LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 941 of 3229

The wax-t ype thermost at locates i n t he top hos e connecti on t o t he radiat or. A l arge di ameter connecti on at the RH lowers ide connect s the modul e t o t he coolant rail. Two smal l diamet er out lets on the front of t he module provi de t he connect ionfor a supply hos e t o t he heat er mat rix, and a degas l ine t o t he cool ant reservoi r.

The t hermal cont rol module promotes rapi d warming of t he engine t o normal operat ing t emperature by clos ing t he returncool ant connect ion from the engi ne to the radiator. During the engine warmi ng period, t he thermost at is cl os ed and t heby-pas s val ve is open. The by-pass port all ows cool ant t o circul ate t hrough t he closed engi ne circuit vi a t he coolant pump,climate control heat er ci rcuit and EGR cooler.

As t he cool ant t emperat ure i ncreas es , the t hermos t at is opened and the by-pas s valve i s clos ed. The hot cool ant ret urningfrom the engine i s all owed to fl ow from the t hermal cont rol module to the radiator, through the open t hermos tat and t ophose connect ion. Return cool ant from t he radiat or fl ows through the bot tom hos e connect ion t o t he cool ant pump, via thecool ant rail .

The t hermos tat commences opening at 83°C (181°F), and i s ful ly open at 91°C (196°F).

The ECT s ens or is locat ed i n t he thermal control modul e and s ecured in the hous ing wi th a clip. The ECT s ens or provi desan engine coolant temperat ure si gnal t o t he Engi ne Control Module (ECM). The si gnal i s us ed by the ECM to cont rol t heoperati on of the 2 cool ing fans .For addit ional informat ion, refer t o: Electroni c Engi ne Controls - 2.2L Dies el (303-14 El ect ronic Engine Cont rols - 2.2LDies el, Des cript ion and Operat ion).

The ECM al so communi cat es the ECT si gnal on t he high speed Controll er Area Network (CAN) bus t o t he Central Junct ionBox (CJB). The CJB t rans mi ts t he ECT s ignal via t he medium s peed CAN bus to the ins trument cl us t er, for di spl ay on thecool ant t emperat ure gage.For addit ional informat ion, refer t o: Ins t rument Clus ter (413-01 Inst rument Cl us t er, Des cript ion and Operat ion).

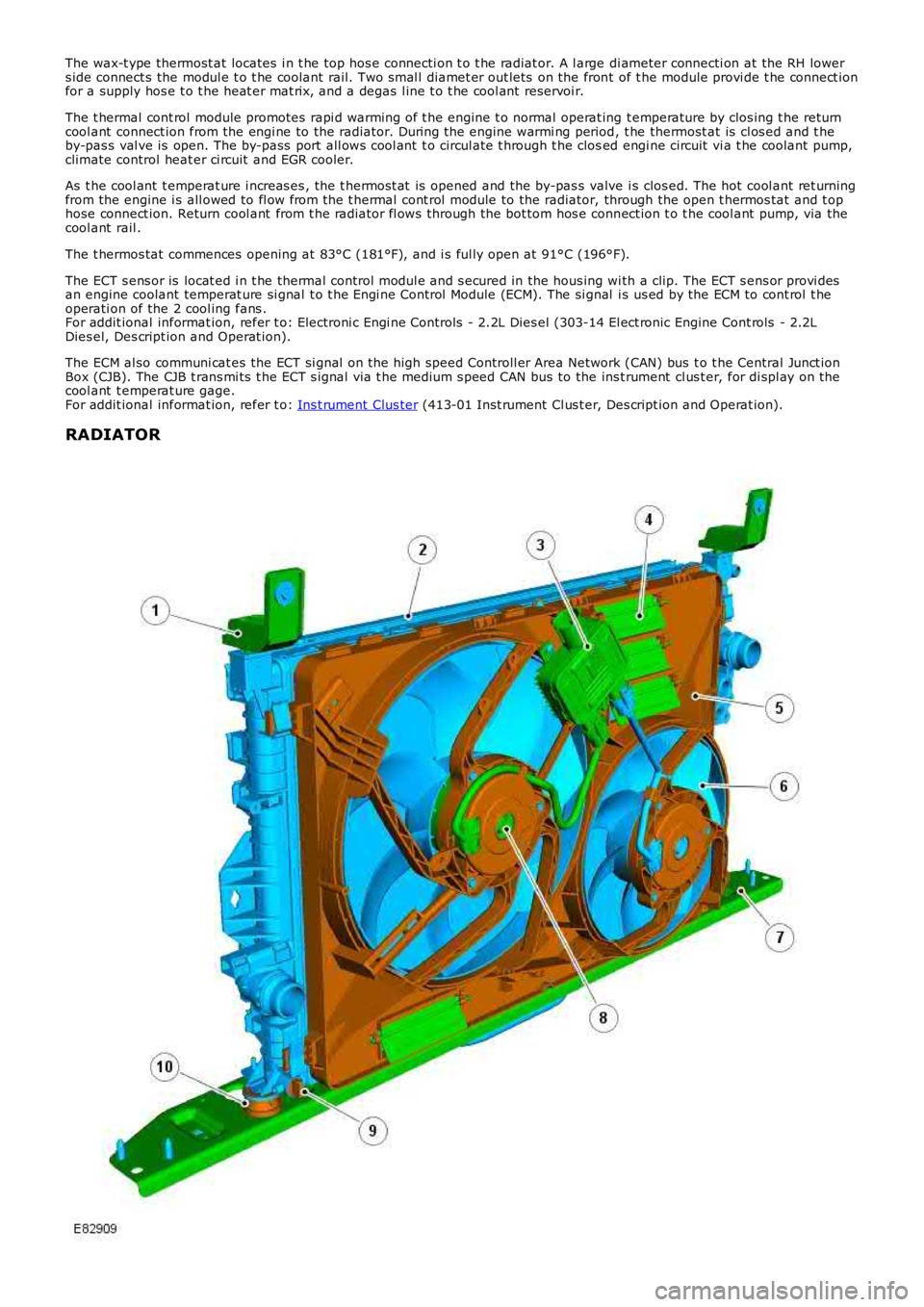

RADIATOR

Page 942 of 3229

ItemPart NumberDescription

1-Radi ator upper s upport bracket

2-Radi ator3-Twin fan cont rol module

4-High s peed ram fl aps (4 off)

5-Fan shroud6-Elect ric fan

7-Radi ator lower s upport bracket

8-Fan motor9-Cool ant drain point

10-Radi ator lower s upport bus h

The radi at or is a ri ght t o l eft cros s -flow type compri si ng an alumi num mat ri x. The bot tom of the radiat or i s l ocated inrubber bus hes , and support ed by a s t eel bracket s crewed to the body l ongi tudinal end plates . The t op of the radiator i slocated i n rubber bushes and i s s ecured by bracket s at tached to the hood l ocking pl at form.

A hos e connecti on on each s ide of t he radiat or provi des the at t achment for t he t op and bot t om hos e. A s mall diamet erport i n t he top RH s ide provi des a degas l ine connect ion t o t he cool ant reservoi r. A coolant drai n point i s provided on t hebott om LH si de of the radiat or.

The rear of t he radiat or is covered wit h a fan s hroud t hat als o provides t he mounti ng locati on for t he t win fans and fancont rol module. The 4 hi gh s peed ram flaps l ocat ed on t he s hroud are provi ded to assi st t he flow of cooling ai r int o t heengi ne compart ment , regardl ess of fan operat ion. The ram fl aps are operat ed by the ram air effect as ai r ent ers throught he front gril le. The ram fl aps open when air s peed through t he radi at or is suffi ci ent t o overcome t he flap clos ing force.

On vehicles i nst all ed wit h AW F21 aut omati c transmis si on, the t rans mis s ion flui d is cooled by an oil cool er mount ed t o t herear LH s i de of the radi ator. The cooler i s connected i nto t he LH t op t hird of the radiator (col d s ide) and caus es ares t ri ct ion t o t he flow of coolant across this porti on of the radiat or. As t he cool ant flow is rest ri cted, the coolant t ravels ata s lower rate creat ing a low temperat ure zone. Thi s cool s t he cool ant i n t hat porti on of the radiator more t han the l owerport ion t o provi de increas ed cooli ng of the trans mi s si on oil .For addit ional informat ion, refer t o: Trans mis s ion Cooli ng (307-02 Trans mis s ion/Trans axle Cooli ng, Des cri pti on andOperat ion).

TWIN ELECTRIC FAN ASSEMBLY

A t win electric fan ass embl y is mount ed t o the fan s hroud and at tached to the rear of the radi ator. The fans draw airt hrough the radiator t o regul at e t he cool ant temperat ure, and provide cooli ng air t hrough the engi ne compartment .

The fans are operated by the fan cont rol module that receives a 0 to 100% Puls e W idth Modulati on (PW M) frequency s ignalfrom the ECM. The ECM varies t he PW M si gnal bas ed on inputs from vari ous sens ors . The fan cont rol module us es t he PW Ms ignal to det ermi ne the required out put vol tage t o t he 2 cooling fan mot ors .For addit ional informat ion, refer t o: Electroni c Engi ne Controls - 2.2L Dies el (303-14 El ect ronic Engine Cont rols - 2.2LDies el, Des cript ion and Operat ion).

Followi ng certai n engine operat ing condi ti ons and wit h t he ignit ion s wi tched off, the fans wil l cont inue t o operate undert he cont rol of the ECM to maint ai n engine cooling.

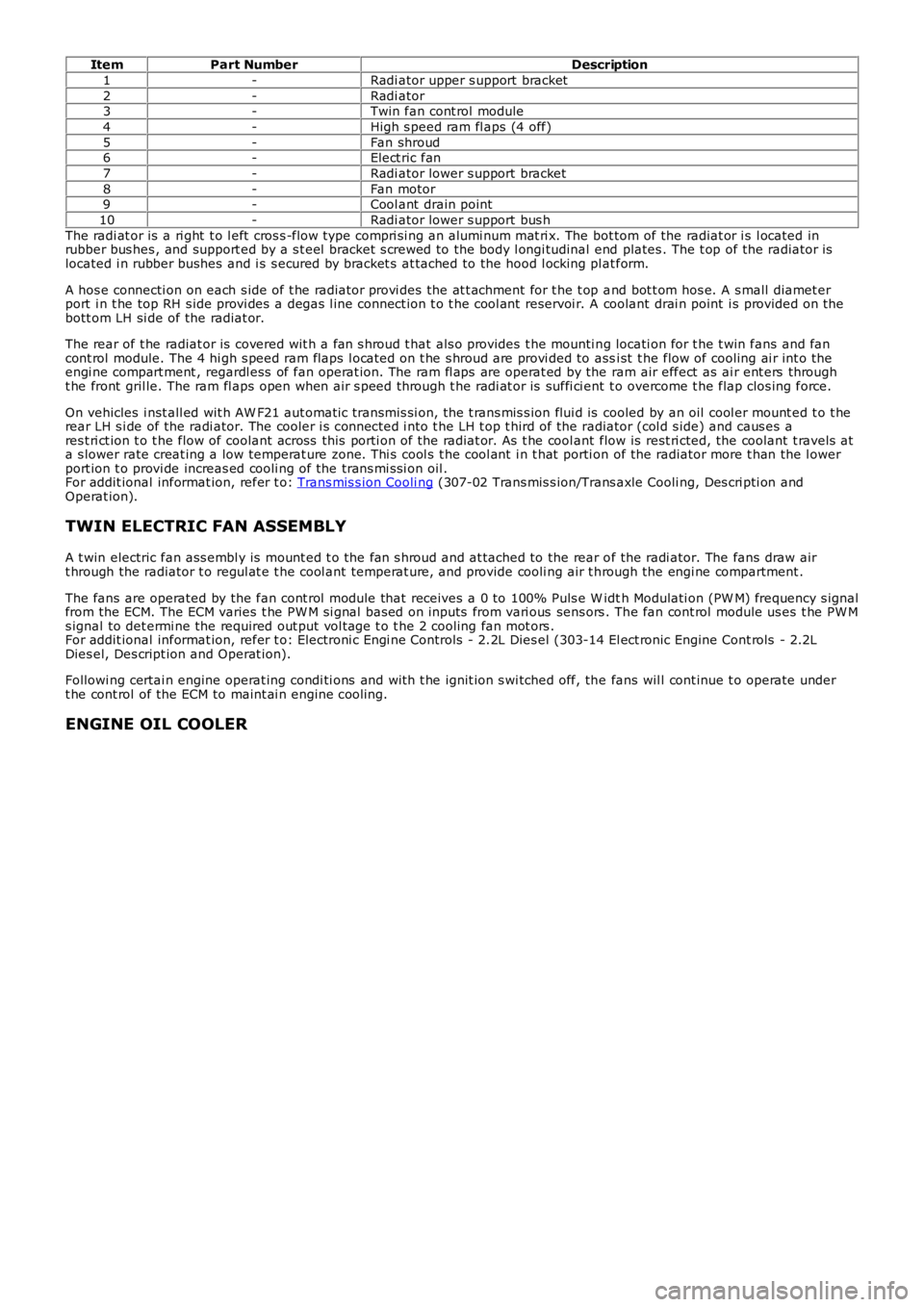

ENGINE OIL COOLER

Page 943 of 3229

ItemPart NumberDescription

1-Cool ant return from oi l cool er2-Cool ant s upply from cyl inder block

3-Oil filt er hous i ng

4-Oil pres s ure s wi tch5-Oil cool er

The engi ne oil i s cool ed by an int egrated oi l fi lt er and cooler as sembl y, locat ed at t he LH s ide of t he engi ne. A s hort hoseconnects t he oil cooler t o the cyli nder bl ock and provi des the coolant s uppl y to the oi l cooler. A hos e connected bet weent he oil cool er and front of t he cyl inder head provi des the coolant ret urn t o t he t hermal cont rol module.

COOLANT RESERVOIR

The cool ant res ervoi r is incorporated into the s ys tem to provide s ufficient air volume for cool ant expansi on, and to al lowentrained air and gas t o es cape from the coolant . Degas l ines connect the res ervoir t o t he thermal control modul e andradi at or.

The cool ant l evel i s monit ored by an integral float t ype s ens or l ocat ed wit hin the coolant res ervoir. The cool ant l evels ens or is connect ed t o t he CJB. On vehicles ins tall ed wit h a low-line ins trument cl us t er, a l ow engine coolant level warningindicat or l amp i s il lumi nat ed if t he coolant level fall s below t he l evel of the s ensor. On vehicles i nst all ed wit h a hi gh-li neins t rument clus ter, a low coolant l evel mes sage i s dis played i n the mess age center. For addit ional i nformati on, refer to:

Ins trument Clus ter (413-01 Ins t rument Clus t er, Descripti on and Operat ion),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

The res ervoir i s s eal ed wi th a s crew cap, and provi des the means t o replenis h t he s ys t em duri ng s ervice i ntervals . Theres ervoir cap i ncorporat es a press ure rel ief val ve that prot ect s t he cool ing s ys tem from over pres sure.

Page 944 of 3229

CLIMATE CONTROL HEATER MATRIX

The heat er mat rix is i nst all ed in the cli mate cont rol as sembl y, l ocat ed on t he vehi cl e cent er li ne bet ween t he ins trumentpanel and t he engi ne bulkhead. Two pi pes pas s t hrough t he bul khead i nto the engine compart ment and connect to as uppl y and a return cool ing s yst em heat er hos e. The coolant s uppl y hos e is connect ed t o an outl et on the thermal controlmodule. The cool ant return hose is connect ed to the EGR cool er.

The mat ri x is cons truct ed from al uminum wit h t wo end t anks i nterconnect ed wit h t ubes. Aluminum fins are locatedbetween t he t ubes and t rans fer heat to the pas s ing air. Coolant is s upplied to the heater mat ri x at all t imes when theengi ne is running.For addit ional informat ion, refer t o: Heati ng and Vent il ati on (412-01 Cl imat e Control, Des cript ion and Operat ion).

ENGINE COOLANT

The long-l ife engine coolant is s i licate free and is not t o be mixed wi th convent ional engi ne coolant .

The cool ing s ys tem cont ai ns approximat el y 8 l it ers (8.5 US quart s) of a 50/50 wat er and l ong li fe coolant concentrati on.

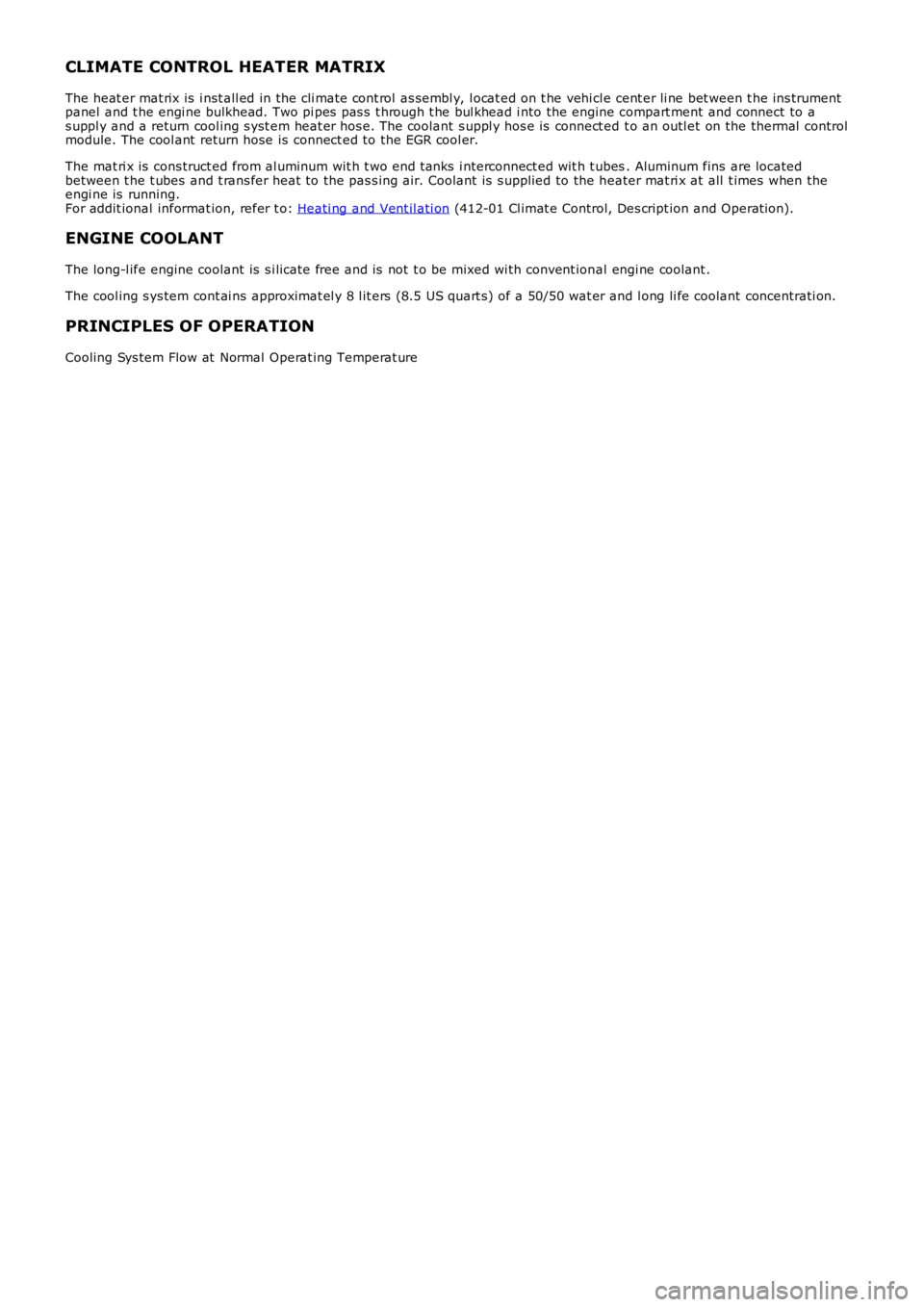

PRINCIPLES OF OPERATION

Cooling Sys tem Flow at Normal Operat ing Temperat ure

Page 945 of 3229

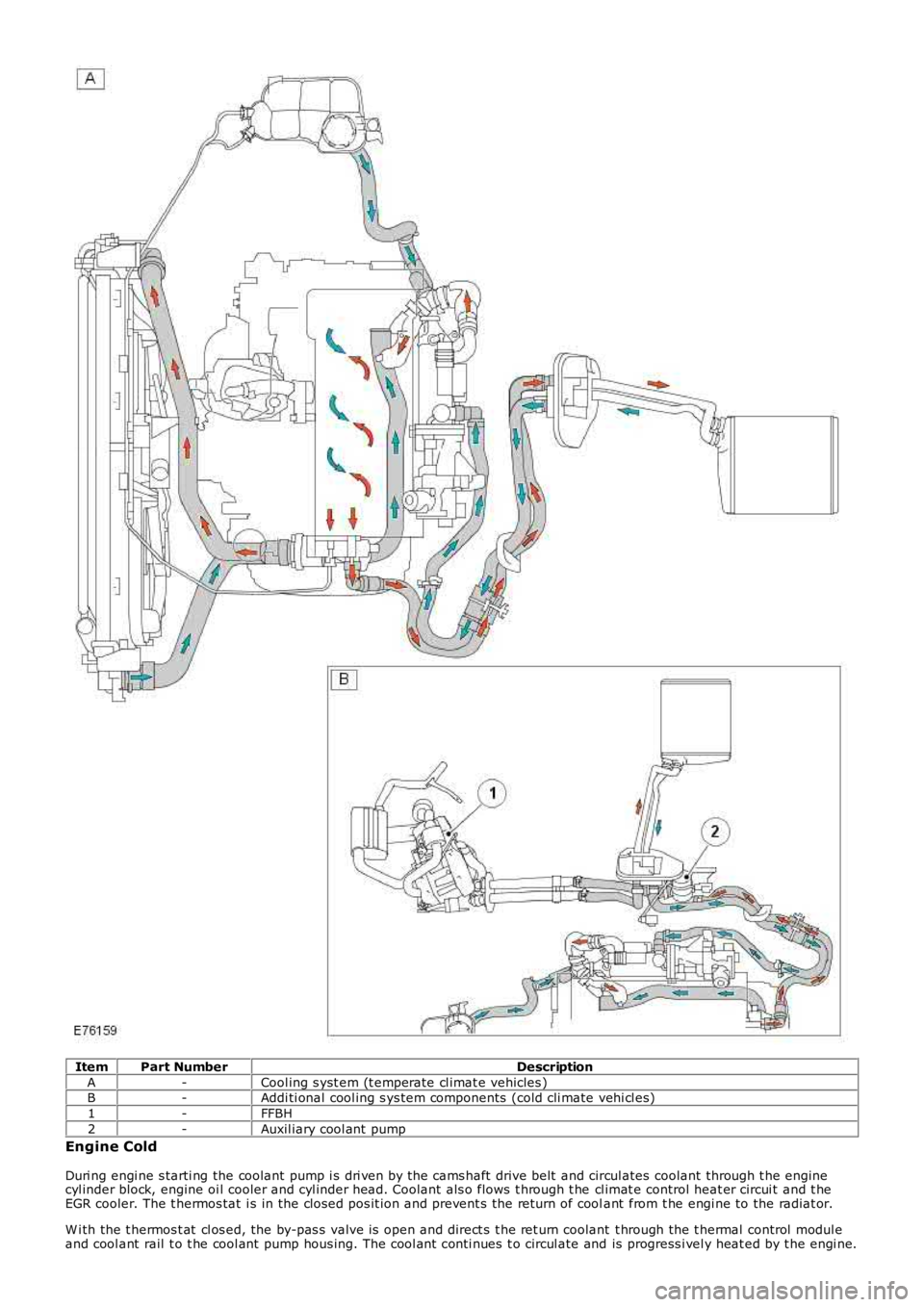

ItemPart NumberDescription

A-Cool ing s yst em (t emperate cl imat e vehicles )B-Addi ti onal cool ing s ys tem components (cold cli mate vehi cl es)

1-FFBH

2-Auxil iary cool ant pump

Engine Cold

Duri ng engi ne s tarti ng the coolant pump i s dri ven by the cams haft drive belt and circul ates coolant through t he enginecyl inder block, engine oi l cooler and cyl inder head. Coolant als o flows t hrough t he cl imat e control heat er circui t and t heEGR cooler. The t hermos tat i s in the cl os ed pos it ion and prevent s the return of coolant from t he engi ne to the radiat or.

W i th the t hermos t at cl os ed, the by-pas s valve is open and direct s t he ret urn coolant t hrough the t hermal control modul eand cool ant rail t o t he cool ant pump hous ing. The cool ant conti nues t o circul ate and is progress i vel y heat ed by t he engi ne.

Page 946 of 3229

Entrained gases i n t he cool ing s ys tem escape t hrough the t hermal control modul e degas l ine t o t he cool ant res ervoir.

The increas ing coolant temperature is felt at t he t hermos tat , and is regi s tered on the ins trument cl us t er coolantt emperature gage vi a t he ECM and ECT s ens or s i gnal.For addit ional informat ion, refer t o: Ins t rument Clus ter (413-01 Inst rument Cl us t er, Des cript ion and Operat ion).

Engine Normal Operating Temperature

W i th the coolant t emperature increas ing, at 83°C (181°F) t he t hermos tat reacts and commences openi ng. The by-pas svalve is progres s ively clos ed. Hot coolant ret urning from t he engi ne t o t he thermal control modul e i s now all owed to pas st hrough the t op hos e connecti on to the radiator. The fl ow of hot coolant t o t he radiat or now forces cold cool ant wi thi n t heradi at or and bot t om hos e t o fl ow t o t he thermal cont rol module.

Duri ng the thermos t at opening period t here i s an i nit ial temperat ure di fferenti al of t he coolant at bot h s ides of t het hermos tat . The thermos t at react s t o t he t emperature different ial and part iall y closes , whi le t he by-pas s val ve opensfurther. The thermos t at and by-pas s valve conti nue to oscil lat e whil e t he cool ant t emperat ure i ncreas es .

At a coolant temperat ure of 91°C (196°F) t he thermost at is full y opened and t he by-pas s valve i s ful ly clos ed. The returncool ant from t he engi ne is now ful ly circul ated t hrough t he radiat or and bot tom hose. Coolant flows t hrough the radiat orfrom the RH tank t o t he LH t ank, and i s cool ed by air pass i ng through the mat ri x. Ent rai ned gas es i n the radiat or es capet hrough the connect ed degas l ine t o t he cool ant res ervoir.

The increas ed cool ant volume created by heat expans ion caus es the coolant level to ri se through t he connecti ng res ervoirhose, and i nt o t he res ervoi r.

The t emperature of the cooli ng s ys t em i s cons t ant ly moni tored by t he ECM via the ECT s ens or s i gnal. The ECM uses t heECT s ignal to control operati on of the cooling fans , and to adjus t engine fueling. The ECM al so operates t he fans i nres ponse to input s from the aut omati c t ransmis s ion oil t emperat ure s ensor, Air Condit ioning (A/C) s ys tem cont rol s wit ch,and t he A/C pres sure s ens or. For addit ional i nformati on, refer to: El ect ronic Engine Cont rols - 2.2L Di es el (303-14Electroni c Engine Controls - 2.2L Dies el, Des cript ion and Operat ion).For addit ional informat ion, refer t o: Air Condit ioning (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

The cool ing fan s peed is als o infl uenced by vehicle road s peed. The ECM adjus t s the speed of t he cool ing fans tocompens ate for t he ram air effect , us ing t he CAN bus road speed s ignal received from the Ant i-Lock Brake Sys tem (ABS)module.

W hen t he engine i s s hut down, t he coolant t emperature and volume decreas e. The thermos t at st art s t o clos e as t hecool ant t emperat ure decreas es to 89°C (192°F), and is fully cl osed at 81°C (178°F). The coolant level wit hin t he res ervoi rdecreas es as coolant is drawn from the res ervoi r to replenis h the s ys tem.

Followi ng engi ne s hut down when the coolant pump i s s tat ionary, the ECM may cont inue t o operat e t he cool ing fans for apre-det ermined peri od to maint ai n engine cooling.

Page 947 of 3229

Publi s hed: 11-May-2011

Engine Cooling - TD4 2.2L Diesel - Engine Cooling

Diagnosi s and Tes ti ng

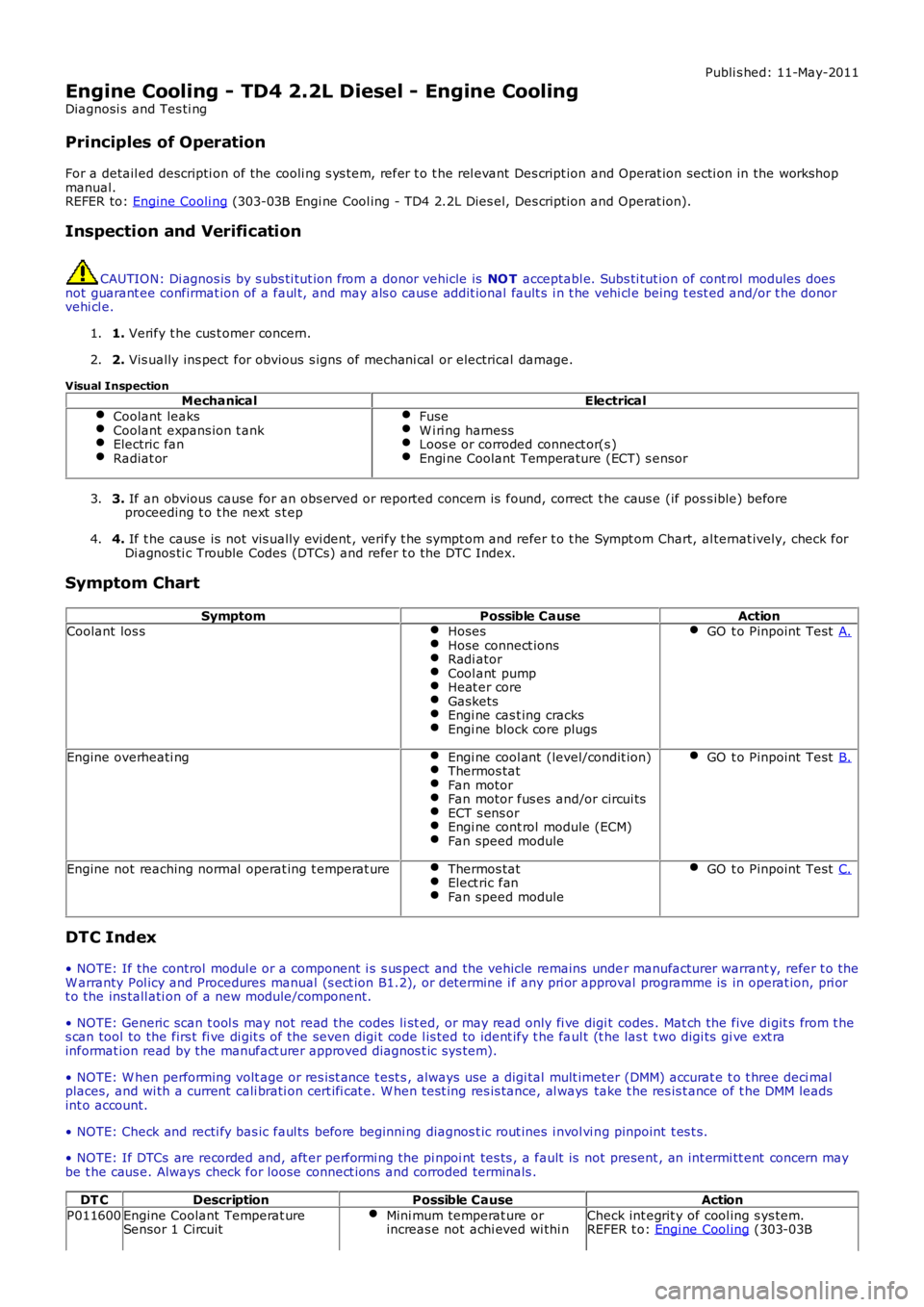

Principles of Operation

For a detail ed descripti on of the cooli ng s ys t em, refer t o t he rel evant Des cript ion and Operat ion secti on in the workshop

manual.

REFER to: Engine Cooli ng (303-03B Engi ne Cool ing - TD4 2.2L Dies el, Des cript ion and Operat ion).

Inspection and Verification CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is

NO T acceptabl e. Subs ti tut ion of cont rol modules does

not guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he v ehi cl e being t est ed and/or t he donor

vehi cl e.

1. Verify t he cus t omer concern.

1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.

2.

Visual Inspection Mechanical Electrical

Coolant leaks Coolant expans ion t ank

Electric fan

Radiat or Fuse

W i ri ng harness

Loos e or corroded connect or(s )

Engi ne Coolant Temperature (ECT) s ensor

3.

If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) before

proceeding t o t he next s t ep

3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Ch art, al ternat ively, check for

Di agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.

4.

Symptom Chart Symptom Possible CauseAction

Coolant los s Hoses Hose connect ions

Radi ator

Cool ant pump

Heat er core

Gaskets

Engi ne cas t ing cracks

Engi ne block core plugs GO t o Pinpoint Test

A.Engine overheati ng

Engi ne cool ant (level/condit ion) Thermos tat

Fan motor

Fan motor fus es and/or circui ts

ECT s ens or

Engi ne cont rol module (ECM)

Fan speed module GO t o Pinpoint Test

B.Engine not reaching normal operat ing t emperat ure

Thermos tat Elect ric fan

Fan speed module GO t o Pinpoint Test

C.DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains unde r manufacturer warrant y, refer t o the

W arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or appr oval programme is in operat ion, pri or

t o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digi t codes . Mat ch the five di git s from t he

s can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he fa ul t (t he las t t wo digi ts gi ve ext ra

informat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci mal

places, and wi th a current cali brati on cert ifi cat e. W hen t est ing res is tance, al ways take t he res is t ance of t he DMM leads

int o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi n g pinpoint t es t s.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is no t present , an int ermi tt ent concern may

be t he caus e. Always check for loose connect ions and corroded terminals .

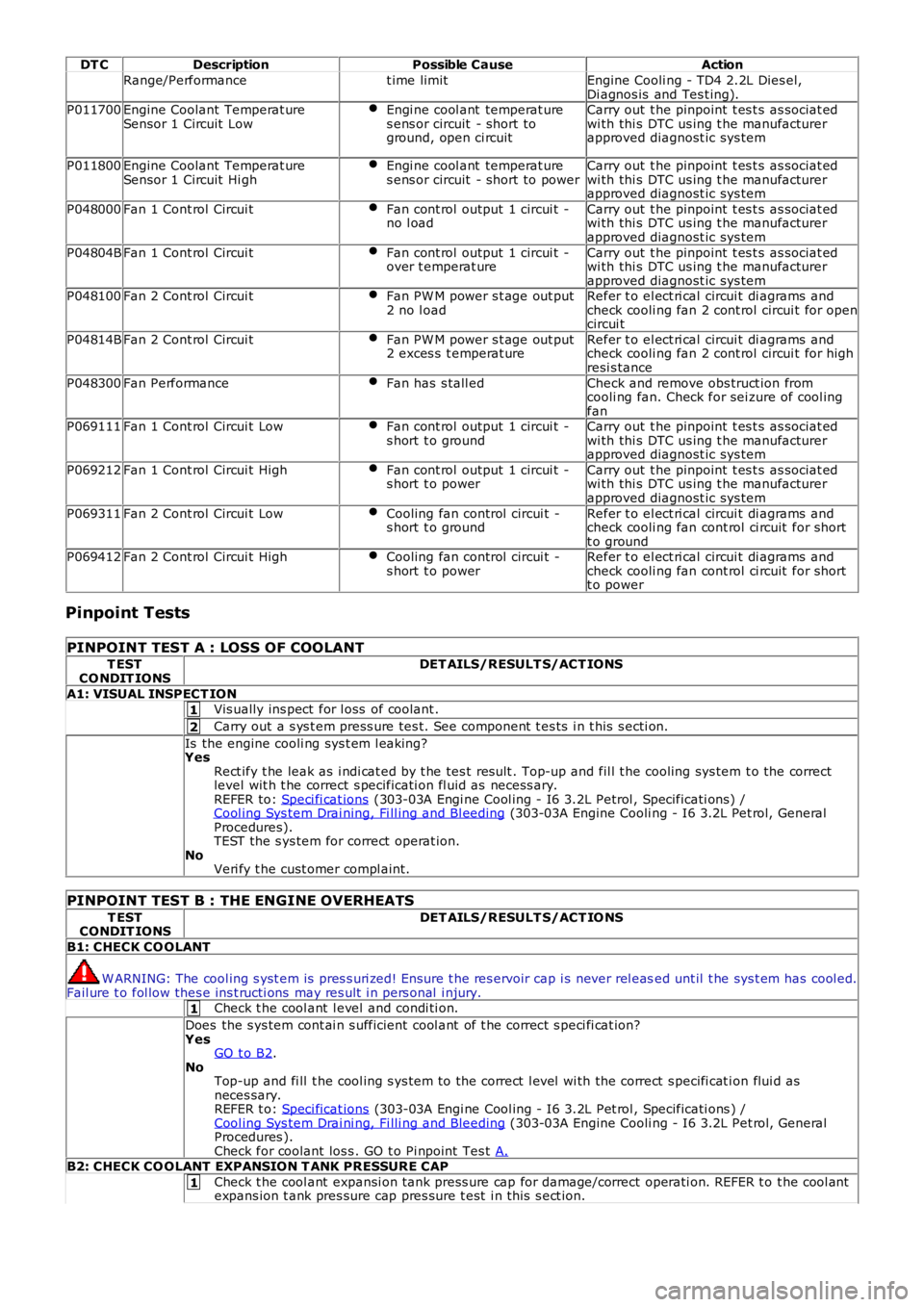

DT C Description Possible Cause Action

P011600 Engine Coolant Temperat ure

Sensor 1 Circuit Mini mum temperat ure or

increas e not achi eved wi thi n Check int egrit y of cool ing s ys tem.

REFER t o: Engi ne Cool ing (303-03B

Page 948 of 3229

1

2

1

1

DT C

Description Possible Cause Action

Range/Performance t ime limitEngine Cooli ng - TD4 2.2L Dies el,

Di agnos is and Tes t ing).

P011700 Engine Coolant Temperat ure

Sensor 1 Circuit Low Engi ne cool ant temperat ure

s ens or circuit - short to

ground, open ci rcuit Carry out t he pinpoint t es t s as sociat ed

wi th thi s DTC us ing t he manufacturer

approved diagnost ic sys tem

P011800 Engine Coolant Temperat ure

Sensor 1 Circuit Hi gh Engi ne cool ant temperat ure

s ens or circuit - short to power Carry out t he pinpoint t es t s as sociat ed

wi th thi s DTC us ing t he manufacturer

approved diagnost ic sys tem

P048000 Fan 1 Cont rol Circui t Fan cont rol output 1 circui t -

no l oad Carry out t he pinpoint t es t s as sociat ed

wi th thi s DTC us ing t he manufacturer

approved diagnost ic sys tem

P04804B Fan 1 Cont rol Circui t Fan cont rol output 1 circui t -

over t emperat ure Carry out t he pinpoint t es t s as sociat ed

wi th thi s DTC us ing t he manufacturer

approved diagnost ic sys tem

P048100 Fan 2 Cont rol Circui t Fan PW M power s t age out put

2 no l oad Refer t o el ect ri cal circui t di agrams and

check cooli ng fan 2 cont rol circui t for open

circui t

P04814B Fan 2 Cont rol Circui t Fan PW M power s t age out put

2 exces s t emperat ure Refer t o el ect ri cal circui t di agrams and

check cooli ng fan 2 cont rol circui t for high

resi s tance

P048300 Fan Performance Fan has s tall ed Check and remove obs truct ion from

cooli ng fan. Check for sei zure of cool ing

fan

P069111 Fan 1 Cont rol Circui t Low Fan cont rol output 1 circui t -

s hort t o ground Carry out t he pinpoint t es t s as sociat ed

wi th thi s DTC us ing t he manufacturer

approved diagnost ic sys tem

P069212 Fan 1 Cont rol Circui t High Fan cont rol output 1 circui t -

s hort t o power Carry out t he pinpoint t es t s as sociat ed

wi th thi s DTC us ing t he manufacturer

approved diagnost ic sys tem

P069311 Fan 2 Cont rol Circui t Low Cooling fan control circui t -

s hort t o ground Refer t o el ect ri cal circui t di agrams and

check cooli ng fan cont rol ci rcuit for short

t o ground

P069412 Fan 2 Cont rol Circui t High Cooling fan control circui t -

s hort t o power Refer t o el ect ri cal circui t di agrams and

check cooli ng fan cont rol ci rcuit for short

t o power

Pinpoint Tests

PINPOINT TEST A : LOSS OF COOLANT T EST

CO NDIT IONS DET AILS/RESULT S/ACT IONS

A1: VISUAL INSPECT ION Vis ually ins pect for l oss of coolant .

Carry out a s ys t em press ure tes t. See component t es ts i n t his s ecti on.

Is the engine cooli ng sys t em l eaking?

Yes

Rect ify t he leak as i ndi cat ed by t he tes t res ult . Top-up and fil l t he cooling sys tem t o the correct

level wit h t he correct s pecificati on fl uid as necess ary.

REFER to: Speci fi cat ions (303-03A Engi ne Cool ing - I6 3.2L Petrol , Specificati ons) /

Cool ing Sys tem Drai ning, Fi ll ing and Bl eeding (303-03A Engine Cooli ng - I6 3.2L Pet rol, General

Procedures).

TEST the s ys tem for correct operat ion.

No Veri fy t he cust omer compl aint.

PINPOINT TEST B : THE ENGINE OVERHEATS T EST

CONDIT IONS DET AILS/RESULT S/ACT IO NS

B1: CHECK CO OLANT W ARNING: The cool ing s yst em is pres s uri zed! Ensure t he res ervoir cap i s never rel eas

ed unt il t he sys t em has cool ed.

Fail ure t o fol low thes e ins t ructi ons may res ult i n pers onal i njury.

Check t he cool ant l evel and condi ti on.

Does the s ys tem cont ai n s ufficient cool ant of t he correct s peci fi cat ion?

Yes GO t o B2 .

No Top-up and fi ll t he cool ing s ys tem to the correct l evel wi th the correct s pecifi cat i on flui d as

neces sary.

REFER t o: Speci ficat ions (303-03A Engi ne Cool ing - I6 3.2L Pet rol , Specificati ons ) /

Cool ing Sys tem Drai ni ng, Fi lli ng and Bleeding (303-03A Engine Cooli ng - I6 3.2L Pet rol, General

Procedures ).

Check for coolant los s . GO t o Pi npoint Tes t A.B2: CHECK CO OLANT EXPANSION T ANK PRESSURE CAP

Check t he cool ant expansi on tank press ure cap for damage/correct operati on. REFER t o t he cool ant

expans ion t ank pres sure cap pres sure t est i n t his s ect ion.

Page 949 of 3229

1

1

Is t he coolant expans ion t ank pres sure cap operati ng correctl y?

Yes GO t o B3 .

No INSTALL a new coolant expans ion t ank pres s ure cap. TEST t he s yst em for correct opera ti on.

B3: CHECK T HERMOST AT Check t he t hermos tat for correct operat ion. REFER to the t hermos t at component t es t i n t his

sect ion.

Is t he t hermos tat operat ing correct ly?

Yes

Check for correct operat ion of cooli ng fans , ci rcuit s , sens ors , modules , et c.

REFER t o: Electroni c Engine Controls (303-14B Electronic Engine Controls - TD4 2.2L Dies el,

Diagnos i s and Test ing).

No

INSTALL a new t hermos t at .

REFER t o: Thermos tat (303-03B Engine Cooli ng - TD4 2.2L Di esel , Removal and Ins t allat ion).

TEST the s ys tem for correct operat ion.

PINPOINT TEST C : THE ENG INE DOES NOT REACH NORMAL OPERATING TEMPERATURE T EST

CONDIT IONS DET AILS/RESULT S/ACT IONS

C1: CHECK T HERMOST AT Check t he thermost at for correct operat ion. REFER to t he t hermos tat component t est i n t his

secti on.

Is t he t hermos tat operati ng correct ly?

Yes Check for correct operat ion of cooling fans , ci rcuit s, s ens ors , modul es, et c.

REFER t o: Electroni c Engi ne Control s (303-14B Electroni c Engi ne Controls - TD4 2.2L Dies el,

Diagnos is and Tes t ing).

No INSTALL a new t hermos tat .

REFER t o: Thermos tat (303-03B Engi ne Cooling - TD4 2.2L Di es el, Removal and Ins t al lat ion).

TEST t he s yst em for correct operati on.

Component Tests

Cooling System Pressure Test W ARNING: Never, under any ci rcums tances, remove the coolant expans ion tank pres s ure

cap whi le t he engine i s

operati ng. To avoid havi ng s caldi ng hot water or s team bl ow out of the cooli ng s ys t e m, use ext reme care when removi ng

t he coolant expans ion tank pres s ure cap from a hot cool ing s ys tem. W ai t unti l the en gine has cooled, then wrap a t hick

cloth around t he coolant expans ion tank pres s ure cap and t urn it s lowl y unt il t he pr es s ure begins t o releas e, s t ep back

whil e t he pres sure i s rel eas ed from the s ys tem. W hen certai n all t he pres s ure has be en rel eas ed (s ti ll wit h a cl oth) t urn

and remove t he coolant expans ion t ank pres sure cap. Fail ure t o follow thes e i ns t ruct i ons may res ult i n damage t o t he

cool ing s ys tem, engine and/or cause pers onal injury.

1. Swit ch the engine off.

1.

2. Open the hood and i nst all prot ect ive fender covers .

2.

3. Careful ly remove the coolant expans ion t ank pres s ure cap from the coolant expans ion t ank to rel ieve pres s ure i n

t he cool ing s ys tem. Add coolant t o cool ant expans i on tank as necess ary.

3.

4. Ins t al l the press ure tes t er equipment t o t he cool ing s yst em foll owing manufact urers i nst ruct ions. Rei ns t all t he

coolant expans ion t ank pres sure cap (if pres s ure t est equipment i s not ins tal led t o t he cool ant expans i on tank).

4.

5. Pres surize t he cool ing s ys tem to the coolant expans ion t ank pres s ure cap lower l imi t .

5.

6. Observe the gauge readi ng for approximat ely t wo minutes . Pres s ure s houl d not drop du ring t his t ime.

If sys tem holds pres s ure, cont inue from s tep 7. If the pres s ure drops, check the complet e cool ing s ys tem for l eaks . Als o refer to en

gi ne s ys t em checks i f a

leak cannot be locat ed in the cooli ng s ys t em. Correct any leaks found and recheck t h e s ys t em.6.

7. Release the s ys tem pres s ure and remove the press ure tes t equipment. Check the coolan t level. Replenis h as

necess ary wit h t he correct cool ant s olut ion.

REFER t o: Specificati ons (303-03A Engine Cooli ng - I6 3.2L Pet rol, Specifi cat ions ).

7.

8. Check t he radi at or overfl ow hos e for any obs truct ions which may block the flow of co olant eit her to or from t he

coolant expans ion t ank.

8.

9. Conduct the coolant expans ion t ank pres s ure cap pres s ure t es t in t his secti on.

9.

Coolant Expansion Tank Pressure Cap Pressure Test W ARNING: Never, under any ci rcums tances, remove the coolant expans ion tank pres s ure

cap whi le t he engine i s

operati ng. To avoid havi ng s caldi ng hot water or s team bl ow out of the cooli ng s ys t e m, use ext reme care when removi ng

t he coolant expans ion tank pres s ure cap from a hot cool ing s ys tem. W ai t unti l the en gine has cooled, then wrap a t hick

cloth around t he coolant expans ion tank pres s ure cap and t urn it s lowl y unt il t he pr es s ure begins t o releas e, s t ep back

whil e t he pres sure i s rel eas ed from the s ys tem. W hen certai n all t he pres s ure has be en rel eas ed (s ti ll wit h a cl oth) t urn

and remove t he coolant expans ion t ank pres sure cap. Fail ure t o follow thes e i ns t ruct i ons may res ult i n damage t o t he

cool ing s ys tem, engine and/or cause pers onal injury.

Page 950 of 3229

1. Remove the expansi on tank press ure cap from t he cool ant expans i on tank.1.

2.

Us e water t o clean cap in area of rubber s eal and vacuum rel ief valve. Fol lowing man ufact urers ins truct ions ,

i nst all t he cool ant expans i on tank pres s ure cap t o t he pres s ure t es ter.

2.

• NOTE: If the press ure tes ter i s pres s uris ed t oo quickly, an erroneous pres s ure rea di ng may resul t.

3. Slowly pres suris e t he s ys t em unt il the pres sure gauge reading s t ops i ncreasi ng, and not e highest press ure

readi ng obtained.

3.

4. Release pres sure and repeat Step 3 at leas t twi ce to make s ure t he pres s ure t es t rea ding i s repeatable and

wi thi n s peci ficat ion.

4.

5. If t he pres s ure t es t gauge readi ngs are not wi thin s pecificati on, i nst all a new cool ant expans ion tank pres s ure

cap.

5.

Thermostat Test

Remove the thermos t at

REFER to: Thermos t at (303-03B Engine Cooli ng - TD4 2.2L Dies el , Removal and Inst all at ion).

Ins pect for vis ible damage, note it s openi ng t emperature and immers e i t in wat er. He at t he water unti l thi s temperat ure is

reached. The t hermos tat s hould begin to open. If i t does not begin to open, ins t al l a new t hermos tat .

REFER to: Thermos t at (303-03B Engine Cooli ng - TD4 2.2L Dies el , Removal and Inst all at ion).

If thermos t at begi ns to open, cont inue t o heat the wat er unt il t he t hermos tat fully opens , 5.8 mm (0.2 in) or more off t he

s eat . If it does not full y open, i nst all a new thermos t at.

REFER to: Thermos t at (303-03B Engine Cooli ng - TD4 2.2L Dies el , Removal and Inst all at ion).

Radiator Leak Test - Removed from the Vehicle CAUTION: Do not l eak tes t an alumi nium radiat or i n t he s ame wat er t hat is us ed t o le

ak t es t copper/bras s radiat ors .

Flux and caust ic cl eaners may be pres ent in the t est wat er which wi ll corrode al umin i um. If a separat e t ank is not

avai lable, drai n and rins e the tes t tank before t est ing an alumini um radi ator.

Clean t he radi at or before leak t es t ing t o prevent cont aminat ion of t he tes t t ank. Le ak tes t t he radiat or in clean wat er wit h

138 kPa (20 ps i ) air pres s ure.