lock MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 417 of 1164

CONTROL SYSTEM F

VB: Battery voltage

incorrect voltage POBSible cause

Alwvs OV’ l ROOM IOA fuse burned l Open circuit in wiring from ROOM IOA fuse to ECU terminal 1A

Always OV

l Main relay malfunction (Refer to page F-171) l Open or short circuit in wiring from main relay to ECU terminal 1B

I

Always OV (Starter turns) l Open or short circuit in wiring from starter interlock switch (USA), ignition

switch (CANADA), to ECU terminal 1C

I

Always OV

Always Vs

Always approx. 5V

l Main relay (FUEL IWJ relay) malfunction (Refer to page F-171) l Open circuit in wiring from main relay to diagnosis connector terminal +B l Open or short circuit in wiring from diagnosis connector terminal MEN to

ECU terminal 1D

l Poor connection at ECU connector l ECU malfunction

l ECU malfunction

Always below

23 MIL always ON

MIL never ON

l Short circuit in wiring from combination meter to ECU terminal 1E l ECU malfunction

l Open circuit in wiring from combination meter to ECU terminal 1E

I

Always Ve l Poor connection at ECU connector l ECU malfunction

Always below

2.5V

Always

VB

No display on Self- * Main relay (FUEL INJ relay) malfunction (Refer to page F-171)

Diagnosis Checker l Open circuit in wiring from main relay to diagnosis connector terminal +B

“88” displayed and

l Open or short circuit in wiring from diagnosis connector terminal FEN to

buzzer sounds con- ECU terminal 1F

tinuously

l Poor connectron at ECU connector l ECU malfunction

Always OV

l Short circuit in wiring from igniter to ECU terminal 1G

I -

I -

I

I -

I -

I

Always below

2.5V

Always VB AIC does not operate l A/C relay malfunction (Refer to page U-55) l Open circurt in wiring from ignition switch to A/C relay l Open circuit in wiring from A/C relay to ECU terminal 1J

A/C switch OFF but

l Short circuit in wiring from A/C relay to ECU terminal IJ

AIC operates l ECU malfunction

l Poor connection at ECU connector l ECU malfunction

Always below l.OV

l Short circuit in wiring from diagnosis connector terminal TEN to ECU termi-

nal 1K

Always Vs

l Open circuit in wiring from diagnosis connector terminal TEN to ECU termi-

nal 1K

l Open circuit in wiring from diaonosis connector terminal GND to ground

Always below

2.W

Always Va DRL ON when ignition

l Short circuit in wiring from DRL relay to ECU terminal IL

switch ON l Short circuit in wiring from DRL relay to DRL unit

DRL never ON

l Open circuit in wiring from DRL relay to ignition switch

l Parking brake switch always ON l DRL unit malfunction (Refer to page T-33)

23UOFX- 134

F-l 51

Page 432 of 1164

F CONTROL SYSTEM

Ve: Battery voltage

erminal Input Output

Connection to Test condition Correct voltage Remark

3u 0 Injector (Nos. 1, 3) Ignition switch ON VB * Engine Signal

Idle Va Monitor: Green

and red lamps

Engine speed above 2,000 rpm on de- Va

flash

celeration (After warm-up)

3v 0 Injector (Nos. 2, 4) ignition switch at idle

VB

Idle VB

Engine speed above 2,000 rpm on de-

VB

celeration (After warm-up)

3W 0 1-2 shift solenoid Solenoid valve ON i&I AT running

valve

Solenoid valve OFF ov

3x 0 2-3 shift solenoid Solenoid valve ON

VB AT running

valve

Solenoid valve OFF ov

3Y 0

ZH;hift solenoid Solenoid valve ON VB AT running

Solenoid valve OFF ov

32 0 Lockup solenoid Solenoid valve ON

VB AT running

valve

Solenoid valve OFF ov

23UOFX-1~

1 I u- l-1 ,

III h-3

I r

3y 13W 13U (3Sl3Cj3+4]3K 31 13Gj3EI 3C 13A 2012h42Kl21 12Gl2E12Cj2A 1 U 11 SllC$O 1 MI1 K 1 I 11 G 1 El 1 C 11 A

32 )3X I3Vj3Tj3R]3Pj3N]3L 3Jj3Hj3F13D 138 2P)2N)2L~2J~2H~2F~2D~2B 1V IlTjlRjlP 1NjlL 1JjlH 1FI lD\lB

-*’

.J’ -

F-l 66

Page 433 of 1164

CONTROL SYSTEM

Ve: Betterv voltaae

Incorrect voltage Possible csuse

Always OV l Main relay (FUEL INJ relay) malfunction (Refer to page F-172) l Open or short circuit in wiring from injector to ECU terminal 3U or 3V

Always Ve

l ECU malfunction

Always OV

Always Ve

l 1-2 shift solenoid valve malfunction (Refer to page K-143) l Short circuit in wiring from solenoid valve to ECU terminal 3W

I

l l-2 shift solenoid valve malfunction (Refer to page K-143) l Ooen circuit in wiring from solenoid valve to ECU terminal 3W

Always OV

l 2-3 shift solenoid valve malfunction (Refer to page K-143) l Short circuit in wirino from solenoid valve to ECU terminal 3X

Always VB

Always OV

l 2-3 shift solenoid valve malfunction (Refer to page K-143) l Open circuit in wiring from solenoid valve to ECU terminal 3X

l 3-4 shift solenoid valve malfunction (Refer to page K-143) l Short circuit in wiring from solenoid valve to ECU terminal 3Y

Always

VB l 3-4 shift solenoid valve malfunction (Refer to page K-143) l Open circuit in wiring from solenoid valve to ECU terminal 3Y

Always OV

l Lockup solenoid valve malfunction (Refer to page K-143) l Short circuit in wiring from solenoid valve to ECU terminal 32

Always Ve

l Lockup solenoid valve malfunction (Refer to page K-143) l Open circuit in wiring from solenoid valve to ECU terminal 32

23UOFX-1 E i0

F-l 67

Page 436 of 1164

F CONTROL SYSTEM

0.7mm (0

GAUGE

1 SUOFX-10 3 03UOFX-235

03UOFX.22 5 IDL

E

03UOFX-22t 5

4. Loosen the two attaching screws.

5. Rotate the throttle sensor clockwise

approx. 30 degrees,

then rotate it back counterclockwise until the continuity

exists.

6. Replace the feeler gauge with a

0.7mm (0.027 in) gauge.

7. Verify that the continuity does not exist.

8. If it exists, repeat Steps 3 through 6. ‘-

9. Tighten the two attaching screws.

Note

l Do not move the throttle sensor from the set posi-

tion when tightening the screws.

10. Open the throttle valve fully a few times.

11. Recheck the adjustment of the throttle sensor.

Adjustment (ATX)

1. Disconnect the connector from the throttle sensor.

2. Connect an ohmmeter between the throttle sensor termi-

nals E and IDL.

3. Loosen the two attaching screws.

4. Insert a

0.25mm (0.01 in) feeler gauge between the throt-

tle stop screw and the stop lever.

5. Rotate the throttle sensor clockwise

approx. 30 degrees,

then rotate it back counterclockwise until there is continuity. i-

6. Replace the feeler gauge with a

0.4mm (0.016 in) gauge

and verify that there is no continuity.

7. If there is continuity, repeat Steps 4 through 6.

8. Tighten the two attaching screws.

Note

l Do not move the throttle sensor from the set posi-

tion when tightening the screws.

9. Open the throttle valve fully and verify that the resistance

between the throttle sensor terminals E and VT is

approx.

5 kQ.

F-l 70

Page 438 of 1164

F CONTROL SYSTEM

23UOFX-15

23UOFX-15

23UOFX-15

LOCK

4

I

13UOFX-oc

F-l 72

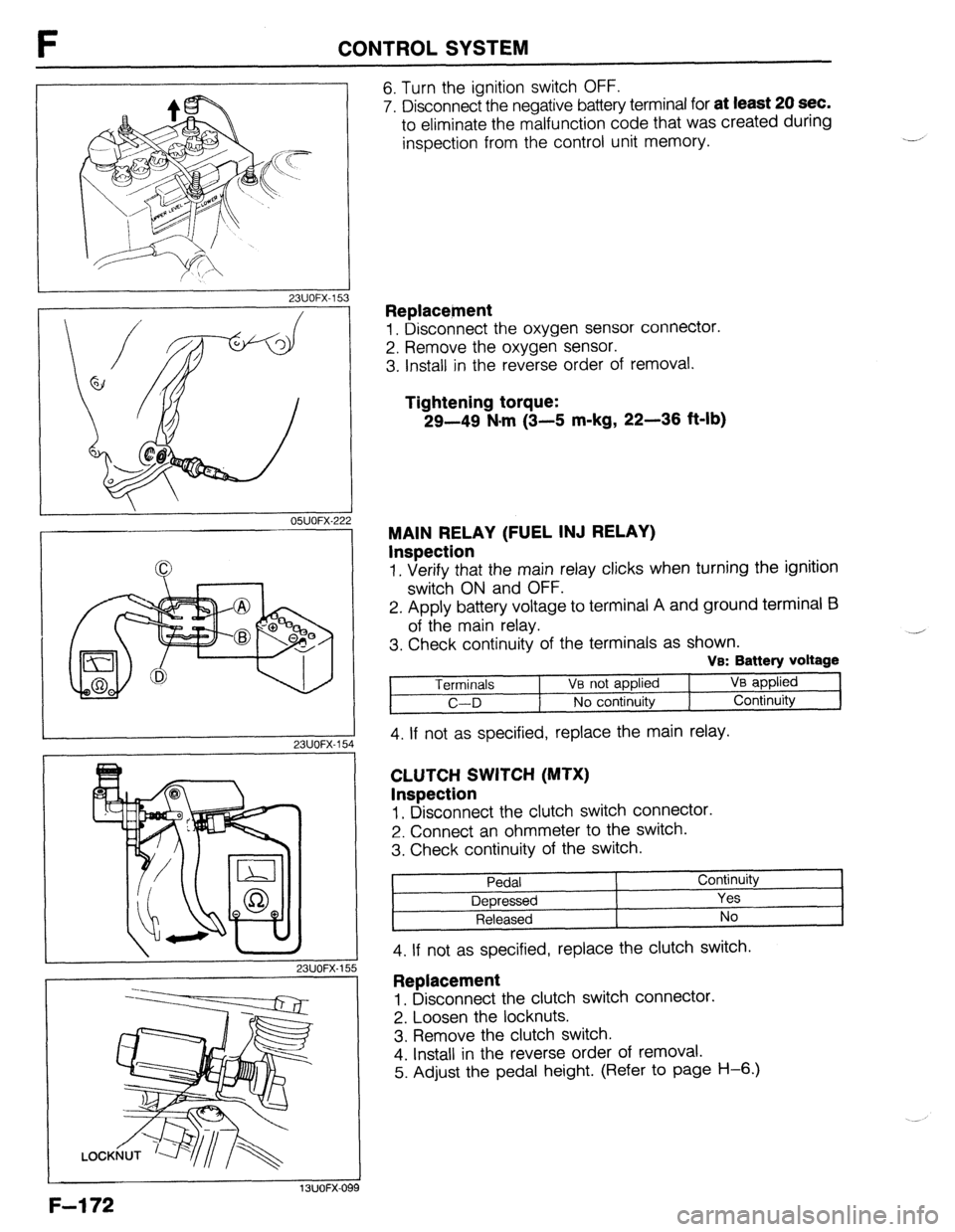

6. Turn the ignition switch OFF.

7. Disconnect the negative battery terminal for

at least 20 sec.

to eliminate the malfunction code that was created during

inspection from the control unit memory.

Replacetnent

1. Disconnect the oxygen sensor connector.

2. Remove the oxygen sensor.

3. Install in the reverse order of removal.

Tightening torque:

29-49 N-m (3-5 m-kg, 22-36 ft-lb)

MAIN RELAY (FUEL INJ RELAY)

Inspection

1. Verify that the main relay clicks when turning the ignition

switch ON and OFF.

2. Apply battery voltage to terminal A and ground terminal E3

of the main relay.

3. Check continuity of the terminals as shown.

VB: Battery voltage

Terminals 1 Ve not applied VB applied

C-D No continuity Continuity

4. If not as specified, replace the main relay.

CLUTCH SWITCH (MTX)

Inspection

1, Disconnect the clutch switch connector.

2. Connect an ohmmeter to the switch.

3. Check continuity of the switch.

Pedal Continuity

Depressed Yes

Released No

4. If not as specified, replace the clutch switch. ,

Replacement

1. Disconnect the clutch switch connector.

2. Loosen the locknuts.

3. Remove the clutch switch.

4. Install in the reverse order of removal.

5. Adjust the pedal height. (Refer to page H-6.)

Page 441 of 1164

G

ENGINE ELECTRICAL SYSTEM

INDEX ......................................................

OUTLINE ..................................................

SPECIFICATIONS .................................... G- 3

TROUBLESHOOTING

GUIDE.. .................... G-

4

DIAGNOSTIC INDEX ................................

SYMPTOM TROUBLESHOOTING..

............. :- t

-

CHARGING SYSTEM ................................. G- 6

PREPARATION .......................................

CIRCUIT DIAGRAM ................................. :I ;

TROUBLESHOOTING .............................. G- 7

BATTERY ............................................... G- 6

ALTERNATOR ........................................ G-10

DRIVE BELT ........................................... G-14

IGNITION SYSTEM .................................... G-15

PREPARATION ....................................... G-15

CIRCUIT DIAGRAM ................................. G-15

TROUBLESHOOTING .............................. G-16

IGNITION TIMING ................................... G-17

HIGH-TENSION LEAD .............................. G-17

SPARK PLUGS ....................................... G-16

IGNITION COIL ....................................... G-19

DISTRIBUTOR ........................................ G-20

IGNITER ................................................ G-23

STARTING SYSTEM .................................. G-24

PREPARATION ....................................... G-24

CIRCUIT DIAGRAM ................................. G-24

STARTER ...............................................

G-25

STARTER INTERLOCK SWITCH (MTX)

........ G-31

03UOGX-001

Page 444 of 1164

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

DIAGNOSTIC INDEX

No. Troubleshooting items

Page

1

Will not crank-starter motor does not operate G-4

2

Will not crank-starter motor spins G-4

3

Cranks slowly G-5 4

Alternator warning lamp illuminates when engine running

G-5

5 Discharged battery G-5

6

Misfire

G-5

03UOGX-004

SYMPTOM TROUBLESHOOTING -

1

iTEl

1

2

3 Will not crank-Starter motor does not operate

INSPECTION

T

Check if engine cranks with fully charged battery

Check if battery voltage is applied at B terminal

TERMINAL

battery voltaae is aoolied at S terminal

when clutch pedal depressed (MTX) and ignition

switch in START position

S TERMINAL

Yes

No

Yes ACTION Check charging system CT- page G-7

Go to next step

Go to next step

No Check wire harness

Yes

l Check magnetic switch l Check field coil l Check armature

No

l Check starter interlock switch (MTX) ccp: page G-31 l Check inhibitor switch (ATX) c=p Section K l Check ignition switch CI Section T l Check wire harness

1 L-T page G-28

CT- page G-29

CT- page G-29

23UOGX.001

03UOGX-006

G-4

Page 457 of 1164

IGNITION SYSTEM G

r

03UOGX-03

SOHC

LOCK BOLTS

DOHC

A LOCK BOLTS I 03UOGX-0’

03UOGX-C

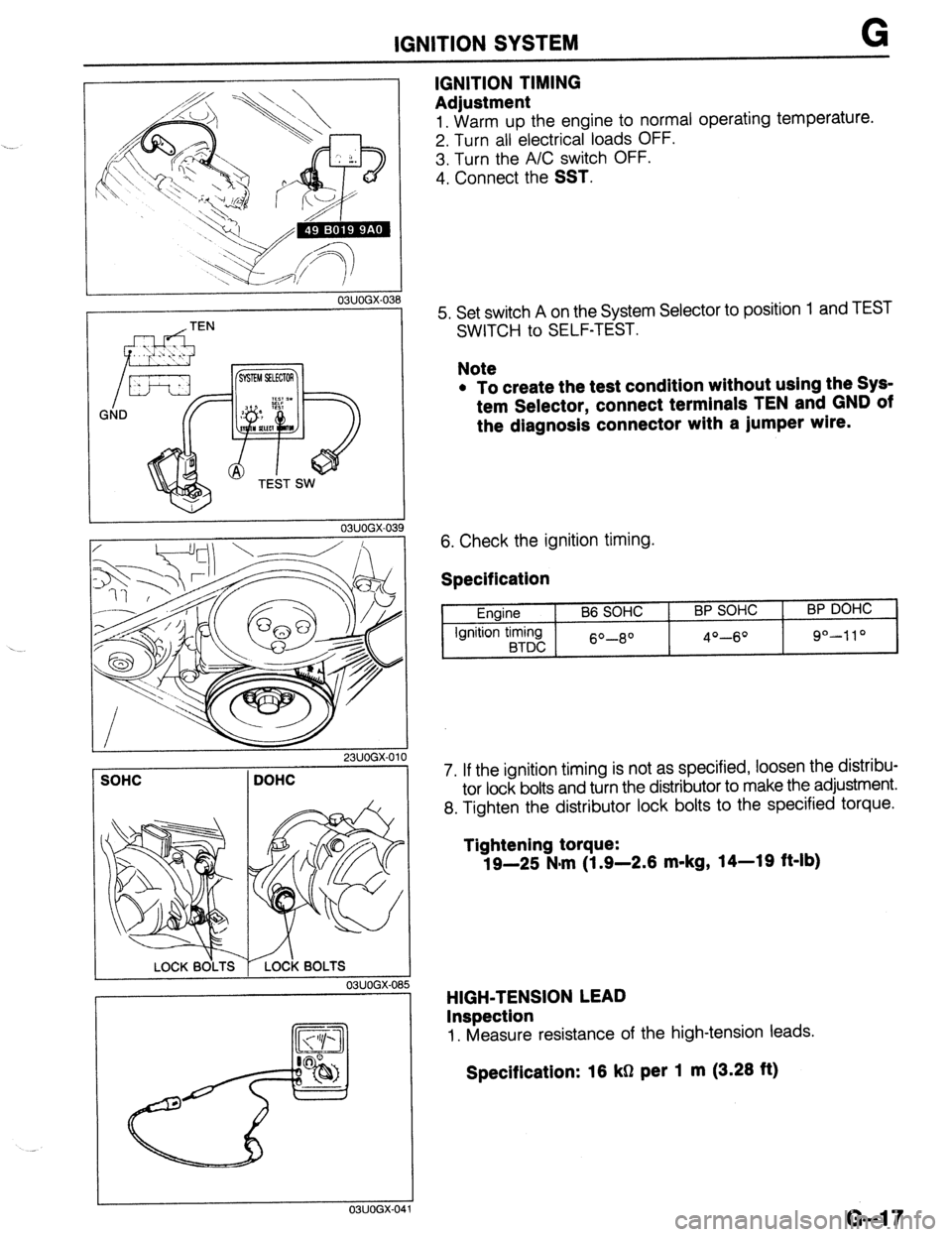

IGNITION TIMING

Adjustment

1. Warm UD the enaine to normal operating temperature.

2. Turn all ‘electricarloads OFF.

3. Turn the A/C switch OFF.

4. Connect the

SST.

5. Set switch A on the System Selector to position

SWITCH to SELF-TEST. 1 and TEST

Note

l To create the test condition without using the Sys-

tem Selector, connect terminals TEN and GND of

the diagnosis connector with a jumper wlre.

6. Check the ignition timing.

Specification

Engine

Ignition timing

BTDC B6 SOHC BP SOHC

60-8O 4O-6O

BP DOHC

9°-110

7. If the ignition timing is not as specified, loosen the distribu-

tor lock bolts and turn the distributor to make the adjustment.

8. Tighten the distributor lock bolts to the specified torque.

Tightening torque:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

HIGH-TENSION LEAD

Inspection

1. Measure resistance of the high-tension leads.

Specification: 16 kg per 1 m (3.26 ft)

G-l 7

Page 470 of 1164

G STARTING SYSTEM

1 03lJOGX.079

23LJOGX-011

I I OBUOGX-081

3. Place the armature on V-blocks, and measure the runout

with a dial indicator.

If the runout is not within specification, repair it with a lathe

or replace the armature.

Runout: 0.05mm (0.002 in)

Maximum: O.lmm (0.004 in)

4. Replace the armature if the outer diameter of the commu-

tator is almost at or less than the grind limit.

5. If the commutator surface is dirty, wipe it with a cloth; if it

is rough, repair it with a lathe or fine sandpaper.

Engine

Grind limit mm (in) 1 B6 1 BP (MTX) 1 BP (ATX)

31.4 (1.24) 1 28.8 (1.13)

6. Segment groove depth

If the depth of the mold between segments is almost at or

less than the minimum, undercut the grooves to the stan-

dard depth.

Depth: OS-0.8mm (0.02-0.03 in)

Minimum: 0.2mm (0.008 in)

Bearing (if equipped)

1. Check for abnormal noise, looseness, or sticking.

2. Replace the bearing(s) if necessary.

I

03UOGX-082

G-30

Page 471 of 1164

STARTING SYSTEM G

STARTER INTERLOCK SWITCH (MTX)

CONTACT

IGNITION SWITCH

IG2 ROD

p IG1 ‘NTERlfM$TCH

i BATTERY

I

STARTER

For operator safety, if the clutch pedal is not depressed during starting, battery power will not be supplied

to the starter and the engine will not crank.

Interlock Switch

Inspection

1. Disconnect the interlock switch connector.

2. Connect an ohmmeter to the switch.

3. Check the continuity.

Clutch pedal

----- I_

Depressed

Released 4.

Replace the switch if necessary.

Continuity

--

Yes

No

G-31