lock MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 477 of 1164

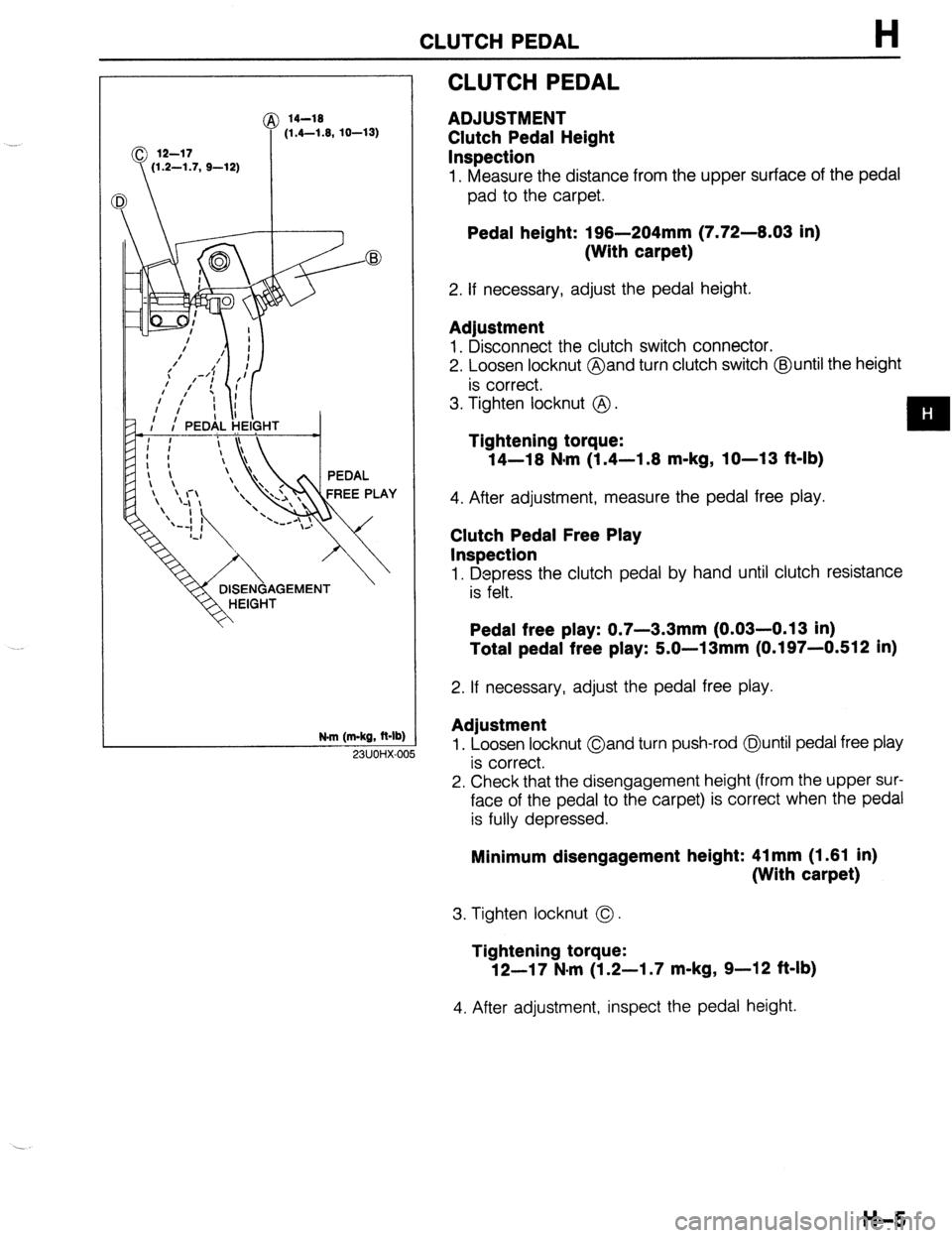

CLUTCH PEDAL H

@ 14-19

(1.4-1.9, 10-13)

N.m (m-kg, R-lb)

CLUTCH PEDAL

ADJUSTMENT

Clutch Pedal Height

Inspection

1. Measure the distance from the upper surface of the pedal

pad to the carpet.

Pedal height: 196-204mm (7.72-6.03 in)

(With carpet)

2. If necessary, adjust the pedal height.

Adjustment

1. Disconnect the clutch switch connector.

2. Loosen locknut @and turn clutch switch @until the height

is correct.

3. Tighten locknut @ .

Tightening torque:

14-16 N*m (1.4-1.6 m-kg, IO-13 f&lb)

4. After adjustment, measure the pedal free play.

Clutch Pedal Free Play

Inspection

1. Depress the clutch pedal by hand until clutch resistance

is felt.

Pedal free play: 0.7-3.3mm (0.03-0.13 in)

Total pedal free play: 5.0-13mm (0.197-0.512 in)

2. If necessary, adjust the pedal free play.

Adjustment

1. Loosen locknut Oand turn push-rod @until pedal free play

is correct.

2. Check that the disengagement height (from the upper sur-

face of the pedal to the carpet) is correct when the pedal

is fully depressed. 23UOHX-OC

Minimum disengagement height: 41 mm (1.61 in)

(With carpet)

3. Tighten locknut 0.

Tightening torque:

12-17 N-m (1.2-I .7 m-kg, 9-12 ft-lb)

4. After adjustment, inspect the pedal height.

H-5

Page 505 of 1164

TRANSAXLE Jl

1, Rear cover

2. Locknut (Primary shaft)

Disassembly Note .,......,,.,......... page Jl-15

3. Stop plate

4. Locknut (Secondary shaft)

Disassembly Note ,..,....,,.,......... page Jl-15

5. 5th shift fork

6. Clutch hub assembly (5th)

Inspection . . . . . . . . . . . . . . . . ..*............... page J l-29

7. Synchronizer ring (5th)

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-27

8. 5th gear

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-28

9. Gear sleeve

Inspection . . . . . . . . . . . . . . . . ..*...*........... page Jl-28

10. Secondary 5th gear

11. Lock bolt and washer

12. Back-up light switch

13. Neutral switch

14. Transaxle case assembly

15. Magnet

16. Reverse idler shaft

17. Reverse idler gear

Inspection.. . . , . . . . . . . . . . . . . . . , , . , . . . . . . . . . . page J l-27

L ,

03UOJl-022

I

I I

03UOJl-023

18. 5th shift rod

19. 5th shift rod end

20. Pin

21. Crank lever shaft

22. Crank lever assembly

23. Shift fork and shift rod assembly

Disassembly Note ,.................... page Jl-16

24. Steel ball

25. Spring

26. Primary shaft gear assembly

27. Secondary shaft gear assembly

28. Differential assembly

29. Clutch housing

30. Synchronizer spring

31. Clutch hub sleeve

32. Synchronizer key

33. Clutch hub

34. 3rd/4th shift fork

35. Interlock sleeve

36. Control lever

37. lstl2nd shift fork

38. Control rod

39. Control end

03UOJl-021

Preinspection

5th gear thrust clearance

1. Measure the 5th gear thrust clearance with a dial indicator.

Clearance: 0.06-0.26mm (0.0024-0.0102 in)

Maximum : 0.31 mm (0.0122 in)

2. If the clearance exceeds the the maximum, check the con-

tact surfaces of 5th gear and the clutch hub. Replace worn

or damaged parts.

Disassembly note

Locknut

1, Mount the transaxle on the SST.

Jl-15

Page 506 of 1164

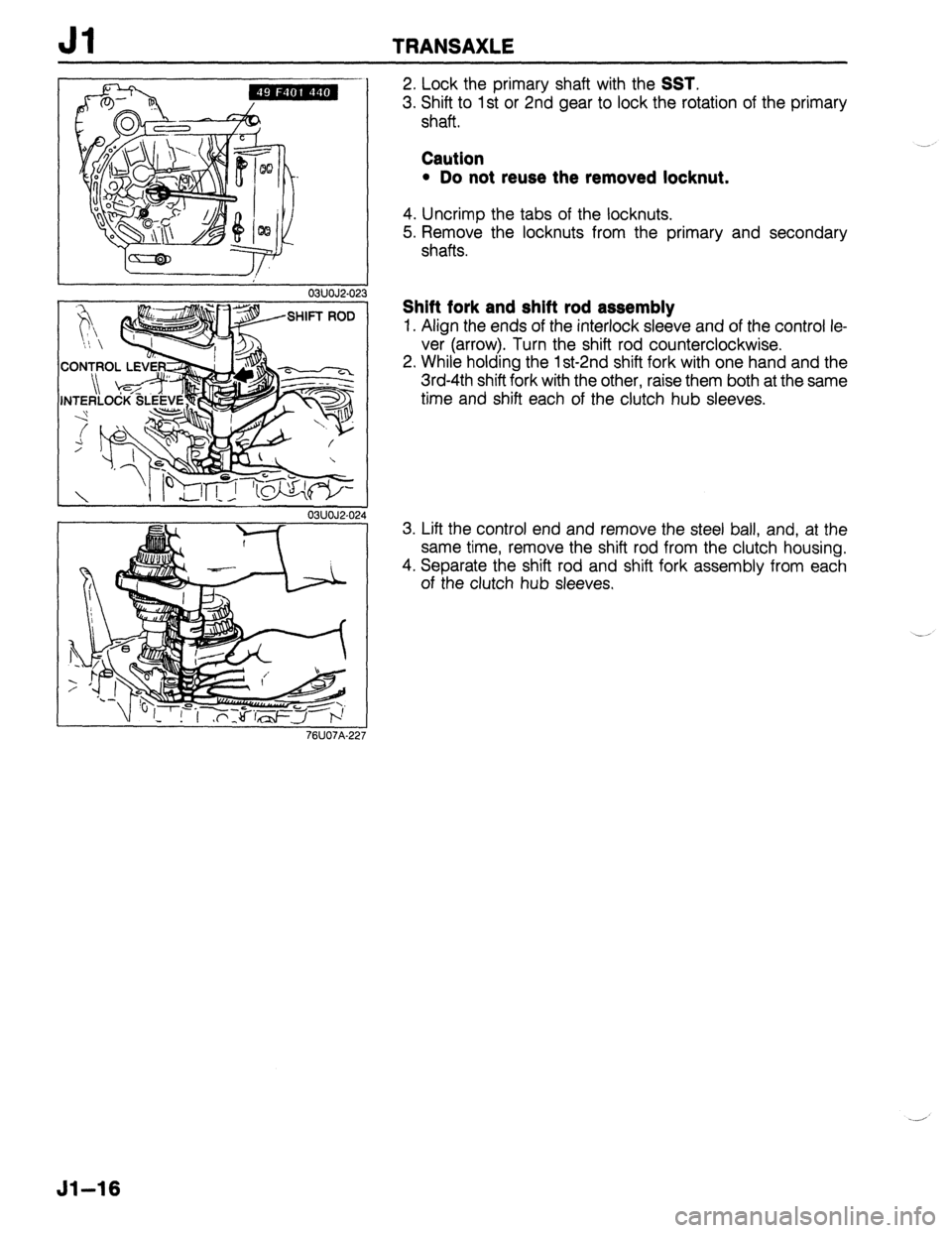

Jl TRANSAXLE

SHIFT ROD “I, -

CON-rPOL LEVE$:,

I I 03UOJ2.0

76U07A.22

2. Lock the primary shaft with the SST.

3. Shift to 1 st or 2nd gear to lock the rotation of the primary

shaft.

Caution

l Do not reuse the removed locknut.

4. Uncrimp the tabs of the locknuts.

5. Remove the locknuts from the primary and secondary

shafts.

Shift fork and shift rod assembly

1. Align the ends of the interlock sleeve and of the control le-

ver (arrow). Turn the shift rod counterclockwise.

2. While holding the 1 st-2nd shift fork with one hand and the

3rd-4th shift fork with the other, raise them both at the same

time and shift each of the clutch hub sleeves.

3. Lift the control end and remove the steel ball, and, at the

same time, remove the shift rod from the clutch housing.

4. Separate the shift rod and shift fork assembly from each

of the clutch hub sleeves.

51-16

Page 535 of 1164

TRANSAXLE Jl

1. Control rod

2. Control end

3. lstl2nd shift fork

4. Control lever

5. Interlock sleeve

6.3rd/4th shift fork

7. Clutch hub

8. Synchronizer key

9. Clutch hub sleeve

10. Synchronizer spring

11. Clutch housing

12. Differential assembly

13. Secondary shaft gear assembly

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-45

14. Primary shaft gear assembly

Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . , . page J 1-45

15. Spring

16. Steel ball

17. Shift fork and shift rod assembly

Assembly Note.. . . . . . . . . . . , . . . . . . . . . , . . , page J 1-45

18. Crank lever assembly

Assembly Note. . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-46

19. Crank lever shaft

Assembly Note.. . . . . . . . . . . , , . . . . . . . . . . . . page Jl -46

20. Pin

21. 5th shift rod end

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page 31-46

22. 5th shift rod

Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . . . page J 1-46

23. Reverse idler gear

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-46

24. Reverse idler shaft

Assembly Note... . . . . . . . . . . . . . . . . . . . . . . . page Jl -46

25 Magnet

26. Transaxle case assembly

Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . . . page Jl -47

27. Neutral switch

28. Back-up light switch

29. Lock bolt and washer

30. Secondary 5th gear

31. Gear sleeve

32. 5th gear

33. Synchronizer ring (5th)

34. Clutch hub assembly (5th)

Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . . . page Jl-47

35. 5th shift fork

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-47

36. Stop plate

37. Locknut (Secondary shaft)

Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . . . page Jl-47

38. Locknut (Primary shaft)

Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . . . page J 1-47

39. Rear cover

13UOJl-005

Assembly note

Primary shaft gear assembly and secondary shaft gear

assembly

1. Install the primary shaft gear assembly and the secondary

shaft gear assembly together.

03UOJl-115 Shift fork and shift rod assembly

1. Shift to 2nd gear and position the shift fork and shift rod

assembly as shown.

03UOJ2-088

51-45

Page 536 of 1164

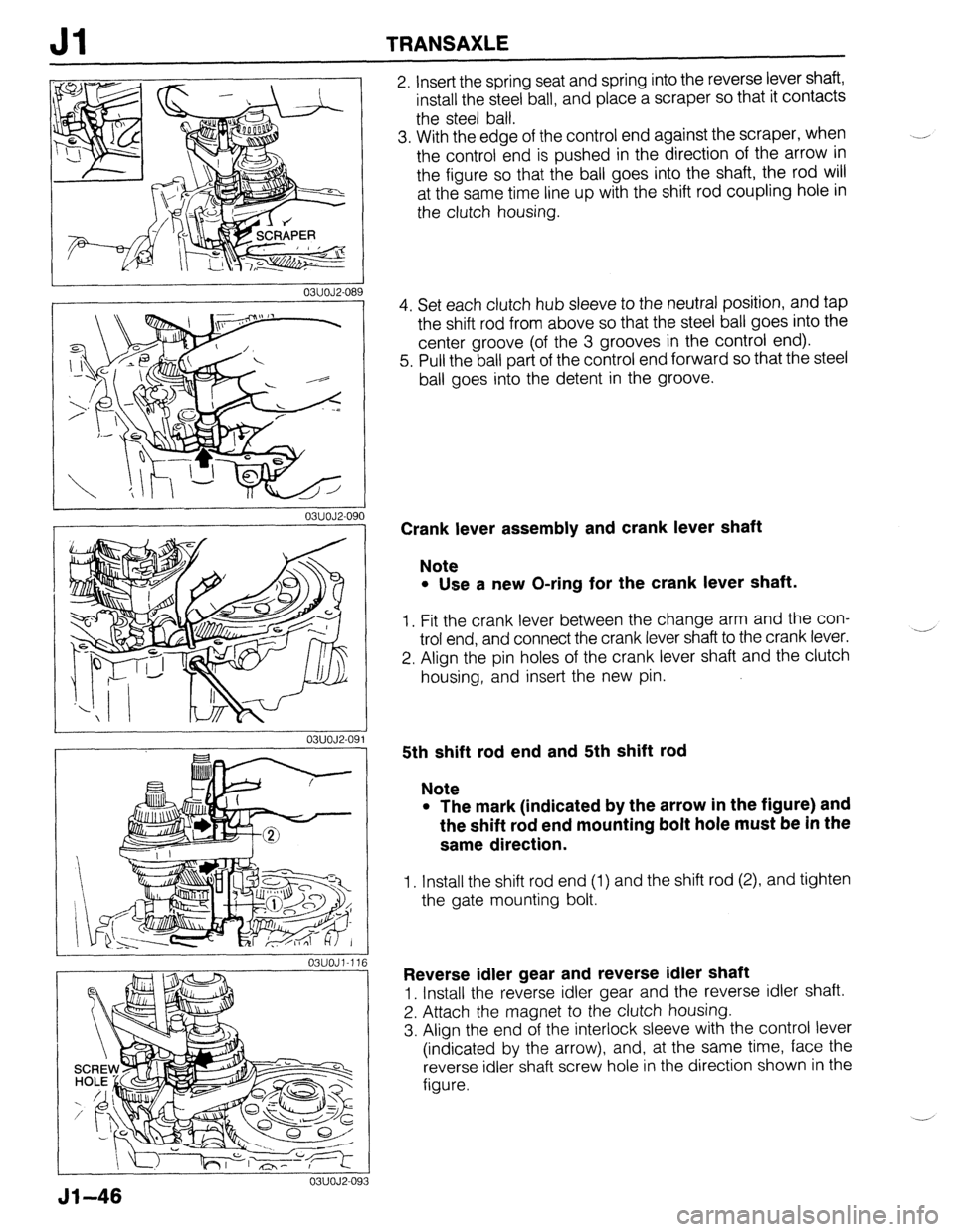

Jl TRANSAXLE

I I 03UOJ2-089

03UOJ2-091 3

03UOJ2-09

2. Insert the spring seat and spring into the reverse lever shaft,

install the steel ball, and place a scraper so that it contacts

the steel ball.

3. With the edge of the control end against the scraper, when

the control end is pushed in the direction of the arrow in

the figure so that the ball goes into the shaft, the rod will

at the same time line up with the shift rod coupling hole in

the clutch housing.

4. Set each clutch hub sleeve to the neutral position, and tap

the shift rod from above so that the steel ball goes into the

center groove (of the 3 grooves in the control end).

5. Pull the ball part of the control end forward so that the steel

ball goes into the detent in the groove.

Crank lever assembly and crank lever shaft

Note

l Use a new O-ring for the crank lever shaft.

1. Fit the crank lever between the change arm and the con-

trol end, and connect the crank lever shaft to the crank lever.

2. Align the pin holes of the crank lever shaft and the clutch

housing, and insert the new pin. -’

5th shift rod end and 5th shift rod

Note

l The mark (indicated by the arrow in the figure) and

the shift rod end mounting bolt hole must be in the

same direction.

1. Install the shift rod end (1) and the shift rod (2), and tighten

the gate mounting bolt.

Reverse idler gear and reverse idler shaft

1. Install the reverse idler gear and the reverse idler shaft.

2. Attach the magnet to the clutch housing.

3. Align the end of the interlock sleeve with the control lever

(indicated by the arrow), and, at the same time, face the

reverse idler shaft screw hole in the direction shown in the

figure.

Jl-46

Page 537 of 1164

TRANSAXLE Jl

- 23UOJl-01

03UOJl-11

03UOJl-14

I 03UOJl-11

Transaxle case assembly

1, Apply a thin coat of sealant to the contact surfaces of the

clutch housing and transaxle case, tighten the transaxle case

installation bolts to the specified torque.

Tightening torque:

19-26 Nom (1.9-2.6 m-kg, 14-19 ft-lb)

Clutch hub assembly (6th) and 6th shlft fork

1. Install the clutch hub assembly (5th) and the 5th shift fork

together.

Locknut

1. Shift to 1 st gear.

2. Lock the primary shaft with the

SST.

3. Tighten new locknuts on the primary and secondary shafts.

Tightening torque:

126-206 N*m (13.0-21 m-kg, 94-152 ft-lb)

4. Stake the locknuts.

5. Measure the 5th gear thrust clearance with a dial indicator.

Clearance: 0.06-0.26mm (0.0024-0.0102 in)

Maximum : 0.31 mm (0.0122 in)

6. If not as specified, reassemble the transaxle.

Jl-47

Page 540 of 1164

03UOJi-12 3

03UOJl-124

L 03UOJl.126 I-

03UOJl-12

Jl TRANSAXLE

Driveshaft

Caution

l Verify that the oil seal is not damaged.

l Do not damage the oil seal

1. Insert the clip with the end-gap at the top of the groove.

2. Apply transaxle oil around the oil seal lip. Install the

driveshaft.

3. Verify that the driveshaft is correctly seated by pulling on

the shaft.

4. Connect the lower arm to the knuckle and tighten the clinch

bolt.

Tightening torque:

43-59 N-m (4.4-6.0 m-kg, 32-43 ft-lb)

Stabilizer (BP SOHC)

1. Tighten the nut until the specified amount of thread is ex-

posed at the end of the bolt.

Dimension A: 17-l 9mm (0.67-0.75 in)

Tie-rod end

1. Install the locknut.

Tightening torque:

42-57 N-m (4.3-5.6 m-kg, 31-42 ft-lb)

2. Secure the locknut with a new cotter pin.

Engine mounting member

1. Install the bolts and nuts as shown.

Tightening torque

@ : 37-52 N,m (3.6-5.3 m-kg, 27-36 ft-lb)

@I: 64-89 N-m (6.5-9.1 m-kg, 47-66 ft-lb)

51-50

Page 543 of 1164

DIFFERENTIAL Jl

DISASSEMBLY / INSPECTION / ASSEMBLY

Caution

l Do not remove the inner race if not necessary.

1. Before disassembly, inspect the backlash of side gear and pinion gear, referring to Preinspection.

2. Disassemble in the order shown in the figure, referring to Disassembly Note.

3. Inspect all parts and repair or replace as necessary.

4. Assemble in the reverse order of disassembly, referring to

Assembly Note.

5. Measure the backlash after assembly, referring to Backlash of Side Gear and Pinion Gear.

1. Roll pin 7. Side bearing inner race

13UOJl-00:

Assembly Note .......................... page Jl -55 Disassembly Note.. ..................

2. Pinion shaft Inspection .................................

3. Thrust washer Assembly Note .........................

4. Pinion gear 8. Speedometer drive gear

Inspect for wear and cracks Assembly Note.. .......................

Preinspection ............................ page J l-53 9. Side bearing inner race

Inspection of backlash.. ............ page Jl-55 Disassembly Note.. ..................

5. Side gear Inspection .................................

Inspect for wear and cracks Assembly Note.. .......................

Preinspection ............................ page J l-53 10. Ring gear and ring case

Inspection of backlash.. ............ page Jl-55 Inspection .................................

6. Thrust washer

03UOJl-13 4

page Jl-54

page Jl -54

page Jl-55

page Jl -55

page Jl-54

page Jl-54

page Jl-55

page Jl-54

Preinspection

Backlash of side gear and pinion gear

Measure the backlash by the following procedure.

1. Install the left and right driveshafts in the differential as-

sem bly.

2. Support the driveshafts on V-blocks as shown in the figure.

3. Measure the backlash of both pinion gears.

Backlash: O-O. 1 mm (O-0.004 in)

51-53

Page 545 of 1164

DIFFERENTIAL Jl

03UOJl-138

Assembly Note

Speedometer drive gear

1. Install the speedometer drive gear as shown in the figure.

1

03UOJl-13!

I

03UOJ2-10

I

03UOJl-14

I 03UOJl-14 .l

Side bearing inner race (Side opposite ring gear)

1. Install the speedometer drive gear.

2. Install the new side bearing inner race with the

SST.

Side bearing inner race (Ring gear side)

1. Install the new bearing inner race with the SST.

Roll pin

1, Install the new roll pin as shown in the figure to hold the

pinion shaft.

Backlash of Side Gear and Pinion Gear

Measure the backlash by the following procedure.

1. Install the driveshafts in the differential assembly.

2. Support the driveshafts on V-blocks as shown in the figure.

3. Measure the backlash of both pinion gears.

Backlash: O-O.1 mm (O-0.004 in)

4. If not as specified, select the proper thrust washers.

(Refer to preinspection, page Jl-53.)

Jl-55

Page 561 of 1164

TRANSAXLE J2

Sth/Reverse Gear and Housing Parts

1. Disassemble in the order shown in the figure, referring to Disassembly Note.

1. Rear cover

2. Locknut (Primary shaft)

Disassembly Note . . . . . . . . . . . . . . . . . . . . . page J2-14

3. Locknut (Secondary shaft)

Disassembly Note . . . . . . . . . . . . . . . . . . . . .

page J2-14

4. Primary reverse synchronizer gear

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page J2-22

5. Synchronizer ring (Reverse)

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page J2-22

6. Secondary reverse synchronizer gear

Inspection ,,.*.....,.,..............I.,..,.. page J2-22

7. Roll pin

8. 5th/Reverse shift fork

9. Clutch hub assembly (5thIReverse) 14. Lock bolt

15. Guide bolt

16. Lock bolt, ball, and spring

17. Transaxle case assembly

18. Magnet

19. Reverse idler shaft

20. Reverse idler gear

21. Lock bolt

22. 5thlReverse shift rod and clip

23. 5th/Reverse shift rod end

24. Pin

25. Crank lever shaft

26. Crank lever assembly

27. Shift fork and shift rod assembly

.- . .

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page J2-22 Disassembly Note . . . . . . . . . . . . . . . . . . . . . page

JZ-14

10. Synchronizer ring (5th) 28. Steel ball

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page J2-22 29. Spring

11. 5th gear 30. Primary shaft gear assembly

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page J2-22 31. Secondary shaft gear assembly

12. Gear sleeve 32. Differential assembly

13. Secondary 5th gear 33. Clutch housing

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page J2-22

52-l 3