MAZDA 6 2002 Suplement Manual PDF

Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 71 of 909

OIL PRESSURE INSPECTION

D–7

D

OIL PRESSURE INSPECTIONA6E331001003201MZR-CD (RF Turbo)

Warning

•Continuous exposure to USED engine oil has caused skin cancer in laboratory mice. Protect your

skin by washing with soap and water immediately after working with engine oil.

•Hot engines and engine oil can cause severe burns. Turn off the engine and wait until it and the

engine oil have cooled.

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Remove the oil pressure switch.

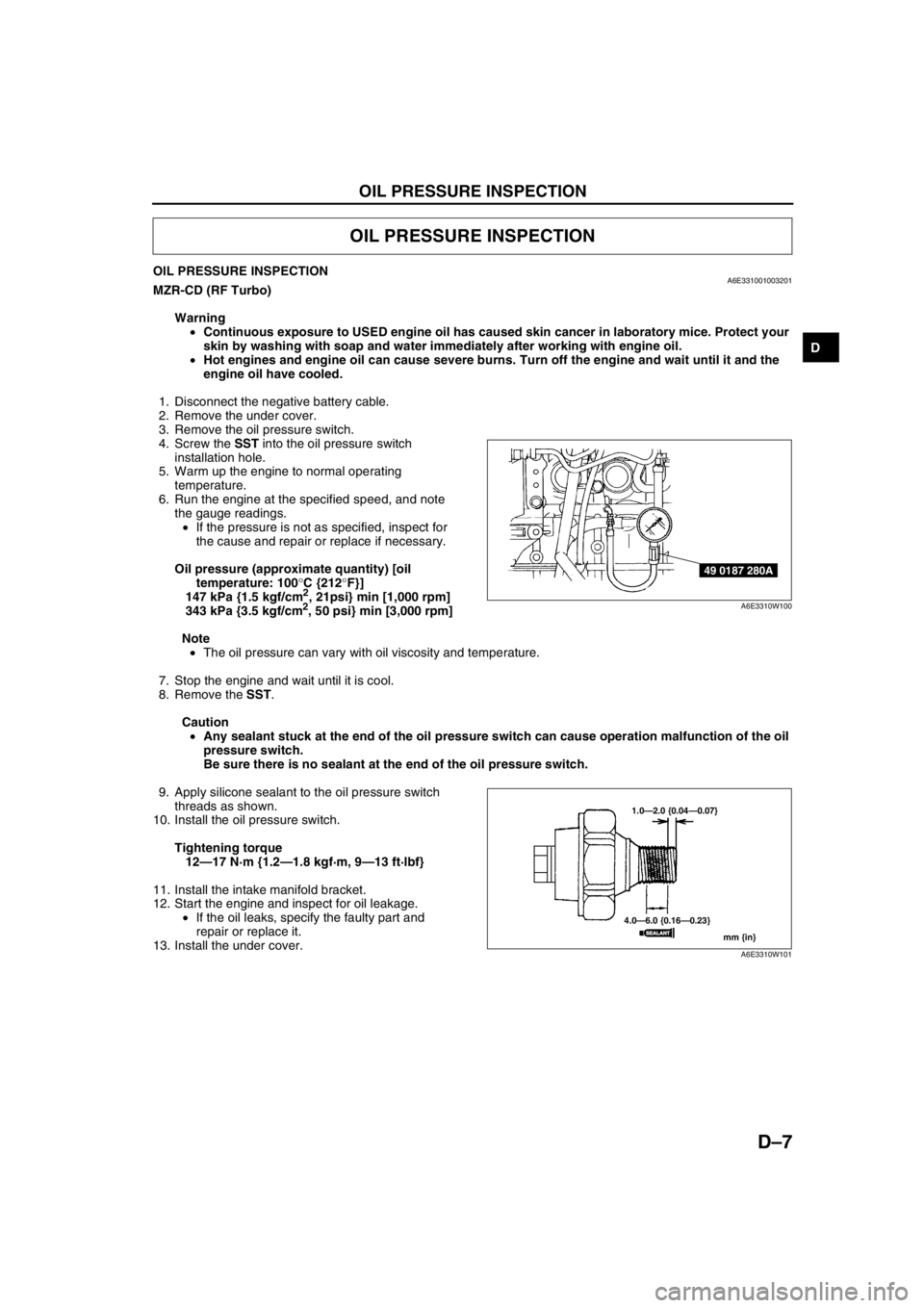

4. Screw the SST into the oil pressure switch

installation hole.

5. Warm up the engine to normal operating

temperature.

6. Run the engine at the specified speed, and note

the gauge readings.

•If the pressure is not as specified, inspect for

the cause and repair or replace if necessary.

Oil pressure (approximate quantity) [oil

temperature: 100°C {212°F}]

147 kPa {1.5 kgf/cm

2, 21psi} min [1,000 rpm]

343 kPa {3.5 kgf/cm2, 50 psi} min [3,000 rpm]

Note

•The oil pressure can vary with oil viscosity and temperature.

7. Stop the engine and wait until it is cool.

8. Remove the SST.

Caution

•Any sealant stuck at the end of the oil pressure switch can cause operation malfunction of the oil

pressure switch.

Be sure there is no sealant at the end of the oil pressure switch.

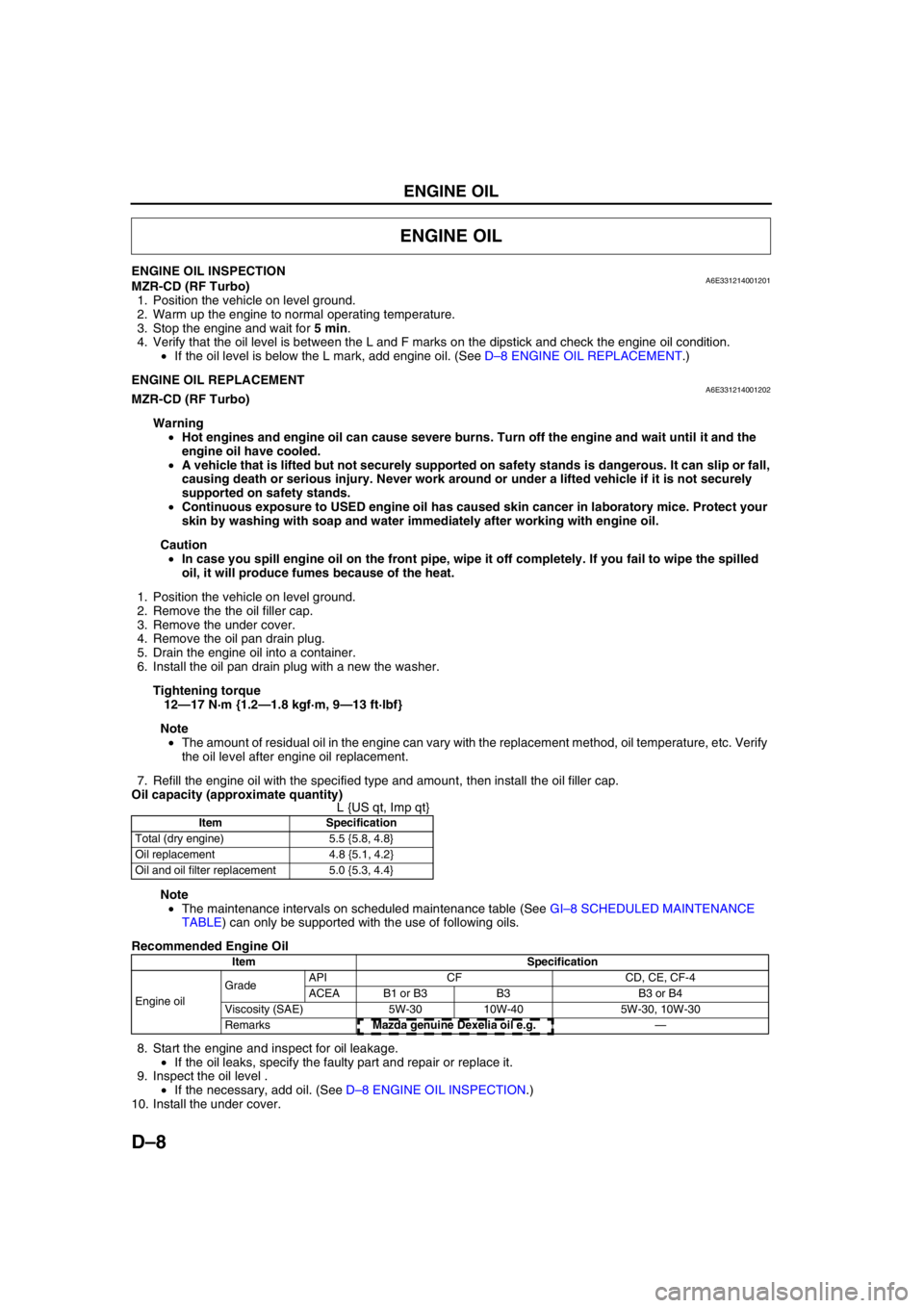

9. Apply silicone sealant to the oil pressure switch

threads as shown.

10. Install the oil pressure switch.

Tightening torque

12—17 N·m {1.2—1.8 kgf·m, 9—13 ft·lbf}

11. Install the intake manifold bracket.

12. Start the engine and inspect for oil leakage.

•If the oil leaks, specify the faulty part and

repair or replace it.

13. Install the under cover.

End Of Sie

OIL PRESSURE INSPECTION

49 0187 280A

A6E3310W100

1.0—2.0 {0.04—0.07}

4.0—6.0 {0.16—0.23}

mm {in}

SEALANTSEALANT

A6E3310W101

Page 72 of 909

D–8

ENGINE OIL

ENGINE OIL INSPECTIONA6E331214001201MZR-CD (RF Turbo)

1. Position the vehicle on level ground.

2. Warm up the engine to normal operating temperature.

3. Stop the engine and wait for 5 min.

4. Verify that the oil level is between the L and F marks on the dipstick and check the engine oil condition.

•If the oil level is below the L mark, add engine oil. (See D–8 ENGINE OIL REPLACEMENT.)

End Of SieENGINE OIL REPLACEMENTA6E331214001202MZR-CD (RF Turbo)

Warning

•Hot engines and engine oil can cause severe burns. Turn off the engine and wait until it and the

engine oil have cooled.

•A vehicle that is lifted but not securely supported on safety stands is dangerous. It can slip or fall,

causing death or serious injury. Never work around or under a lifted vehicle if it is not securely

supported on safety stands.

•Continuous exposure to USED engine oil has caused skin cancer in laboratory mice. Protect your

skin by washing with soap and water immediately after working with engine oil.

Caution

•In case you spill engine oil on the front pipe, wipe it off completely. If you fail to wipe the spilled

oil, it will produce fumes because of the heat.

1. Position the vehicle on level ground.

2. Remove the the oil filler cap.

3. Remove the under cover.

4. Remove the oil pan drain plug.

5. Drain the engine oil into a container.

6. Install the oil pan drain plug with a new the washer.

Tightening torque

12—17 N·m {1.2—1.8 kgf·m, 9—13 ft·lbf}

Note

•The amount of residual oil in the engine can vary with the replacement method, oil temperature, etc. Verify

the oil level after engine oil replacement.

7. Refill the engine oil with the specified type and amount, then install the oil filler cap.

Oil capacity (approximate quantity)

L {US qt, Imp qt}

Note

•The maintenance intervals on scheduled maintenance table (See GI–8 SCHEDULED MAINTENANCE

TABLE) can only be supported with the use of following oils.

Recommended Engine Oil

8. Start the engine and inspect for oil leakage.

•If the oil leaks, specify the faulty part and repair or replace it.

9. Inspect the oil level .

•If the necessary, add oil. (See D–8 ENGINE OIL INSPECTION.)

10. Install the under cover.

End Of Sie

ENGINE OIL

Item Specification

Total (dry engine) 5.5 {5.8, 4.8}

Oil replacement 4.8 {5.1, 4.2}

Oil and oil filter replacement 5.0 {5.3, 4.4}

Item Specification

Engine oil GradeAPI CF CD, CE, CF-4

ACEA B1 or B3 B3 B3 or B4

Viscosity (SAE) 5W-30 10W-40 5W-30, 10W-30

RemarksMazda genuine Dexelia oil e.g. —

Page 73 of 909

OIL FILTER, OIL COOLER

D–9

D

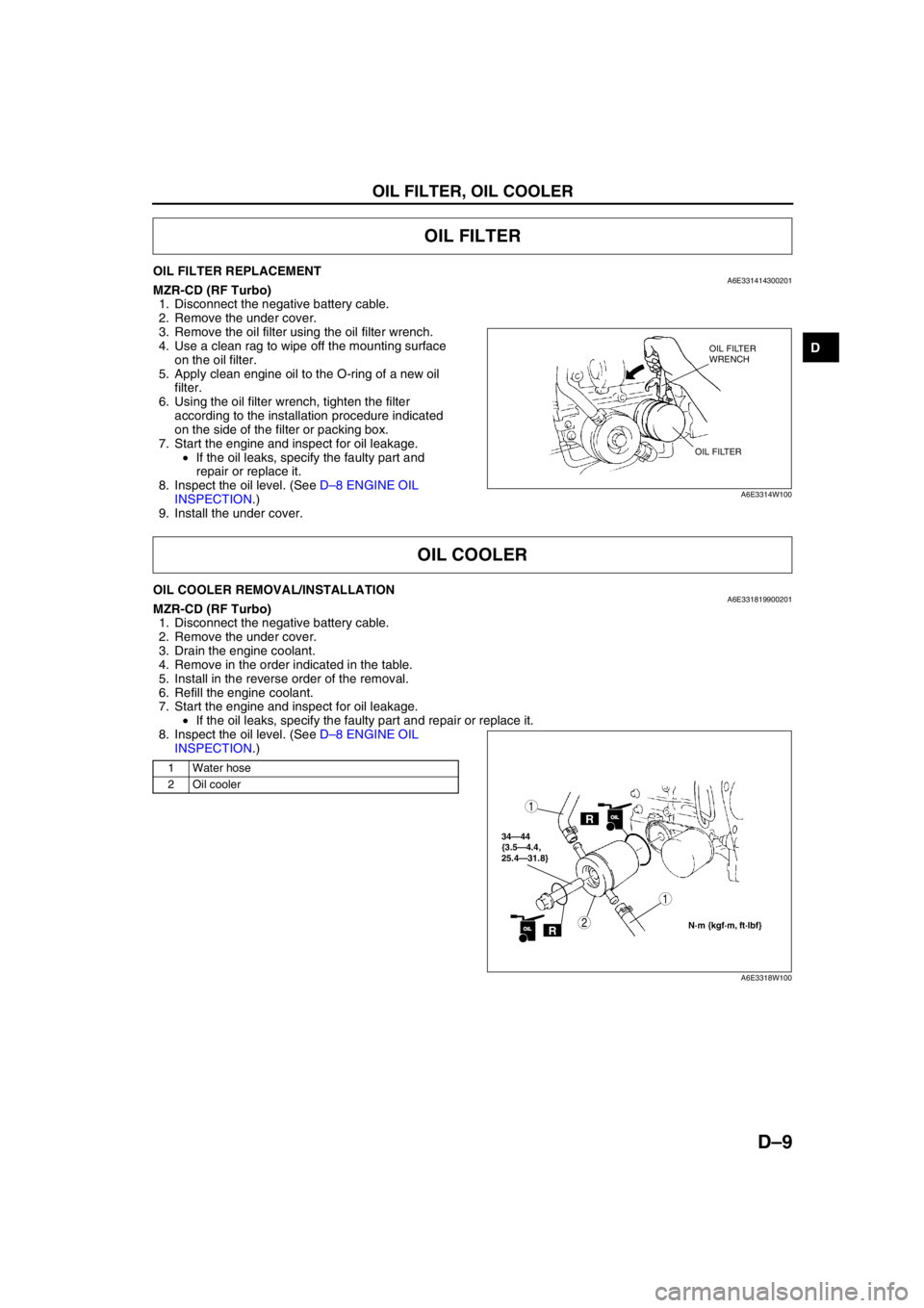

OIL FILTER REPLACEMENTA6E331414300201MZR-CD (RF Turbo)

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Remove the oil filter using the oil filter wrench.

4. Use a clean rag to wipe off the mounting surface

on the oil filter.

5. Apply clean engine oil to the O-ring of a new oil

filter.

6. Using the oil filter wrench, tighten the filter

according to the installation procedure indicated

on the side of the filter or packing box.

7. Start the engine and inspect for oil leakage.

•If the oil leaks, specify the faulty part and

repair or replace it.

8. Inspect the oil level. (See D–8 ENGINE OIL

INSPECTION.)

9. Install the under cover.

End Of Sie

OIL COOLER REMOVAL/INSTALLATIONA6E331819900201MZR-CD (RF Turbo)

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Drain the engine coolant.

4. Remove in the order indicated in the table.

5. Install in the reverse order of the removal.

6. Refill the engine coolant.

7. Start the engine and inspect for oil leakage.

•If the oil leaks, specify the faulty part and repair or replace it.

8. Inspect the oil level. (See D–8 ENGINE OIL

INSPECTION.)

.

End Of Sie

OIL FILTER

OIL FILTER

WRENCH

OIL FILTER

A6E3314W100

OIL COOLER

1 Water hose

2 Oil cooler

ROILOIL

34—44

{3.5—4.4,

25.4—31.8}

1

2N·m {kgf·m, ft·lbf}ROILOIL

1

A6E3318W100

Page 74 of 909

D–10

OIL PAN

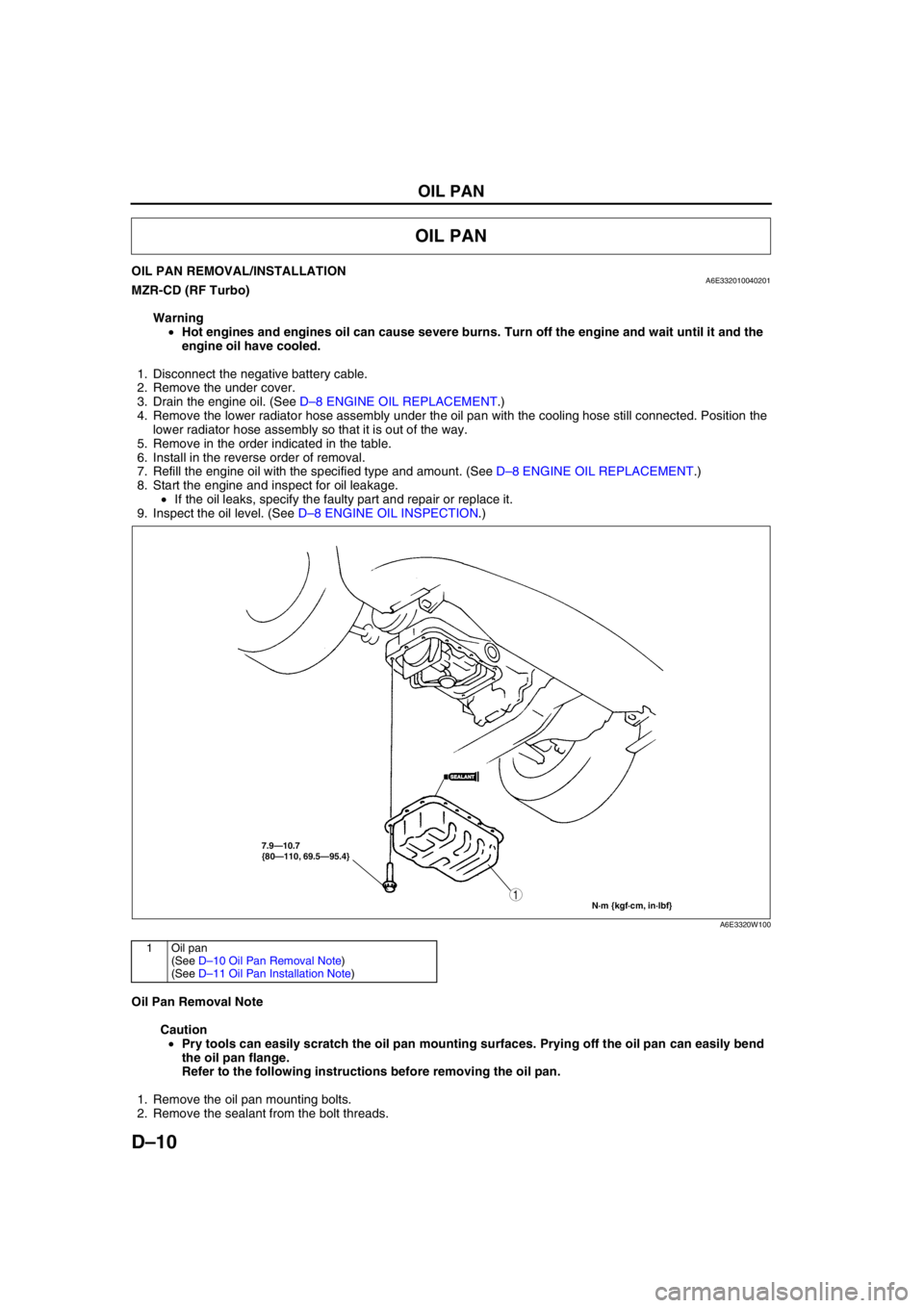

OIL PAN REMOVAL/INSTALLATIONA6E332010040201MZR-CD (RF Turbo)

Warning

•Hot engines and engines oil can cause severe burns. Turn off the engine and wait until it and the

engine oil have cooled.

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Drain the engine oil. (See D–8 ENGINE OIL REPLACEMENT.)

4. Remove the lower radiator hose assembly under the oil pan with the cooling hose still connected. Position the

lower radiator hose assembly so that it is out of the way.

5. Remove in the order indicated in the table.

6. Install in the reverse order of removal.

7. Refill the engine oil with the specified type and amount. (See D–8 ENGINE OIL REPLACEMENT.)

8. Start the engine and inspect for oil leakage.

•If the oil leaks, specify the faulty part and repair or replace it.

9. Inspect the oil level. (See D–8 ENGINE OIL INSPECTION.)

.

Oil Pan Removal Note

Caution

•Pry tools can easily scratch the oil pan mounting surfaces. Prying off the oil pan can easily bend

the oil pan flange.

Refer to the following instructions before removing the oil pan.

1. Remove the oil pan mounting bolts.

2. Remove the sealant from the bolt threads.

OIL PAN

7.9—10.7

{80—110, 69.5—95.4}

N·m {kgf·cm, in·lbf}

1

SEALANTSEALANT

A6E3320W100

1Oil pan

(See D–10 Oil Pan Removal Note)

(See D–11 Oil Pan Installation Note)

Page 75 of 909

OIL PAN

D–11

D

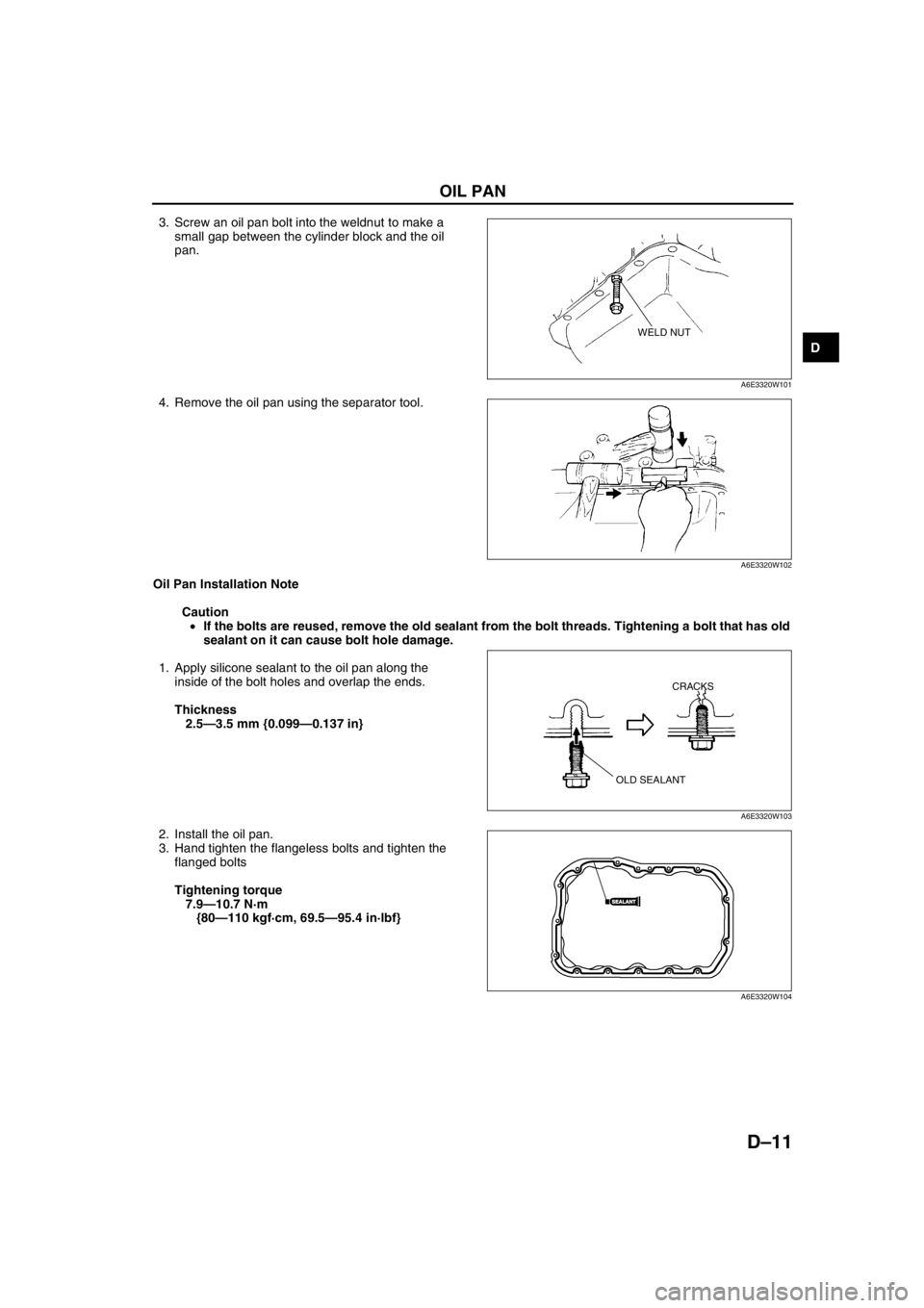

3. Screw an oil pan bolt into the weldnut to make a

small gap between the cylinder block and the oil

pan.

4. Remove the oil pan using the separator tool.

Oil Pan Installation Note

Caution

•If the bolts are reused, remove the old sealant from the bolt threads. Tightening a bolt that has old

sealant on it can cause bolt hole damage.

1. Apply silicone sealant to the oil pan along the

inside of the bolt holes and overlap the ends.

Thickness

2.5—3.5 mm {0.099—0.137 in}

2. Install the oil pan.

3. Hand tighten the flangeless bolts and tighten the

flanged bolts

Tightening torque

7.9—10.7 N·m

{80—110 kgf·cm, 69.5—95.4 in·lbf}

End Of Sie

WELD NUT

A6E3320W101

A6E3320W102

OLD SEALANTCRACKS

A6E3320W103

SEALANTSEALANT

A6E3320W104

Page 76 of 909

E–1

E

ECOOLING SYSTEM

OUTLINE................................................................ E-2

OUTLINE OF CONSTRUCTION.......................... E-2

FEATURES .......................................................... E-2

SPECIFICATIONS ............................................... E-3

COOLING SYSTEM................................................ E-4

STRUCTURAL VIEW ........................................... E-4

COOLING FLOW DIAGRAM ............................... E-5

COOLING FAN .................................................... E-5

OUTLINE................................................................ E-6

SUPPLEMENTAL SERVICE INFORMATION ..... E-6

LOCATION INDEX ............................................... E-6

RADIATOR CAP..................................................... E-7

RADIATOR CAP INSPECTION ........................... E-7

ENGINE COOLANT................................................ E-8

ENGINE COOLANT LEAKAGE INSPECTION .... E-8

THERMOSTAT....................................................... E-9

THERMOSTAT REMOVAL/INSTALLATION ....... E-9

THERMOSTAT INSPECTION ........................... E-10

WATER PUMP...................................................... E-11

WATER PUMP REMOVAL/INSTALLATION...... E-11

FAN MOTOR........................................................ E-12

COOLING FAN MOTOR

REMOVAL/INSTALLATION ............................ E-12

COOLING FAN MOTOR INSPECTION ............. E-13 FEATURES

SERVICE

Page 77 of 909

E–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E360202000205•The construction and operation of the water pump and the thermostat for the new Mazda6 (GG, GY) MZR-CD

(RF Turbo) engine model are the same as the current Mazda 323 (BJ) RF Turbo engine model. (European

specs.) (See Mazda 323 RF Turbo Workshop Manual Supplement 1633-10-98G.)

•The construction and operation of the cooling system except for the water pump and the thermostat for the new

Mazda6 (GG, GY) MZR-CD (RF Turbo) engine model are the same as the current Mazda6 (GG) L3 engine

model except for the following features. (See Mazda6 Training Manual 3359-1*-02C.)

•The construction and operation of the engine cooling system for the new Mazda6 (GG, GY) L8, LF, and L3

engine models is the same as the current Mazda6 (GG) L8, LF, and L3 engine models. (See Mazda6 Training

Manual 3359-1*-02C.)

End Of Sie

FEATURESA6E360202000206Modification to fit the engine performance

•Cooling fan motor output has been changed. (MZR-CD (RF Turbo) engine model)

End Of Sie

OUTLINE

Page 78 of 909

OUTLINE

E–3

E

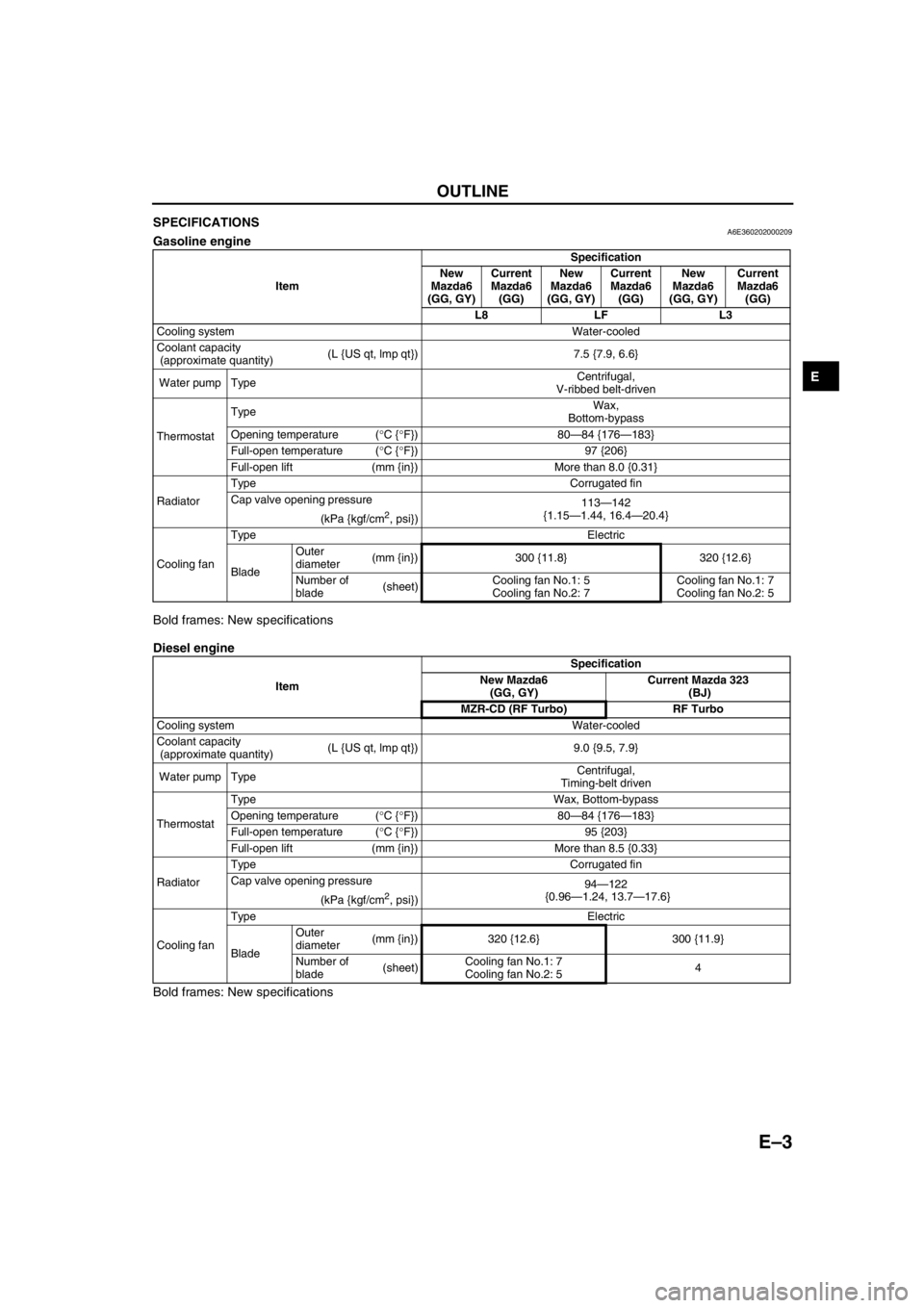

SPECIFICATIONSA6E360202000209Gasoline engine

Bold frames: New specifications

Diesel engine

Bold frames: New specifications

End Of Sie

ItemSpecification

New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)

L8 LF L3

Cooling system Water-cooled

Coolant capacity

(approximate quantity)(L {US qt, lmp qt}) 7.5 {7.9, 6.6}

Water pump TypeCentrifugal,

V-ribbed belt-driven

ThermostatTypeWax,

Bottom-bypass

Opening temperature (°C {°F}) 80—84 {176—183}

Full-open temperature (°C {°F}) 97 {206}

Full-open lift (mm {in}) More than 8.0 {0.31}

RadiatorType Corrugated fin

Cap valve opening pressure

113—142

{1.15—1.44, 16.4—20.4}

(kPa {kgf/cm

2, psi})

Cooling fanType Electric

BladeOuter

diameter(mm {in}) 300 {11.8} 320 {12.6}

Number of

blade(sheet)Cooling fan No.1: 5

Cooling fan No.2: 7Cooling fan No.1: 7

Cooling fan No.2: 5

ItemSpecification

New Mazda6

(GG, GY)Current Mazda 323

(BJ)

MZR-CD (RF Turbo) RF Turbo

Cooling system Water-cooled

Coolant capacity

(approximate quantity)(L {US qt, lmp qt}) 9.0 {9.5, 7.9}

Water pump TypeCentrifugal,

Timing-belt driven

ThermostatType Wax, Bottom-bypass

Opening temperature (°C {°F}) 80—84 {176—183}

Full-open temperature (°C {°F}) 95 {203}

Full-open lift (mm {in}) More than 8.5 {0.33}

RadiatorType Corrugated fin

Cap valve opening pressure

94—122

{0.96—1.24, 13.7—17.6}

(kPa {kgf/cm

2, psi})

Cooling fanType Electric

BladeOuter

diameter(mm {in}) 320 {12.6} 300 {11.9}

Number of

blade(sheet)Cooling fan No.1: 7

Cooling fan No.2: 54

Page 79 of 909

E–4

COOLING SYSTEM

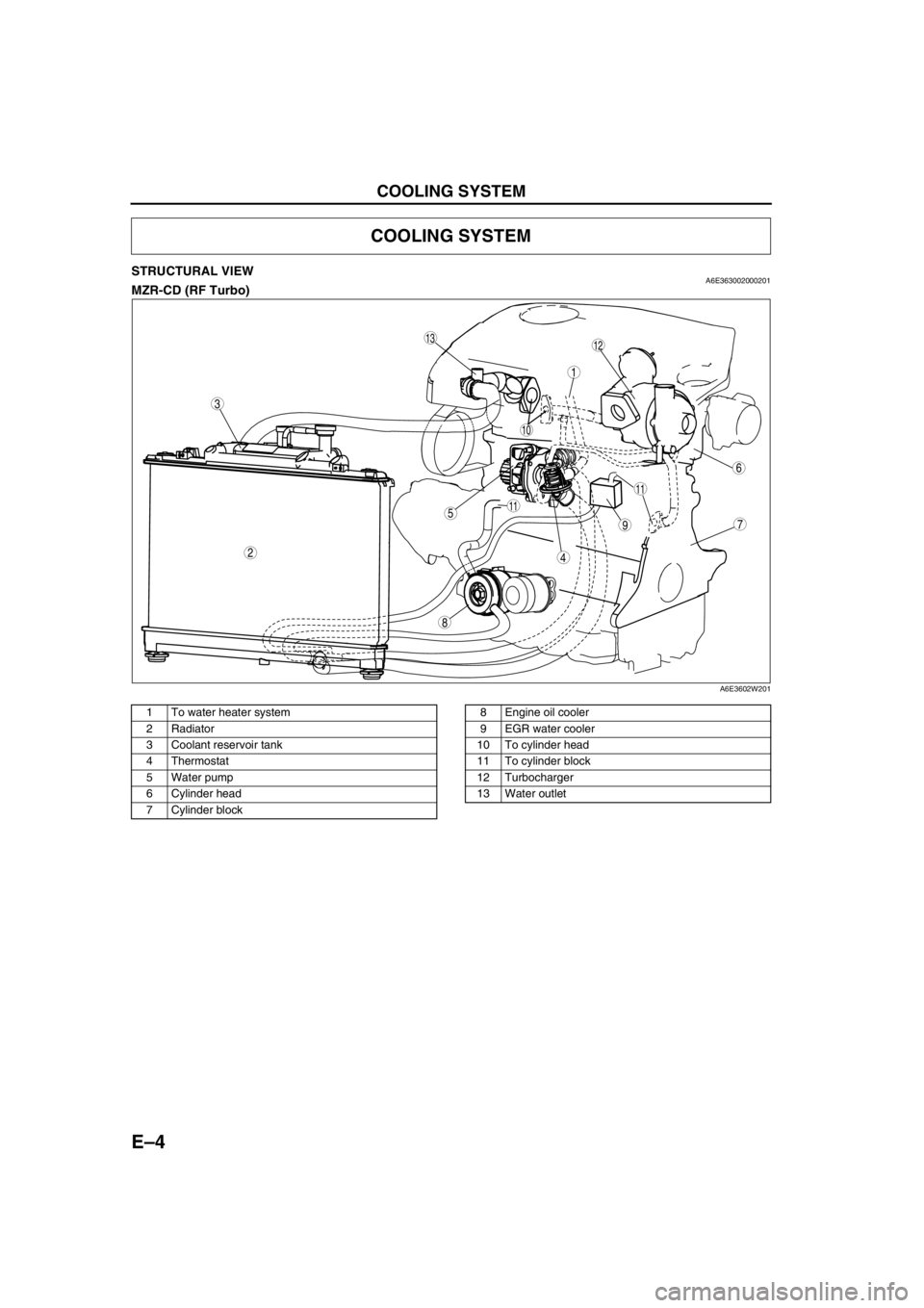

STRUCTURAL VIEWA6E363002000201MZR-CD (RF Turbo)

.

End Of Sie

COOLING SYSTEM

8

75

4

3

1

2

6

10

11

11

9

1312

A6E3602W201

1 To water heater system

2 Radiator

3 Coolant reservoir tank

4Thermostat

5 Water pump

6 Cylinder head

7 Cylinder block8 Engine oil cooler

9EGR water cooler

10 To cylinder head

11 To cylinder block

12 Turbocharger

13 Water outlet

Page 80 of 909

COOLING SYSTEM

E–5

E

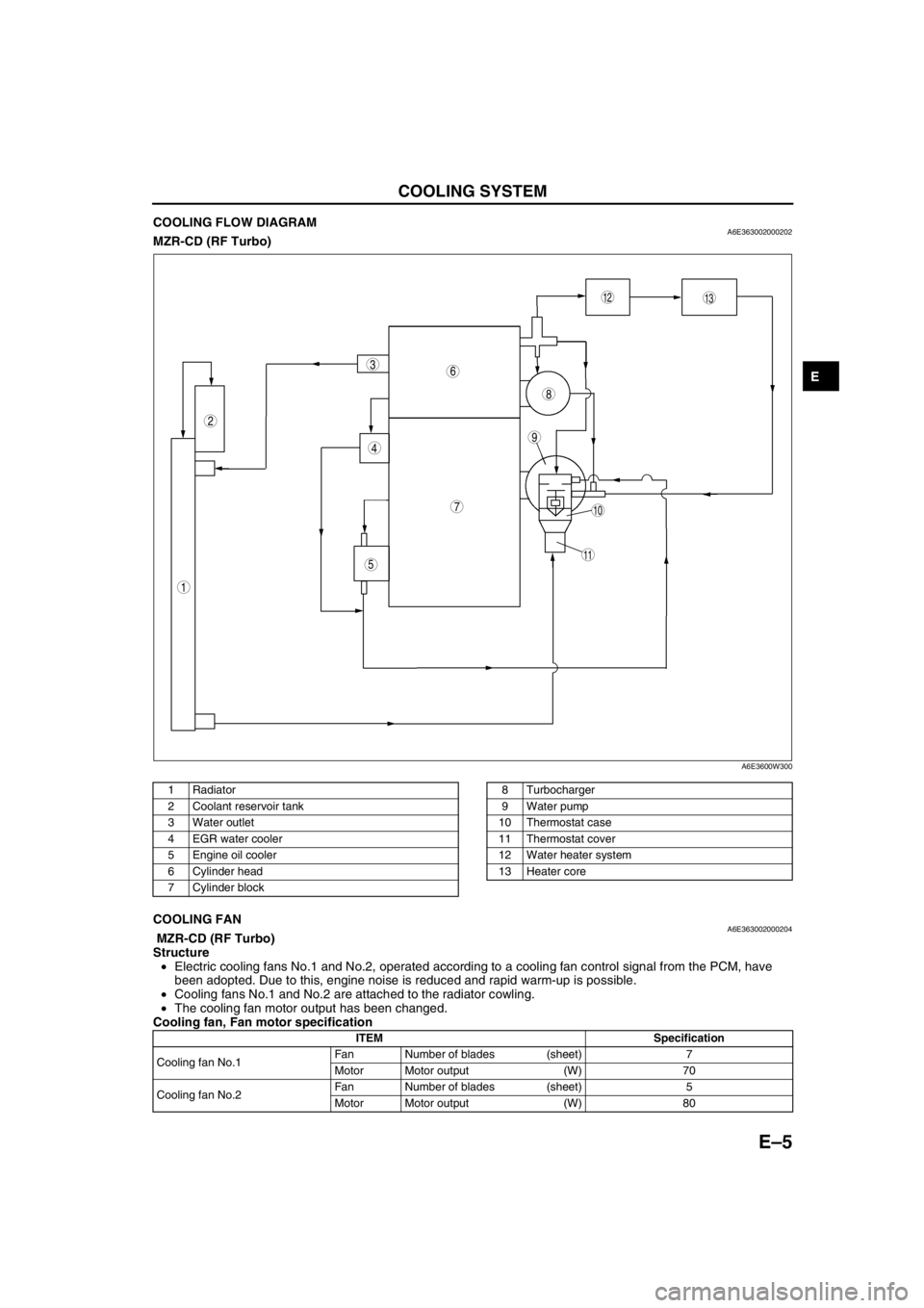

COOLING FLOW DIAGRAMA6E363002000202MZR-CD (RF Turbo)

.

End Of SieCOOLING FANA6E363002000204 MZR-CD (RF Turbo)

Structure

•Electric cooling fans No.1 and No.2, operated according to a cooling fan control signal from the PCM, have

been adopted. Due to this, engine noise is reduced and rapid warm-up is possible.

•Cooling fans No.1 and No.2 are attached to the radiator cowling.

•The cooling fan motor output has been changed.

Cooling fan, Fan motor specification

End Of Sie

9

8

7

5

4

3

1

2

10

13

11

12

6

A6E3600W300

1Radiator

2 Coolant reservoir tank

3 Water outlet

4EGR water cooler

5 Engine oil cooler

6 Cylinder head

7 Cylinder block8 Turbocharger

9 Water pump

10 Thermostat case

11 Thermostat cover

12 Water heater system

13 Heater core

ITEM Specification

Cooling fan No.1Fan Number of blades (sheet) 7

Motor Motor output (W) 70

Cooling fan No.2Fan Number of blades (sheet) 5

Motor Motor output (W) 80