MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 351 of 1865

3A COOLING FAN

COOLING FAN

SYSTEM CIRCUIT

IG1 IG Relay

*

No.1

relay

Water thermo switch

I With A/C

CM)

Main fan

1

L..±

No.2

relay

IG2

Add.

relay ol

(M)

A/C sw.

Add fan

86U03X-019

CIRCUIT INSPECTION

1. Turn the ignition switch ON.

2. Disconnect the water thermo switch connector, and

check that the fan operates.

3. If the fan doesn't operate, check the fuse, fan re-

lay, fan motor, thermo switch and wiring harness.

76G03A-010

3 A—12

Page 352 of 1865

COOLING FAN 3A

FAN MOTOR

Removal and Installation

1. Remove in the sequence shown in the figure.

2. Install in the reverse order of removal.

7—10 N-m (70—100 cm-kg, 61—87 in-lb)

1.8—2.2 N-m (18—22 cm-kg, 16—19 In-lb)

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

7—10 N-m (70—100 cm-kg, 61—87 In-lb)

76G03A-011

1. Cooling fan assembly (Refer to page 3A—7) 3. Fan

2. Cowling 4. Fan motor

Inspection

1. Connect an ammeter and battery to the fan motor

connectors.

2. Check that the fan motor operates smoothly at the

specified current or less.

Current

MTX: 5.6—7.6 A

ATX: 8.0—11.0 A

3. Replace the fan motor if necessary.

76G03A-012

3 A—13

Page 353 of 1865

3A COOLING FAN

WATER THERMO SWITCH

1. Remove the cooling fan water thermo switch.

Note

Make sure that the ignition switch is OFF. If

not, the fan will operate when the connector

is removed.

76G03A-013

76G03A-014

Place the water thermo switch in water.

Heat the water gradually, and check for continui-

ty of the switch with an ohmmeter. Replace if

necessary.

Water thermo switch (ON OFF):

97°C (207°F)....ECE, Hong Kong, Singapore

91

°C (196°F)....General, Middle East

Install the water thermo switch and a new O-ring.

Caution

Do not use sealing tape.

3 A—14

Page 354 of 1865

3B

COOLING SYSTEM

(DIESEL)

OUTLINE 3B— 2

COOLANT FLOW CHART 3B— 2

SPECIFICATIONS 3B— 3

TROUBLESHOOTING GUIDE 3B— 3

COOLANT 3B— 4

INSPECTION 3B— 4

REPLACEMENT 3B— 4

RADIATOR CAP 3B— 5

INSPECTION 3B— 5

RADIATOR 3B— 6

REMOVAL AND INSTALLATION 3B— 6

INSPECTION 3B— 6

WATER PUMP 3B— 7

REMOVAL 3B— 7

INSPECTION 3B— 8

INSTALLATION 3B— 8

THERMOSTAT 3B— 9

REMOVAL 3B— 9

INSPECTION 3B— 9

INSTALLATION 3B— 9

COOLING FAN 3B—10

SYSTEM CIRCUIT 3B—10

CIRCUIT INSPECTION 3B—10

FAN MOTOR 3B—11

WATER THERMO SWITCH 3B—12

76G03B-001

Page 355 of 1865

3B OUTLINE

OUTLINE

COOLANT FLOW CHART

76G03B-002

1. Water pump 4. Coolant reservoir

2. Thermostat 5. CSD coolant passage

3. Radiator 6. Oil cooler

3B-2

Page 356 of 1865

TROUBLESHOOTING GUIDE

3B

SPECIFICATIONS

Cooling system Water-cooled, forced circulation

Coolant capacity liters (US

qt,

Imp

qt)

With heater 9.5 (10.0, 8.4) Coolant capacity liters (US

qt,

Imp

qt)

Without heater 9.0 (9.5, 7.9)

Water pump Type Centrifugal, timing belt driven Water pump

Water seal Unified mechanical seal

Thermostat

Type Wax, two stage

Thermostat

Opening temperature °C(°F) Main Sub

Thermostat

Opening temperature °C(°F)

86.5-89.5 (188-193) 78.5—81.5 (173-179) Thermostat

Full-open temperature °C(°F) 100 (212) 100 (212)

Thermostat

Full-open lift

mm (in)

8.0 (0.31) min. 1.5 (0.06) min.

Radiator

Type Corrugated

fin

Radiator Cap valve opening pressure

kPa (kg/cm2,

psi)

74-103 (0.75-1.05, 11—15)

Cooling

fan

Type Electric

Cooling

fan

Capacity

W

120

Cooling

fan

Switching temprature orvopi OFF

- ON ^

91 (196) Cooling

fan

Number

of

blade 4

Cooling

fan

Outer diameter

mm

(in) 340 (13.4)

76G03B-003

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Overheating

Insufficient coolant Add 3B-

4

Coolant leakage Repair

—

Radiator fins clogged Clean 3B—

6

Radiator cap malfunction Replace 3B—

5

Cooling fan malfunction Repair 3B-11 Thermostat malfunction Replace 3B—

9

Water passage clogged Clean 3B—

4

Water pump malfunction ReDair

or

replace 3B—

7

Corrosion

Impurities

in

coolant Replace 3B-

4

76G03B-004

3B—3

Page 357 of 1865

3B COOLANT

86U03X-004

69G03A-006

COOLANT

INSPECTION

Coolant Level (Engine cold)

1. Check that the coolant level is near the radiator inlet

port.

2. Check that the coolant level in the coolant reser-

voir is between the FULL and Low marks.

Add coolant if necessary.

Warning

a) Never remove the radiator cap while the en-

gine is hot.

b)Wrap a thick cloth around the cap when

removing it.

Coolant Quality

1. Check that there is no build-up of rust or scales

around the radiator cap or radiator filler neck.

2. Check that coolant is free from oil.

3. Replace the coolant, if necessary.

Coolant Leakage

1. Connect a tester and SST to the radiator inlet port.

2. Apply 103 kPa (1.05 kg/cm2, 15 psi) pressure

to the system.

3. Check that the pressure is held.

If not, check for coolant leakage.

Warning

When removing either the radiator cap or the

tester, loosen it slowly until the pressure in

the radiator is released, and then remove it.

86U03X-005

REPLACEMENT

1. Remove the radiator cap and loosen the drain plug.

2. Drain the coolant into a suitable container.

Warning

a) Never open the radiator cap while the en-

gine is hot.

b)Wrap a thick cloth around the cap when

loosening.

c) Use caution when draining hot coolant.

86U03X-006

3B—4

Page 358 of 1865

RADIATOR CAP 3B

86U03X-028

86U03X-007

86U03X-008

3. Set the heater control switch to the maximum heat

position.

4. Flush the cooling system with water until all traces

of color are gone, then let the system drain com-

pletely.

5. Fill with the proper mixture and amount of ethy-

lene glycol-based coolant.

Caution

a) Do not use alcohol- or methanol-based

coolant.

b) Use only soft (demineralized) water in the

coolant mixture.

Anti-freeze solution mixture percentage

Protection Volume percentage Gravity

at

20°C (68°F) Protection Solution Water

Gravity

at

20°C (68°F)

Above —16°C (3°F) 35 65 1.054

Above -26°C (-15°F) 45 55 1.066

Above -40°C (-40°F) 55 45 1.078

6. Run the engine at idle with the radiator cap re-

moved. Let any air bleed from the system, and add

more coolant.

7. Install the radiator cap, and inspect all connections

for leakage.

RADIATOR CAP

INSPECTION

Radiator Cap Valve

1. Remove foreign material (such as water residue)

from between the radiator cap valve and the valve

seat.

2. Attach the radiator cap to a tester with the SST.

Apply pressure gradually to 74—103 kPa

(0.75—1.05 kg/cm2, 11—15 psi).

3. Wait about 10 seconds; then check that the pres-

sure has not decreased.

Negative Pressure Valve

1. Pull the negative-pressure valve to open it. Check

that it closes completely when released.

2. Check for damage on the contact surfaces, and

for cracked or deformed seal packing.

3. Replace the radiator cap if necessary.

86U03X-009

3B-5

Page 359 of 1865

3B RADIATOR

Note

a) Position the hose clamp in the original location on the hose.

b) Squeeze the clamp lightly with large pliers to ensure a good fit. 86U03X-010

RADIATOR

REMOVAL AND INSTALLATION

1. Drain the engine coolant.

2. Remove in the sequence shown in the figure.

3. Install in the reverse order of removal.

1. Coolant reservoir hose

2. Fast idle solenoid

3. Coolant level sensor connector

4. Cooling fan connector

76G03B-005

5. Upper and lower radiator hose

6. Cooling fan and radiator assembly

7. Cooling fan

INSPECTION

Check the following points. Repair or replace if

necessary.

1. Cracks, damage, or water leakage

2. Bent fins (Repair with a screwdriver)

3. Distorted or bent radiator inlet

86U03X-012

3B-6

Page 360 of 1865

WATER PUMP 3B

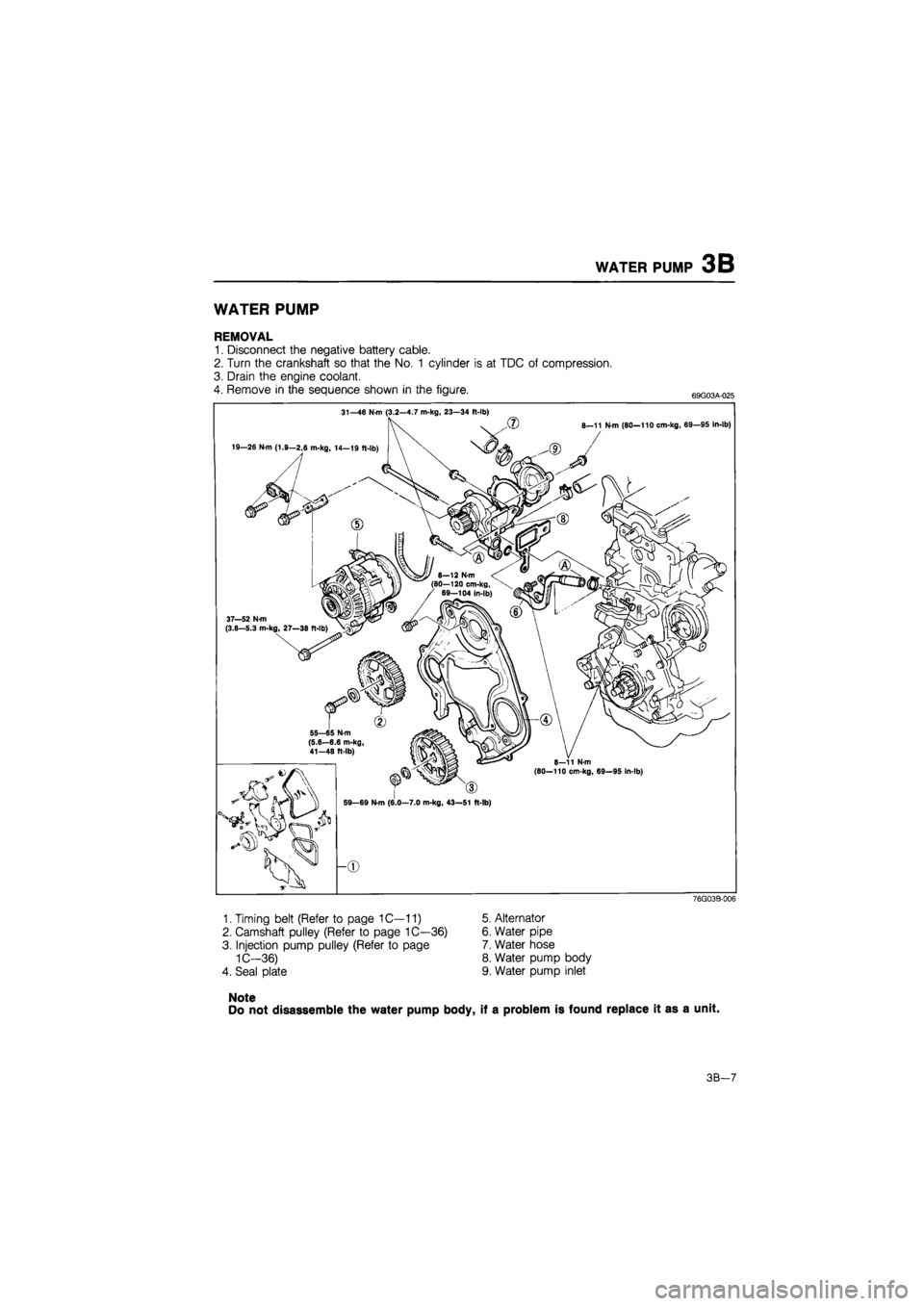

WATER PUMP

REMOVAL

1. Disconnect the negative battery cable.

2. Turn the crankshaft so that the No. 1 cylinder is at TDC of compression.

3. Drain the engine coolant.

4. Remove in the sequence shown in the figure. 69G03A-025

31—46 N m (3.2—4.7 m-kg, 23—34 ft-lb)

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

(?) 8—11 N-m (80—110 cm-kg, 69—95 In-lb)

37—52 N-m (3.8—5.3 m-kg, 27—38 ft

55—65 N-m (5.6—6.6 m-kg, 41-48 ft-lb)

(80—110 cm-kg, 69—95 In-lb)

59—69 N-m (6.0—7.0 m-kg, 43—51 ft-lb)

76G03B-006

1. Timing belt (Refer to page 1C—11)

2. Camshaft pulley (Refer to page 1C—36)

3. Injection pump pulley (Refer to page

1C—36)

4. Seal plate

Note

Do not disassemble the water pump body, if a problem is found replace it as a unit.

5. Alternator

6. Water pipe

7. Water hose

8. Water pump body

9. Water pump inlet

3B-7