MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1781 of 1865

15 HEATER

86U15X-218

86U15X-219

86U15X-220

r.". 1

T 1 11 1.11 -4

y -L -v* X /

1

C I y

1 A +

Voltmeter

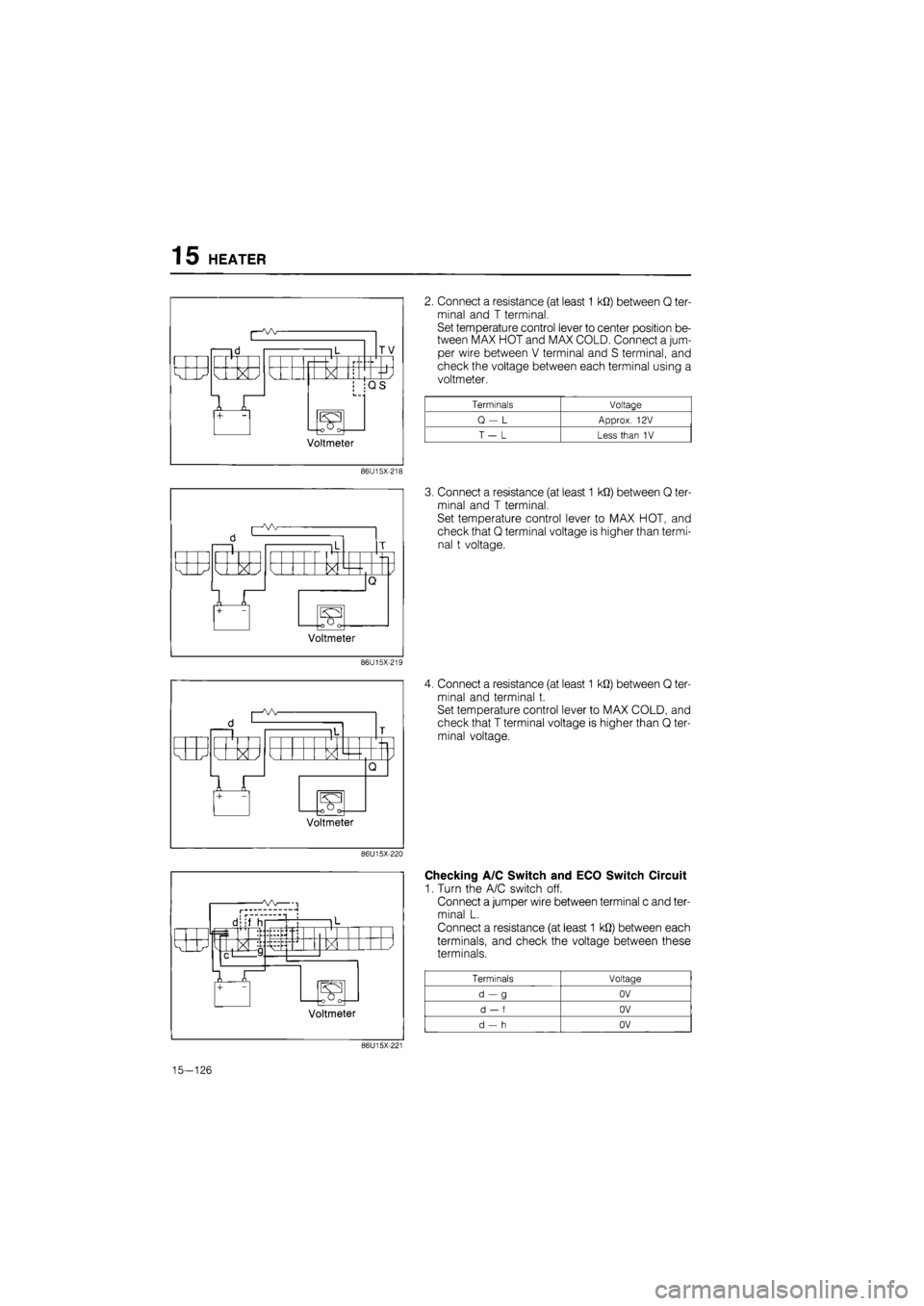

2. Connect a resistance (at least 1 kfi) between Q ter-

minal and T terminal.

Set temperature control lever to center position be-

tween MAX HOT and MAX COLD. Connect a jum-

per wire between V terminal and S terminal, and

check the voltage between each terminal using a

voltmeter.

Terminals Voltage

Q - L Approx. 12V

T - L Less than 1V

3. Connect a resistance (at least 1 kfi) between Q ter-

minal and T terminal.

Set temperature control lever to MAX HOT, and

check that Q terminal voltage is higher than termi-

nal t voltage.

4. Connect a resistance (at least 1 M2) between Q ter-

minal and terminal t.

Set temperature control lever to MAX COLD, and

check that T terminal voltage is higher than Q ter-

minal voltage.

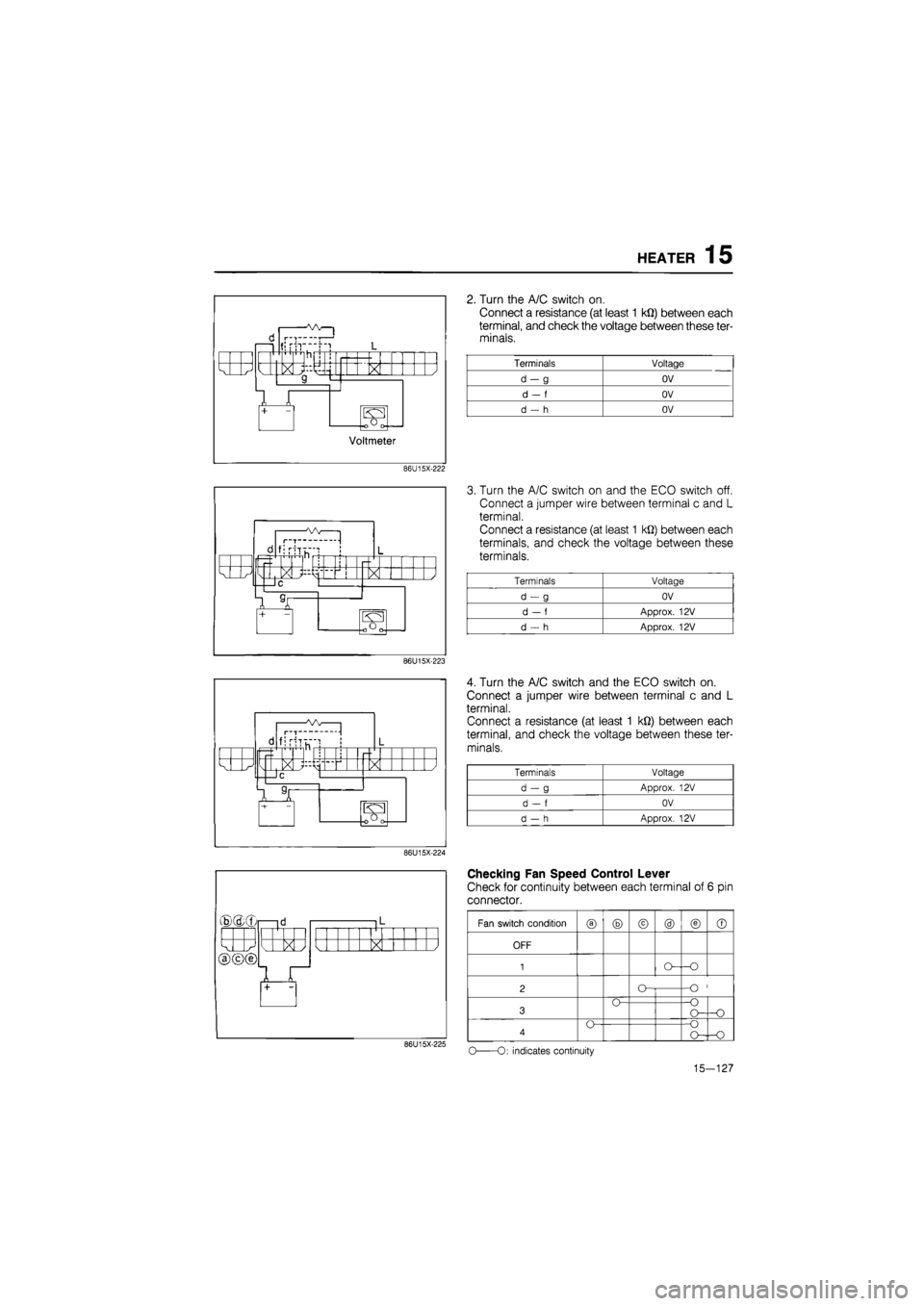

Checking A/C Switch and ECO Switch Circuit

1. Turn the A/C switch off.

Connect a jumper wire between terminal c and ter-

minal L.

Connect a resistance (at least 1 kQ) between each

terminals, and check the voltage between these

terminals.

Terminals Voltage

d-g OV

d - f OV

d - h OV

86U15X-221

15-126

Page 1782 of 1865

HEATER 15

f! !"H

a

+

1 d-V' X /

S3

Voltmeter

86U15X-222

2. Turn the A/C switch on.

Connect a resistance (at least 1 kQ) between each

terminal, and check the voltage between these ter-

minals.

Terminals Voltage

d-g OV

d

- f

OV

d

- h

OV

d I—T-

fjrh

X }

®(dxr

X /

86U15X-223

d fi riTu~"! 1 L r-

k J M > < / —IC

7 T — 101 [oOrv

86U15X-224

X

86U15X-225

3. Turn the A/C switch on and the ECO switch off.

Connect a jumper wire between terminal c and L

terminal.

Connect a resistance (at least 1 kQ) between each

terminals, and check the voltage between these

terminals.

Terminals Voltage

d-g OV

d

- f

Approx.

12V

d

- h

Approx.

12V

4. Turn the A/C switch and the ECO switch on.

Connect a jumper wire between terminal c and L

terminal.

Connect a resistance (at least 1 kQ) between each

terminal, and check the voltage between these ter-

minals.

Terminals Voltage

d-g Approx.

12V

d

- f

OV

d

- h

Approx.

12V

Checking Fan Speed Control Lever

Check for continuity between each terminal of 6 pin

connector.

Fan switch condition

® ® © @ © ©

OFF

1

2 O--O

3 O--O O— -O

4 O--O O--O

o

-O: indicates continuity

15-127

Page 1783 of 1865

15 HEATER

i l< i |l

k J X / X X L<

1 +

L<

1 + 1

Checking Dim Indicator Circuits

(Indicator circuit)

1. Connect a jumper wire-between terminal c and ter-

minal L.

Check for illumination at A/C switch indicator with

A/C switch on.

Check for illumination at ECO switch indicator with

ECO switch on.

86U15X-226

d 1 |L

k J X / I k

1 Jl +

2. Check that the mode control switch and REC-

FRESH select switch indicators when the respec-

tive switches ON.

86U15X-227

3. Apply 12V to terminal a, and check that the indi-

cators are dim.

86U15X-228

b —id 1 L

1 1 j

k XI N_ > < / a

ir

Checking Illumination Circuit

1. Connect a jumper wire between terminal b and ter-

minal L.

2. Apply 12V to terminal a, and check that the indi-

cators are dim.

86U15X-229

15-128

Page 1784 of 1865

16

AIR CONDITIONING

SYSTEM

OUTLINE 16— 2

AIR DISTRIBUTION 16— 2

AIR CONDITIONING COMPONENTS 16— 4

TROUBLESHOOTING GUIDE 16— 5

CIRCUIT DIAGRAM 16— 6

REFRIGERATION SYSTEM 16— 8

COMPRESSOR 16—13

ON-VEHICLE INSPECTION 16—13

REMOVAL OF COMPRESSOR 16—13

DISASSEMBLY OF MAGNETIC

CLUTCH 16—14

DISASSEMBLY OF COMPRESSOR 16—16

ASSEMBLY OF COMPRESSOR 16—18

ASSEMBLY OF MAGNETIC CLUTCH 16—20

PERFORMANCE TEST OF

COMPRESSOR 16—22

INSTALLATION OF COMPRESSOR 16—23

CONDENSER 16—24

ON-VEHICLE INSPECTION 16—24

REMOVAL OF CONDENSER 16—24

INSTALLATION OF CONDENSER.. 16—24

RECEIVER-DRIER 16—25

ON-VEHICLE INSPECTION 16—25

REMOVAL OF RECEIVER-DRIER... 16—25

INSTALLATION OF

RECEIVER-DRIER 16—25

COOLING UNIT 16—26

ON-VEHICLE INSPECTION OF

EXPANSION VALVE 16—26

REMOVAL OF COOLING UNIT 16—26

DISASSEMBLY OF COOLING UNIT 16—27

INSPECTION OF EVAPORATOR.... 16—27

ASSEMBLY OF COOLING UNIT.... 16—27

INSTALLATION OF COOLING UNIT 16—28

REFRIGERANT LINES 16—29

ON-VEHICLE INSPECTION 16—29

REPLACEMENT OF REFRIGERANT

LINES 16—29

A/C RELAY 16—30

REMOVAL OF RELAY 16—30

INSPECTION OF A/C RELAY 16—30

INSTALLATION OF A/C RELAY 16—30

THERMOSTAT 16—30

ON-VEHICLE INSPECTION 16—30

REMOVAL OF THERMOSTAT 16-30

INSTALLATION OF THERMOSTAT. 16—30

REFRIGERANT PRESSURE SWITCH 16—31

76G16X-001

Page 1785 of 1865

16 OUTLINE

OUTLINE

AIR DISTRIBUTION

Vehicles with air conditioner

Side ventilator outlet

1

Center ventilator outlet

- Defroster = outlet

FRESH air inlet

REC air inlet

Side . ventilator < outlet

Floor outlet

Temperature control lever

*

REC-FRESH air selector lever

•QDOODDDaaacziciz) ^^^ ° cQ^

^J 'i, *

OFF

1 7 3 4

Mode control lever

Mode control switch

A/C

DECO

Blower switch

REC-FRESH air selector switch

«?/ ^ W ^

izzi • izn •

C^) A/C - ECDN

• CUD

<=i ac3 a ua • • Jf OFF 12 3 4. SJ

Temperature control lever Blower switch

69G16X002

16-2

Page 1786 of 1865

OUTLINE 16

The air distribution is shown in the figure.

"I.The door (D1) is used to select either fresh air from outside or recirculated air. Setting the

RECIRC/FRESH control lever (switch) to the FRESH position will allow outside air to come inside.

Setting the RECIRC/FRESH control lever (switch) to the RECIRC position will allow inside air to recir-

culate.

2. Outlet airflow is controlled by doors D3, D4, D5.

Moving (pushing) the mode control lever (switch) opens and shuts the doors (D3, D4, D5) and cre-

ates the air passage according to the lever position.

1) Setting the lever to the VENT position (push the VENT switch) creates the air passage to the venti-

lator outlets, and air comes into the passenger compartment from the ventilator outlets.

2) Setting the lever to the BI-LEVEL position (push the BI-LEVEL switch) creates the air passage

to the ventilator outlets and to the floor outlets.

3) Setting the lever to the HEAT position (push the HEAT switch) creates the air passage to the floor

outlets.

(A little air comes from the defroster outlets.)

4) Setting the lever to the DEF/HEAT position (push the DEF/HEAT switch) creates the air passage

to the floor outlets and to the defroster outlets.

5) Setting the lever to the DEF position (push the DEF switch) creates the air passage to the defroster

outlets.

3. The cooling or heating temperature is controlled by doors D2.

76G16X-002

16-3

Page 1787 of 1865

16 OUTLINE

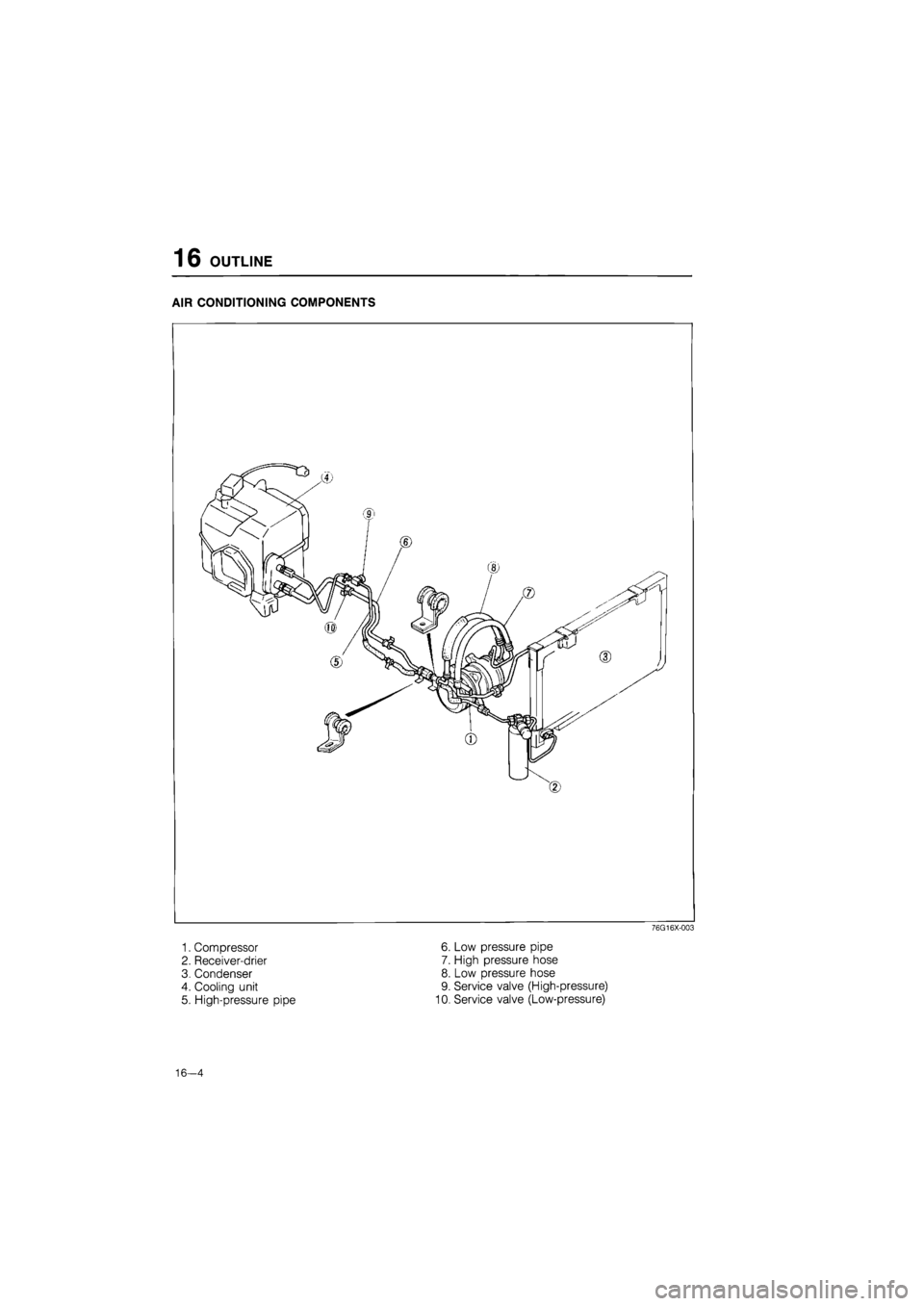

AIR CONDITIONING COMPONENTS

76G16X-003

1. Compressor 6. Low pressure pipe

2. Receiver-drier 7. High pressure hose

3. Condenser 8. Low pressure hose

4. Cooling unit 9. Service valve (High-pressure)

5. High-pressure pipe 10. Service valve (Low-pressure)

16—4

Page 1788 of 1865

OUTLINE 16

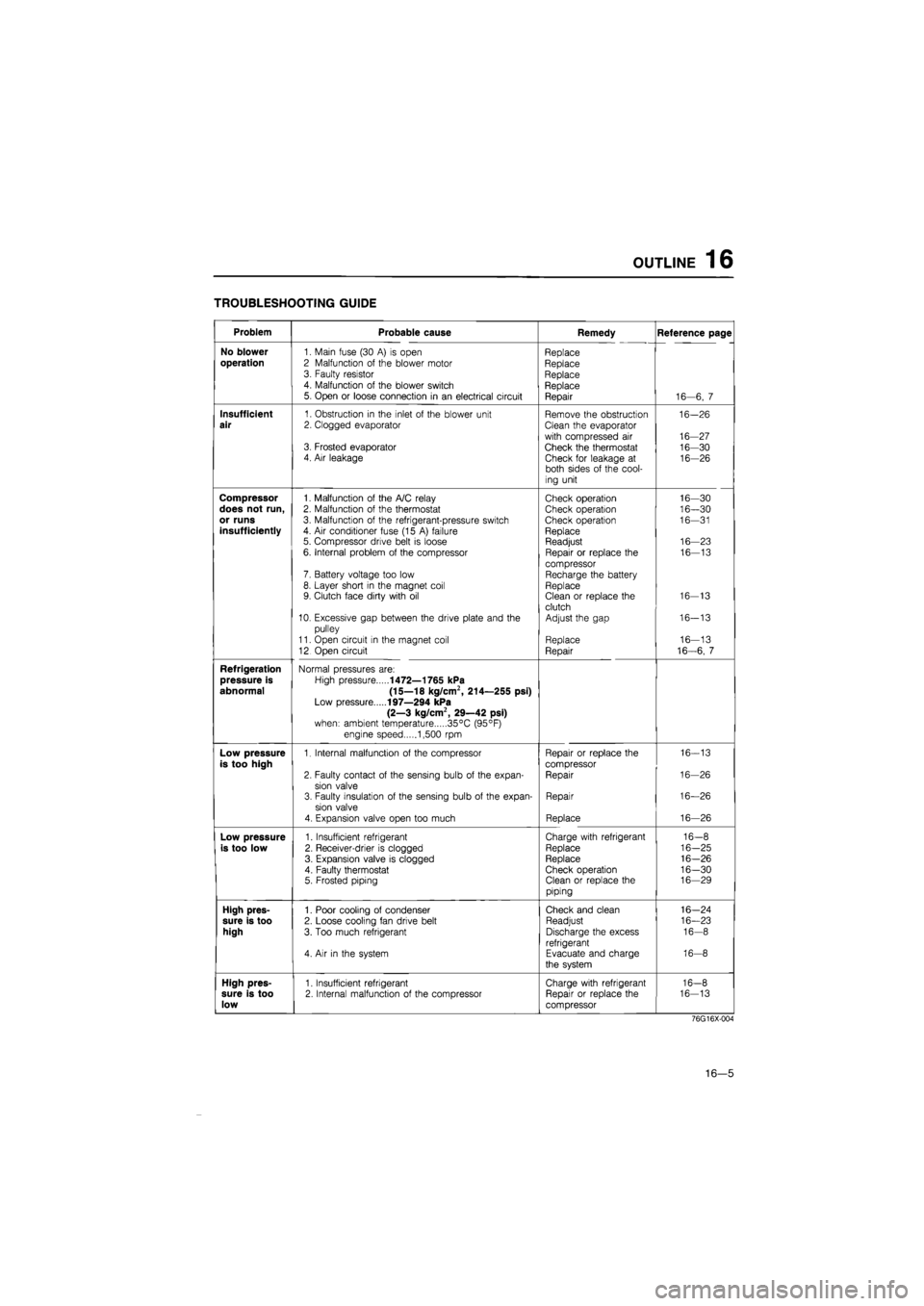

TROUBLESHOOTING GUIDE

Problem Probable cause Remedy Reference page

No blower

1. Main fuse (30

A) is

open Replace

operation

2 Malfunction

of

the blower motor Replace 3. Faulty resistor Replace 4. Malfunction

of

the blower switch Replace 5. Open

or

loose connection

in an

electrical circuit Repair 16—6,

7

Insufficient

1. Obstruction

in

the inlet

of

the blower unit Remove the obstruction 16-26

air

2. Clogged evaporator Clean the evaporator

with compressed

air

16-27 3. Frosted evaporator Check the thermostat 16-30 4. Air leakage Check for leakage

at

16-26 both sides

of

the cool-

ing unit

Compressor

1. Malfunction

of

the A/C relay Check operation 16—30

does not run,

2. Malfunction

of

the thermostat Check operation 16—30

or runs

3. Malfunction

of

the refrigerant-pressure switch Check operation 16—31

insufficiently

4.

Air

conditioner fuse (15

A)

failure Replace 5. Compressor drive belt

is

loose Readjust 16—23

6. Internal problem

of

the compressor Repair

or

replace

the

16—13

compressor 7. Battery voltage too low Recharge the battery 8. Layer short

in

the magnet coil Replace 9. Clutch face dirty with

oil

Clean

or

replace the 16-13

clutch 10. Excessive gap between the drive plate and

the

Adjust the gap 16-13

pulley

11. Open circuit

in

the magnet coil Replace 16—13

12 Open circuit Repair 16-6,

7

Refrigeration

Normal pressures are:

pressure is

High pressure

1472—1765 kPa

abnormal (15—18 kg/cm2, 214—255 psi)

Low pressure

197—294 kPa

(2—3 kg/cm2, 29—42 psi)

when: ambient temperature 35°C (95°F)

engine speed 1,500

rpm

Low pressure

1. Internal malfunction

of

the compressor Repair

or

replace the 16-13

is too high

compressor

2. Faulty contact

of

the sensing bulb

of

the expan-Repair 16-26

sion valve 3. Faulty insulation

of

the sensing bulb

of

the expan-Repair 16—26

sion valve

4. Expansion valve open too much Replace 16—26

Low pressure

1. Insufficient refrigerant Charge with refrigerant 16-8

is too low

2. Receiver-drier

is

clogged Replace 16-25

3. Expansion valve

is

clogged Replace 16-26

4. Faulty thermostat Check operation 16-30 5. Frosted piping Clean

or

replace the 16—29

piping

High pres-

1. Poor cooling

of

condenser Check and clean 16-24

sure is too

2. Loose cooling fan drive belt Readjust 16—23

high

3. Too much refrigerant Discharge the excess 16-8

refrigerant 4.

Air in

the system Evacuate and charge 16-8

the system

High pres-

1. Insufficient refrigerant Charge with refrigerant 16-8

sure is too

2. Internal malfunction

of

the compressor Repair

or

replace the 16-13

low

compressor

76G16X-004

16—5

Page 1789 of 1865

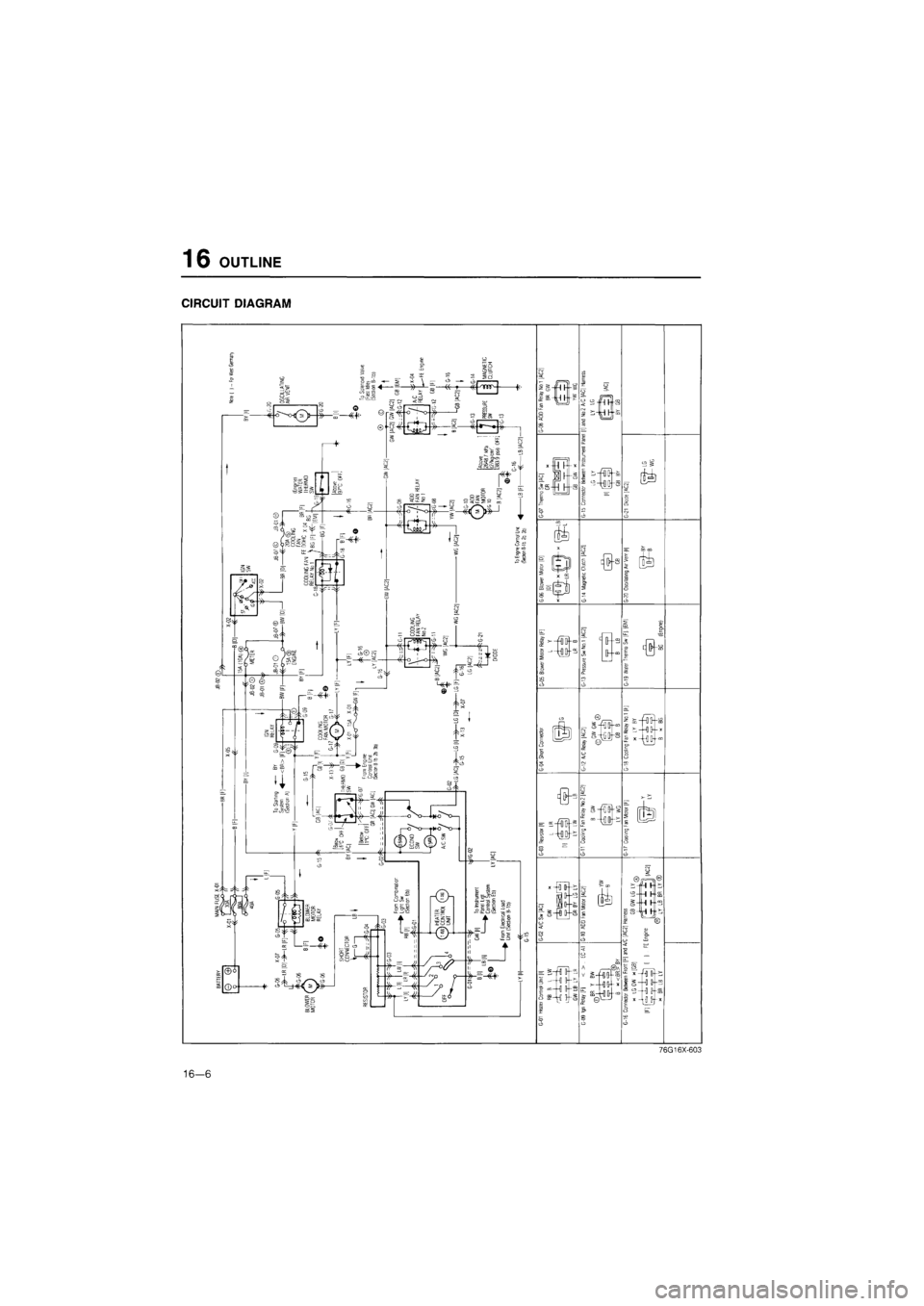

16 OUTLINE

CIRCUIT DIAGRAM

76G16X-603

16—6

Page 1790 of 1865

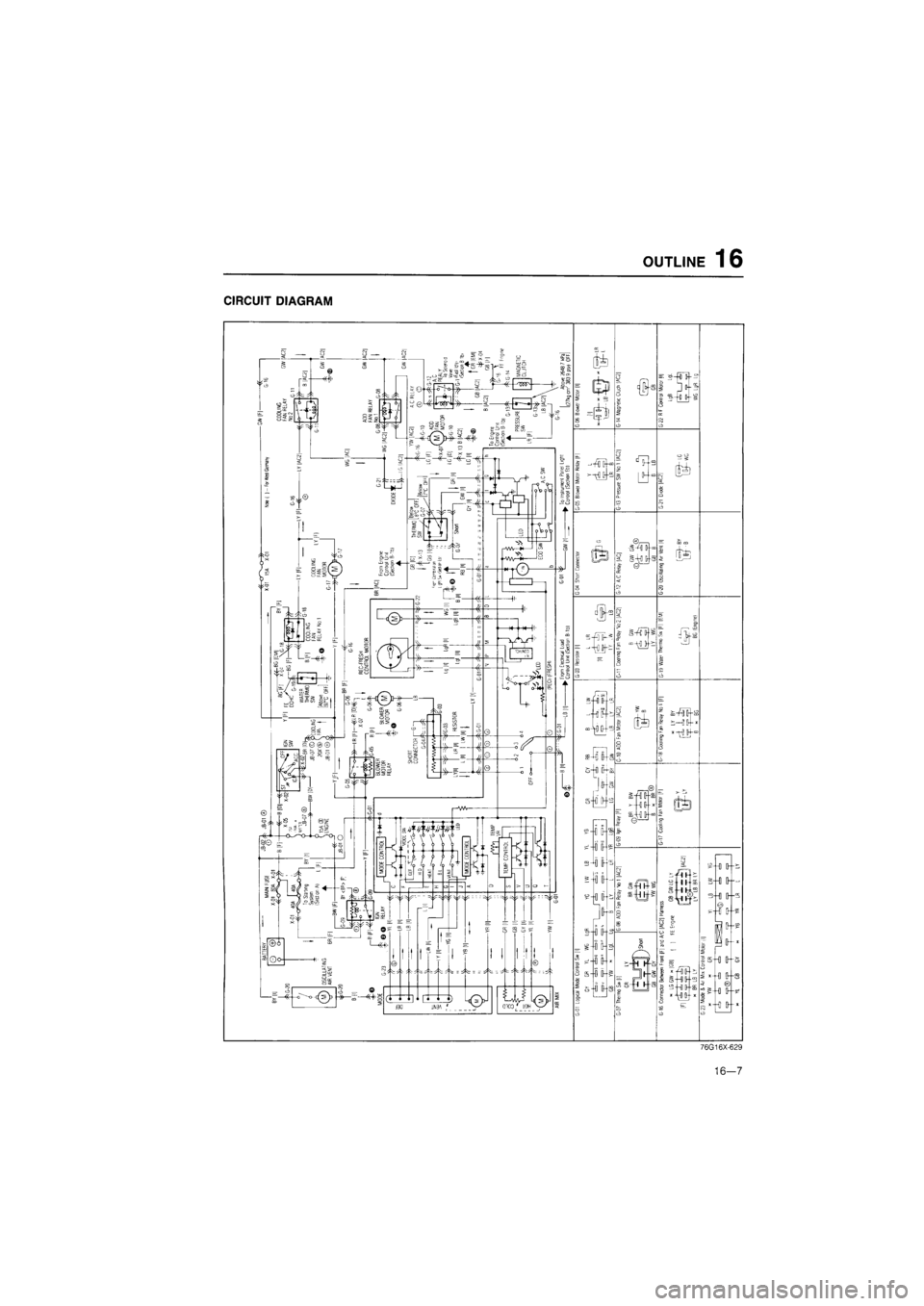

OUTLINE

16

CIRCUIT DIAGRAM

76G16X-629

16—7