LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: Soft hard, Expansion Valve, spare tire, audio, center console, air condition, compressor pressure

Page 3931 of 4500

Fig. 15: ECU Power Source Circuit (Driver Seat ECU) - Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 3932 of 4500

INSPECTION PROCEDURE

1.INSPECT FUSE (D/C CUT, D P/SEAT, MPX-IG, AM1, MPX-B1)

a. Remove the D/C CUT fuse from the FL block.

b. Remove the D P/SEAT, MPX-IG and AM1 fuses from the driver side J/B.

c. Remove the MPX-B1 fuse from the passenger side J/B.

d. Measure the resistance of the fuse.

Standard: Below 1 ohms

NG: REPLACE FUSE

OK: GO TO NEXT STEP

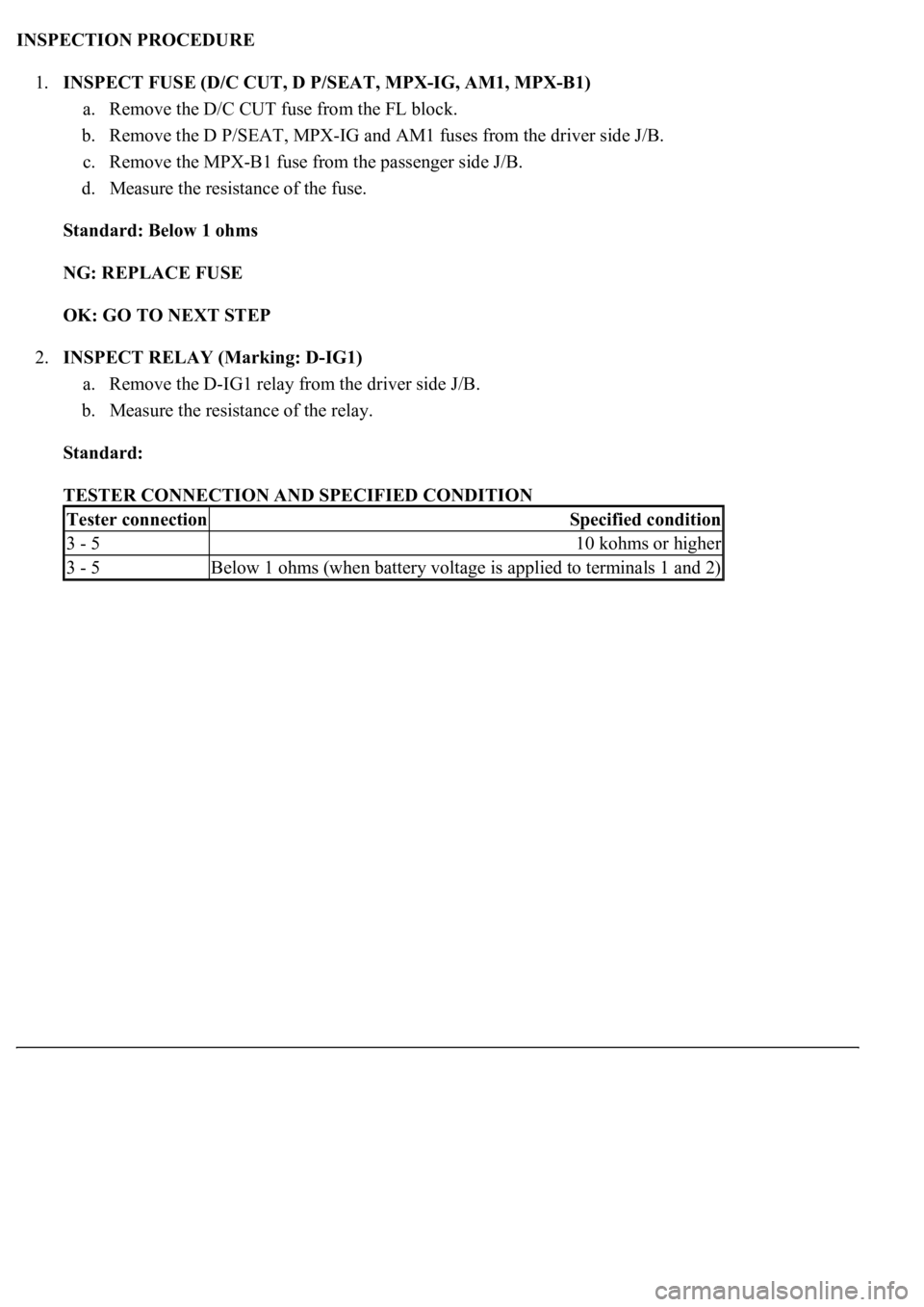

2.INSPECT RELAY (Marking: D-IG1)

a. Remove the D-IG1 relay from the driver side J/B.

b. Measure the resistance of the relay.

Standard:

TESTER CONNECTION AND SPECIFIED CONDITION

Tester connectionSpecified condition

3 - 510 kohms or higher

3 - 5Below 1 ohms (when battery voltage is applied to terminals 1 and 2)

Page 3933 of 4500

Fig. 16: Identifying D-IG1 Relay Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPLACE RELAY

OK: GO TO NEXT STEP

3.CHECK WIRE HARNESS (DRIVER SEAT ECU - BATTERY AND BODY GROUND)

a. Disconnect the D27 and D28 ECU connectors.

b. Measure the voltage and resistance of the wire harness side connectors.

Fig. 17: Identifying D27 And D28 Driver Seat ECU Connectors Terminals

Page 3934 of 4500

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Standard:

TESTER CONNECTION AND SPECIFIED CONDITION

NG: REPAIR OR REPLACE HARNESS AND CONNECTOR

OK: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS

TABLE

CIRCUIT DESCRIPTION

This circuit supplies power to operate the driver side J/B ECU.

WIRING DIAGRAM

Tester ConnectionSwitch ConditionSpecified Condition

D27-14 (+B) - Body groundAlways10 to 14 V

D28-9 (SYSB) - Body groundAlways10 to 14 V

D28-10 (IG) - Body groundIgnition switch OFF --> ON0 V --> 10 to 14 V

D27-6 (GND) - Body groundAlwaysBelow 1 ohms

D28-1 (SGND) - Body groundAlwaysBelow 1 ohms

Page 3935 of 4500

Fig. 18: Power Source Circuit (Driver Door ECU) - Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

1.INSPECT FUSE (MPX-B1, AM1, MPX-IG, D DOOR)

a. Remove the MPX-IG and AM1 fuses from the driver side J/B.

b. Remove the D DOOR and MPX-B1 fuses from the passenger side J/B.

c. Measure the resistance of the fuse.

Standard: Below 1 ohms

Page 3936 of 4500

NG: REPLACE FUSE

OK: GO TO NEXT STEP

2.INSPECT RELAY (D-IG1)

a. Remove the D-IG1 relay from the driver side J/B.

b. Measure the resistance of the relay.

Standard:

TESTER CONNECTION AND SPECIFIED CONDITION

Fig. 19: Identifying D

-IG1 Relay Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPLACE RELAY

OK: GO TO NEXT STEP

3.CHECK WIRE HARNESS (DRIVER DOOR ECU - BATTERY AND BODY GROUND)

Tester connectionSpecified condition

3 - 510 kohms or higher

3 - 5Below 1 ohms (when battery voltage is applied to terminals 1 and 2)

Page 3937 of 4500

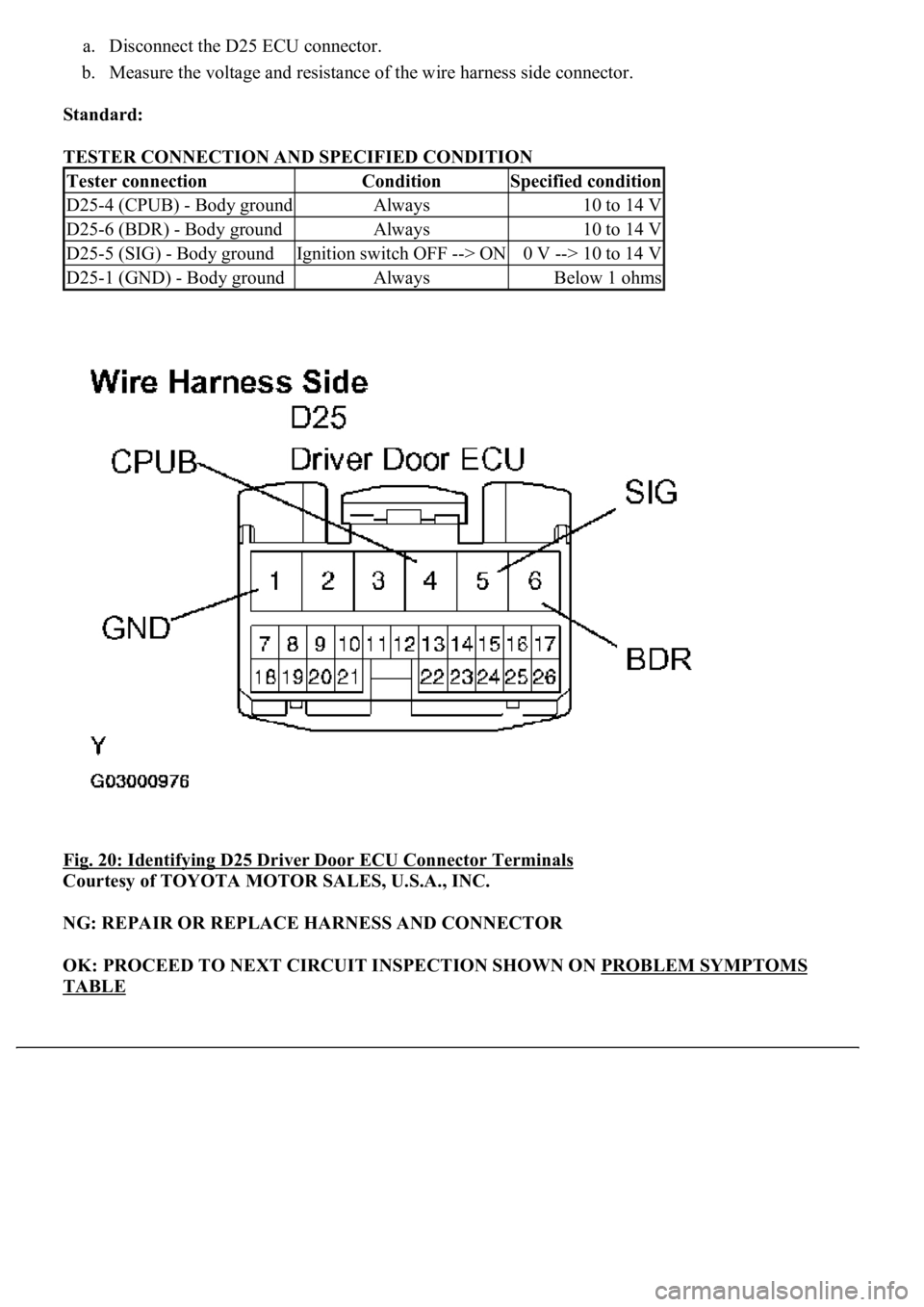

a. Disconnect the D25 ECU connector.

b. Measure the voltage and resistance of the wire harness side connector.

Standard:

TESTER CONNECTION AND SPECIFIED CONDITION

Fig. 20: Identifying D25 Driver Door ECU Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS AND CONNECTOR

OK: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS

TABLE

Tester connectionConditionSpecified condition

D25-4 (CPUB) - Body groundAlways10 to 14 V

D25-6 (BDR) - Body groundAlways10 to 14 V

D25-5 (SIG) - Body groundIgnition switch OFF --> ON0 V --> 10 to 14 V

D25-1 (GND) - Body groundAlwaysBelow 1 ohms

Page 3938 of 4500

CIRCUIT DESCRIPTION

The driver seat ECU receives signals from the power seat control switches and operates each power seat motor

according to its switch position.

WIRING DIAGRAM

Fig. 21: Power Seat Motor Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 3939 of 4500

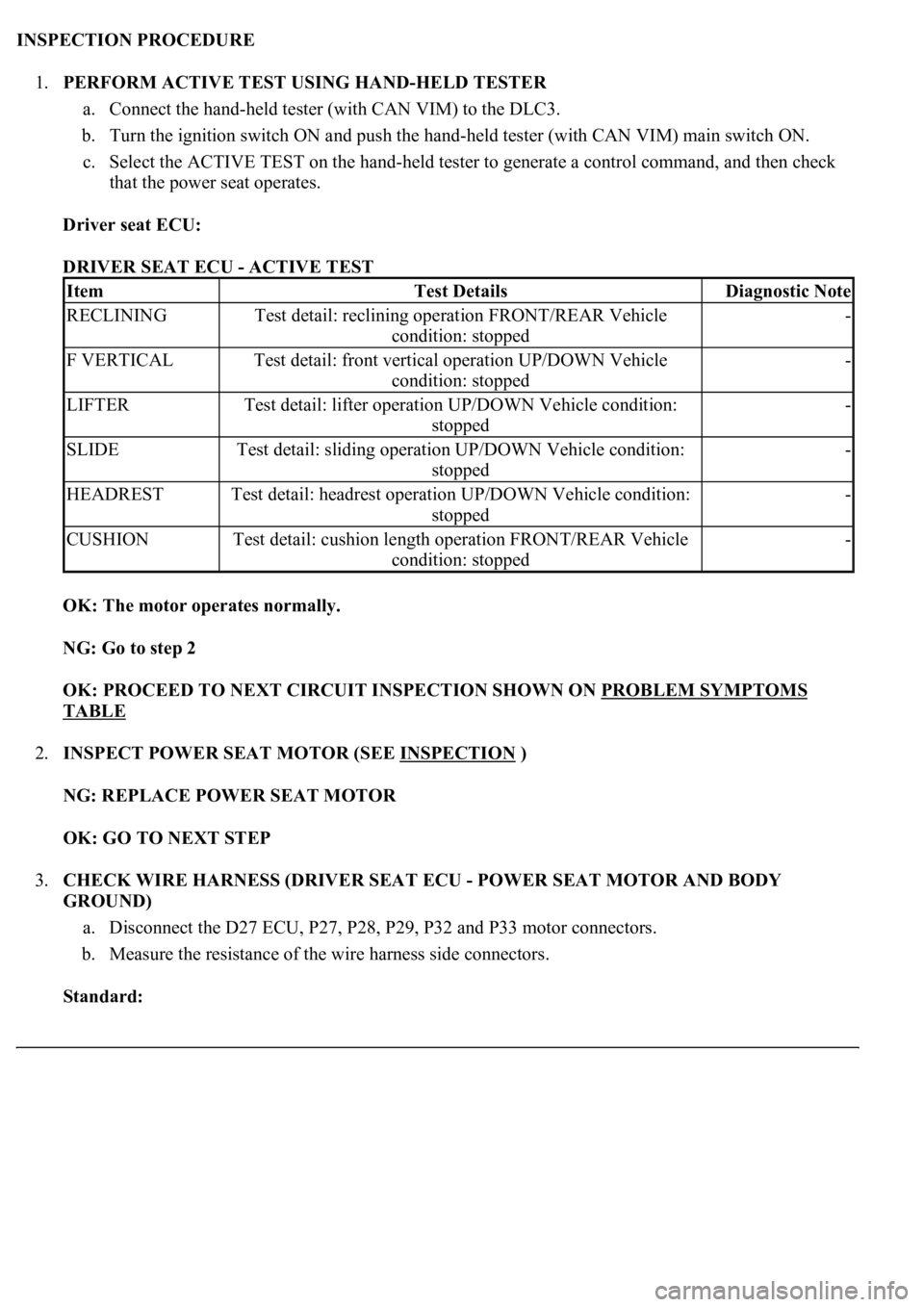

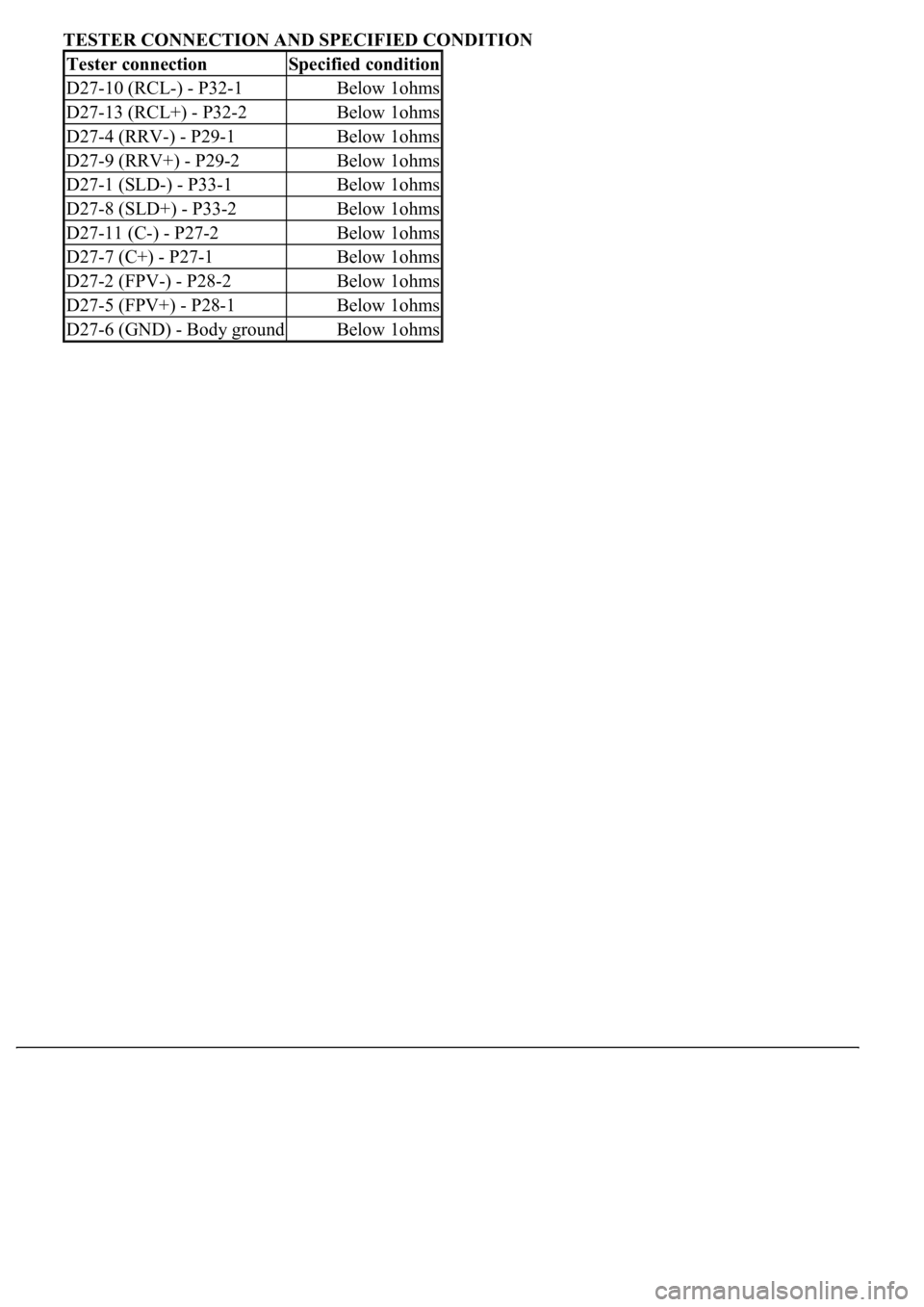

INSPECTION PROCEDURE

1.PERFORM ACTIVE TEST USING HAND-HELD TESTER

a. Connect the hand-held tester (with CAN VIM) to the DLC3.

b. Turn the ignition switch ON and push the hand-held tester (with CAN VIM) main switch ON.

c. Select the ACTIVE TEST on the hand-held tester to generate a control command, and then check

that the power seat operates.

Driver seat ECU:

DRIVER SEAT ECU - ACTIVE TEST

OK: The motor operates normally.

NG: Go to step 2

OK: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS

TABLE

2.INSPECT POWER SEAT MOTOR (SEE INSPECTION

)

NG: REPLACE POWER SEAT MOTOR

OK: GO TO NEXT STEP

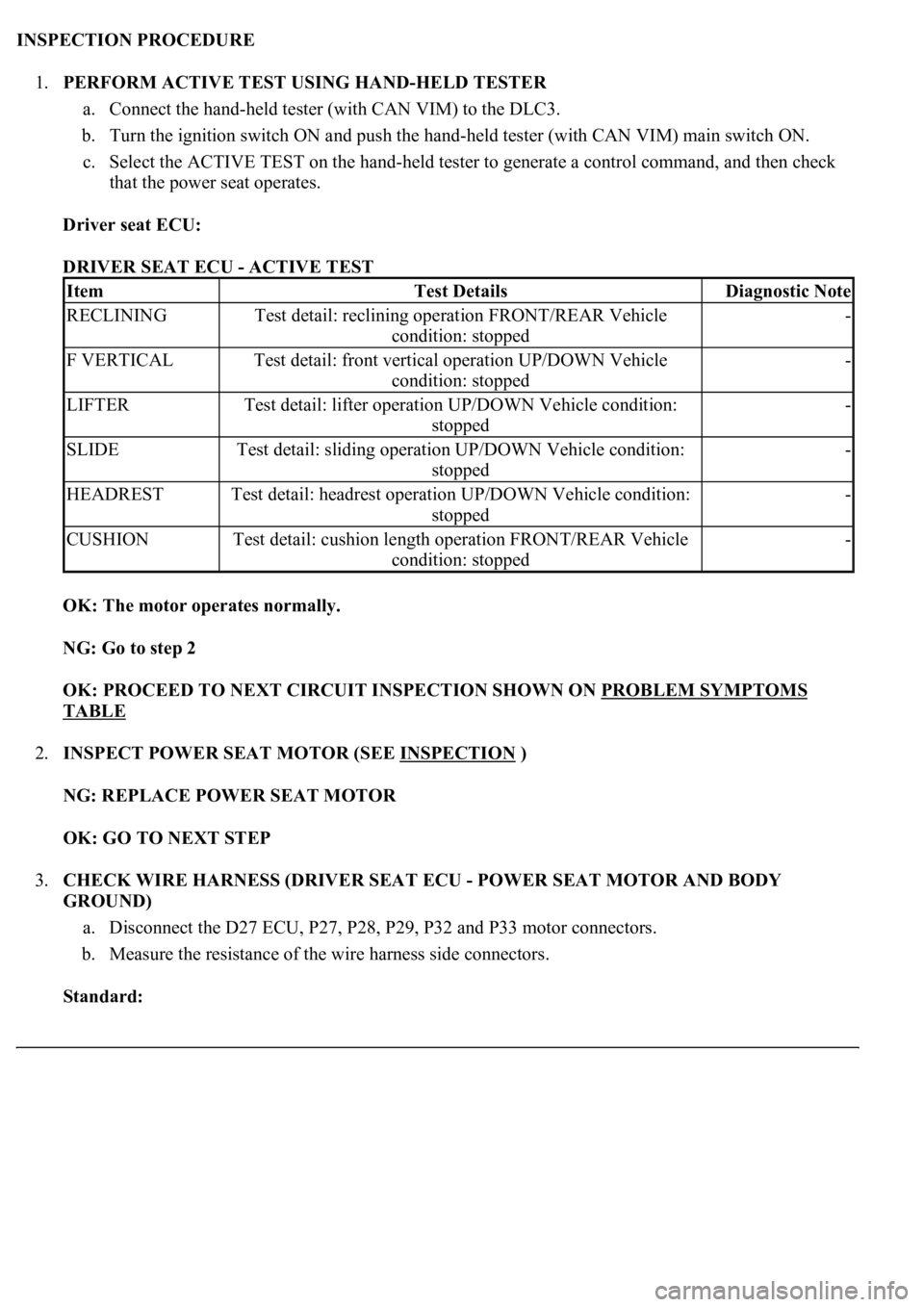

3.CHECK WIRE HARNESS (DRIVER SEAT ECU - POWER SEAT MOTOR AND BODY

GROUND)

a. Disconnect the D27 ECU, P27, P28, P29, P32 and P33 motor connectors.

b. Measure the resistance of the wire harness side connectors.

Standard:

ItemTest DetailsDiagnostic Note

RECLININGTest detail: reclining operation FRONT/REAR Vehicle

condition: stopped-

F VERTICALTest detail: front vertical operation UP/DOWN Vehicle

condition: stopped-

LIFTERTest detail: lifter operation UP/DOWN Vehicle condition:

stopped-

SLIDETest detail: sliding operation UP/DOWN Vehicle condition:

stopped-

HEADRESTTest detail: headrest operation UP/DOWN Vehicle condition:

stopped-

CUSHIONTest detail: cushion length operation FRONT/REAR Vehicle

condition: stopped-

Page 3940 of 4500

TESTER CONNECTION AND SPECIFIED CONDITION

Tester connectionSpecified condition

D27-10 (RCL-) - P32-1Below 1ohms

D27-13 (RCL+) - P32-2Below 1ohms

D27-4 (RRV-) - P29-1Below 1ohms

D27-9 (RRV+) - P29-2Below 1ohms

D27-1 (SLD-) - P33-1Below 1ohms

D27-8 (SLD+) - P33-2Below 1ohms

D27-11 (C-) - P27-2Below 1ohms

D27-7 (C+) - P27-1Below 1ohms

D27-2 (FPV-) - P28-2Below 1ohms

D27-5 (FPV+) - P28-1Below 1ohms

D27-6 (GND) - Body groundBelow 1ohms

Trending: mirror, intake manifold inlet, clock, belt, steering interlock cable, C1752, coolant level