LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: torque, idler tensioner pulley, fuel pressure, dlc3, wiring diagram, fuse diagram, seats

Page 3941 of 4500

Page 3942 of 4500

Fig. 22: Identifying D27 Driver Seat ECU Connector Terminals And Power Seat Motor Connector

Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE WIRE HARNESS AND CONNECTOR

OK: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS

TABLE

CIRCUIT DESCRIPTION

The position sensor detects seat movement and sends pulse signals to the driver seat ECU for use with the

memory function.

The ECU records the number of pulses relative to a previously recorded seat position and uses this data to

return the seat to that position.

If a malfunction occurs in a position sensor and seat movement does not result in pulse signals being input into

the ECU, the memory function is deactivated.

WIRING DIAGRAM

Page 3943 of 4500

Fig. 23: Position Sensor Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 3944 of 4500

INSPECTION PROCEDURE

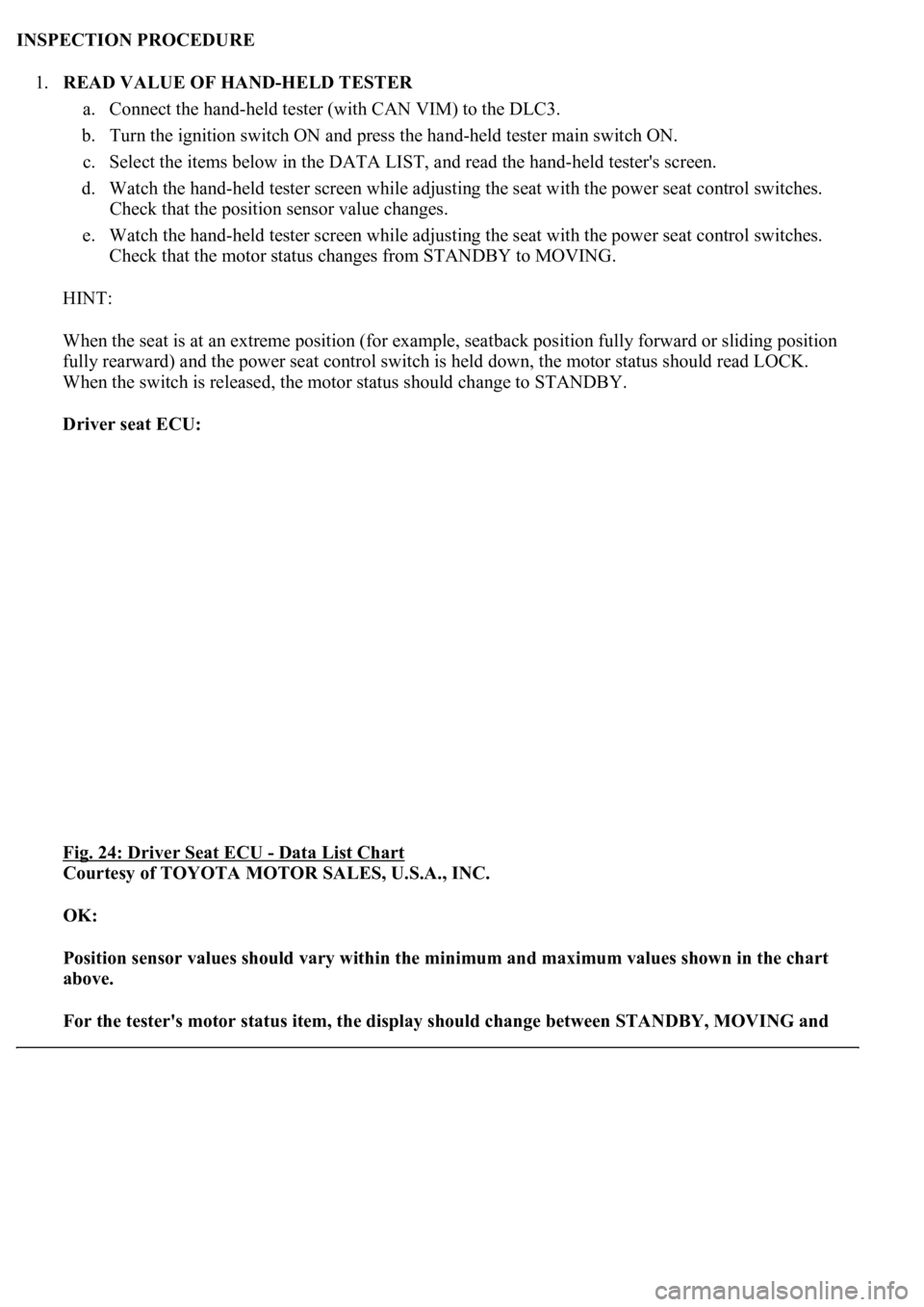

1.READ VALUE OF HAND-HELD TESTER

a. Connect the hand-held tester (with CAN VIM) to the DLC3.

b. Turn the ignition switch ON and press the hand-held tester main switch ON.

c. Select the items below in the DATA LIST, and read the hand-held tester's screen.

d. Watch the hand-held tester screen while adjusting the seat with the power seat control switches.

Check that the position sensor value changes.

e. Watch the hand-held tester screen while adjusting the seat with the power seat control switches.

Check that the motor status changes from STANDBY to MOVING.

HINT:

When the seat is at an extreme position (for example, seatback position fully forward or sliding position

fully rearward) and the power seat control switch is held down, the motor status should read LOCK.

When the switch is released, the motor status should change to STANDBY.

Driver seat ECU:

Fig. 24: Driver Seat ECU

- Data List Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK:

Position sensor values should vary within the minimum and maximum values shown in the chart

above.

For the tester's motor status item, the display should change between STANDBY, MOVING and

Page 3945 of 4500

LOCK according to the chart above.

NG: Go to step 2

OK: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS

TABLE

2.CHECK WIRE HARNESS (DRIVER SEAT ECU - POWER SEAT SENSOR AND BODY

GROUND)

a. Disconnect the D27 and D28 ECU connectors.

b. Disconnect the P40, P41, P42, P43, P44 and P45 sensor connectors.

c. Measure the resistance of the wire harness side connectors.

Standard:

TESTER CONNECTION AND SPECIFIED CONDITION

Tester connectionSpecified condition

D27-12 (H+) - P40-1 (UP)Below 1 ohms

D27-3 (H-) - P40-5 (DOWN)Below 1 ohms

D28-7(SSRH) - P40-4(O/P)Below 1 ohms

D28-16 (PVCC) - P40-2 (VCC)Below 1 ohms

D28-16 (PVCC) - P44-3 (VCC)Below 1 ohms

D28-13 (SSRR) - P44-1 (O/P)Below 1 ohms

D28-16 (PVCC) - P43-3 (VCC)Below 1 ohms

D28-6 (SSRV) - P43-1 (O/P)Below 1 ohms

D28-16 (PVCC) - P45-3 (VCC)Below 1 ohms

D28-5 (SSRS) -P45-1 (O/P)Below 1 ohms

D28-16 (PVCC) - P41-3 (VCC)Below 1 ohms

D28-15 (SSRC) - P41-1 (O/P)Below 1 ohms

D28-16 (PVCC) - P42-3 (VCC)Below 1 ohms

D28-14 (SSFV) - P42-1 (O/P)Below 1 ohms

D28-1 (SGND) - Body groundBelow 1 ohms

P40-3 (GND) - Body groundBelow 1 ohms

P44-2 (GND) - Body groundBelow 1 ohms

P43-2 (GND) - Body groundBelow 1 ohms

P45-2 (GND) - Body groundBelow 1 ohms

P41-2 (GND) - Body groundBelow 1 ohms

P42-2 (GND) - Body groundBelow 1 ohms

Page 3946 of 4500

Fig. 25: Identifying D27, D28 Driver Seat ECU Connector Terminals And Power Seat Sensor

Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS AND CONNECTOR

Page 3947 of 4500

OK: GO TO NEXT STEP

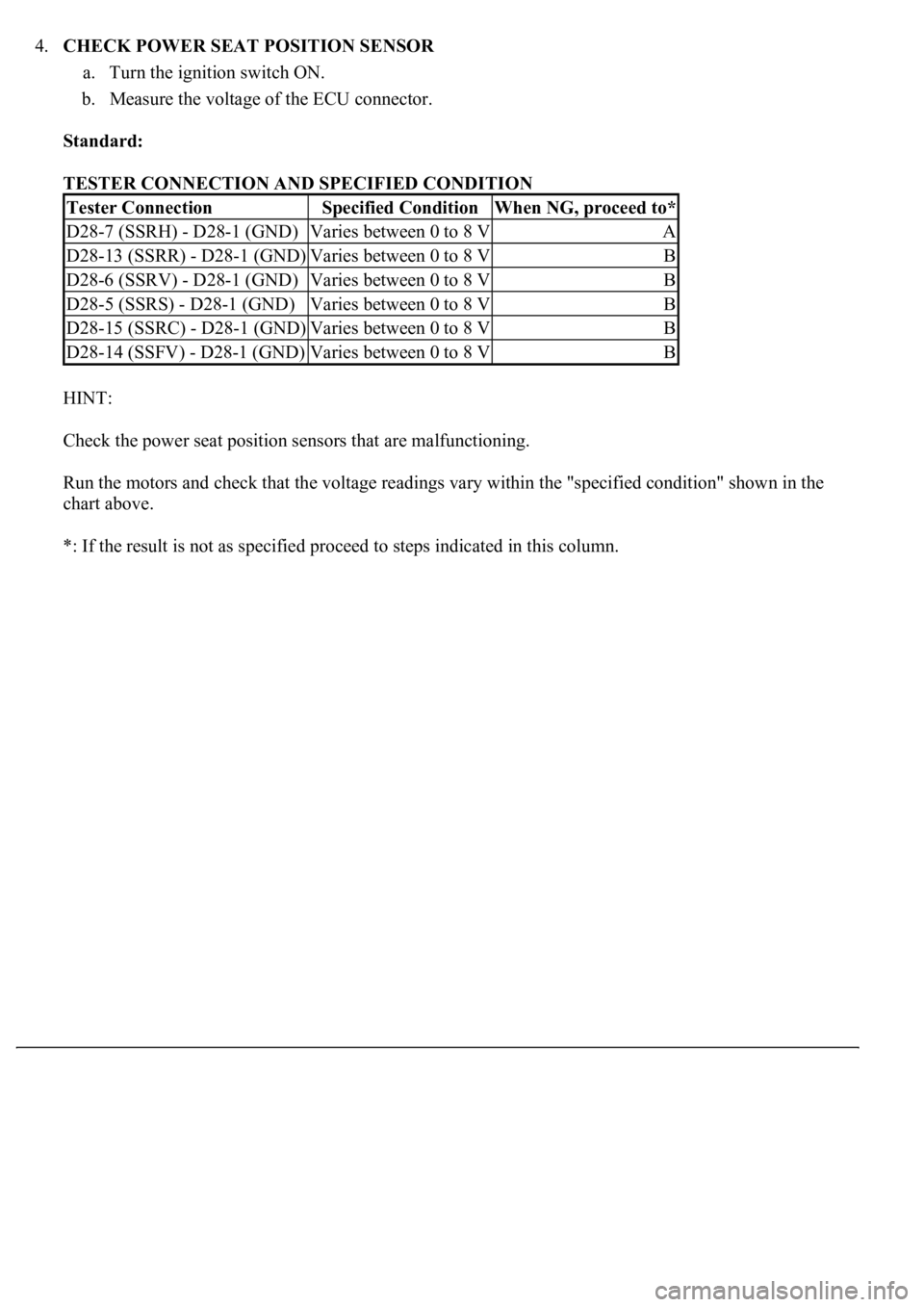

3.CHECK DRIVER SEAT ECU (SENSOR POWER SOURCE VOLTAGE)

a. Turn the ignition switch ON.

b. Measure the voltage of the ECU connector.

Standard:

TESTER CONNECTION AND SPECIFIED CONDITION

Fig. 26: Identifying D28 Driver Seat ECU Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPLACE DRIVER SEAT ECU

OK: GO TO NEXT STEP

Tester connectionSpecified condition

D28-16 (PVCC) - Body ground8V

Page 3948 of 4500

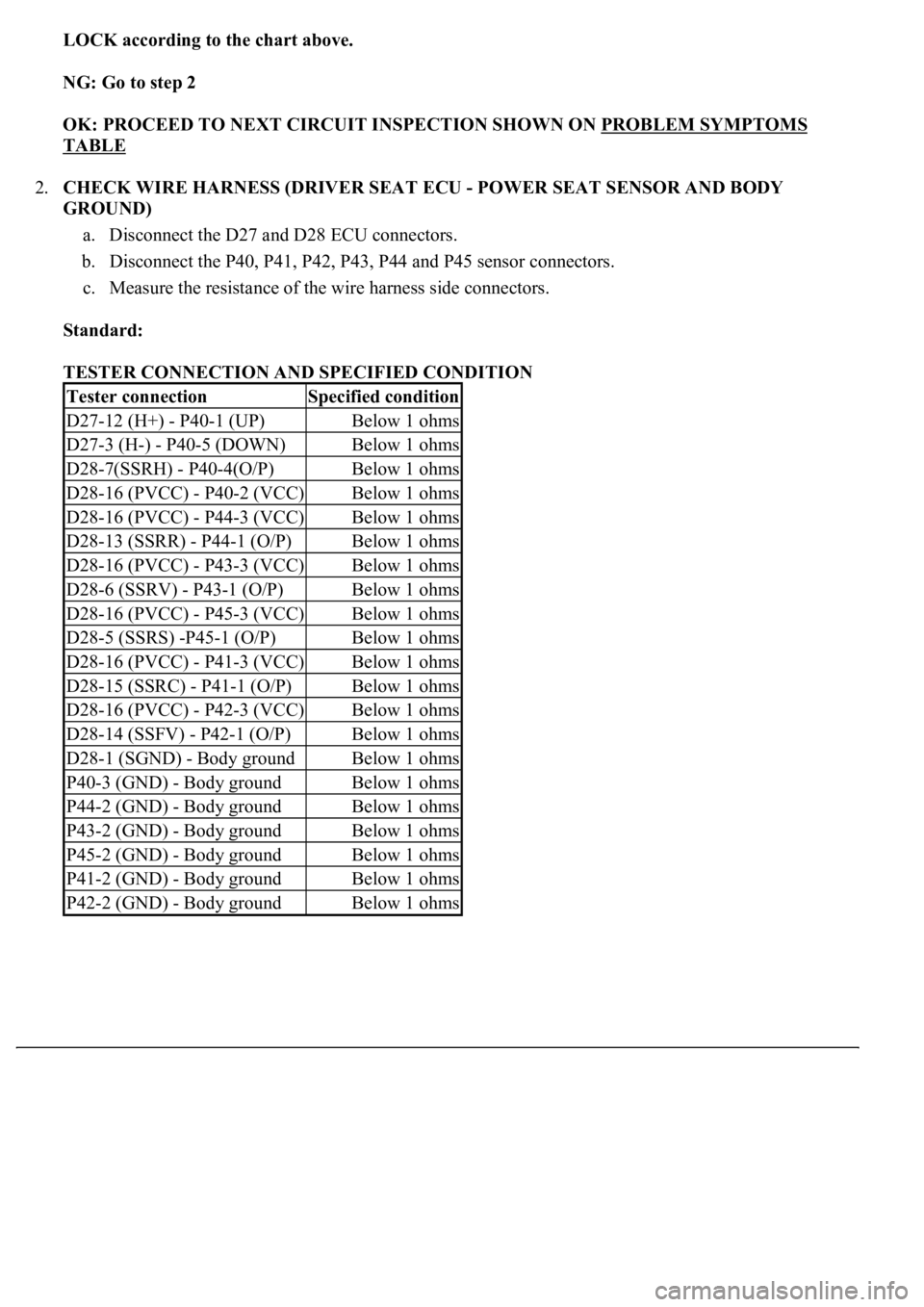

4.CHECK POWER SEAT POSITION SENSOR

a. Turn the ignition switch ON.

b. Measure the voltage of the ECU connector.

Standard:

TESTER CONNECTION AND SPECIFIED CONDITION

HINT:

Check the power seat position sensors that are malfunctioning.

Run the motors and check that the voltage readings vary within the "specified condition" shown in the

chart above.

*: If the result is not as specified proceed to steps indicated in this column.

Tester ConnectionSpecified ConditionWhen NG, proceed to*

D28-7 (SSRH) - D28-1 (GND)Varies between 0 to 8 VA

D28-13 (SSRR) - D28-1 (GND)Varies between 0 to 8 VB

D28-6 (SSRV) - D28-1 (GND)Varies between 0 to 8 VB

D28-5 (SSRS) - D28-1 (GND)Varies between 0 to 8 VB

D28-15 (SSRC) - D28-1 (GND)Varies between 0 to 8 VB

D28-14 (SSFV) - D28-1 (GND)Varies between 0 to 8 VB

Page 3949 of 4500

Fig. 27: Identifying D28 Driver Seat ECU Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

A: REPLACE FRONT SEAT HEADREST ADJUSTER

B: REPLACE FRONT POWER SEAT ADJUSTER

OK: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS

TABLE

CIRCUIT DESCRIPTION

Pressing the lumbar switch activates the lumbar support motor.

Because the lumbar support switch is not connected to the driver seat ECU, pressing this switch does not

operate ECU operations such as the memory function.

WIRING DIAGRAM

Page 3950 of 4500

Fig. 28: Lumbar Support Switch Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

1.INSPECT LUMBAR SUPPORT SWITCH

a. Remove the lumbar support switch.

b. Measure the resistance.

Standard:

Upper side control

TESTER CONNECTION AND SPECIFIED CONDITION

Trending: brake pads, radio antenna, oil reset, fuse box location, Identifying ac, oil filter, traction control