LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: CD changer, sat nav, wheel torque, headlamp, service indicator, weight, washer fluid

Page 1941 of 4500

OK: When cruise control main switch operation is performed the standard values will be above.

NG: REPLACE ECM (SEE REPLACEMENT

)

OK: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS

TABLE

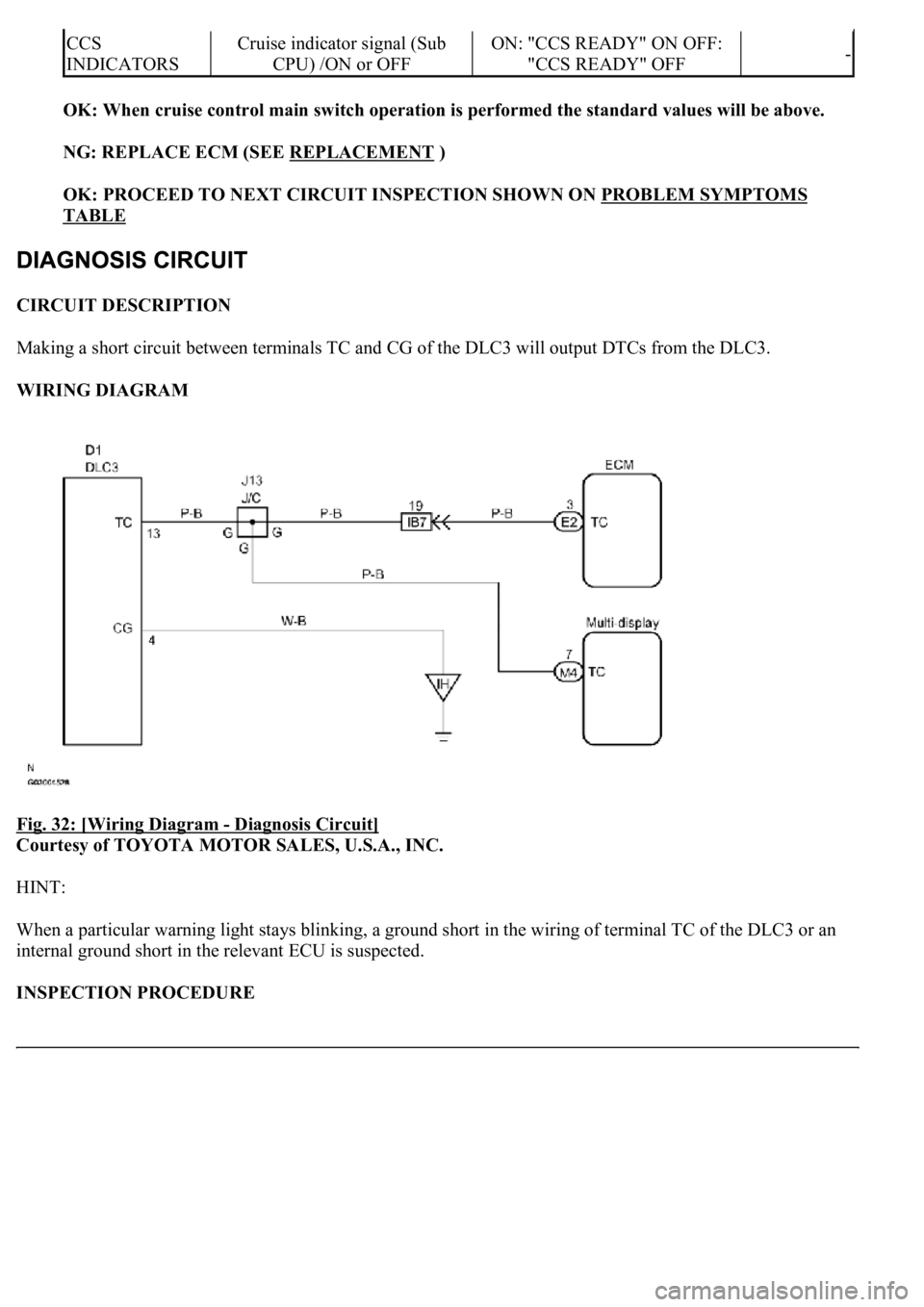

CIRCUIT DESCRIPTION

Making a short circuit between terminals TC and CG of the DLC3 will output DTCs from the DLC3.

WIRING DIAGRAM

Fig. 32: [Wiring Diagram

- Diagnosis Circuit]

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

When a particular warning light stays blinking, a ground short in the wiring of terminal TC of the DLC3 or an

internal ground short in the relevant ECU is suspected.

INSPECTION PROCEDURE

CCS

INDICATORSCruise indicator signal (Sub

CPU) /ON or OFFON: "CCS READY" ON OFF:

"CCS READY" OFF-

Page 1942 of 4500

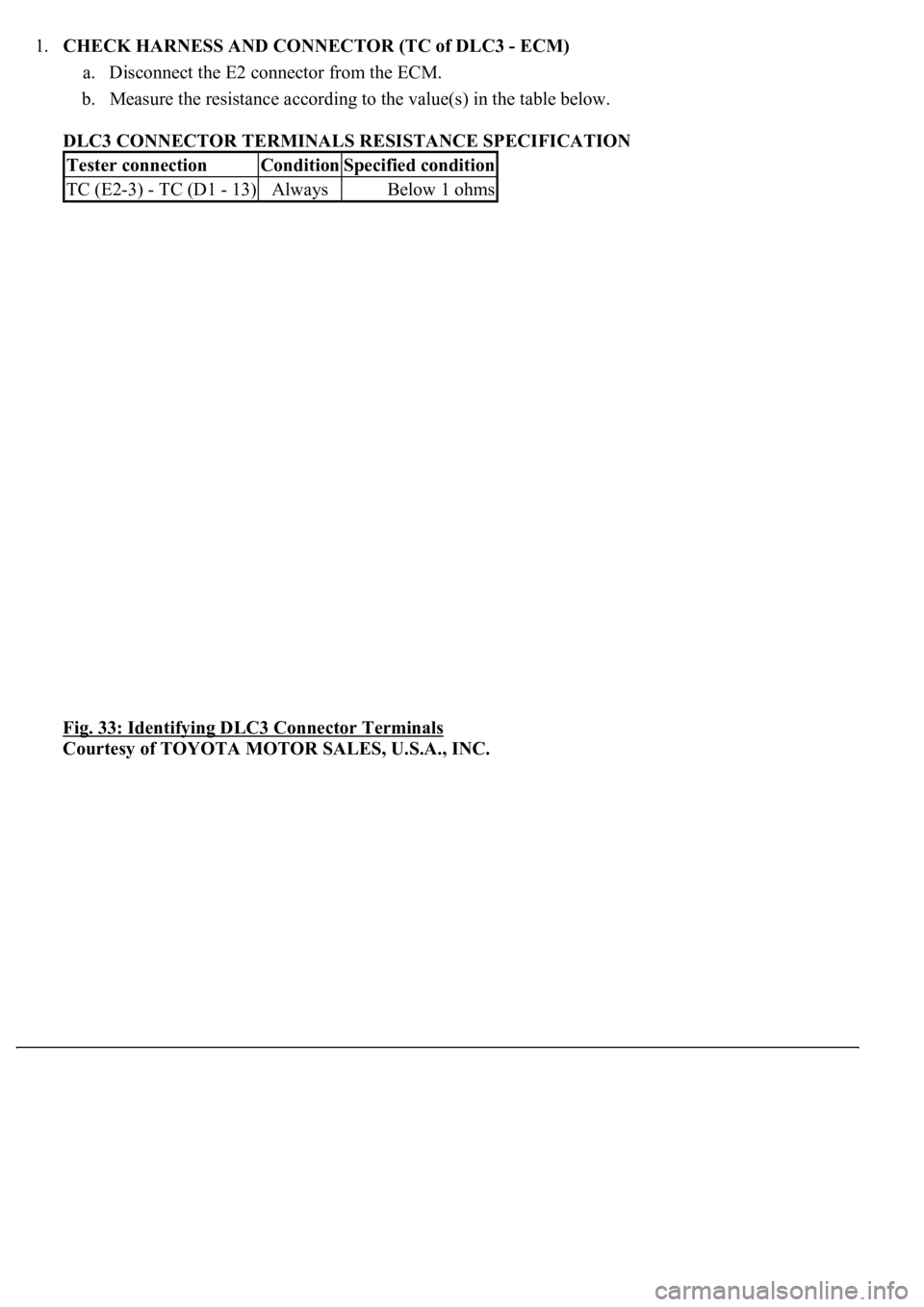

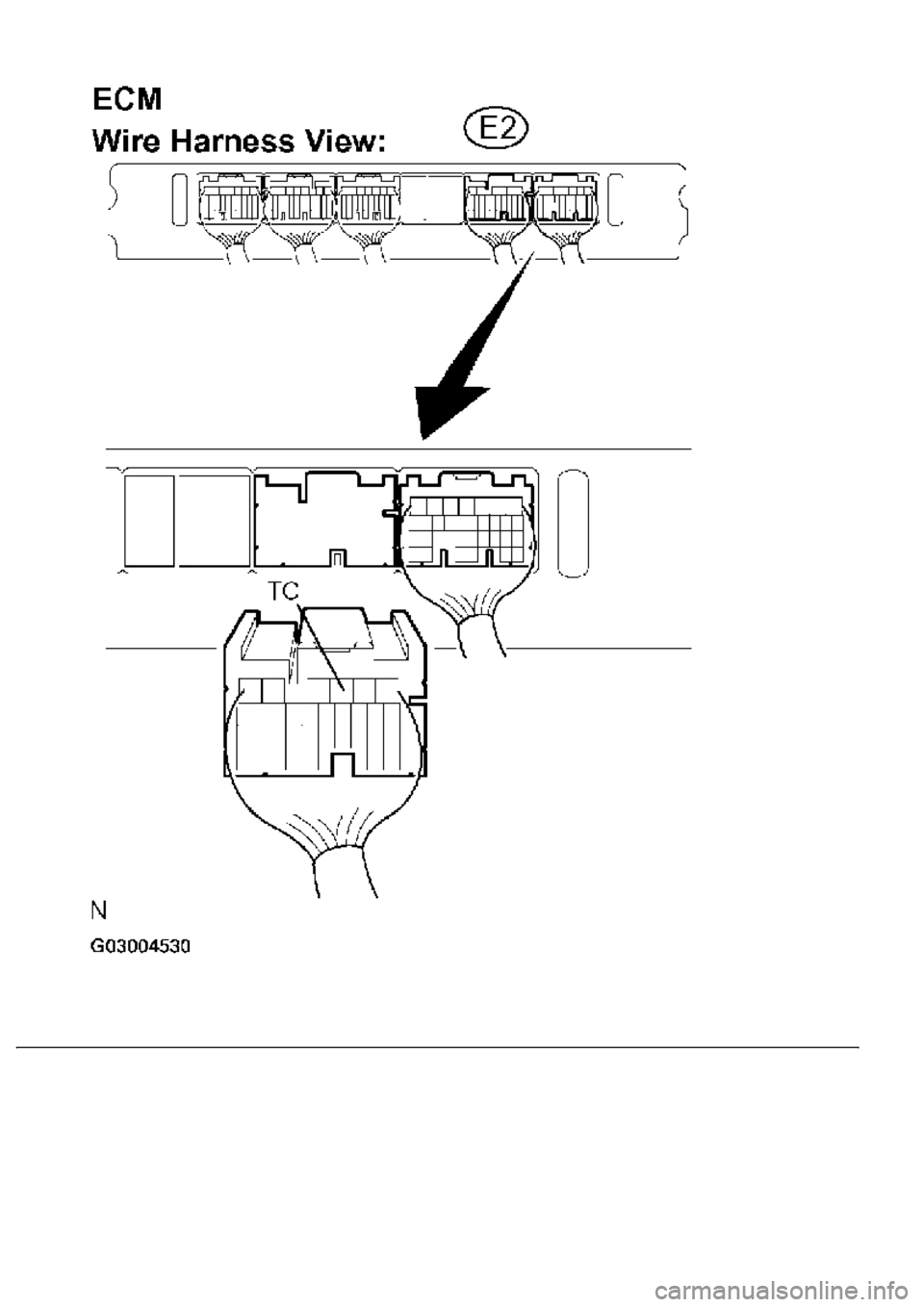

1.CHECK HARNESS AND CONNECTOR (TC of DLC3 - ECM)

a. Disconnect the E2 connector from the ECM.

b. Measure the resistance according to the value(s) in the table below.

DLC3 CONNECTOR TERMINALS RESISTANCE SPECIFICATION

Fig. 33: Identifying DLC3 Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Tester connectionConditionSpecified condition

TC (E2-3) - TC (D1 - 13)AlwaysBelow 1 ohms

Page 1943 of 4500

Page 1944 of 4500

Fig. 34: Disconnecting E2 Connector From ECM

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR (DLC3 - ECM)

OK: Go to next step

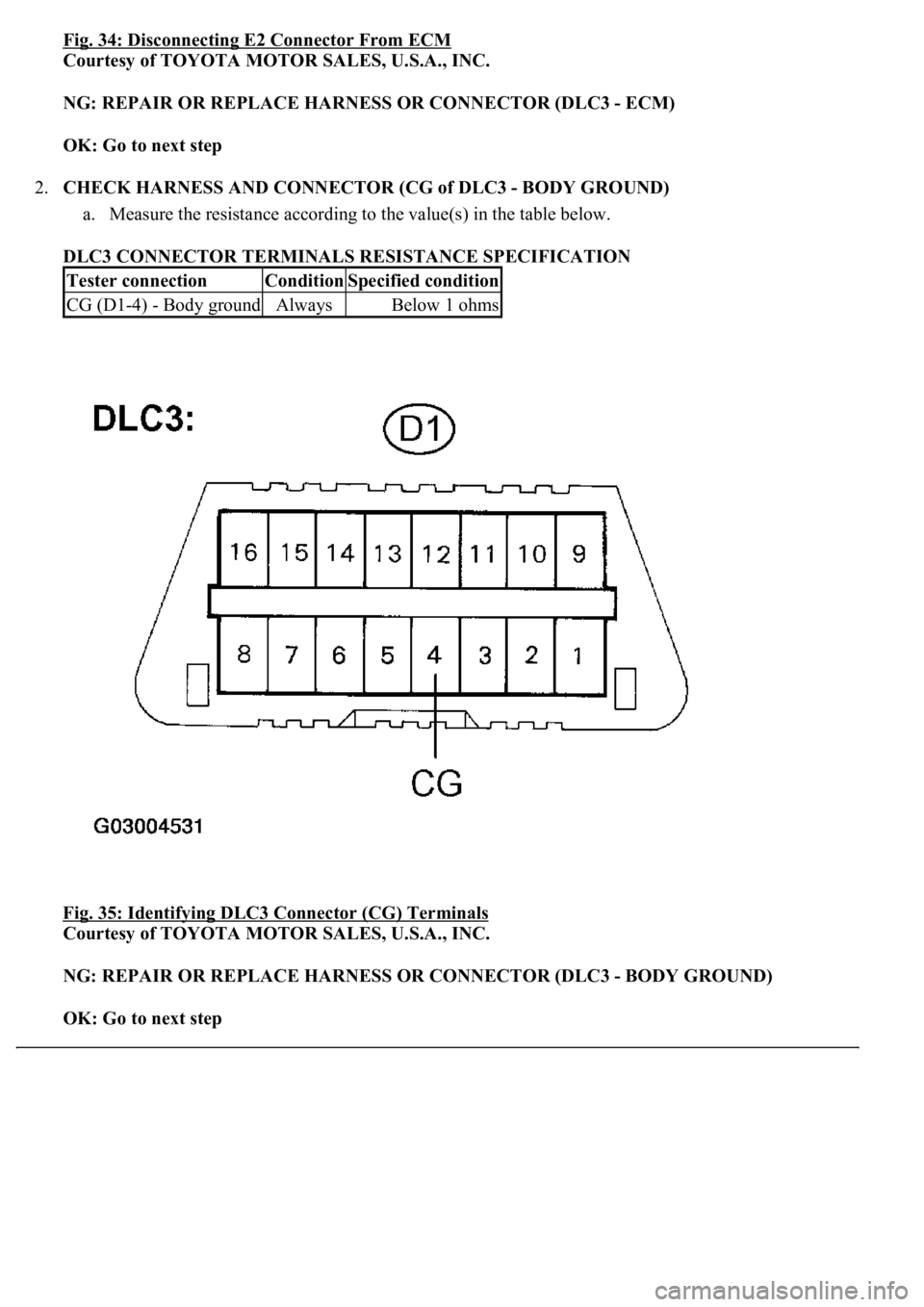

2.CHECK HARNESS AND CONNECTOR (CG of DLC3 - BODY GROUND)

a. Measure the resistance according to the value(s) in the table below.

DLC3 CONNECTOR TERMINALS RESISTANCE SPECIFICATION

Fig. 35: Identifying DLC3 Connector (CG) Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR (DLC3 - BODY GROUND)

OK: Go to next step

Tester connectionConditionSpecified condition

CG (D1-4) - Body groundAlwaysBelow 1 ohms

Page 1945 of 4500

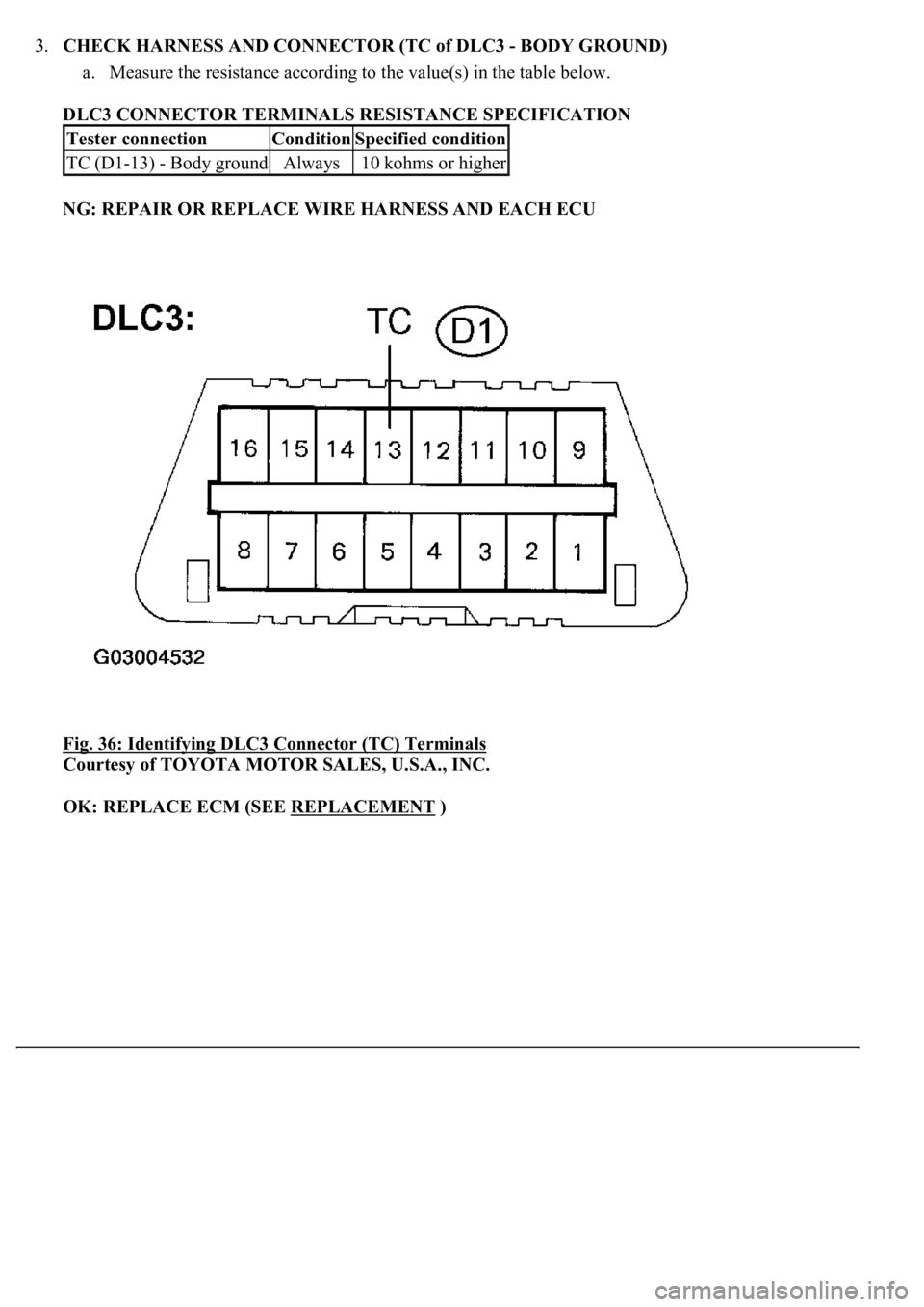

3.CHECK HARNESS AND CONNECTOR (TC of DLC3 - BODY GROUND)

a. Measure the resistance according to the value(s) in the table below.

DLC3 CONNECTOR TERMINALS RESISTANCE SPECIFICATION

NG: REPAIR OR REPLACE WIRE HARNESS AND EACH ECU

Fig. 36: Identifying DLC3 Connector (TC) Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK: REPLACE ECM (SEE REPLACEMENT

)

Tester connectionConditionSpecified condition

TC (D1-13) - Body groundAlways10 kohms or higher

Page 1946 of 4500

PRECAUTION

REPLACEMENT

1.SEPARATE BATTERY NEGATIVE TERMINAL

2.REMOVE INSTRUMENT PANEL UNDER COVER SUB-ASSY NO. 2 (See step 21 in

REPLACEMENT

)

3.REMOVE INSTRUMENT PANEL GARNISH SUB-ASSY (See step 22 in REPLACEMENT

)

4.REMOVE GLOVE COMPARTMENT PLATE (See step 23 in REPLACEMENT

)

5.REMOVE CHOKE KNOB HOLE COVER (See REPLACEMENT

)

6.REMOVE INSTRUMENT PANEL FINISH PANEL (See step 26 in REPLACEMENT

)

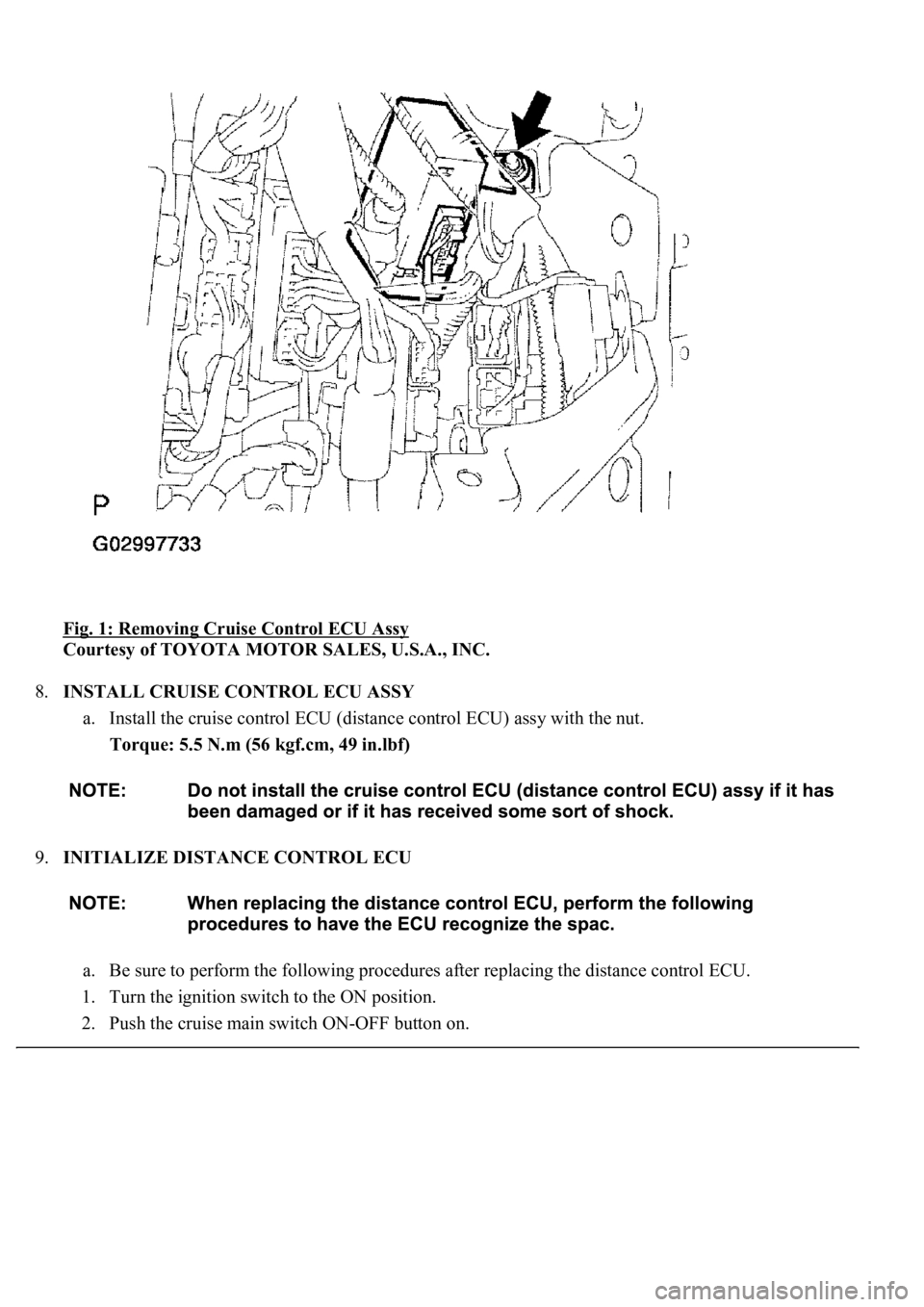

7.REMOVE CRUISE CONTROL ECU ASSY

a. Disconnect the connector.

b. Remove the nut and cruise control ECU (distance control ECU) assy.

Page 1947 of 4500

Fig. 1: Removing Cruise Control ECU Assy

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

8.INSTALL CRUISE CONTROL ECU ASSY

a. Install the cruise control ECU (distance control ECU) assy with the nut.

Torque: 5.5 N.m (56 kgf.cm, 49 in.lbf)

9.INITIALIZE DISTANCE CONTROL ECU

a. Be sure to perform the following procedures after replacing the distance control ECU.

1. Turn the ignition switch to the ON position.

2. Push the cruise main switch ON-OFF button on.

Page 1948 of 4500

3. With the brake pedal depressed, push the cruise control main switch to RES/ACC 3 times within 3

seconds. Check that the VSC buzzer sounds at this time.

REPLACEMENT

1.SEPARATE BATTERY NEGATIVE TERMINAL

2.REMOVE ENGINE UNDER COVER NO. 1 (See REPLACEMENT

)

3.REMOVE FRONT WHEEL OPENING EXTENSION PAD LH (See REPLACEMENT

)

4.REMOVE FRONT FENDER LINER LH (See REPLACEMENT

)

5.REMOVE FRONT WHEEL OPENING EXTENSION PAD RH (See REPLACEMENT

)

6.REMOVE FRONT FENDER LINER RH (See REPLACEMENT

)

7.REMOVE FRONT BUMPER COVER (See step 5 in REPLACEMENT

)

8.REMOVE FRONT BUMPER REINFORCEMENT SUB-ASSY (See step 9 in REPLACEMENT

)

9.REMOVE LASER SENSOR

a. Disconnect the connector and remove the laser sensor.

Page 1949 of 4500

Fig. 2: Removing Laser Sensor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

10.INSTALL LASER SENSOR

11.INSTALL FRONT BUMPER REINFORCEMENT SUB-ASSY (See step 25 in REPLACEMENT

)

12.ADJUST FOG LIGHT AIM (See ADJUSTMENT

)

13.CHECK FOG LIGHT AIM

14.ADJUST LASER SENSOR (See ADJUSTMENT

)

ADJUSTMENT

Page 1950 of 4500

HINT:

There is a limitation on laser optical axis adjustment.

Since the laser sensor is installed in the bumper reinforcement, it is important that the laser sensor,

bumper reinforcement, and other related parts are installed properly.

When the sensor is removed from the vehicle for trouble diagnosis or repair, it is necessary to adjust the

laser optical axis after the operation.

1.ADJUST LASER SENSOR

a. Preparation for adjusting the laser optical axis

1. Adjust the tire pressure properly (see INSPECTION

).

2. Luggage in the vehicle, such as in the trunk, should be unloaded.

3. Clean the light-luminous and light-receiving portions of the laser sensor.

HINT:

Prepare a 10 m (32.81 ft) string, with a sharp-pointed weight (plumb bob), and a 5 m (16.41 ft) tape

measure.

Trending: fuel pump, battery capacity, change time, Manifold gasket, B2799, immobilizer, child lock