MAZDA 6 2002 Suplement Service Manual

Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 41 of 909

B2–10

TIMING BELT

.

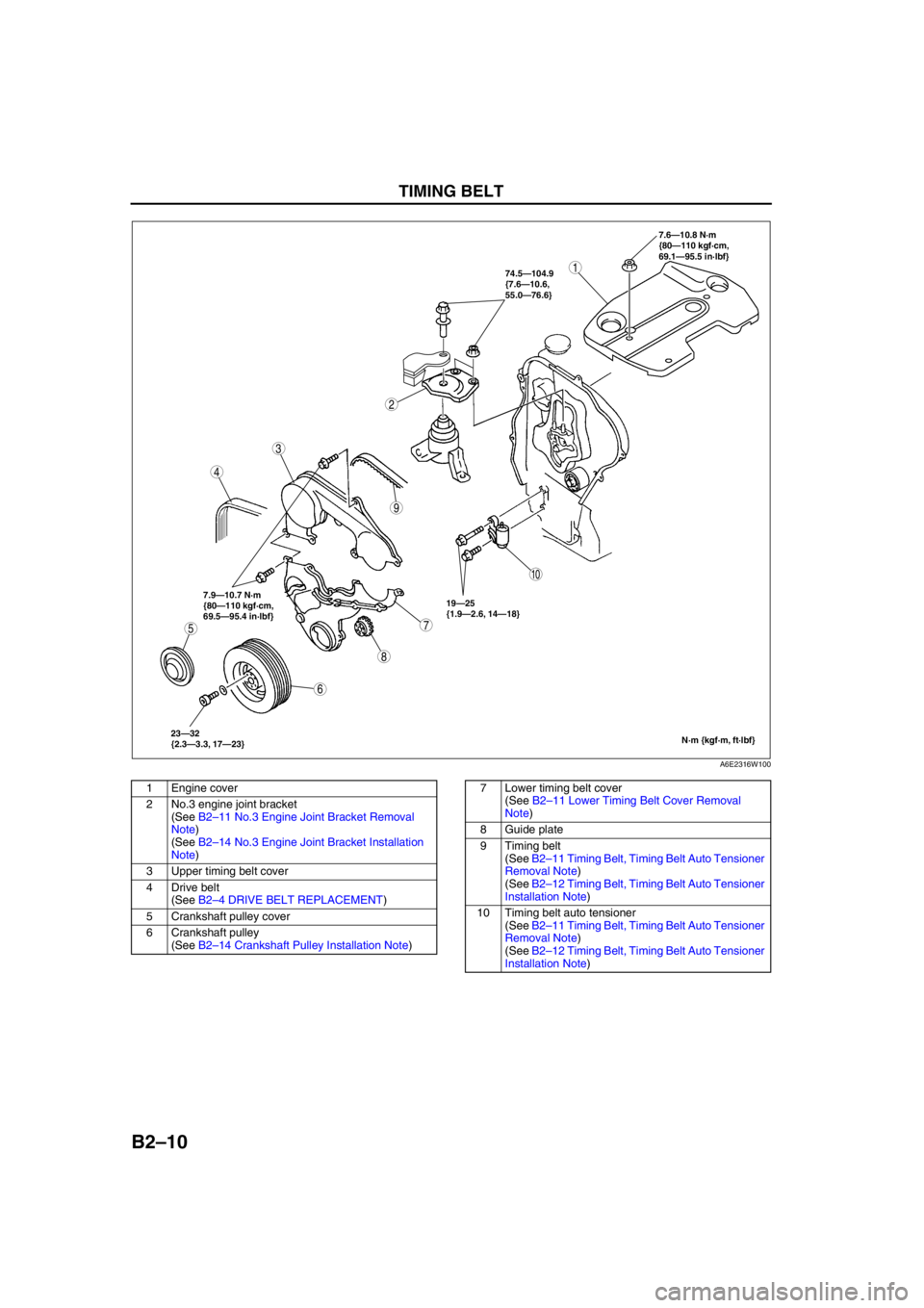

N·m {kgf·m, ft·lbf} 7.6—10.8 N·m

{80—110 kgf·cm,

69.1—95.5 in·lbf}

7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}

23—32

{2.3—3.3, 17—23}19—25

{1.9—2.6, 14—18} 74.5—104.9

{7.6—10.6,

55.0—76.6}

9

8

75

4

3

1

2

10

6

A6E2316W100

1 Engine cover

2 No.3 engine joint bracket

(See B2–11 No.3 Engine Joint Bracket Removal

Note)

(See B2–14 No.3 Engine Joint Bracket Installation

Note)

3 Upper timing belt cover

4Drive belt

(See B2–4 DRIVE BELT REPLACEMENT)

5 Crankshaft pulley cover

6 Crankshaft pulley

(See B2–14 Crankshaft Pulley Installation Note)7 Lower timing belt cover

(See B2–11 Lower Timing Belt Cover Removal

Note)

8 Guide plate

9 Timing belt

(See B2–11 Timing Belt, Timing Belt Auto Tensioner

Removal Note)

(See B2–12 Timing Belt, Timing Belt Auto Tensioner

Installation Note)

10 Timing belt auto tensioner

(See B2–11 Timing Belt, Timing Belt Auto Tensioner

Removal Note)

(See B2–12 Timing Belt, Timing Belt Auto Tensioner

Installation Note)

Page 42 of 909

TIMING BELT

B2–11

B2

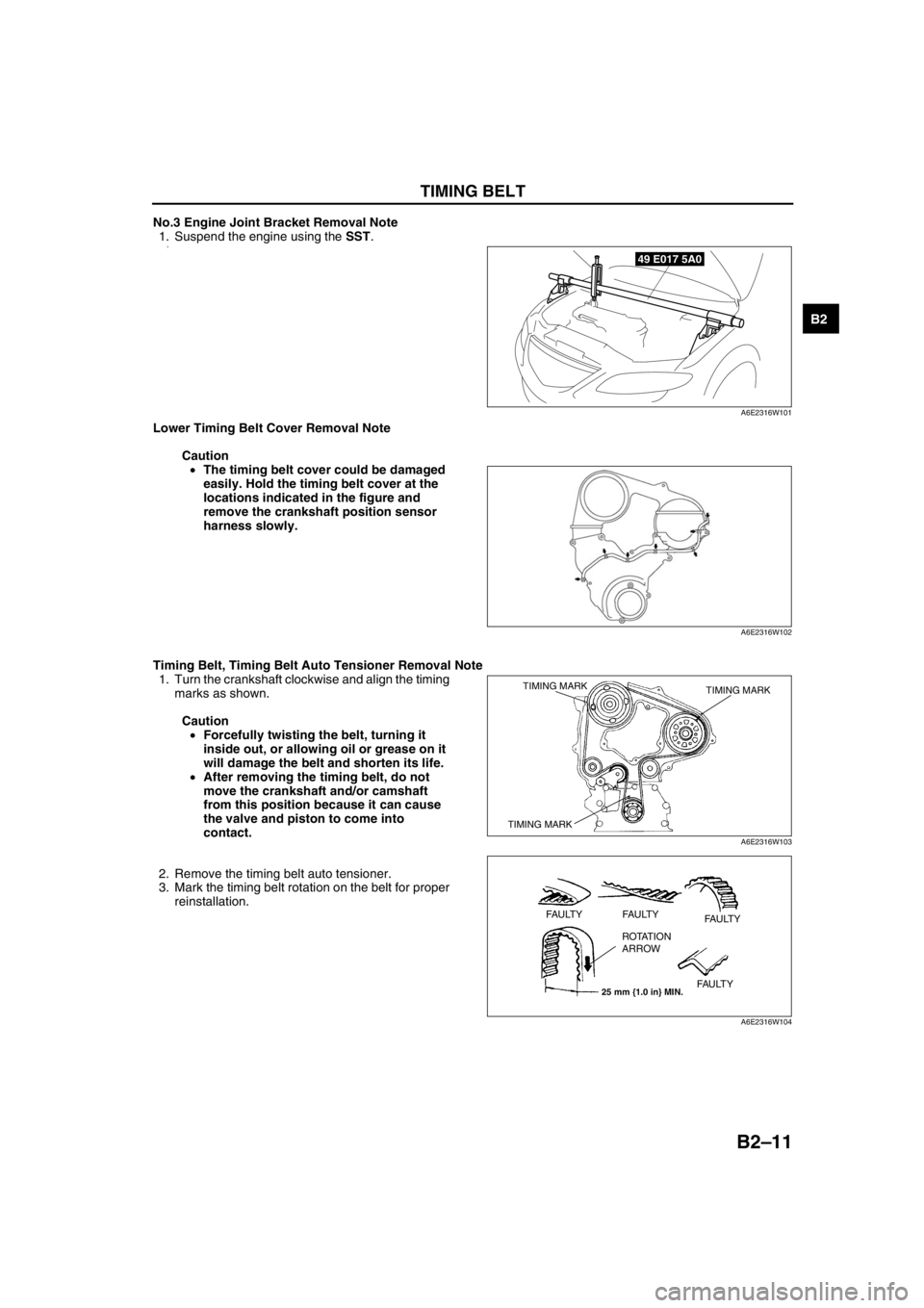

No.3 Engine Joint Bracket Removal Note

1. Suspend the engine using the SST.

2.

Lower Timing Belt Cover Removal Note

Caution

•The timing belt cover could be damaged

easily. Hold the timing belt cover at the

locations indicated in the figure and

remove the crankshaft position sensor

harness slowly.

Timing Belt, Timing Belt Auto Tensioner Removal Note

1. Turn the crankshaft clockwise and align the timing

marks as shown.

Caution

•Forcefully twisting the belt, turning it

inside out, or allowing oil or grease on it

will damage the belt and shorten its life.

•After removing the timing belt, do not

move the crankshaft and/or camshaft

from this position because it can cause

the valve and piston to come into

contact.

2. Remove the timing belt auto tensioner.

3. Mark the timing belt rotation on the belt for proper

reinstallation.

49 E017 5A0

A6E2316W101

A6E2316W102

TIMING MARK TIMING MARK

TIMING MARK

A6E2316W103

25 mm {1.0 in} MIN.

FAULTY FAULTY

FAULTY

FAULTY ROTATION

ARROW

A6E2316W104

Page 43 of 909

B2–12

TIMING BELT

Timing Belt, Timing Belt Auto Tensioner Installation Note

1. Measure the tensioned rod projection length.

•If not as specified, replace the timing belt auto

tensioner.

2. Inspect the timing belt auto tensioner for oil

leakage.

•If not as specified, replace the timing belt auto

tensioner.

Projection (free length)

12.9—14.6 mm {0.508—0.574 in}

Caution

•Placing the timing belt auto tensioner

horizontally can cause oil leakage and

damage the timing belt auto tensioner. Place the timing belt auto tensioner vertically when using a

vise.

3. Verify the thrust of the timing belt auto tensioner

rod in the following order:

•If the timing belt auto tensioner rod is rigid

when it is pushed with a force of

approximately 235 N {24 kgf, 53 Ibf}, push it

down slowly and fix the pin in the hole.

•If there is no resistance on the timing belt auto

tensioner rod and it moves slightly when it is

pushed with a force of approximately 235 N

{24 kgf, 53 Ibf};

(1) Push it down slowly two or three times to the

bottom end of the rod.

(2) If the rod protrudes approximately 8.1 mm

{0.32 in}, verify that there is resistance on the

timing belt auto tensioner rod.

Caution

•To prevent damage to the inside of the

timing belt auto tensioner, do not press

down the timing belt auto tensioner rod

with a force greater than the specified

235 N {24 kgf, 53 lbf}.

Be careful that the rod does not touch the

bottom.

•If the timing belt auto tensioner rod

projection is restored, push it down slowly and fix the pin in the hole.

—If the resistance is not restored, replace the timing belt auto tensoner.

A6E2316W105

PIN

A6E2316W106

Page 44 of 909

TIMING BELT

B2–13

B2

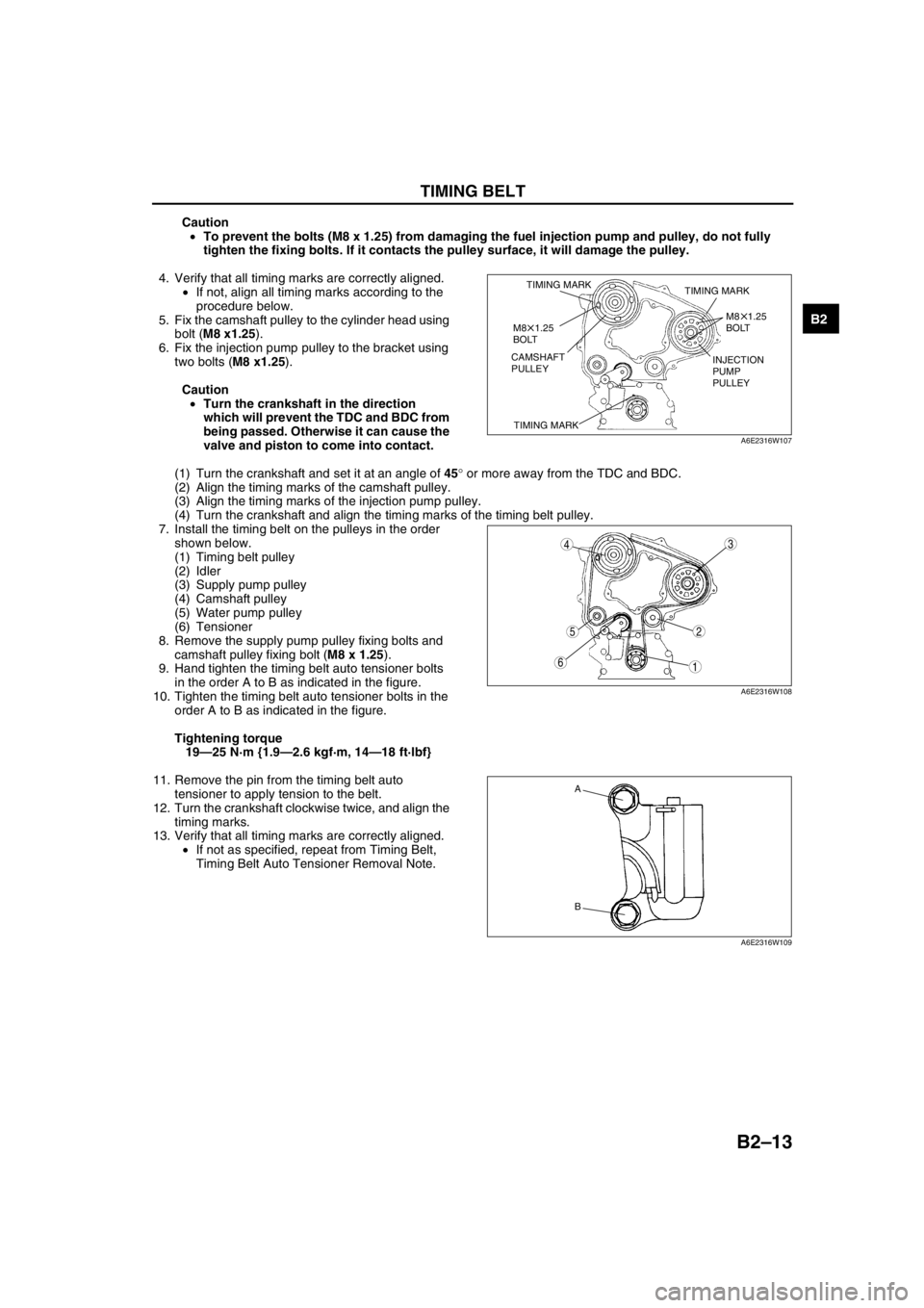

Caution

•To prevent the bolts (M8 x 1.25) from damaging the fuel injection pump and pulley, do not fully

tighten the fixing bolts. If it contacts the pulley surface, it will damage the pulley.

4. Verify that all timing marks are correctly aligned.

•If not, align all timing marks according to the

procedure below.

5. Fix the camshaft pulley to the cylinder head using

bolt (M8 x1.25).

6. Fix the injection pump pulley to the bracket using

two bolts (M8 x1.25).

Caution

•Turn the crankshaft in the direction

which will prevent the TDC and BDC from

being passed. Otherwise it can cause the

valve and piston to come into contact.

(1) Turn the crankshaft and set it at an angle of 45° or more away from the TDC and BDC.

(2) Align the timing marks of the camshaft pulley.

(3) Align the timing marks of the injection pump pulley.

(4) Turn the crankshaft and align the timing marks of the timing belt pulley.

7. Install the timing belt on the pulleys in the order

shown below.

(1) Timing belt pulley

(2) Idler

(3) Supply pump pulley

(4) Camshaft pulley

(5) Water pump pulley

(6) Tensioner

8. Remove the supply pump pulley fixing bolts and

camshaft pulley fixing bolt (M8 x 1.25).

9. Hand tighten the timing belt auto tensioner bolts

in the order A to B as indicated in the figure.

10. Tighten the timing belt auto tensioner bolts in the

order A to B as indicated in the figure.

Tightening torque

19—25 N·m {1.9—2.6 kgf·m, 14—18 ft·lbf}

11. Remove the pin from the timing belt auto

tensioner to apply tension to the belt.

12. Turn the crankshaft clockwise twice, and align the

timing marks.

13. Verify that all timing marks are correctly aligned.

•If not as specified, repeat from Timing Belt,

Timing Belt Auto Tensioner Removal Note.

TIMING MARK

TIMING MARKTIMING MARK

M8 1.25

BOLT

M8 1.25

BOLT

CAMSHAFT

PULLEYINJECTION

PUMP

PULLEY

A6E2316W107

5

43

1

2

6

A6E2316W108

A

B

A6E2316W109

Page 45 of 909

B2–14

TIMING BELT

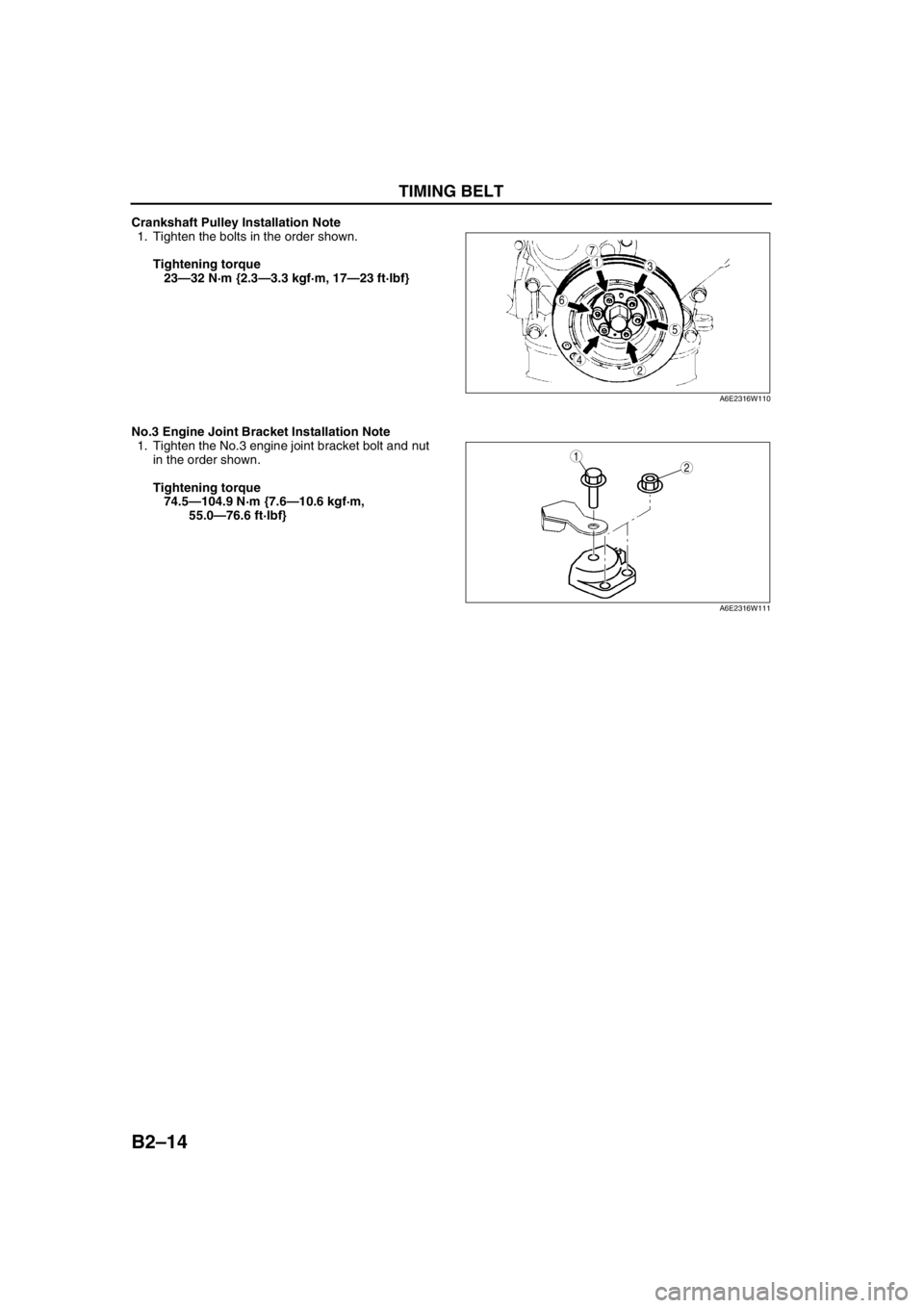

Crankshaft Pulley Installation Note

1. Tighten the bolts in the order shown.

Tightening torque

23—32 N·m {2.3—3.3 kgf·m, 17—23 ft·lbf}

No.3 Engine Joint Bracket Installation Note

1. Tighten the No.3 engine joint bracket bolt and nut

in the order shown.

Tightening torque

74.5—104.9 N·m {7.6—10.6 kgf·m,

55.0—76.6 ft·lbf}

7

5

4

3

6

1

2

A6E2316W110

12

A6E2316W111

Page 46 of 909

CYLINDER HEAD GASKET

B2–15

B2

End Of Sie

CYLINDER HEAD GASKET REPLACEMENTA6E231810271201

Warning

•Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, always complete the “Fuel Line

Safety Procedure”. (See F2–45 Fuel Line Safety Procedures.)

1. Remove the timing belt. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

2. Remove the vacuum pump. (See P–13 VACUUM PUMP REMOVAL/INSTALLATION (MZR-CD (RF

TURBO)).)

3. Remove the P/S oil pump with the oil hose still connected. Position the P/S oil pump so that it is out of the way.

Use wire or rope to secure. (See N–16 POWER STEERING OIL PUMP (MZR-CD (RF Turbo)) REMOVAL/

INSTALLATION.)

4. Remove the turbocharger. (See F2–57 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

5. Remove all the glow plugs. (See F2–42 GLOW PLUG REMOVAL/INSTALLATION.)

6. Remove in the order shown in the table.

7. Install in the reverse order of removal.

8. Inspect valve clearance. (See B2–5 VALVE CLEARANCE INSPECTION.)

9. Inspect the engine oil level.

•If necessary, add oil. (See D–8 ENGINE OIL INSPECTION.)

10. Inspect the compression. (See B2–8 COMPRESSION INSPECTION.)

11. Start the engine and:

(1) Inspect the pulleys and the drive belt for runout and contact.

(2) Inspect the engine oil, engine coolant, and fuel leakage.

(3) Inspect the idle speed. (See F2–34 IDLE SPEED INSPECTION.)

CYLINDER HEAD GASKET

Page 47 of 909

B2–16

CYLINDER HEAD GASKET

.

SST

SST

SSTR

R

R

R

R

SEALANTSEALANT

SEALANTSEALANT

SEALANTSEALANT

SEALANTSEALANT

SEALANTSEALANT

OILOIL

OILOIL

7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}

7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}

7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf} 7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}

7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}55—64

{5.6—6.6, 41—47}

38—51

{3.8—5.3,

28—38}

52—61

{5.3—6.3,

39—45}

29 {3.0, 22}

+90 105

+90 105

+90 105

50—60

{5.0—6.0,

37—44}

19—25

{1.9—2.6,

14—18}

50—60 {5.0—6.0, 37—44}

46—58 {4.6—6.0, 34—43} 59—68

{6.0—7.0, 44—50}25—30

{2.5—3.1, 18—22}

38—51

{3.8—5.3,

28—38}19—25

{1.9—2.6,

14—18}

N·m {kgf·m, ft·lbf}

98

7

54

3

1

2

10

19

18

17

15

16

14

13

11

12

20

25

24

2321

22

6

SST

55—64

{5.6—6.6, 41—47}

—

— —

39—44

{4.0—4.4,

28.8—32.4}

22—26

{2.2—2.7,

16—19}

SEALANTSEALANT

A6E2318W100

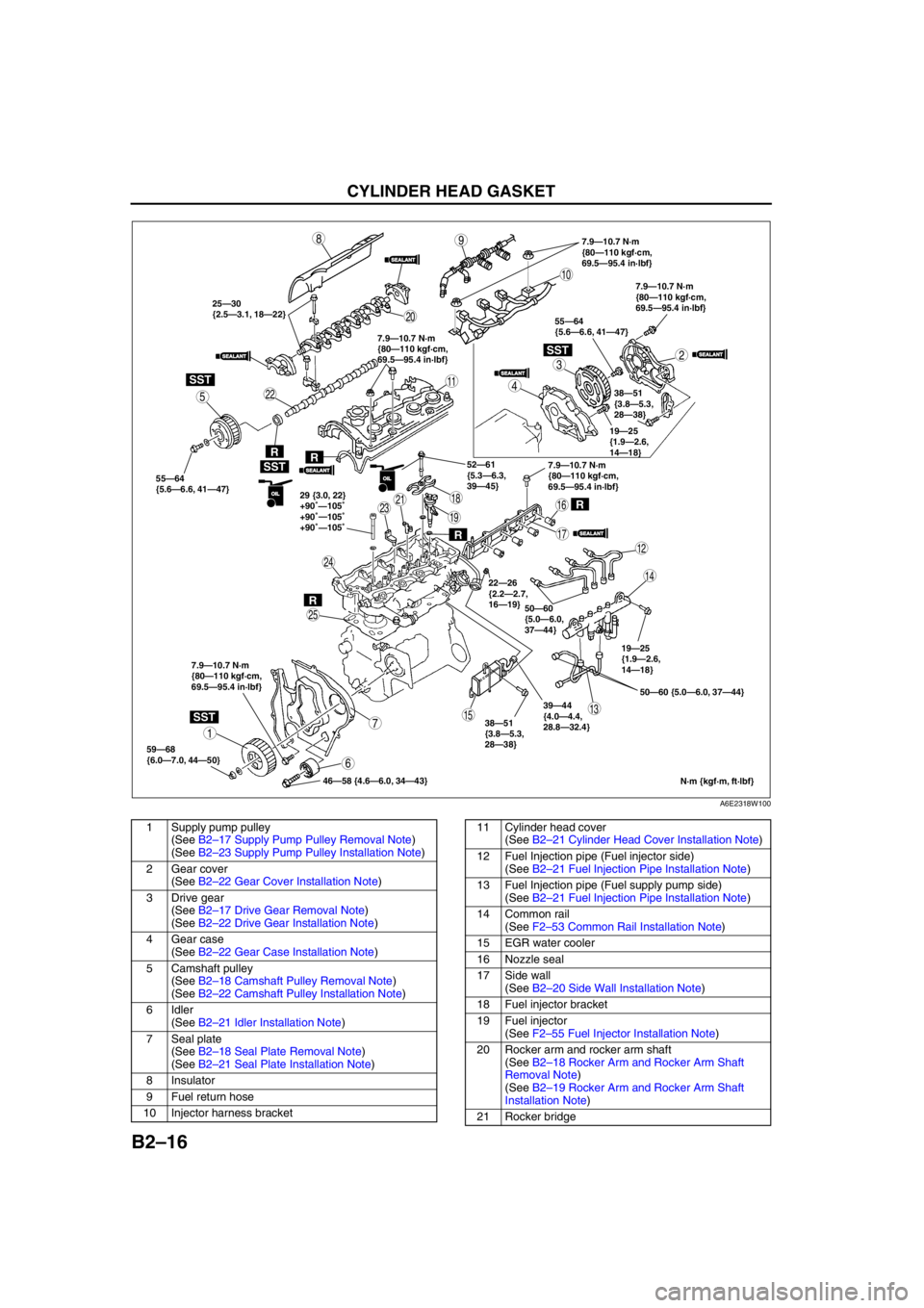

1 Supply pump pulley

(See B2–17 Supply Pump Pulley Removal Note)

(See B2–23 Supply Pump Pulley Installation Note)

2 Gear cover

(See B2–22 Gear Cover Installation Note)

3 Drive gear

(See B2–17 Drive Gear Removal Note)

(See B2–22 Drive Gear Installation Note)

4 Gear case

(See B2–22 Gear Case Installation Note)

5 Camshaft pulley

(See B2–18 Camshaft Pulley Removal Note)

(See B2–22 Camshaft Pulley Installation Note)

6 Idler

(See B2–21 Idler Installation Note)

7 Seal plate

(See B2–18 Seal Plate Removal Note)

(See B2–21 Seal Plate Installation Note)

8 Insulator

9 Fuel return hose

10 Injector harness bracket11 Cylinder head cover

(See B2–21 Cylinder Head Cover Installation Note)

12 Fuel Injection pipe (Fuel injector side)

(See B2–21 Fuel Injection Pipe Installation Note)

13 Fuel Injection pipe (Fuel supply pump side)

(See B2–21 Fuel Injection Pipe Installation Note)

14 Common rail

(See F2–53 Common Rail Installation Note)

15 EGR water cooler

16 Nozzle seal

17 Side wall

(See B2–20 Side Wall Installation Note)

18 Fuel injector bracket

19 Fuel injector

(See F2–55 Fuel Injector Installation Note)

20 Rocker arm and rocker arm shaft

(See B2–18 Rocker Arm and Rocker Arm Shaft

Removal Note)

(See B2–19 Rocker Arm and Rocker Arm Shaft

Installation Note)

21 Rocker bridge

Page 48 of 909

CYLINDER HEAD GASKET

B2–17

B2

Supply Pump Pulley Removal Note

1. Verify that timing marks are correctly aligned.

Caution

•To prevent the bolts (M8 x 1.25) from damaging the supply pump and pulley, do not fully tighten

the fixing bolts. If it contacts the pulley surface, it will damage the pulley.

2. Fix the supply pump pulley to the bracket using

two bolts (M8 x 1.25).

3. Loosen the supply pump pulley lock nut.

4. Separate the supply pump pulley from the supply

pump shaft using the SST.

5. Remove the supply pump pulley fixed bolts

(M8 x 1.25).

Drive Gear Removal Note

1. Hold the camshaft using the SST.

2. Remove the drive gear lock bolt.

22 Camshaft

23 Breather pipe24 Cylinder head

(See B2–18 Cylinder Head Removal Note)

(See B2–19 Cylinder Head Installation Note)

25 Cylinder head gasket

M8 1.25

BOLT

A6E2318W101

49 S120 215B

A6E2318W102

49 S120 710

A6E2318W103

Page 49 of 909

B2–18

CYLINDER HEAD GASKET

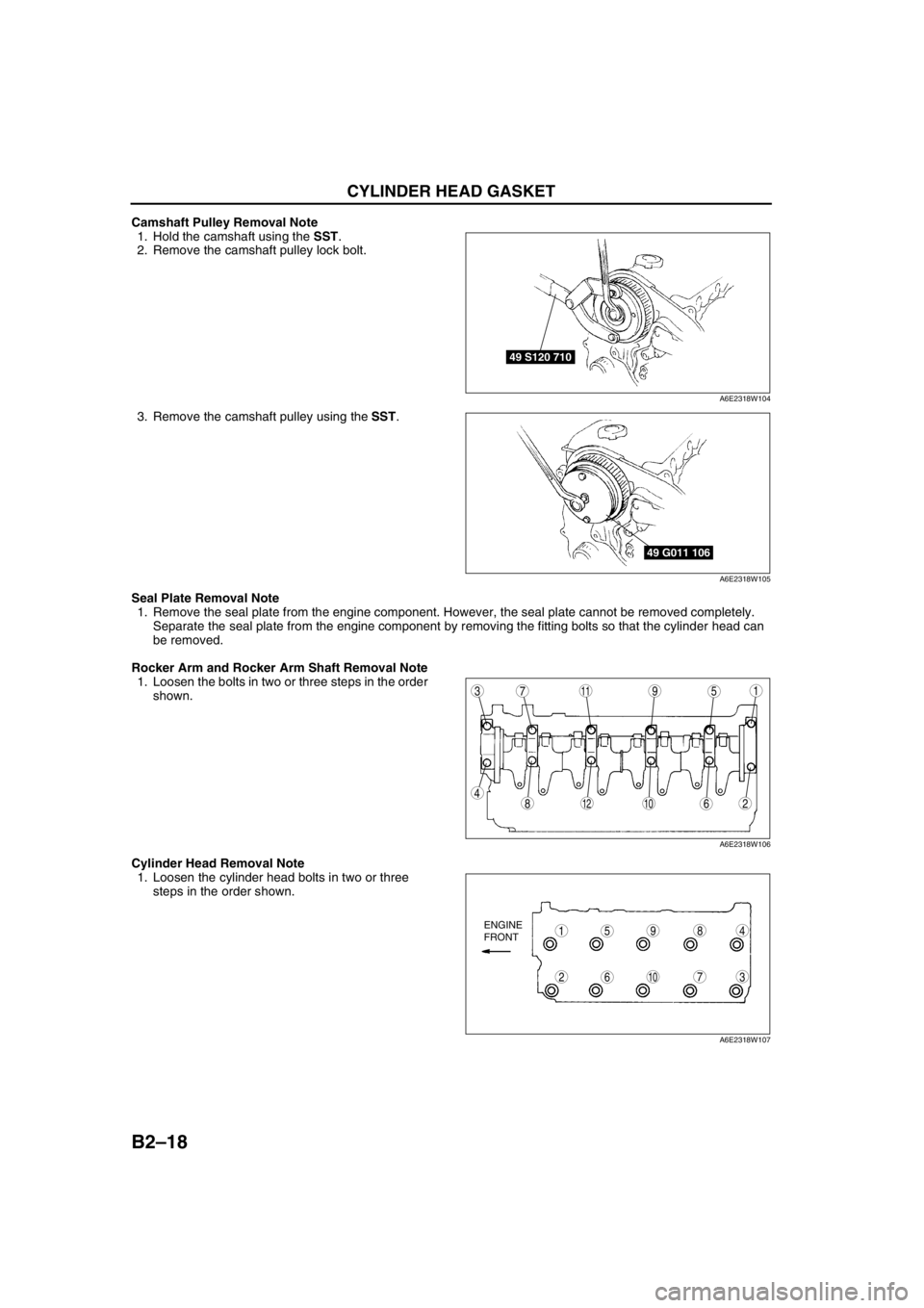

Camshaft Pulley Removal Note

1. Hold the camshaft using the SST.

2. Remove the camshaft pulley lock bolt.

3. Remove the camshaft pulley using the SST.

Seal Plate Removal Note

1. Remove the seal plate from the engine component. However, the seal plate cannot be removed completely.

Separate the seal plate from the engine component by removing the fitting bolts so that the cylinder head can

be removed.

Rocker Arm and Rocker Arm Shaft Removal Note

1. Loosen the bolts in two or three steps in the order

shown.

Cylinder Head Removal Note

1. Loosen the cylinder head bolts in two or three

steps in the order shown.

49 S120 710

A6E2318W104

49 G011 106

A6E2318W105

9

8

75

4

3

10

11

1262

1

A6E2318W106

98

7

54

3106

1

2

ENGINE

FRONT

A6E2318W107

Page 50 of 909

CYLINDER HEAD GASKET

B2–19

B2

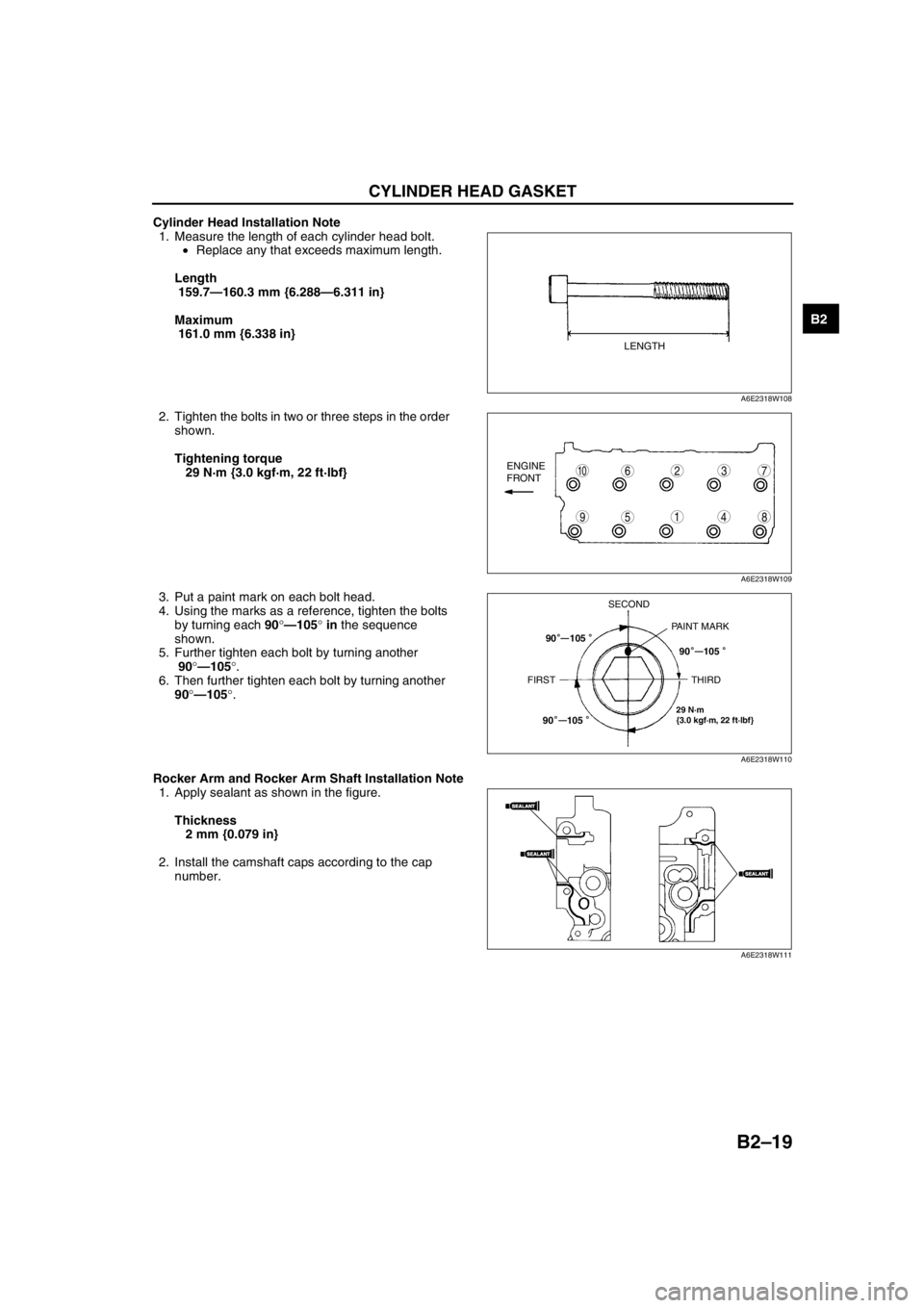

Cylinder Head Installation Note

1. Measure the length of each cylinder head bolt.

•Replace any that exceeds maximum length.

Length

159.7—160.3 mm {6.288—6.311 in}

Maximum

161.0 mm {6.338 in}

2. Tighten the bolts in two or three steps in the order

shown.

Tightening torque

29 N·m {3.0 kgf·m, 22 ft·lbf}

3. Put a paint mark on each bolt head.

4. Using the marks as a reference, tighten the bolts

by turning each 90°—105° in the sequence

shown.

5. Further tighten each bolt by turning another

90°—105°.

6. Then further tighten each bolt by turning another

90°—105°.

Rocker Arm and Rocker Arm Shaft Installation Note

1. Apply sealant as shown in the figure.

Thickness

2 mm {0.079 in}

2. Install the camshaft caps according to the cap

number.

LENGTH

A6E2318W108

98

7

54

3106

1

2ENGINE

FRONT

A6E2318W109

29 N·m

{3.0 kgf·m, 22 ft·lbf}

SECOND

PAINT MARK

FIRST THIRD90 105

90 105

90 105

—

——

A6E2318W110

SEALANTSEALANT

SEALANTSEALANT

SEALANTSEALANT

A6E2318W111