engine MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 647 of 1164

ENGINE SPEED SENSING POWER STEERING N

ENGINE SPEED SENSING POWER STEERING

PREPARATION

SST

19 6032 306

Nrench, plug For

removal and

installation of

Plug 49 8032 312

Protector, slipper

seal For

installation of seal

ring

$9 B032 314

Yipper seal

ormer For

form of seal ring 49 F032 303

Handle

19 8032 315

nstaller, oil seal For

installation of oil

seal 49 8032 309

Installer body,

pinion seal For

installation of

oil seal

49 B032 316

Support block,

Pul For

removal of oil

seal & bearing 49 8032 310

Protector, pinion

seal For

installation of

oil seal

49 8032 317

Remover, bearing

& oil seal For

removal of oil

seal & bearing 49 8032 311

Protector, slipper

seal For

installation of

pinion shaft

49 GO30 797

Handle For

installation of

pinion seal 49 8032 320

Wrench For

removal and

installation of

adjustment cover

locknut

49 0180 5108 For 49 8032 321 For

measurement of hermetic

Attachment,

preload ,+&--I pinion torque Adapter

Q inspection

^

49 8032 305

Holder, power

steering pump For

installation of oil

N-23

Page 648 of 1164

N ENGINE SPEED SENSING POWER STEERING

19 1232 670A

Gauge set,

Dower steering

49 HO32 301

wrench

49 8032 304

Adapter

49 8032 307

Wrench, outer

box

49 8032 308

Remover body,

rod seal

49 8032 319

Protector body,

rod seal

49 9200 020

Tension gauge,

V-ribbed belt For

measurement of

fluid pressure

For

removal of

tie-rod

For

measurement of

fluid pressure

For

removal and

installation of

outer box

For

removal of oil

seal

For

installation of

inner guide 81 oil

seal

For

measurement of

drive belt tension 49 1232 673

Valve body

(Part of

49 1232 670A)

49 1232 672

Gauge

(Part of

49 1232 670A)

49 HO02 671

Adapter

49 8032 313

Protector, outer

box

49 8032 318

Guide, rod seal

49 0118 850C

Puller, ball joint

I

-

For

measurement of

fluid pressure

For

measurement of

fluid pressure

For

measurement of

fluid pressure

For

installation of

outer box

For

installation of

inner guide & oil

seal

For

removal of

tie rods end

23UONX-0.

N-24

Page 649 of 1164

ENGINE SPEED SENSING POWER STEERING N

TROUBLESHOOTING GUIDE

Adjust or replace

Repair or replace Shimmy (Steering

wheel vibrates

left/right)

N-25

Page 650 of 1164

ENGINE SPEED SENSING POWER STEERING

23UONX-03

03UONX-032

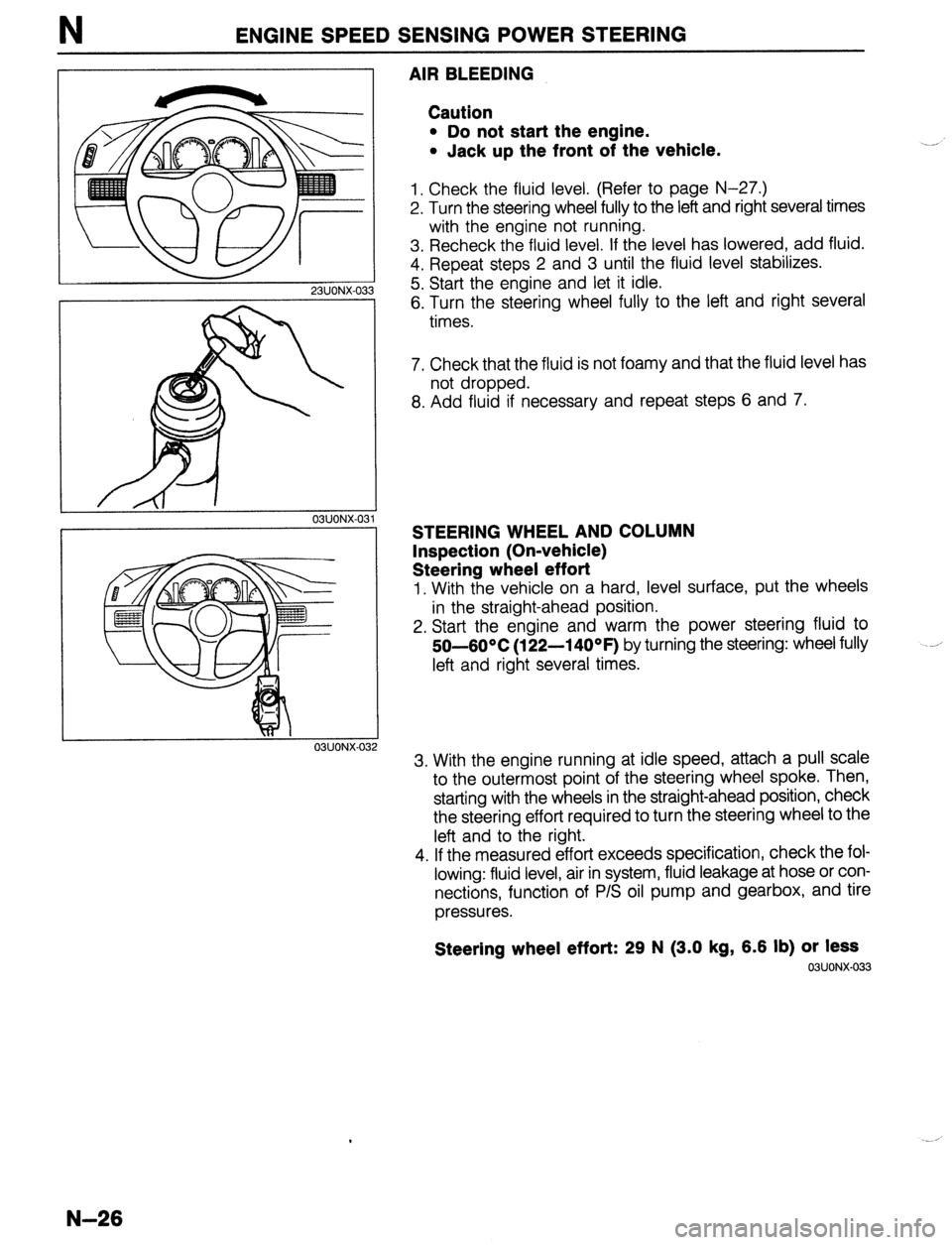

AIR BLEEDING

Caution

l Do not start the engine.

l Jack up the front of the vehicle.

1. Check the fluid level. (Refer to page N-27.)

2. Turn the steering wheel fully to the left and right several times

with the engine not running.

3. Recheck the fluid level. If the level has lowered, add fluid.

4. Repeat steps 2 and 3 until the fluid level stabilizes.

5. Start the engine and let it idle.

6. Turn the steering wheel fully to the left and right several

times.

7. Check that the fluid is not foamy and that the fluid level has

not dropped.

8. Add fluid if necessary and repeat steps 6 and 7.

STEERING WHEEL AND COLUMN

Inspection (On-vehicle)

Steering wheel effort

1. With the vehicle on a hard, level surface, put the wheels

in the straight-ahead position.

2. Start the engine and warm the power steering fluid to

50-60°C

(122-14OOF) by turning the steering: wheel fully

left and right several times.

3. With the engine running at idle speed, attach a pull scale

to the outermost point of the steering wheel spoke. Then,

starting with the wheels in the straight-ahead position, check

the steering effort required to turn the steering wheel to the

left and to the right.

4. If the measured effort exceeds specification, check the fol-

lowing: fluid level, air in system, fluid leakage at hose or con-

nections, function of P/S oil pump and gearbox, and tire

pressures.

Steering wheel effort: 29 N (3.0 kg, 6.6 lb) or less 03UONX-033

N-26

Page 651 of 1164

ENGINE SPEED SENSING POWER STEERING N

r-

-l

03UONX-034

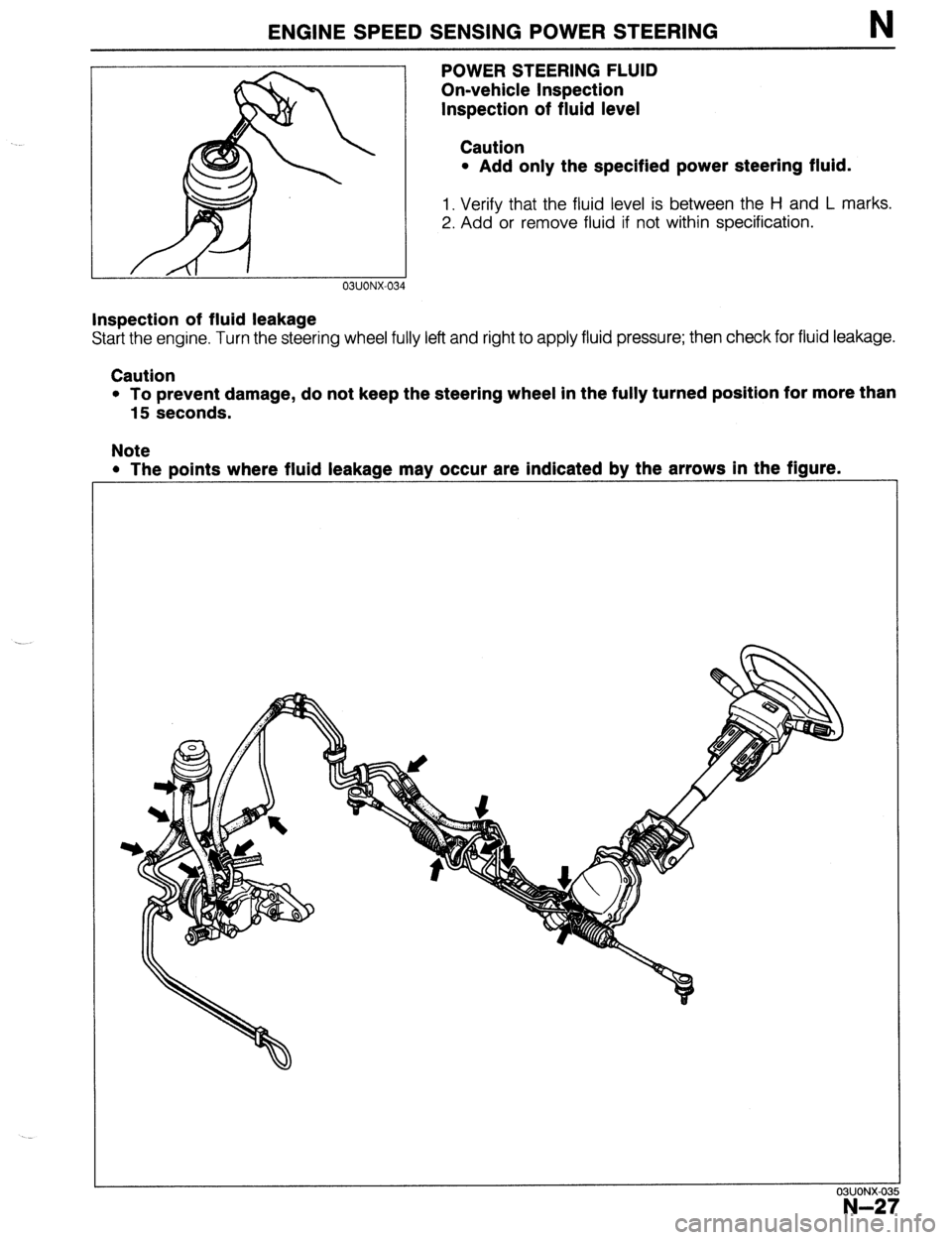

POWER STEERING FLUID

On-vehicle Inspection

Inspection of fluid level

Caution

l Add only the specified power steering fluid.

1. Verify that the fluid level is between the H and L marks.

2. Add or remove fluid if not within specification.

Inspection of fluid leakage

Start the engine. Turn the steering wheel fully left and right to apply fluid pressure; then check for fluid leakage.

Caution

+ To prevent damage, do not keep the steering wheel in the fully turned position for more than

15 seconds.

Note

l The points where fluid leakage may occur are indicated by the arrows in the figure.

03UONX-035

N-27

Page 652 of 1164

N ENGINE SPEED SENSING POWER STEERING

03UONXGI

23UONX-03

23UONX-OZ

THERMOMETER

-Y

23UONX-03

Inspection of fluid pressure

1. Assemble the SST as shown in the figure.

Tightening torque:

39-49 Nern (4.0-5.0 m-kg, 29-36 ft-lb)

2. Disconnect the pressure hose on the oil pump side, and

attach the SST.

Note

l Before disconnecting the hose, make marks at the

connections for proper reinstallation.

3. Bleed the air from the system. (Refer to page N-26.)

4. Open the gauge valve fully. Start the engine and turn the

steering wheel fully left and right to raise the fluid tempera-

ture to 50-60°C (122-14OOP).

5. Close the gauge valve completely. Increase the engine

speed to 1,000-l ,500 rpm and measure the fluid pres-

sure generated by the oil pump. If the pressure is below

specification, replace the oil pump assembly.

Oil pump fluid pressure:

7,356 kPa (75 kg/cm2, 1,067 psi)

Caution

l If the valve Is left closed for more than 15 seconds,

the fluid temperature will increase excessively and

adversely affect the oil pump.

6. Open the gauge valve fully again and increase the engine

speed to l,OOO-1,500 rpm.

7. Turn the steering wheel fully to the left and right and meas-

ure the fluid pressure generated by the gear housing. If the

pressure is below specification, replace the gear housing

assembly.

Gear housing fluid pressure:

7,356 kPa (75 kg/cm2, 1,067 psi)

Caution

l If the steering wheel is kept in the fully turned po-

sition for more than 15 seconds, the fluid tempera-

ture will rise excessively.

N-28

Page 653 of 1164

ENGINE SPEED SENSING POWER STEERING N

8. Remove the gauge set. Install and tighten the pressure hose

to the specified torque.

Tightening torque:

16-24 N-m (1.6-2.4 m-kg, 12-17 ft-lb)

9. Bleed the air from the system. (Refer to page N-26.)

23UONX-037

N-29

Page 654 of 1164

N ENGINE SPEED SENSING POWER STEERING

STEERING GEAR AND LINKAGE

Removal / Installation

1. Loosen the wheel lug nuts.

2. Jack up the front of the vehicle and support it with safety stands.

3. Remove the wheels.

4. Remove in the order shown in the figure, referring to

Removal Note.

5. Install in the reverse order of removal, referring to Installation Note.

6. After installation, bleed air from the steering system and adjust the toe-in if necessary. (Refer to Section R.)

2.0-5.9 N.m (20-60 cm-kg, 17-52 In-lb) _

(4.3-5.5, 31-42)

31-L46

(3.2-4.7, 23-34;>

16-23

(1.6-2.3, 12-17)

Y

N.m (m-kg, ft-lb)

23UONX-02

Note

l Use a container or rags to collect the power steering fluid when disconnecting the pressure

pipe and return hose.

l Lower the steering brackets and steerlng gear and linkage as an assembly; then separate the

steering gear and linkage.

1. Cotter pin 8. Extension bar/Control rod (MTX)

2. Nut 9. Nut (Steering gear mounting bolt)

3. Tie rod end/Steering knuckle Installation note .,,...*................... page N-14

Removal note . . . . . . . . . . . . . . . . . . . . . . . . . ,. page N- 6 10. Steering gear and linkage

4. Pressure pipe Removal note . . . . . . . . . . . . . . . . . . . . . . . ..a... page N-14

5. Return hose Disassembly / Inspection . . . . . . . . . . . . page N-31

6. Set plate Assembly . . . . . . . . . . . . . . . ..*.................. page N-34 .li;

7. Fixing bolt (intermediate shaft/pinion shaft)

Installation note . . . . . . . . . . . . . . . . . . . . . . . . . . page N-14

N-30

Page 655 of 1164

ENGINE SPEED SENSING POWER STEERING N

Disassembly / Inspection

1. Disassemble in the order shown in the figure, referring to Disassembly Note.

2. insoect all Darts and reoair or reolace as necessarv.

N.m (m-kg, ft-lb:

L.

311 rnNX.rf

_” _-..,. -39

1. Oil pipe

Disassembly Note ,., ,......... .., ,., ,.. page N-32

2. Tie rod end

3. Locknut

4. Boot clip

5. Boot wire

6. Boot

7. Tie rod

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . page N-32

Inspection for damage

Inspect operation of ball joint

8. Washer

9. Cover

10. Locknut

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . page N-32

11. Adjusting cover

12. Spring

13. Pressure pad

14. Housing cover

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . page N-32

15. Locknut

16. Bearing

17. Plug

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . page N-32

Inspection . . . . . . . . . . . . . . . . . . . . ..*............ page N-33

18. O-ring 19. Oil seal

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . page N-33

20. Bearing

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . page N-33

21. Pinion shaft assembly

Inspect for damage and wear

22. Seal ring

23. Outer box assembly

Disassembly note ,....,..,.....,........ page N-33

24. O-ring

25. U-gasket

26. Steering rack

Inspection . . . . . . . . . . ..*...........*.......... page N-33

27. Seal ring

28. O-ring

29. Oil seal

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . page N-33

30. Inner guide

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . page N-33

31. Bearing

32. Oil seal

33. Mounting rubber

34. Mounting bracket

35. Gear housing

Inspect for damage and crack

N-31

Page 656 of 1164

ENGINE SPEED SENSING POWER STEERING

i

93GONX-02t

93GONX-02 ‘8

93GONX-029

I I

93GONX-030

N-32

Disassembly note

Oil pipe

Caution

l After disconnecting the pipes, use a plug or adhe-

sive type tape to seal each port to prevent the en-

try of foreign materials.

Tie rod

1. Use the SST to remove the tie rod.

Caution

l To avoid scratching the rack, secure the rack in a

vise protected with brass pads or cloth.

Locknut

1, Use the SST to remove the locknut.

Housing cover

1. Use a drill @1.5mm (0.06 in)) to make a recessed area (ap-

prox. 1.5mm (0.06 in)) at the punch-crimped part of the

threaded part.

Caution

l if the drill diameter and/or the depth of the recess

are excessive, the threads will be too loose when

the plug is reused.

Plug

1. Use the SST to remove the plug.