lock MAZDA PROTEGE 1992 Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 244 of 1164

D OIL PAN

BPSOHCANDDOHC 37-52 (3.8-5.3, 27-38)

I -

16-21 (1.8-2.1, 12-15)

---P 31-46 (3.2-4.7, 23-3’

37-52 (3.8-5.3, 27-36

Ax. GASKET. 1

REPLACE,

cd h 37-52 (3.8-5.3, 27-38) GiSKET,

REPLACE

/ 29-41 (3.0-4.2, 22-30)

-v

44

7.6-l 1 N.m (80-l 10 cm-kg, 69-95 in-lb) N.m (m-kg, ft-It

1 SUODX-0

1. Front exhaust pipe and bracket 3. Oil strainer

2. Oil pan 4. Main bearing support plate (MBSP)

Removal Note . . . . . . . . . . . below Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . page D-l I

. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspect for cracks, deformation and

damage

Installation Note *............,....,......* page D-l 1 Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . . page D-l 1

Removal Note

Oil pan

B6 SOHC

1. Remove the oil pan mounting bolt.

2. Insert a screwdriver or a suitable tool between the MBSP

and oil pan, and pry them.

Caution

l Do not insert the prying tool between the MBSP and

cylinder block.

l Do not damage or scratch the contact surfaces.

3. Remove the oil pan.

D-IO

Page 245 of 1164

OIL PAN

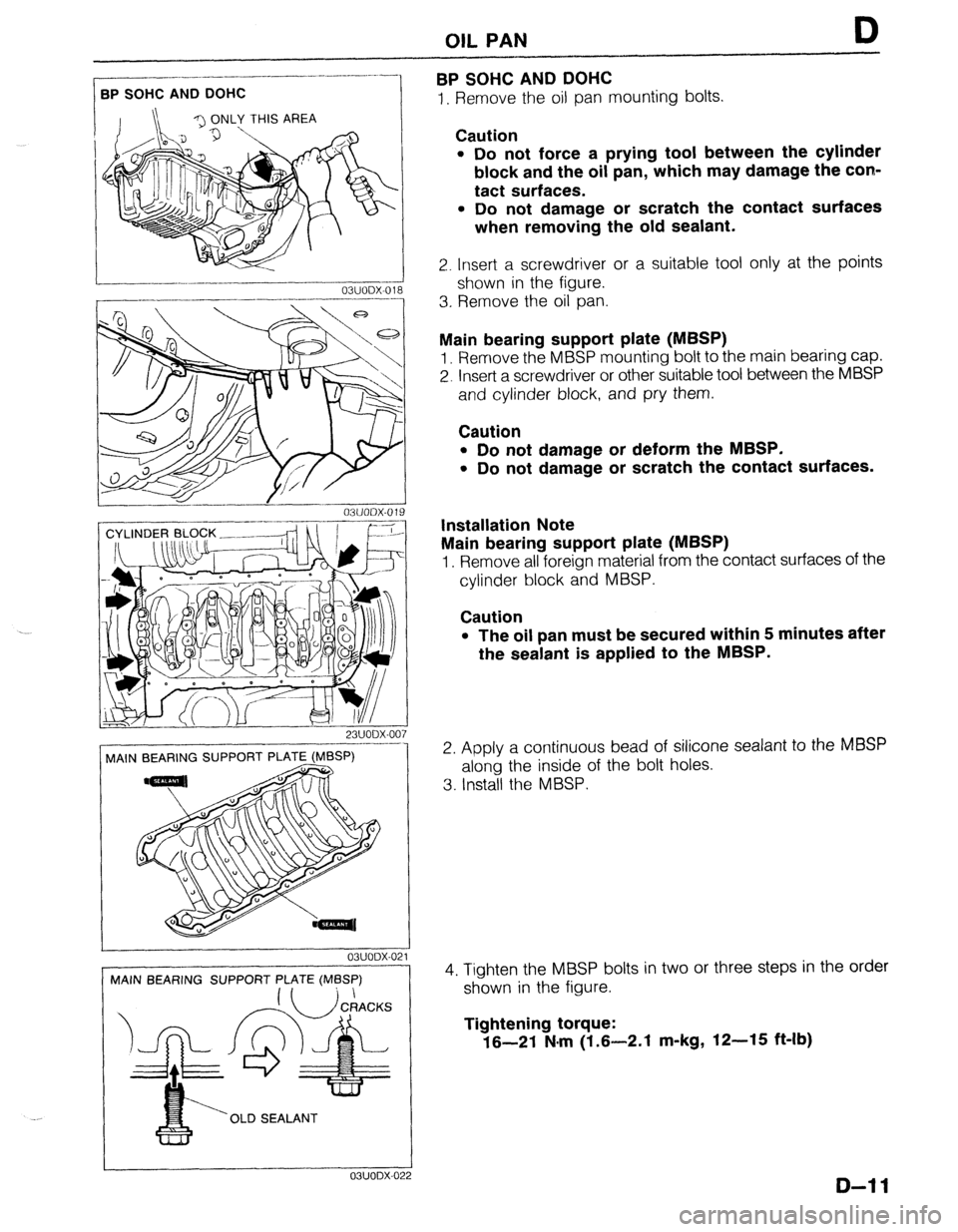

BPSOHCANDDOHC

D

I. Remove the oil pan mounting bolts. .-_-__------- BPSOHCANDDOHC

23UODX-007

MAIN BEARING SUPPORT PLATE (MBSP)

! 03UODX-021

MAIN BEARING SUPPORT PLATE (MBSP)

‘OLD SEALANT ---1_1

OBUODX-0: !2

Caution

l Do not force a prying tool between the cylinder

block and the oil pan, which may damage the con-

tact surfaces.

l Do not damage or scratch the contact surfaces

when removing the old sealant.

2. Insert a screwdriver or a suitable tool only at the points

shown in the figure.

3. Rernove the oil pan.

Main bearing support plate (MBSP)

1. Remove the MBSP mounting bolt to the main bearing cap.

2. Insert a screwdriver or other suitable tool between the MBSP

and cylinder block, and pry them.

Caution

l Do not damage or deform the MBSP.

l Do not damage or scratch the contact surfaces.

Installation Note

Main bearing support plate (MBSP)

1. Remove all foreign material from the contact surfaces of the

cylinder block and MBSP.

Caution

l The oil pan must be secured within 5 minutes after

the sealant is applied to the MBSP.

2. Apply a continuous bead of silicone sealant to the MBSP

along the inside of the bolt holes.

3. Install the MBSP.

4. Tighten the MBSP bolts in two or three steps in the order

shown in the figure.

Tightening torque:

16-21 N.m (1.6-2.1 m-kg, 12-15 ft-lb)

D-l 1

Page 282 of 1164

F OUTLINE

COMPONENT DESCRIPTIONS

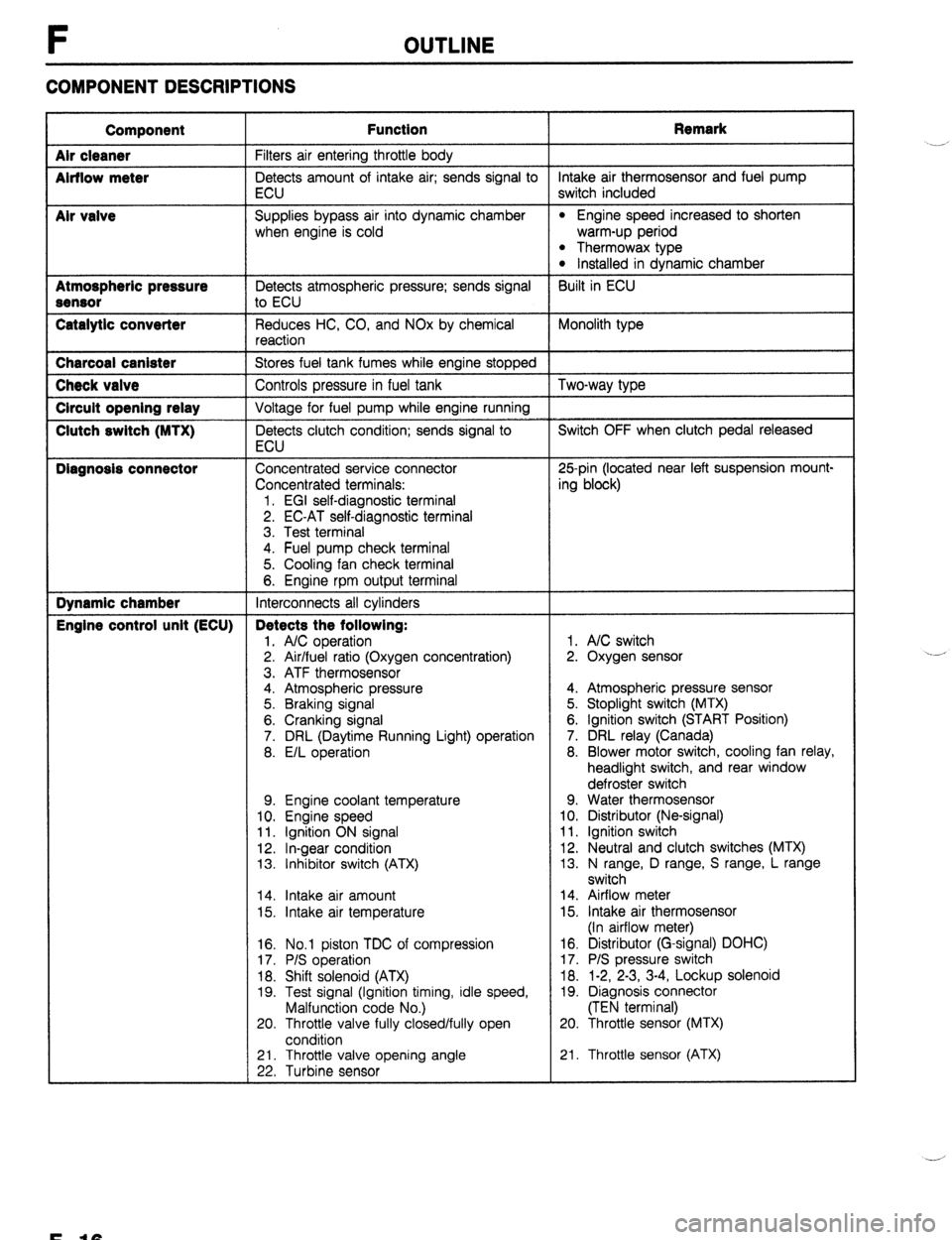

Component

Air cleaner

Airflow meter

Mr valve

Atmospheric pressure

Sensor

Catalytic converter Function Remark

Filters air entering throttle body

Detects amount of intake air; sends signal to intake air thermosensor and fuel pump

ECU switch included

Supplies bypass air into dynamic chamber

l Engine speed increased to shorten

when engine is cold warm-up period

l Thermowax type l Installed in dynamic chamber

Detects atmospheric pressure; sends signal Built in ECU

to ECU

Reduces HC, CO, and NOx by chemical Monolith type

reaction Charcoal canister

Stores fuel tank fumes while engine stopped Check valve

Controls pressure in fuel tank Two-way type Circuit opening relay

Voltage for fuel pump while engine running Clutch switch (MTX)

Detects clutch condition; sends signal to Switch OFF when clutch pedal released

ECU Diagnosis connector

Concentrated service connector 25pin (located near left suspension mount-

Concentrated terminals: ing block)

1. EGI self-diagnostic terminal

2. EC-AT self-diagnostic terminal

3. Test terminal

4. Fuel pump check terminal

5. Cooling fan check terminal

6. Engine rpm output terminal Dynamic chamber

Interconnects all cylinders Engine control unit (ECU) Detects the following:

1. A/C operation 1. A/C switch

2. Air/fuel ratio (Oxygen concentration) 2. Oxygen sensor

3. ATF thermosensor

4. Atmospheric pressure 4. Atmospheric pressure sensor

5. Braking signal 5. Stoplight switch (MTX)

6. Cranking signal 6. Ignition switch (START Position)

7. DRL (Daytime Running Light) operation 7. DRL relay (Canada)

8. E/L operation 8. Blower motor switch, cooling fan relay,

headlight switch, and rear window

defroster switch

9. Engine coolant temperature 9. Water thermosensor

10. Engine speed 10. Distributor (Ne-signal)

11. Ignition ON signal 11. Ignition switch

12. In-gear condition 12. Neutral and clutch switches (MTX)

13. Inhibitor switch (ATX) 13. N range, D range, S range, L range

switch

14. Intake air amount 14. Airflow meter

15. Intake air temperature 15. Intake air thermosensor

(In airflow meter)

16. No.1 piston TDC of compression

17. P/S operation

18. Shift solenoid (ATX)

19. Test signal (Ignition timing, idle speed,

Malfunction code No.)

20. Throttle valve fully closed/fully open

condition 16. Distributor (G-signal) DOHC)

17. P/S pressure switch

18. 1-2, 2-3, 3-4, Lockup solenoid

19. Diagnosis connector

(TEN terminal)

20. Throttle sensor (MTX)

21. Throttle valve opening angle

22. Turbine sensor 21. Throttle sensor (ATX) .__r

F-10

Page 300 of 1164

F TROUBLESHOOTING GUIDE

4

CRANKS NORMALLY BUT WILL NOT START (PARTIAL COMBUSTION) - AFTER WARM-UP *Engine cranks at normal speed and shows partial combustion but will not continue to run after running and

DESCRIP- hot soaked

TION *Battery in normal condition

*Engine starts normally when cold

[TROUBLESHOOTING HINTS] 3 Air/Fuel mixture too rich

@ Vapor lock

l Insufficient fuel injection control

*Fuel pressure not held in fuel line after engine stopped

(Correction for coolant temperature)

*High RVP (winter) fuel used in warm weather

l Injector fuel leakage @ Pressure regulator control system malfunction [BP]

switch ON, then check if en

D‘ page F-134

Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm’, 36-46 psi) ne pressure w

+ If fuel line pressure quickly in-

if fuel return hose is clogged

or

F-=34

Page 306 of 1164

F TROUBLESHOOTING GUIDE

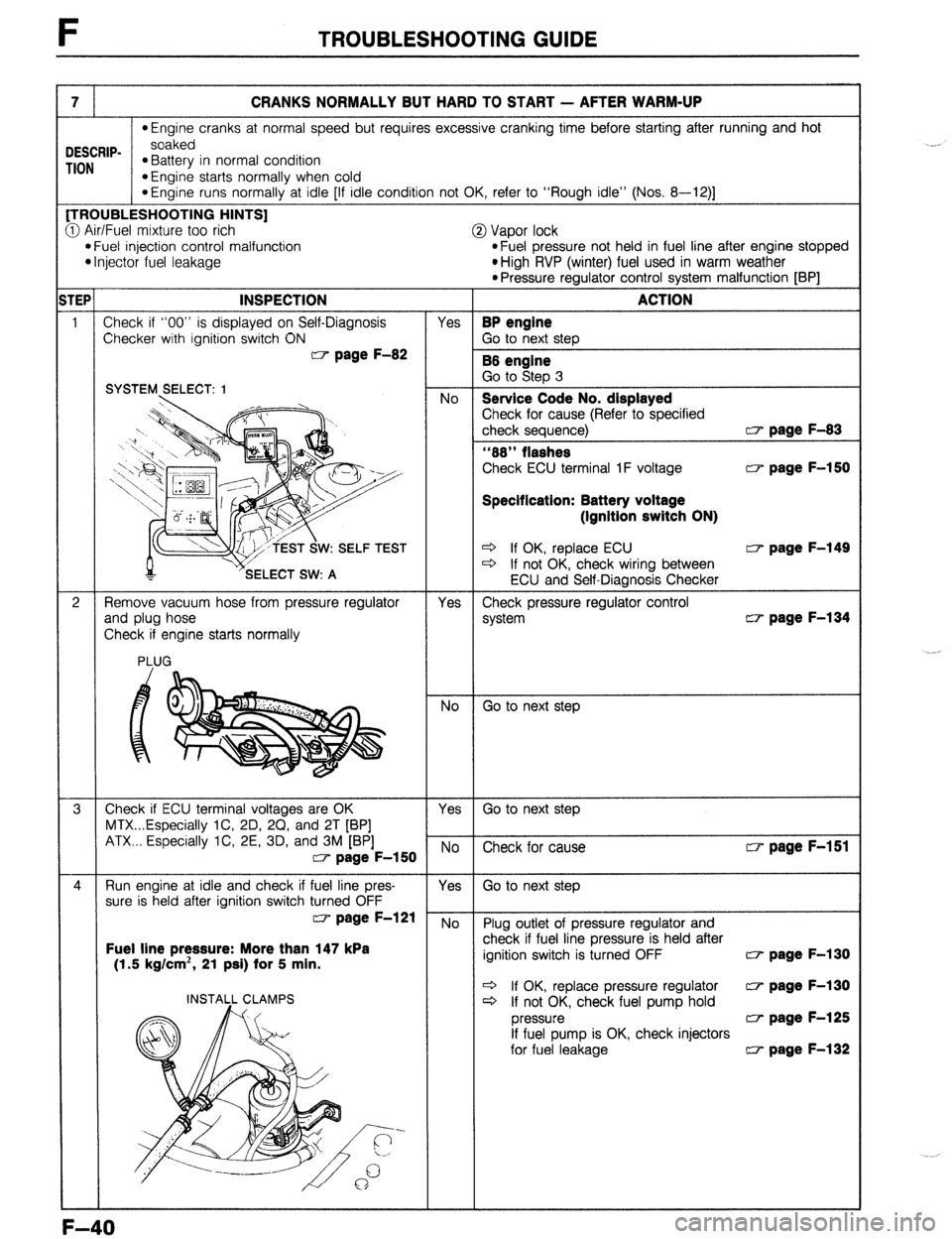

7 CRANKS NORMALLY BUT HARD TO START - AFTER WARM-UP

*Engine cranks at normal speed but requires excessive cranking time before starting after running and hot

DESCRIP- soaked

TION *Battery in normal condition

*Engine starts normally when cold

*Engine runs normally at idle [If idle condition not OK, refer to “Rough idle” (Nos. 8-12)] [TROUBLESHOOTING HINTS]

3 Air/Fuel mixture too rich

@ Vapor lock l Fuel injection control malfunction

*Fuel pressure not held in fuel line after engine stopped l Injector fuel leakage

*High RVP (winter) fuel used in warm weather

l Pressure regulator control system malfunction [BP] w page F-150

Specification: Battery voltage

(Ignition switch ON)

W: SELF TEST c3 If OK, replace ECU w page F-149 * If not OK, check wiring between CT- page F-134

Fuel line pressure: More than 147 kPa

(1.5 kg/cm*, 21 psi) for 5 min. w page F-130

+ If OK, replace pressure regulator CT- page F-130

c3 If not OK, check fuel pump hold w page F-125

If fuel pump is OK, check injectors

for fuel leakage (3 page F-132

F-40

Page 345 of 1164

ENGINE TUNE-UP F

03UOFX.051

03UOFX-051

- w4TEN I

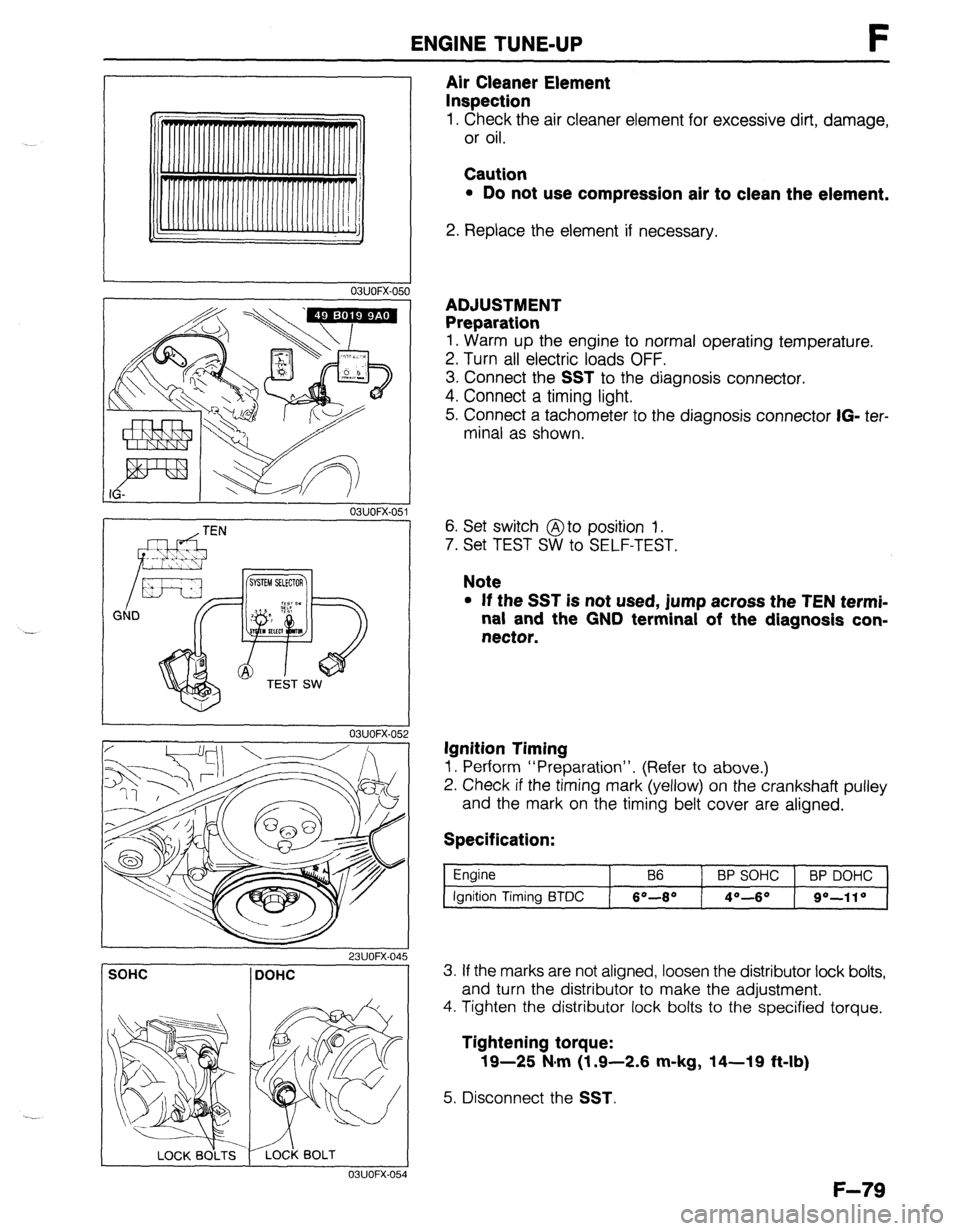

Air Cleaner Element

Inspection

1. Check the air cleaner element for excessive dirt, damage,

or oil.

Caution

l Do not use compression air to clean the element.

2. Replace the element if necessary.

ADJUSTMENT

Preparation

1. Warm up the engine to normal operating temperature.

2. Turn all electric loads OFF.

3. Connect the

SST to the diagnosis connector.

4. Connect a timing light.

5. Connect a tachometer to the diagnosis connector

IG- ter-

minal as shown.

6. Set switch @to position 1.

7. Set TEST SW to SELF-TEST.

Note

l If the SST is not used, jump across the TEN termi-

nal and the GND terminal of the diagnosis con-

nector.

Ignition Timing

1. Perform “Preparation”. (Refer to above.)

2. Check if the timing mark (yellow) on the crankshaft pulley

and the mark on the timing belt cover are aligned.

Specification:

Engine

Ignition Timing BTDC B6 BP SOHC BP DOHC

6O-8* 4O--6O go-110

SOHC DOHC

I 03UOFX-054

3. If the marks are not aligned, loosen the distributor lock bolts,

and turn the distributor to make the adjustment.

4. Tighten the distributor lock bolts to the specified torque.

Tightening torque:

19-25 N#m (1.9-2.6 m-kg, 14-19 ft-lb)

5. Disconnect the SST.

F-79

Page 350 of 1164

F SELF-DIAGNOSIS FUNCTION

Troubleshooting

If a service code number is shown on the SST, check for the cause by using the chart related to the code

number shown.

Service code number

CODE LOCATION OF

NO.

MALFUNCTION OUTPUT SIGNAL PATTERN

SELF-DIAGNOSIS FAIL-SAFE

02

Ne-signal

:E nl-u No Ne-signal

-

03 G-signal

(DOHC) No G-signal Cancels 2-group

injection

06* Vehicle speed

sensor ON

OFF No input signal from Shifting performed

vehicle speed normally

sensor

08 Airflow meter ON

OFF Open or short circuit Basic fuel injection

amount fixed as for two

driving modes

(1) Idle switch ON

(2) Idle switch OFF

09 Water

thermosensor ON

OFF Maintains constant 20%

(68OF) command

10 Intake air

thermosensor Maintains constant 20°C

(68OF) command

12

Throttle sensor

“,E l--uL-l Throttle opening judged

as full stroke lockup not

provided

Atmospheric ON Maintains constant

14 pressure sensor command of sea level

(in ECU)

OFF pressure

15 Oxygen sensor

(inactivation) ON

OFF Sensor output

continues less than

0.55V 95 sec. after

engine starts

(1500 rpm) Cancels engine feedback

operation

Oxygen sensor ON Sensor output Cancels engine feedback

17

(Inversion) continues uncharged operatron

OFF 50 sec. after engine

exceeds 1500 rpm

Solenoid valve ON

25 (pressure

regulator)

OFF u 1 nnluln Open or short crrcurt

“If the marked code numbers appeor, refer to Section K

F-84

Page 351 of 1164

SELF-DIAGNOSIS FUNCTION F

:ODE LOCATION OF

NO.

MALFUNCTION

26 Solenoid valve ON

(purge control)

OFF OUTPUT SIGNAL PATTERN nnnnnll 1 SELF4IAGNOSIS

Open or

short circuit FAIL-SAFE

-

ON

34

ISC valve

OFF u 1 llllJlll r -

41 Solenoid valve ON

(WCS)

[DOHC]

OFF -

Pulse ON No input signal Shifting performed in

55*

i nnnnn

from pulse accordance with signals

generator

OFF generator from vehicle speed

sensor

Open or Solenoid valve(s)

60* 1-2 shift ON

short circuit

solenoid valve

uuuuul performs the shifting with

as little interference as

OFF

possible with driving

performance

2-3 shift ON Lockup not provided

61*

solenoid valve

OFF

UUUI n

3-4 shift ON

62’

solenoid valve

OFF u u u u inn

1.6 sec. 4 sec.

63* Lockup solenoid

valve

u u&m I- Shifting performed

normally

Lockup not provided

0.4 sec.

0.4 sec.

*If the marked code numbers appeor, refer to Section K

Note

l The HOLD indicator does not flash the service code numbers.

l If there is more than one failure present, the code numbers will be indicated in numerical or-

der, lowest number first.

* After repairing a problem, turn the ignition switch OFF and disconnect the negative battery

cable at least 20 seconds to erase the service code numbers from the engine control unit (ECU)

memory.

23UOFX-051

F-85

Page 404 of 1164

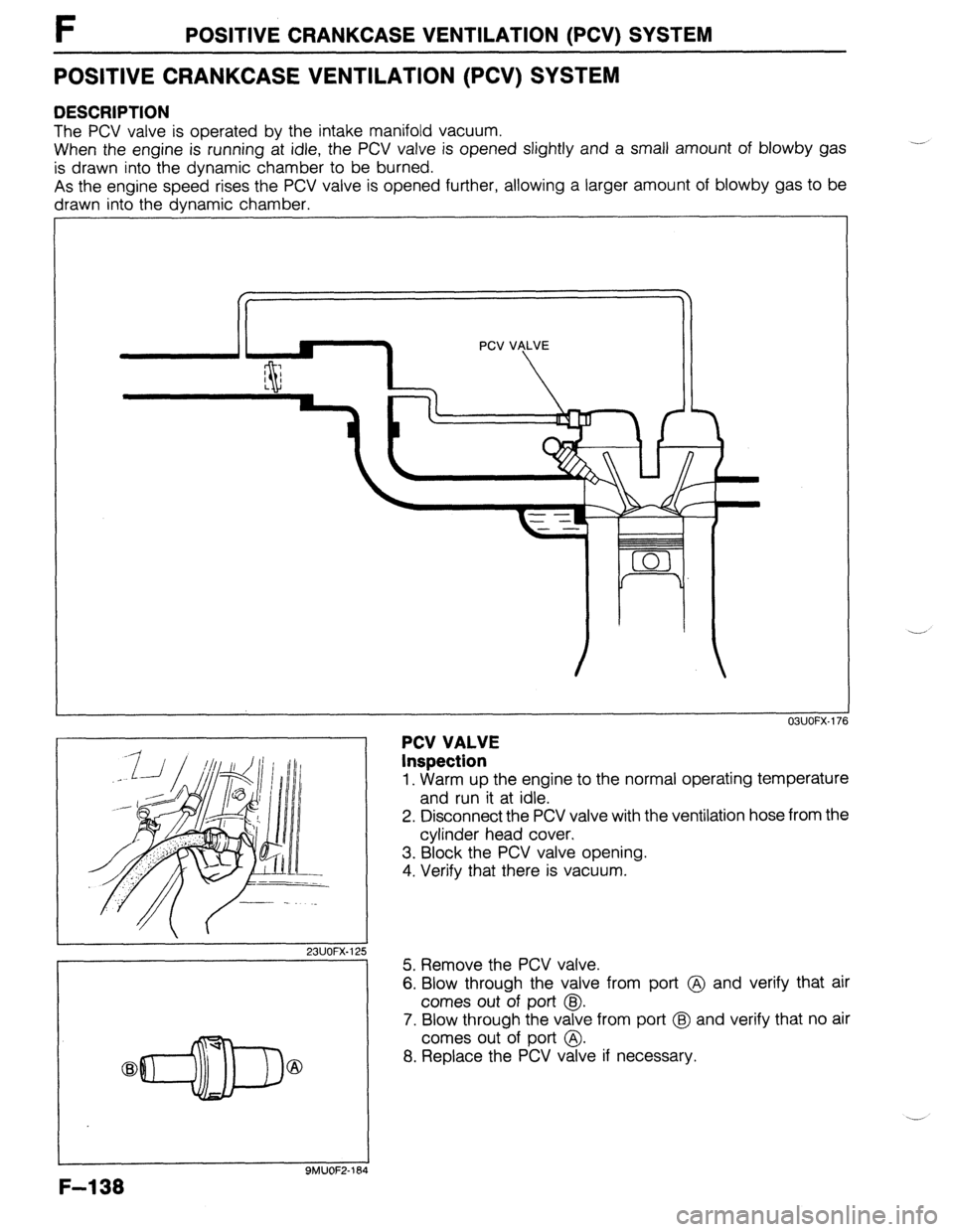

F POSITIVE CRANKCASE VENTILATION (PCV) SYSTEM

POSITIVE CRANKCASE VENTILATION (PCV) SYSTEM

DESCRIPTION

The PCV valve is operated by the intake manifold vacuum.

When the engine is running at idle, the PCV valve is opened slightly and a small amount of blowby gas

is drawn into the dynamic chamber to be burned.

As the engine speed rises the PCV valve is opened further, allowing a larger amount of blowby gas to be

drawn into the dynamic chamber.

23UOFX.1; !5

-7

F-l 38

9MUOF2-164

PCV VALVE

Inspection

OBUOFX-176

1. Warm up the engine to the normal operating temperature

and run it at idle.

2. Disconnect the PCV valve with the ventilation hose from the

cylinder head cover,

3. Block the PCV valve opening.

4. Verify that there is vacuum.

5. Remove the PCV valve.

6. Blow through the valve from port @ and verify that air

comes out of port @I.

7. Blow through the valve from port @ and verify that no air

comes out of port @.

8. Replace the PCV valve if necessary.

Page 408 of 1164

F DECELERATION CONTROL SYSTEM

DECELERATION CONTROL SYSTEM

DESCRIPTION

The dashpot is used to prevent the throttle valve from suddenly closing

03UOFX-185

1

DASHPOT

Inspection

1. Open the throttle valve fully. Push the dashpot rod with a

finger and verify that it goes into the dashpot slowly.

2. Release the rod and check that it comes out quickly.

3. Replace the dashpot if not as specified.

,,

OBUOFX-18

4. Warm up the engine and run it at idle.

5. Connect a tachometer to the diagnosis connector IG-

terminal and increase engine speed to 4,000 rpm.

6. Slowly decrease the engine speed and check that the le-

ver touches the dashpot rod at the specified speed.

Specification:

l B6 ..**.............,....,.............. Approx. 3,000 rpm

l BP SOHC . ..*..................*.... Approx. 2,700 rpm

l BP DOHC . . . . . . . . . . . . . . . . . . . . ...“... Approx. 3,500 rpm

7. If not as specified, loosen the locknut and turn the dashpot

to adjust.

F-l 42