion).

P046100Fuel l evel s ensor A ci rcuitrange/performanceFuel level sens or st uck/jammedCheck t he fuel l evel s ens or for correctoperati on. Inst all a new s ens or asneces sary.REFER to: Fuel Level Sender (310-01A FuelTank and Li nes - I6 3.2L Petrol, Removaland Ins t al lat ion).

P046400Fuel l evel s ensor A ci rcuiti nt ermit tentFuel level sens or A circui t: hi ghres is tanceFuel level sens or fail ure

Check t he fuel l evel s ens or and circuit s .Refer to the el ect ri cal guides . Ins tal l a news ens or as neces s ary.REFER to: Fuel Level Sender (310-01A FuelTank and Li nes - I6 3.2L Petrol, Removaland Ins t al lat ion).

P062800Fuel pump A cont rol circui tl owFuel pump module cont rolci rcuit : s hort ci rcuit t o groundFuel pump module cont rolci rcuit : open ci rcuitFuel pump control modul efail ure

Check t he fuel pump control modul e andci rcuit s . Refer to the el ect ri cal guides . Referto the warrant y policy and proceduresmanual i f a module is s us pect.

P062900Fuel pump A cont rol circui thighFuel pump module cont rolci rcuit : s hort ci rcuit t o powerFuel pump control modul efail ure

Check t he fuel pump control modul e andci rcuit s . Refer to the el ect ri cal guides . Referto the warrant y policy and proceduresmanual i f a module is s us pect.

P134600Fuel l evel s ensor B ci rcuitFuel level sens or ejectormalfunct ionCarry out a compl ete vehicl e read for relat edDTCs. Recti fy as necess ary.

P210100Throt tl e actuator controlmot or ci rcuitrange/performance

Thrott le act uat or cont rol mot orci rcuit : s hort ci rcuit t o groundThrott le act uat or cont rol mot orci rcuit : open ci rcuitThrott le act uat or cont rol mot orci rcuit : s hort ci rcuit t o powerThrott le act uat or cont rol mot orfail ure

Check t he t hrott le motor and circui ts . Referto the el ect ri cal guides . Ins tal l a newthrott le body as neces s ary.REFER to: Throt tl e Body (303-04A FuelCharging and Controls - I6 3.2L Petrol ,Removal and Inst all at ion).

P210177Throt tl e actuator controlmot or ci rcuitrange/performance

Thrott le bodycont aminated/st ickingThrott le act uat or cont rol mot orfail ure

Check t he t hrott le body condit ion andoperati on. Cl ean the t hrot tl e body andrecheck. Ins t al l a new t hrot tl e body asneces sary.

Page 984 of 3229

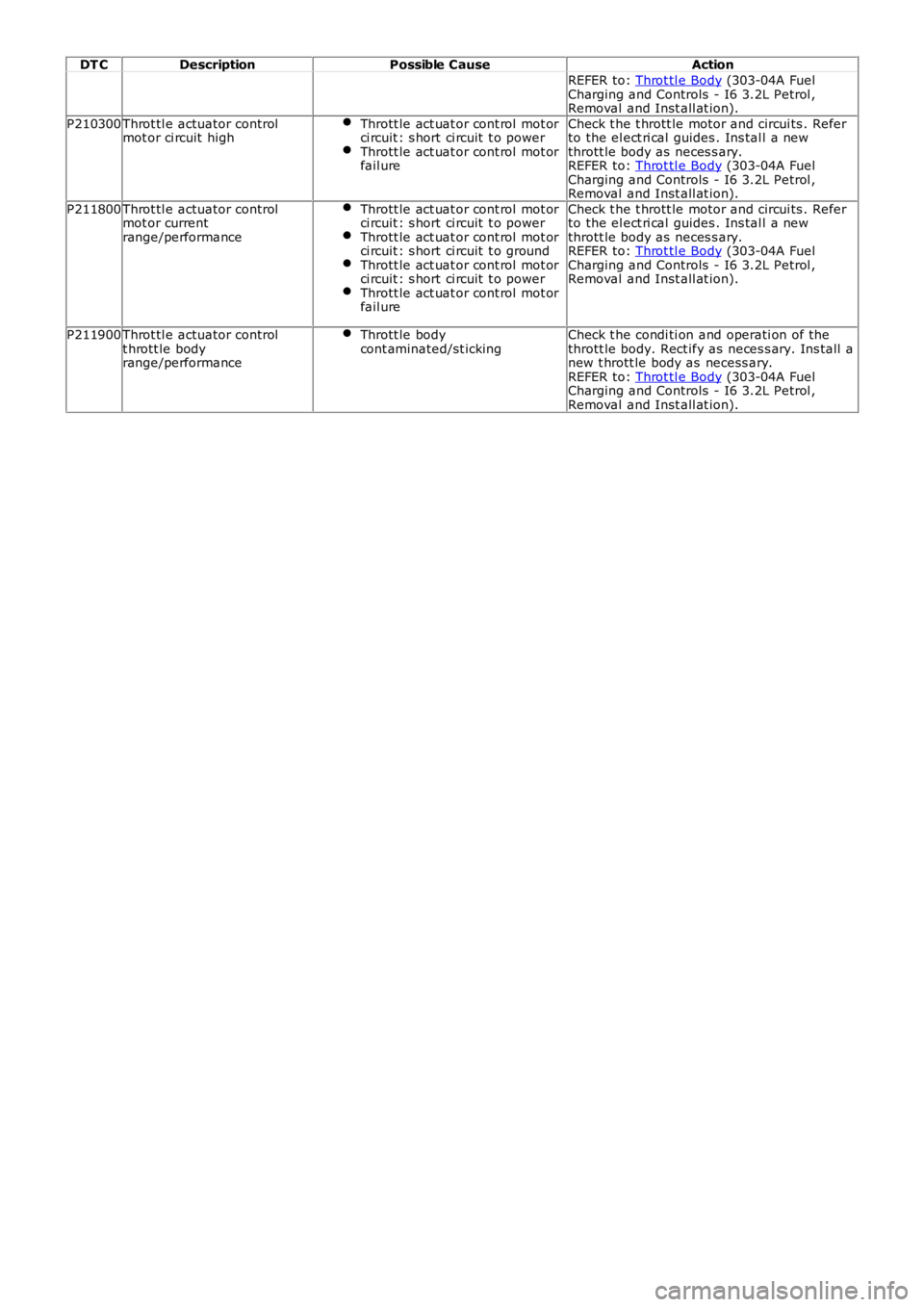

DT CDescriptionPossible CauseAction

REFER to: Throt tl e Body (303-04A FuelCharging and Controls - I6 3.2L Petrol ,Removal and Inst all at ion).

P210300Throt tl e actuator controlmot or ci rcuit highThrott le act uat or cont rol mot orci rcuit : s hort ci rcuit t o powerThrott le act uat or cont rol mot orfail ure

Check t he t hrott le motor and circui ts . Referto the el ect ri cal guides . Ins tal l a newthrott le body as neces s ary.REFER to: Throt tl e Body (303-04A FuelCharging and Controls - I6 3.2L Petrol ,Removal and Inst all at ion).

P211800Throt tl e actuator controlmot or currentrange/performance

Thrott le act uat or cont rol mot orci rcuit : s hort ci rcuit t o powerThrott le act uat or cont rol mot orci rcuit : s hort ci rcuit t o groundThrott le act uat or cont rol mot orci rcuit : s hort ci rcuit t o powerThrott le act uat or cont rol mot orfail ure

Check t he t hrott le motor and circui ts . Referto the el ect ri cal guides . Ins tal l a newthrott le body as neces s ary.REFER to: Throt tl e Body (303-04A FuelCharging and Controls - I6 3.2L Petrol ,Removal and Inst all at ion).

P211900Throt tl e actuator controlt hrott le bodyrange/performance

Thrott le bodycont aminated/st ickingCheck t he condi ti on and operati on of thethrott le body. Rect ify as neces s ary. Ins tal l anew t hrott le body as necess ary.REFER to: Throt tl e Body (303-04A FuelCharging and Controls - I6 3.2L Petrol ,Removal and Inst all at ion).

Page 985 of 3229

Publi s hed: 11-May-2011

Fuel Charging and Controls - I6 3.2L Petrol - Throttle Body

Removal and Inst all ati on

Removal

1. W ARNING: Make sure t o s upport the vehicle wit h axles tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he engi ne undershi eld.

Refer t o: Engi ne Unders hi eld (501-02 Front End Body Panel s ,Removal and Ins tall ati on).

2.

3.

4.

Releas e t he air cleaner out let pipe.5.

Page 986 of 3229

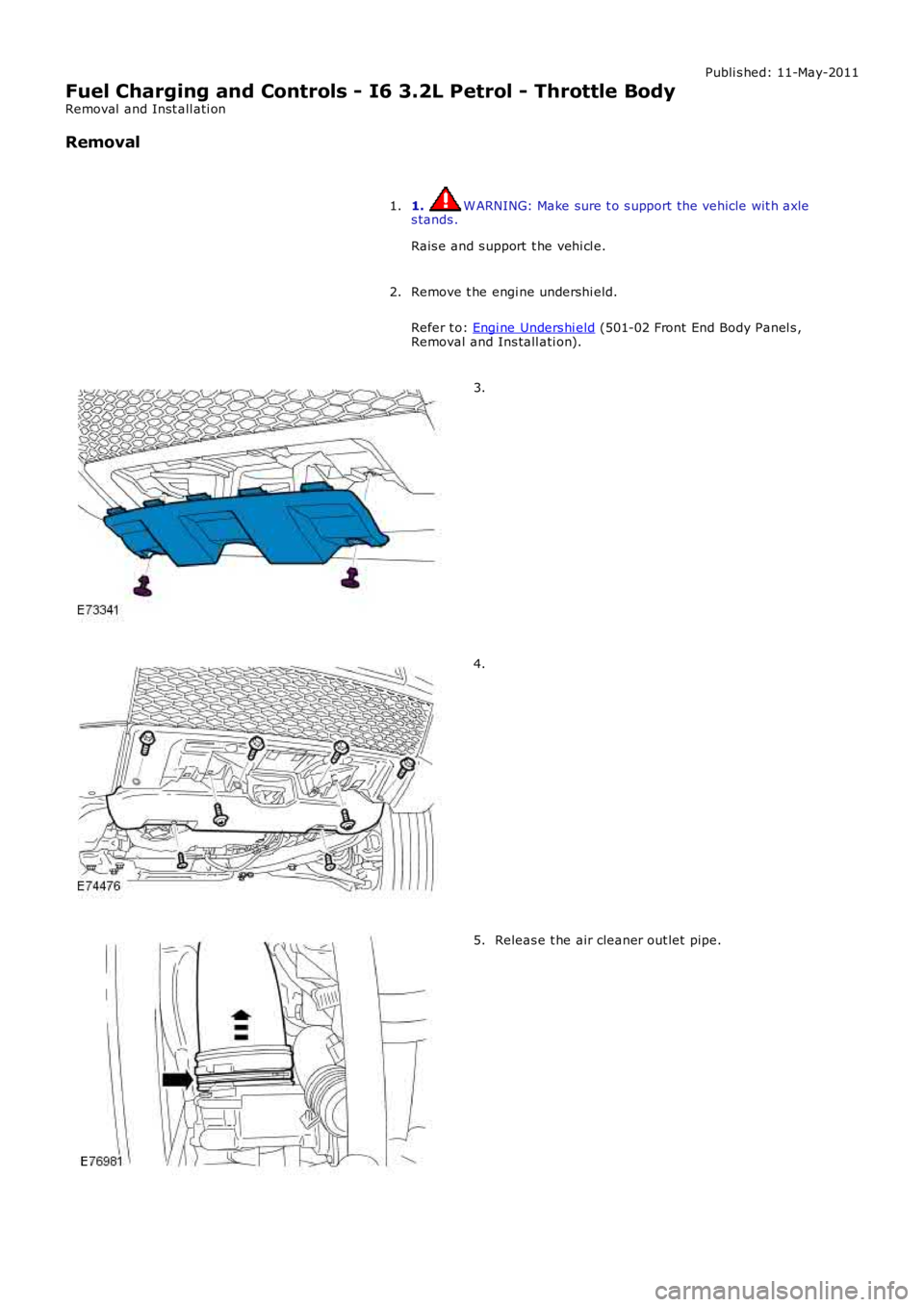

Remove t he thrott le body.

6.

Remove and dis card t he gas ket .

7.

Installation

Clean t he component mat ing faces .

1.

Inst all a new gas ket.

2. 3. CAUTION: Make s ure that the mati ng faces are

clean and free of foreign materi al.

Inst all t he thrott le body and t ighten the s crews i n t he

s equence s hown.

T orque: 8 Nm 3.

Inst all t he engi ne undershi eld.

Refer t o: Engi ne Unders hi eld (501-02 Front End Body Panel s ,

Removal and Ins tall ati on).

4.

Inst all t he front unders hiel d.

5.

Inst all t he front towing eye cover.

6.

Page 987 of 3229

Publi s hed: 11-May-2011

Fuel Charging and Controls - I6 3.2L Petrol - Fuel Injector

Removal and Inst all ati on

Removal

• NOTE: The process to remove a fuel injector i s s hown the t he Fuel Rai l procedure.

Remove t he fuel inject or.

Refer t o: Fuel Rail (303-04A Fuel Chargi ng and Cont rol s - I6 3.2LPetrol, Removal and Ins tall ati on).

1.

Installation

Inst all t he fuel inject or.

Refer t o: Fuel Rail (303-04A Fuel Chargi ng and Cont rol s - I6 3.2LPetrol, Removal and Ins tall ati on).

1.

Page 988 of 3229

Publi s hed: 11-May-2011

Fuel Charging and Controls - I6 3.2L Petrol - Fuel Rail

Removal and Inst all ati on

Removal

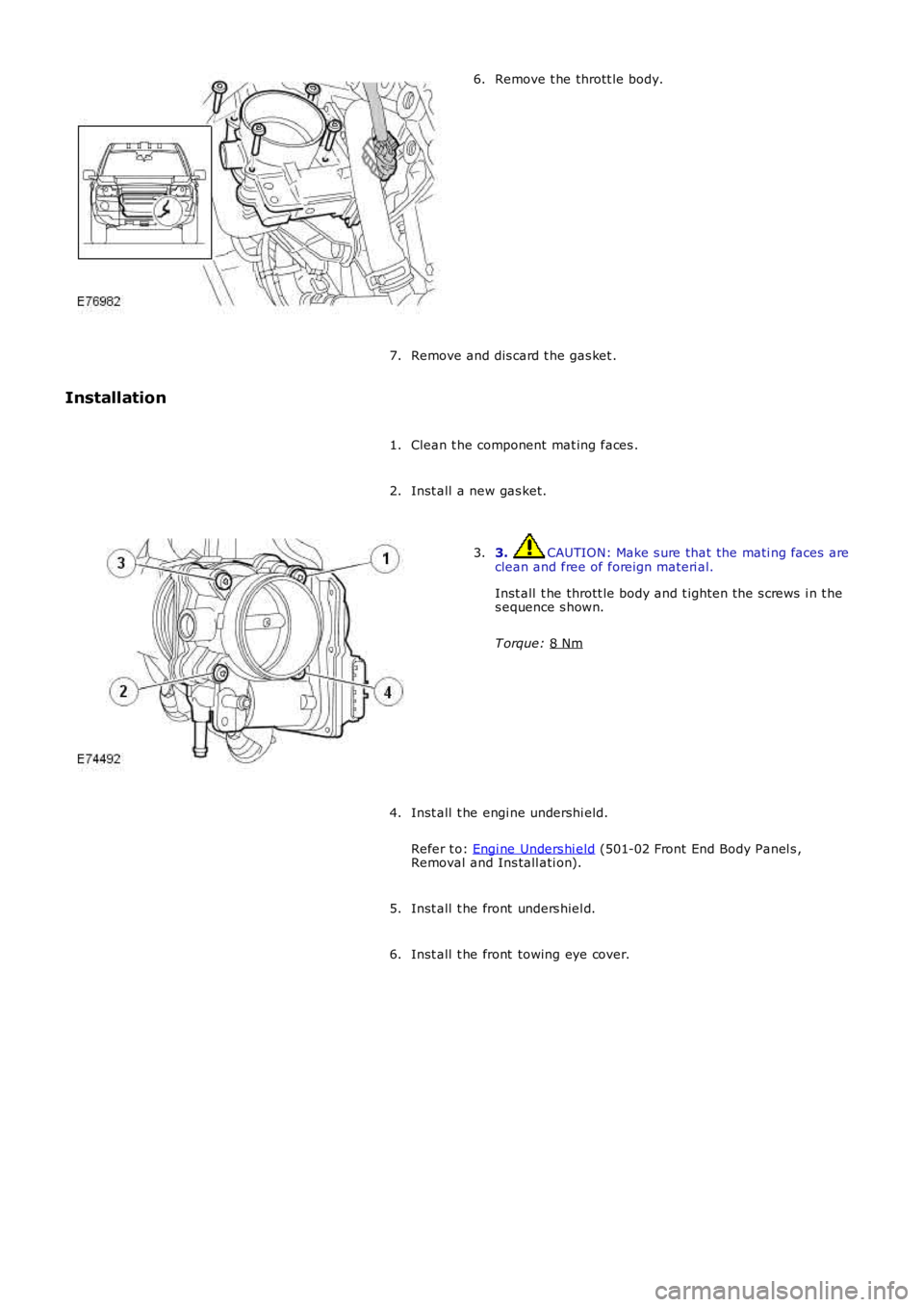

W ARNING: W ait for a mi nimum of 1 mi nut e after t he engi ne has st opped before carrying out any repair t o t he fuelinject ion s ys tem.

Remove t he cover and dis connect the bat tery ground cabl e.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

1.

Remove t he engi ne cover.

Refer t o: Engi ne Cover - I6 3.2L Pet rol (501-05 Int eri or Trim andOrnament ati on, Removal and Ins tal lat ion).

2.

3. W ARNINGS:

Avoid fl ames , s parks or li ght ed s ubst ances .

Be prepared t o collect es caping fuel.

Releas e t he fuel pres s ure.

3.

4.

5. CAUTIONS:

Ext reme cl eanli ness must be exerci sed whenhandl ing t hese components .

Make s ure that all openings are sealed.

5.

Page 989 of 3229

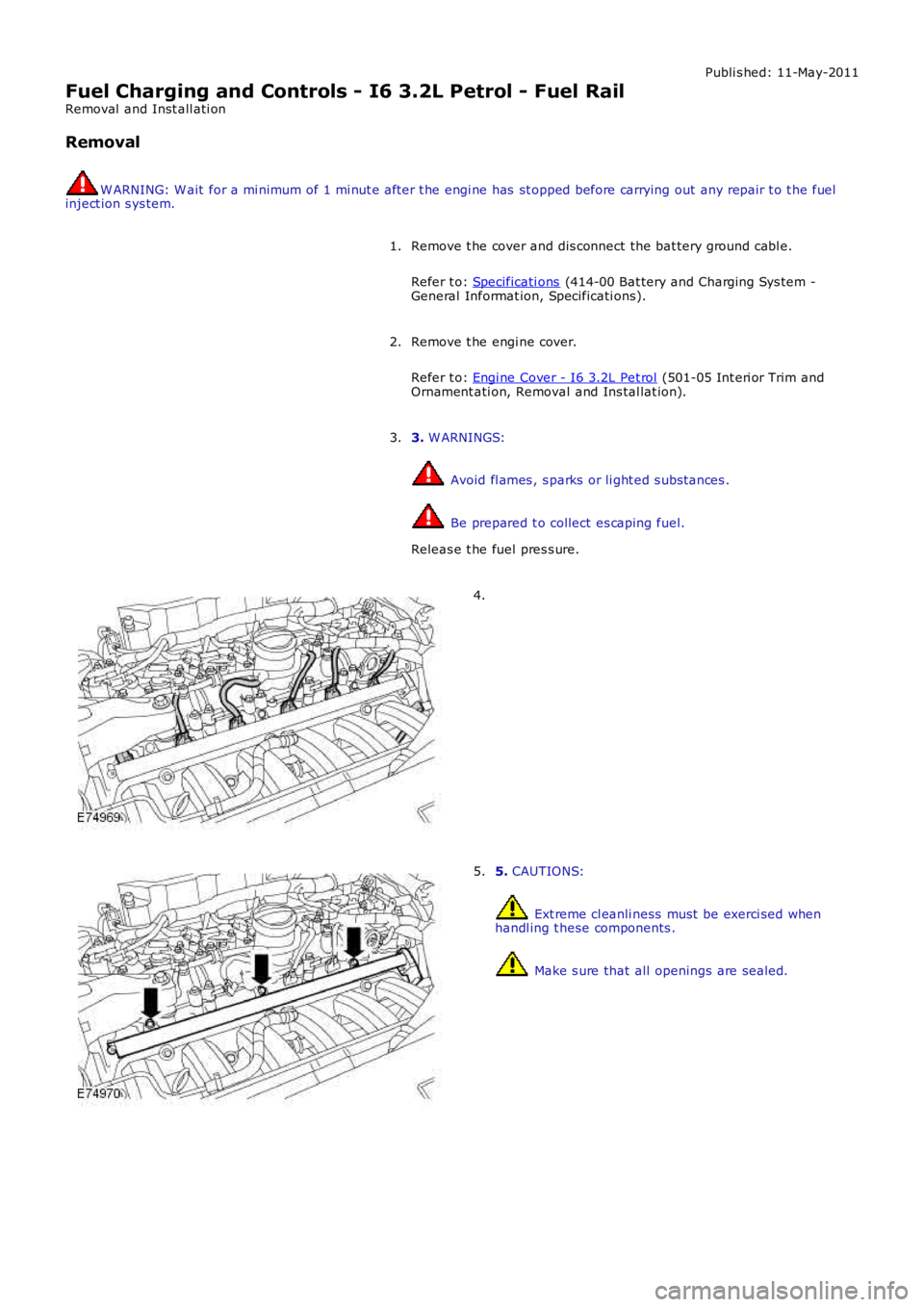

6. NOTE: Do not remove t he fuel i nject ors , i f the rail isbeing removed for acces s .6.

7. CAUTION: A new O-ring seal is to be ins tall ed.7.

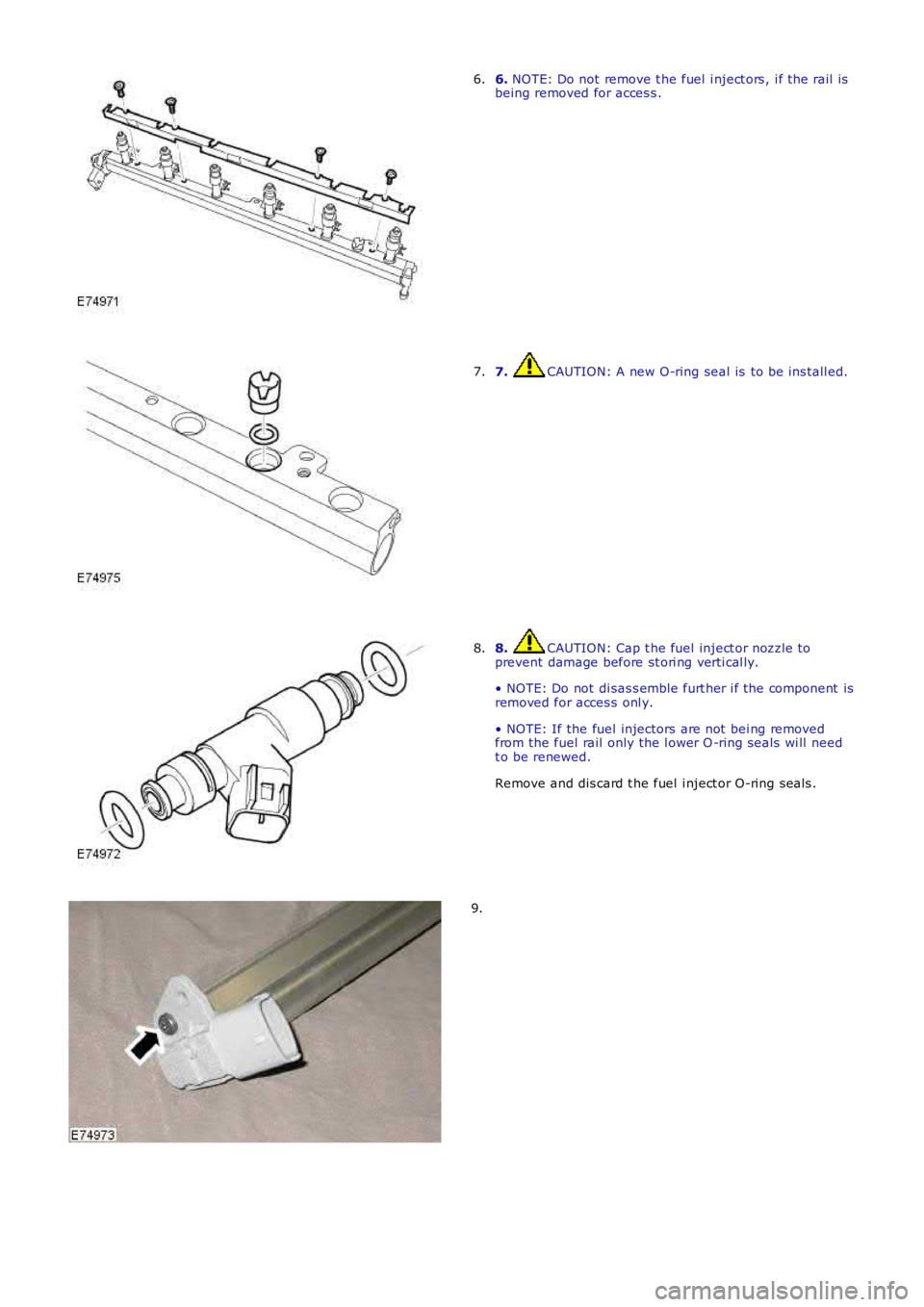

8. CAUTION: Cap t he fuel inject or nozzle toprevent damage before st ori ng verti cal ly.

• NOTE: Do not di sas s emble furt her i f the component isremoved for acces s onl y.

• NOTE: If the fuel injectors are not bei ng removedfrom the fuel rail only the l ower O -ring s eals wi ll needt o be renewed.

Remove and dis card t he fuel i nject or O-ring seals .

8.

9.

Page 990 of 3229

10.

Installation 1. CAUTION: A new O-ring seal is to be ins tall ed.

Inst all t he fuel rai l Schraeder val ve.

T orque: 6 Nm 1.

2. CAUTION: A new O-ring seal is to be ins tall ed.

Inst all t he fuel rai l press ure s ens or.

T orque: 6 Nm 2.

3. NOTE: Ins t al l new O-ri ng seal s.

Lubricat e and ins tal l the new O-rings .

3.

If removed, ins tall t he inject ors .

4.

5. CAUTION: A new O-ring seal is to be ins tall ed.

Inst all t he fuel li ne to fuel rai l seal ass embl y.

5.

Inst all t he fuel inject or cl amp plat e.

T orque: 6 Nm 6.

Inst all t he fuel rai l.

T orque: 10 Nm 7.

Connect and s ecure t he electrical connect ors .

8.

Inst all t he engi ne cover.

Refer t o: Engi ne Cover - I6 3.2L Pet rol (501-05 Int eri or Trim and

Ornament ati on, Removal and Ins tal lat ion).

9.

Connect t he batt ery ground cable and ins tall t he cover.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -

General Informat ion, Specificati ons).

10.