LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: Ecm, oil level, center console, catalytic converter, headrest, trailer, electronic modulated

Page 3331 of 4500

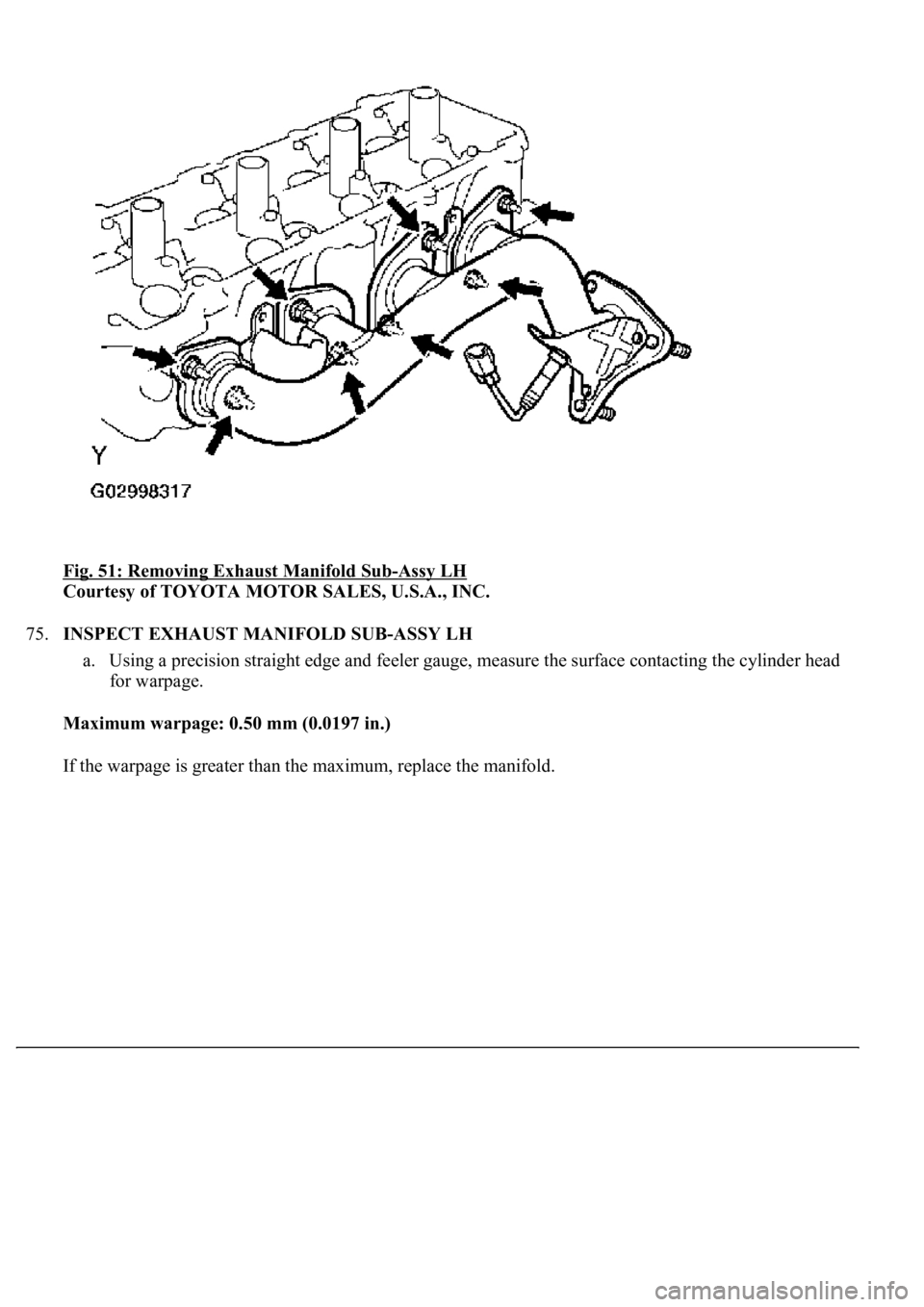

Fig. 51: Removing Exhaust Manifold Sub-Assy LH

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

75.INSPECT EXHAUST MANIFOLD SUB-ASSY LH

a. Using a precision straight edge and feeler gauge, measure the surface contacting the cylinder head

for warpage.

Maximum warpage: 0.50 mm (0.0197 in.)

If the warpa

ge is greater than the maximum, replace the manifold.

Page 3332 of 4500

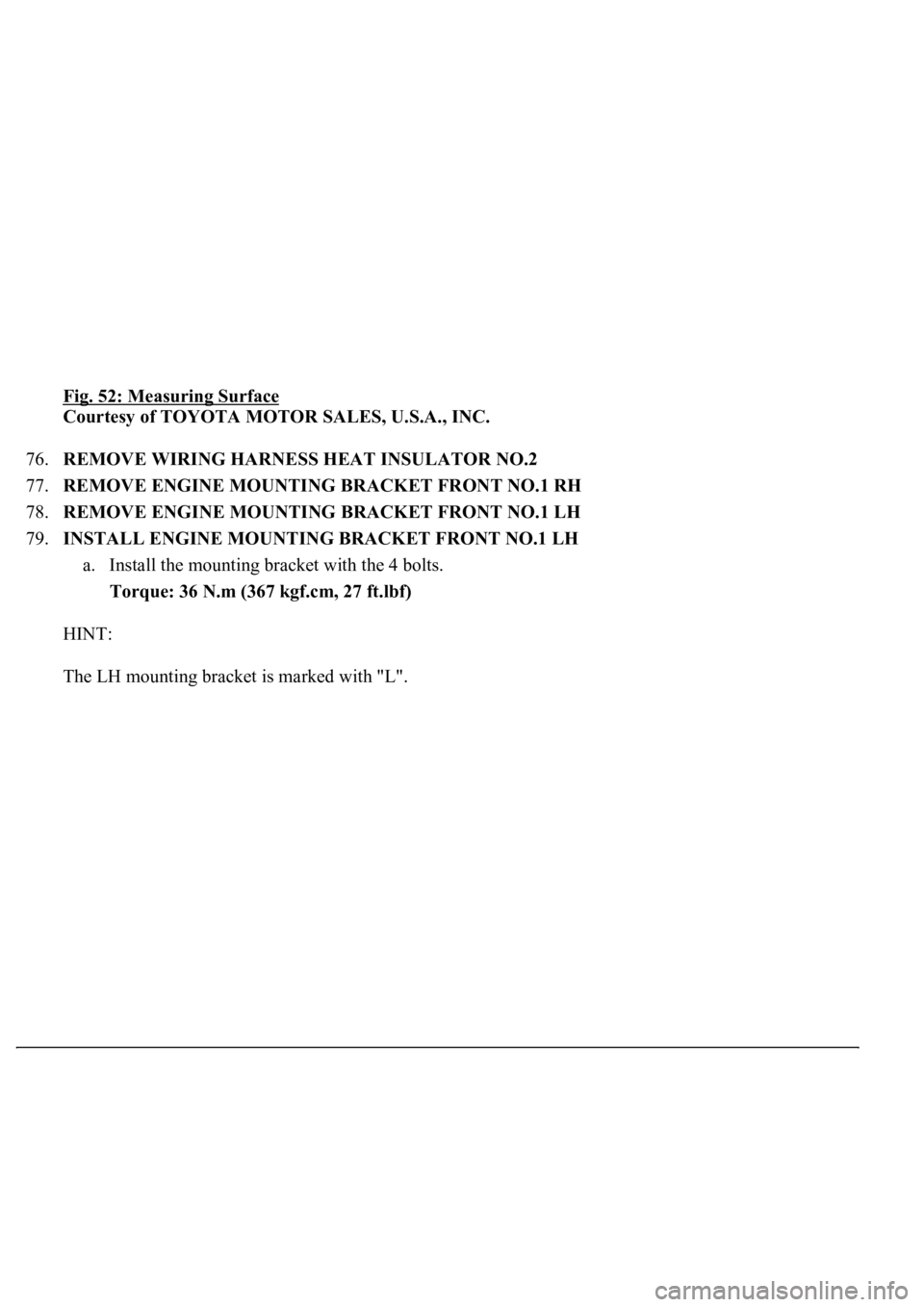

Fig. 52: Measuring Surface

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

76.REMOVE WIRING HARNESS HEAT INSULATOR NO.2

77.REMOVE ENGINE MOUNTING BRACKET FRONT NO.1 RH

78.REMOVE ENGINE MOUNTING BRACKET FRONT NO.1 LH

79.INSTALL ENGINE MOUNTING BRACKET FRONT NO.1 LH

a. Install the mounting bracket with the 4 bolts.

Torque: 36 N.m (367 kgf.cm, 27 ft.lbf)

HINT:

The LH mountin

g bracket is marked with "L".

Page 3333 of 4500

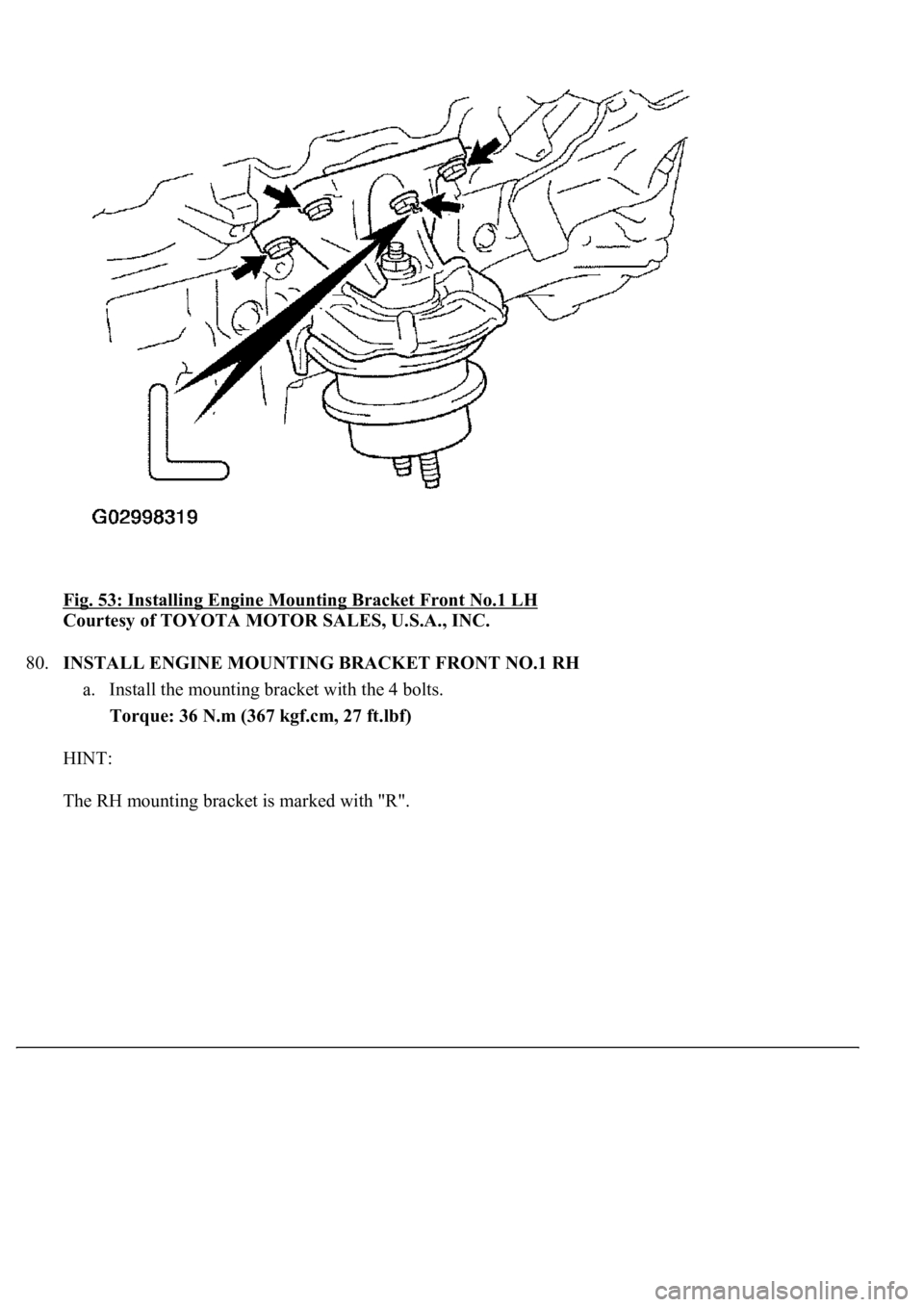

Fig. 53: Installing Engine Mounting Bracket Front No.1 LH

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

80.INSTALL ENGINE MOUNTING BRACKET FRONT NO.1 RH

a. Install the mounting bracket with the 4 bolts.

Torque: 36 N.m (367 kgf.cm, 27 ft.lbf)

HINT:

The RH mountin

g bracket is marked with "R".

Page 3334 of 4500

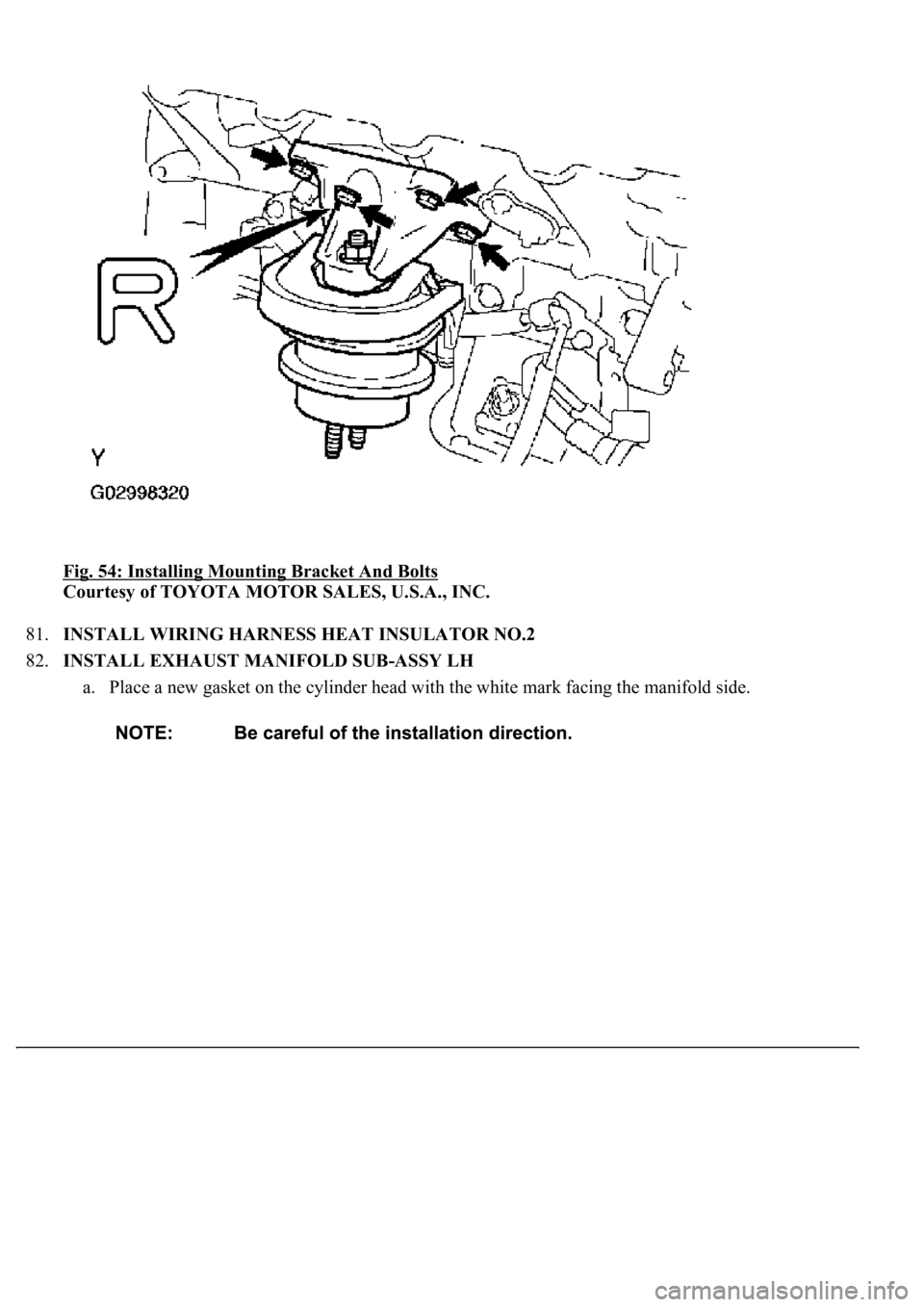

Fig. 54: Installing Mounting Bracket And Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

81.INSTALL WIRING HARNESS HEAT INSULATOR NO.2

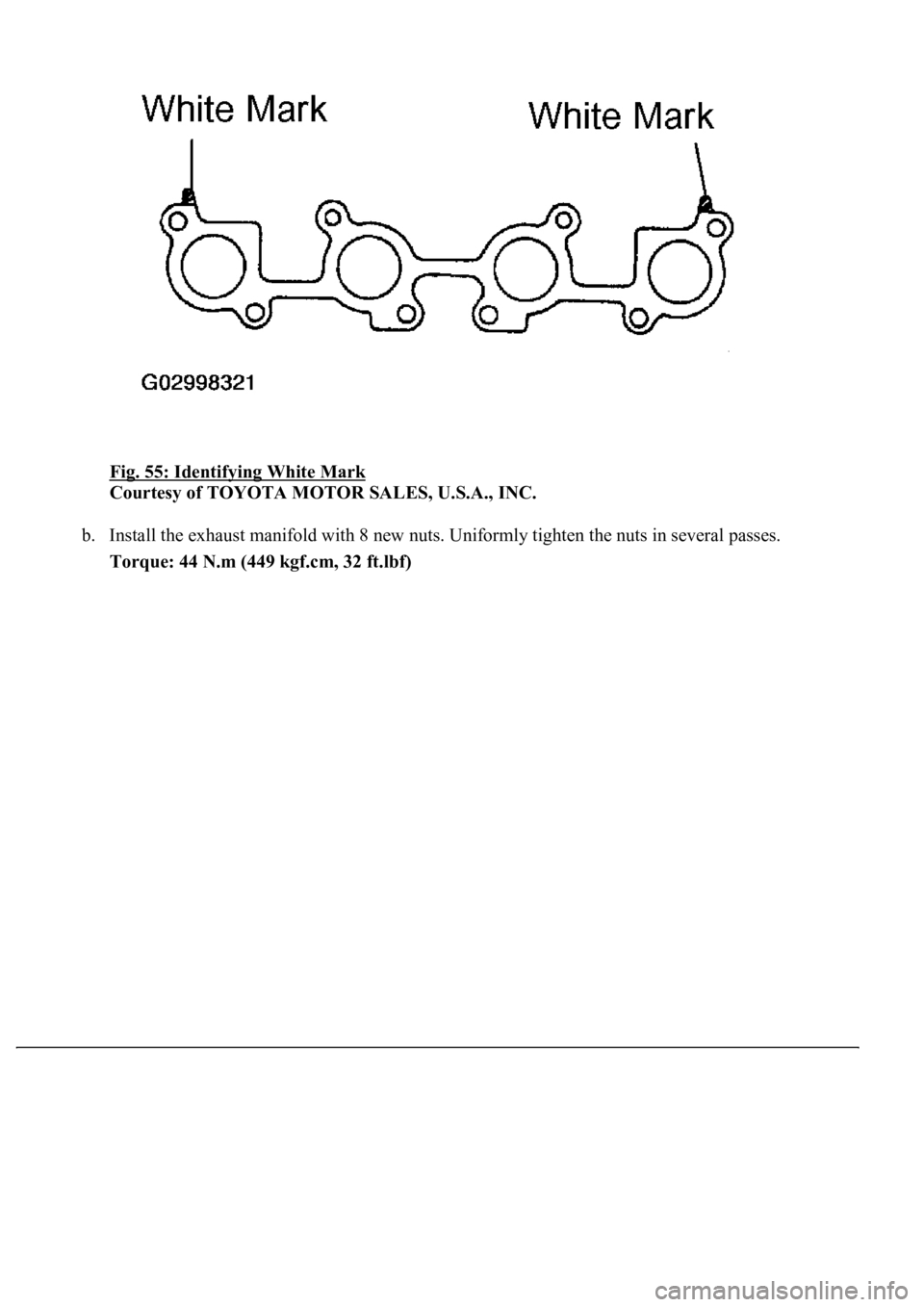

82.INSTALL EXHAUST MANIFOLD SUB-ASSY LH

a. Place a new gasket on the cylinder head with the white mark facing the manifold side.

Page 3335 of 4500

Fig. 55: Identifying White Mark

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Install the exhaust manifold with 8 new nuts. Uniformly tighten the nuts in several passes.

Torque: 44 N.m (449 kgf.cm, 32 ft.lbf)

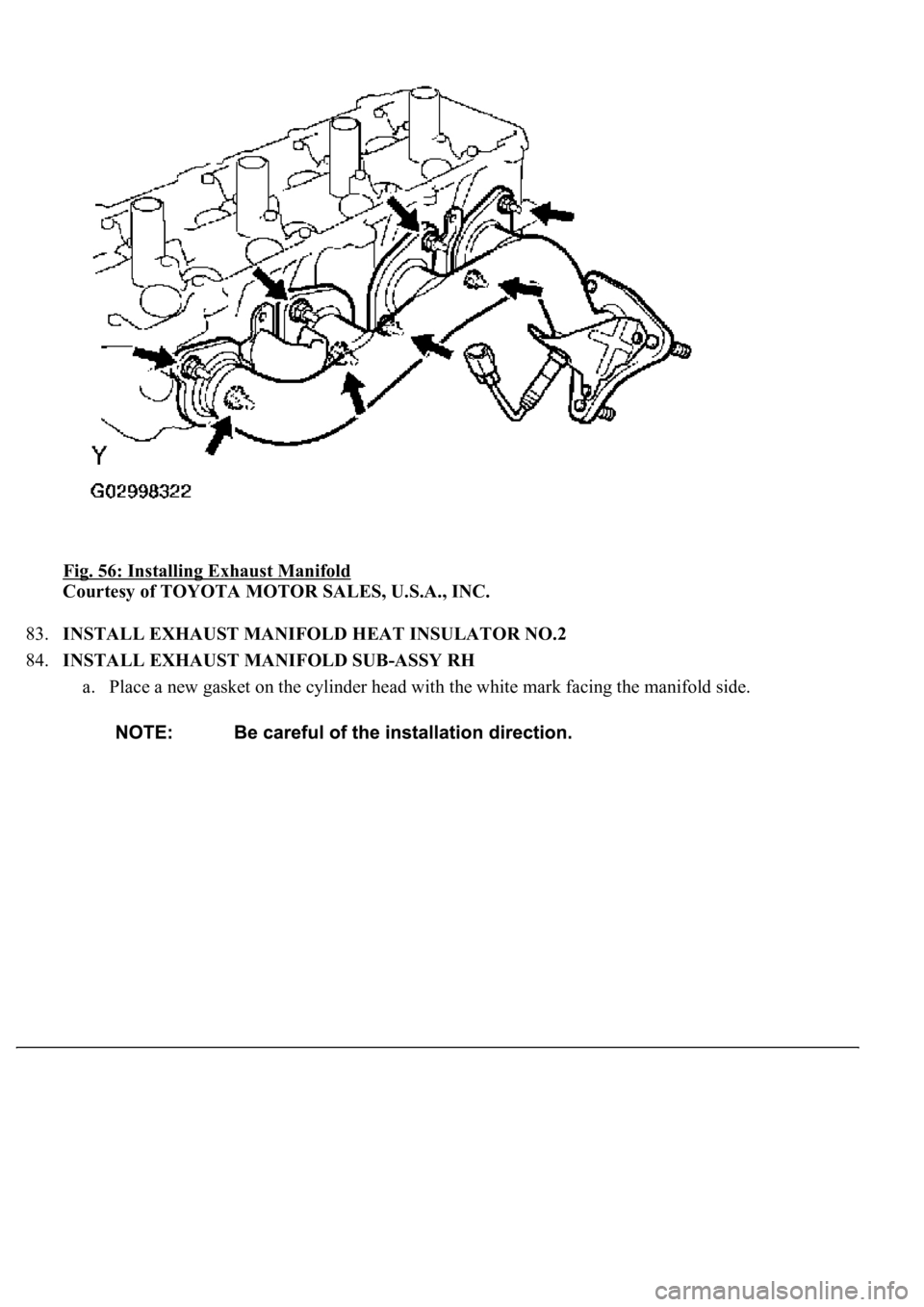

Page 3336 of 4500

Fig. 56: Installing Exhaust Manifold

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

83.INSTALL EXHAUST MANIFOLD HEAT INSULATOR NO.2

84.INSTALL EXHAUST MANIFOLD SUB-ASSY RH

a. Place a new gasket on the cylinder head with the white mark facing the manifold side.

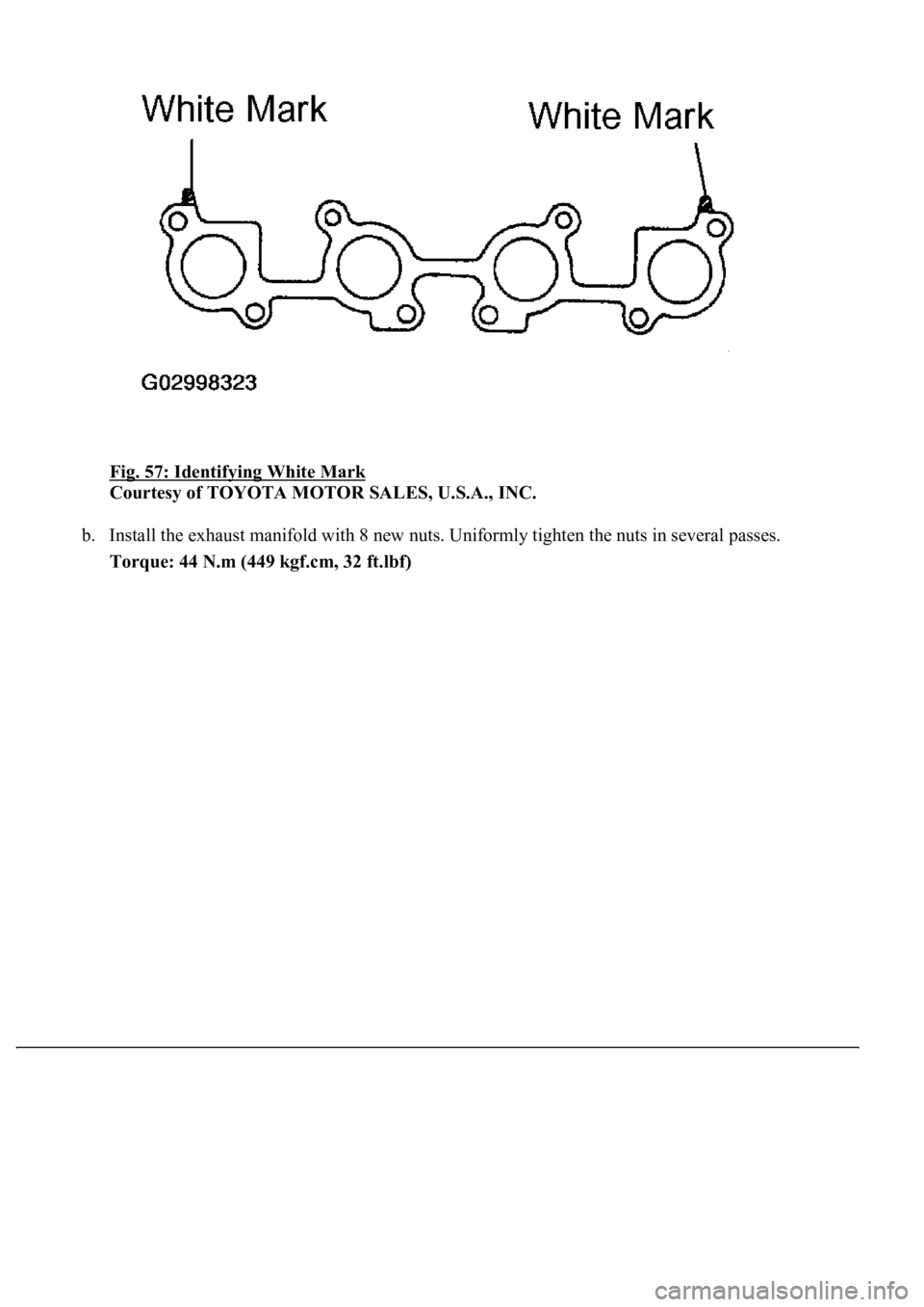

Page 3337 of 4500

Fig. 57: Identifying White Mark

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Install the exhaust manifold with 8 new nuts. Uniformly tighten the nuts in several passes.

Torque: 44 N.m (449 kgf.cm, 32 ft.lbf)

Page 3338 of 4500

Fig. 58: Installing Exhaust Manifold

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

85.INSTALL EXHAUST MANIFOLD HEAT INSULATOR NO.1

86.INSTALL ENGINE OIL LEVEL SENSOR

87.INSTALL CRANKSHAFT POSITION SENSOR (See REPLACEMENT

)

88.INSTALL OIL FILTER BRACKET SUB-ASSY

Torque: 18 N.m (184 kgf.cm, 13 ft.lbf)

89.INSTALL IGNITION COIL ASSY

Torque: 7.5 N.m (77 kgf.cm, 66 in.lbf)

90.INSTALL ENGINE HANGER NO.2

Torque: 37 N.m (377 kgf.cm, 27 ft.lbf)

91.INSTALL ENGINE HANGER NO. 1

Torque: 37 N.m (377 kgf.cm, 27 ft.lbf)

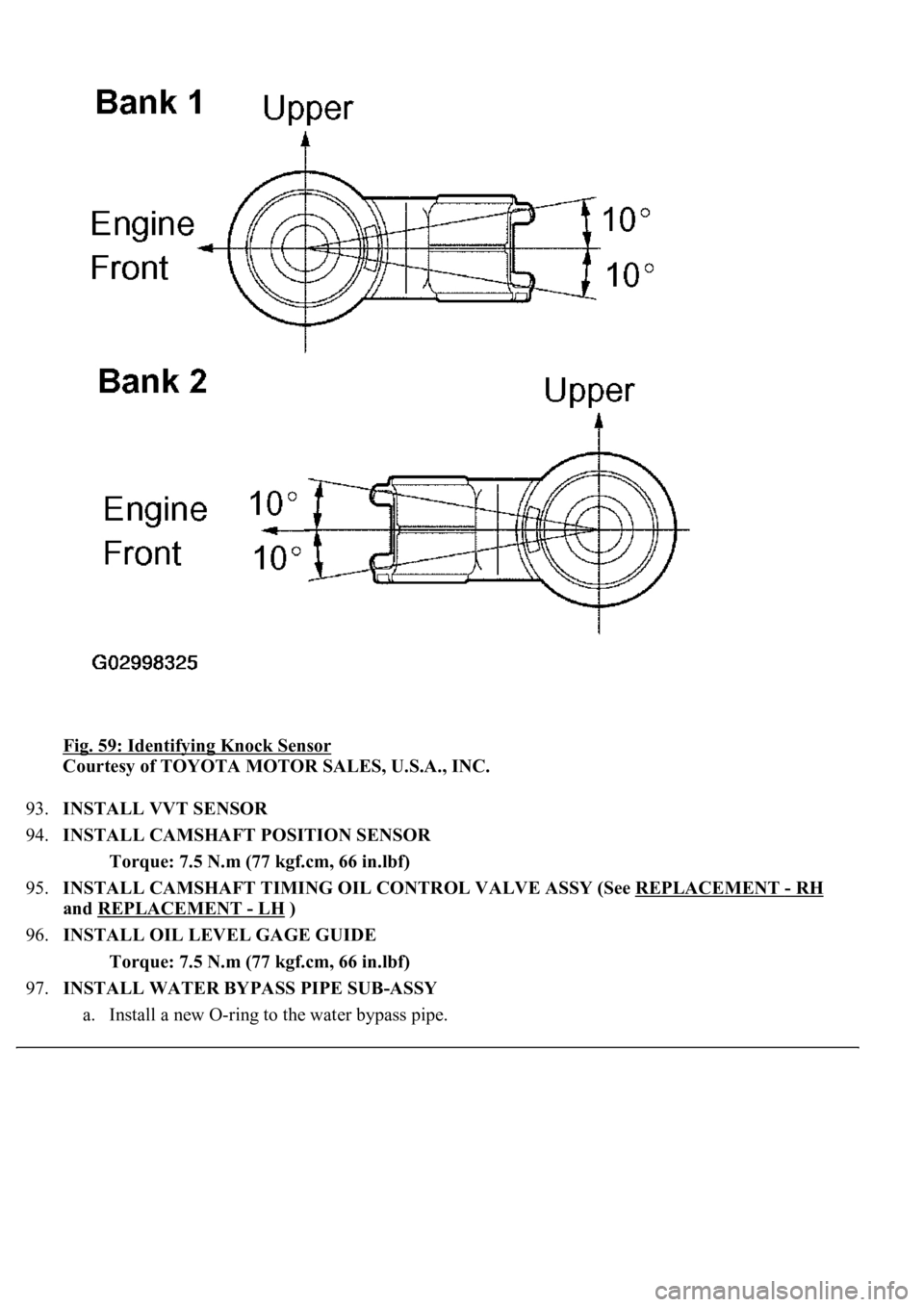

92.INSTALL KNOCK SENSOR

a. Install the 2 knock sensors with the 2 nuts, as shown in the illustration.

Torque: 20 N.m (204 kgf.cm, 15 ft.lbf)

b. Connect the 2 knock sensor connectors.

Page 3339 of 4500

Fig. 59: Identifying Knock Sensor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

93.INSTALL VVT SENSOR

94.INSTALL CAMSHAFT POSITION SENSOR

Torque: 7.5 N.m (77 kgf.cm, 66 in.lbf)

95.INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSY (See REPLACEMENT

- RH

and REPLACEMENT

- LH )

96.INSTALL OIL LEVEL GAGE GUIDE

Torque: 7.5 N.m (77 kgf.cm, 66 in.lbf)

97.INSTALL WATER BYPASS PIPE SUB-ASSY

a. Install a new O-rin

g to the water bypass pipe.

Page 3340 of 4500

b. Apply soapy water to the O-ring.

c. Push in the water bypass pipe end into the pipe hole of the water pump.

d. Install the water bypass pipe with the bolt.

Torque: 18 N.m (184 kgf.cm, 13 ft.lbf)

e. Install the wire clamp to the bracket of the water bypass pipe.

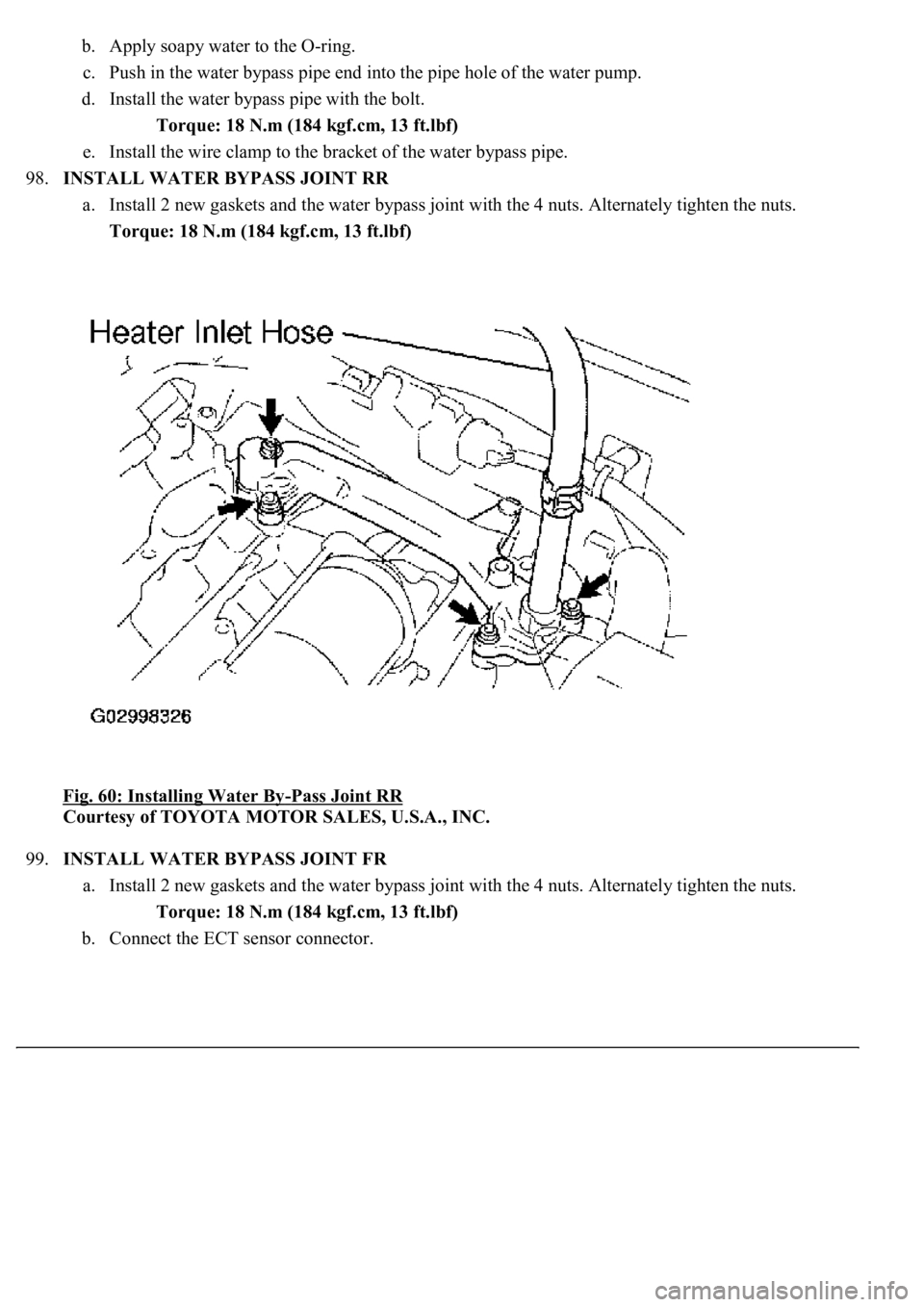

98.INSTALL WATER BYPASS JOINT RR

a. Install 2 new gaskets and the water bypass joint with the 4 nuts. Alternately tighten the nuts.

Torque: 18 N.m (184 kgf.cm, 13 ft.lbf)

Fig. 60: Installing Water By

-Pass Joint RR

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

99.INSTALL WATER BYPASS JOINT FR

a. Install 2 new gaskets and the water bypass joint with the 4 nuts. Alternately tighten the nuts.

Torque: 18 N.m (184 kgf.cm, 13 ft.lbf)

b. Connect the ECT sensor connector.

Trending: evaporator removal, Rear control Arm, Door lock, height adjustment, Expansion Valve, wheel bolt torque, wipers