engine MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 725 of 1164

FRONT SUSPENSION (STRUT) R

r

03UORX-03

STABILl2;ER BAR

I

Removal note

Stabilizer bar

1. Remove the nuts of the steering gear box mounting brack-

et, and move the gear box forward.

2. Support the engine with the

SST, and remove the cross-

member mounting bolts.

3. Lower the crossmember slowly, and remove the stabilizer

bar from the crossmember.

Installation note

Stabilizer bushing

Align the bushing with the installation position line painted on

the stabilizer bar.

Stabilizer nut

1. Tighten the stabilizer nut so that the specified thread is ex-

posed at the end of the bolt.

Specification: 17-l 9mm (0.67-0.75 in)

Stabilizer bar

1. Install the stabilizer bar to the crossmember.

2. Install the crossmember and tighten the mounting bolts to

the specified torque.

Tightening torque:

93-127 N#m (9.5-12.9 m-kg, 69-93 ft-lb)

3. Tighten the nuts of the steering gear box mounting bracket

to the specified torque.

Tightening torque:

37-52 N*m (3.6-5.3 m-kg, 27-36 ft-lb)

R-19

Page 869 of 1164

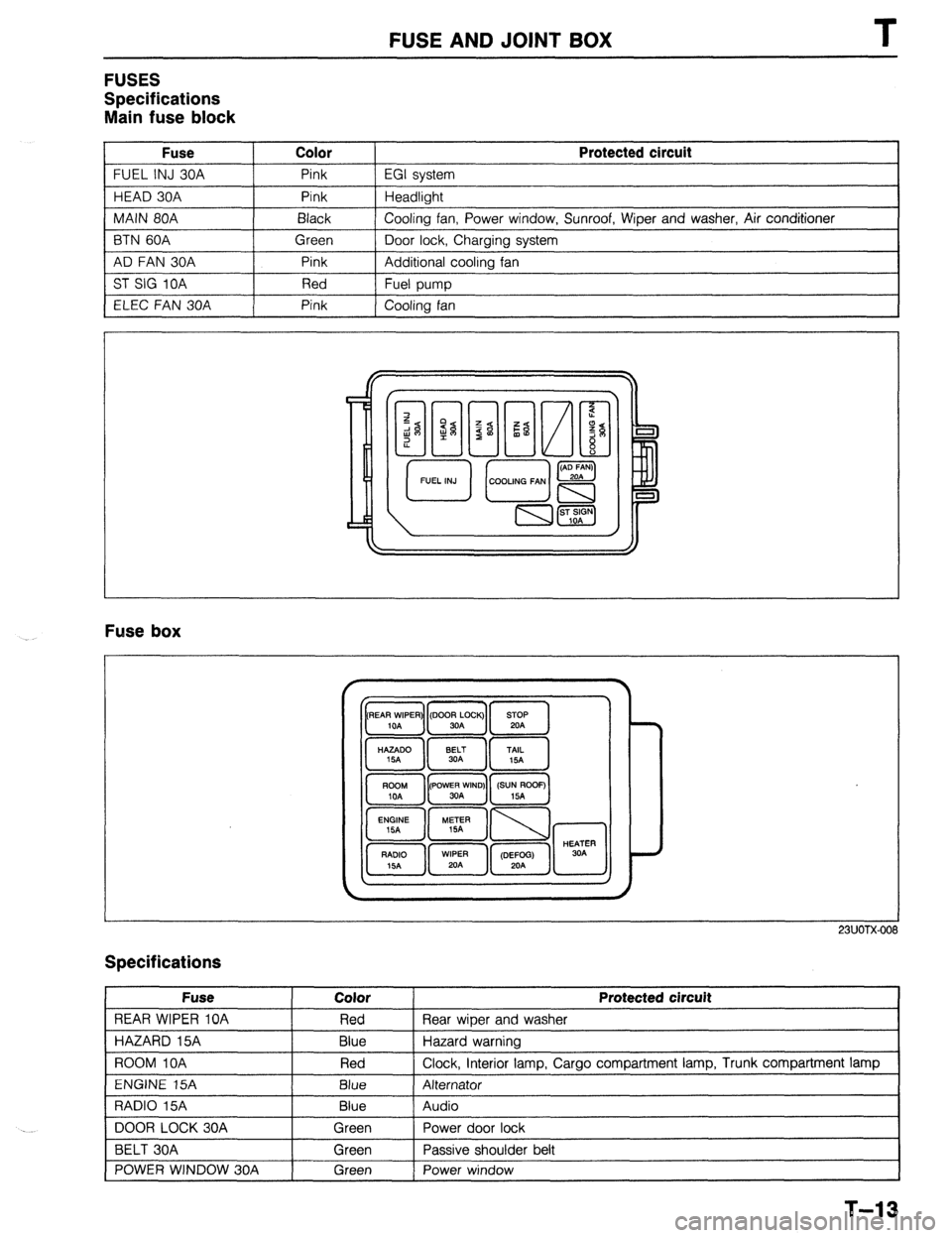

FUSE AND JOINT BOX

FUSES

Specifications

Main fuse block

Fuse Color

FUEL INJ 30A Pink

HEAD 30A Pink

MAIN 80A Black

BTN 60A Green

AD FAN 30A Pink

ST SIG 10A Red

ELEC FAN 30A Pink Protected circuit

EGI system

Headlight

Cooling fan, Power window, Sunroof, Wiper and washer, Air conditioner

Door lock, Charging system

Additional cooling fan

Fuel pump

Cooling fan

Fuse box

23UOTX-001

Specifications

Fuse

REAR WIPER 10A

HAZARD 15A

ROOM IOA

ENGINE 15A

RADIO 15A

DOOR LOCK 30A

BELT 30A

POWER WINDOW 30A Color

Red

Blue

Red

Blue

Blue

Green

Green

Green Protected circuit

Rear wiper and washer

Hazard warning

Clock, interior lamp, Cargo compartment lamp, Trunk compartment lamp

Alternator

Audio

Power door lock

Passive shoulder belt

Power window

1

T-13

Page 895 of 1164

EXTERIOR LIGHTING SYSTEM T

Stoplight

Circuit diaaram

GTOPLIGHTS F-2

SHIFT-LOCK

BLUB TRADE NUMBER

STOPLIGHT: 1157 (27W)

HIGH MOUNT

STOPLIGHT: 921 (18.4W) G (F) *ENGINE CONTROL UNIT

(SECTION B- lc;26)

G (F) *CRUISE CONTROL UNIT

(SECTION 01)

WITH REAR SPOILER

HIGH MOUNl-

STOPLIGHT

STOPLIGHT STOPLIGHT

-06 STOPLIGHT

SWITCH (F) F-07 HIGH MOUNT STOP-E-12 STOPLIGHT LH(R) E-13 STOPLIGHT RH(R)

LIGHT (R3)

WITH

REAR SPOILER---+ (R2)

03UOTX-057

T-39

Page 917 of 1164

WARNING SYSTEM T

13UOTX-07

63U15X-05

, I//

‘nF -

-

-

FUEL

13UOTX.08C

- CHARGE

13UOTX-08

13UOTX-08

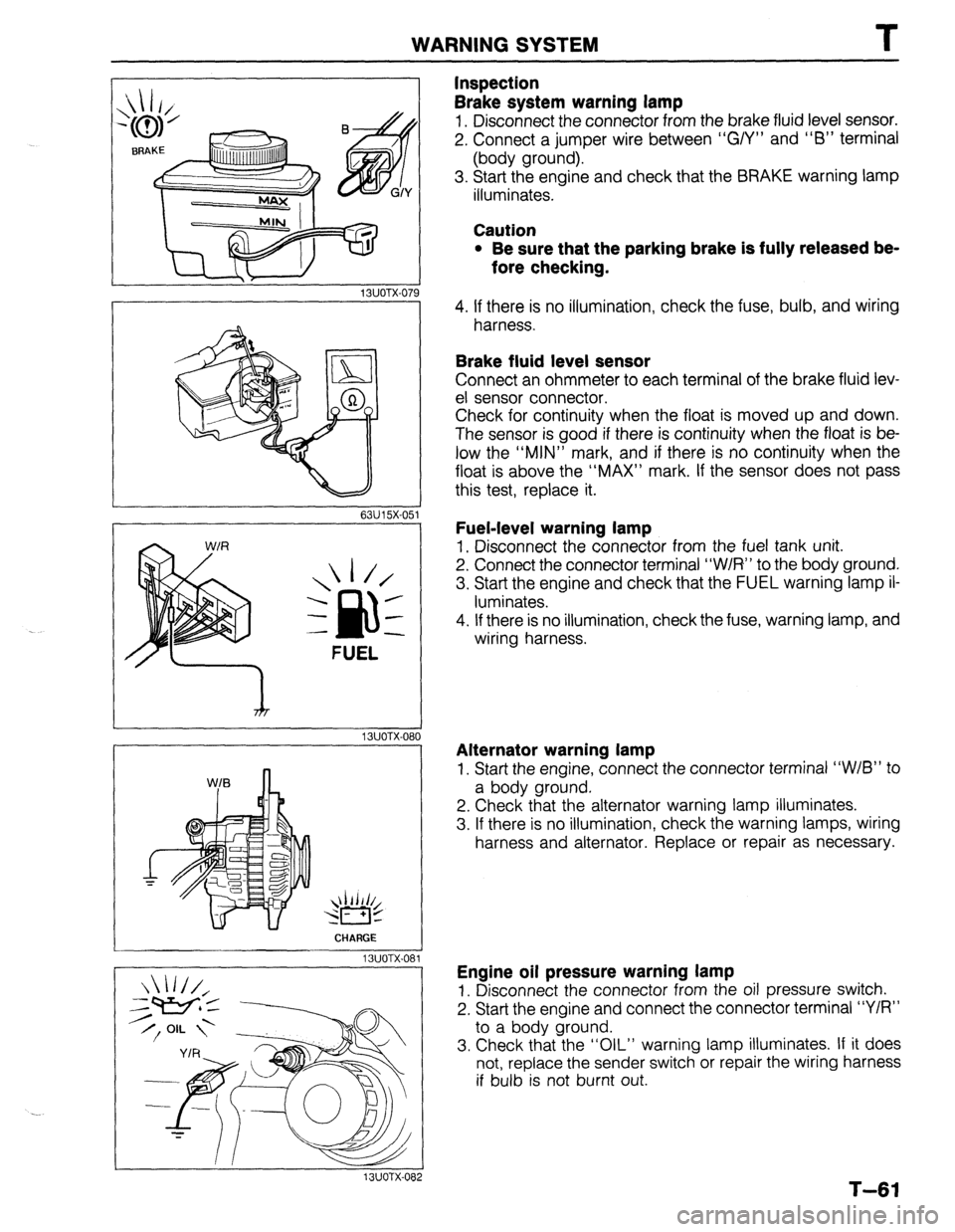

Inspection

Brake system warning lamp

1. Disconnect the connector from the brake fluid level sensor.

2. Connect a jumper wire between “G/Y” and “6” terminal

(body ground).

3. Start the engine and check that the BRAKE warning lamp

illuminates.

Caution

l Be sure that the parking brake is fully released be-

fore checking.

4. If there is no illumination, check the fuse, bulb, and wiring

harness.

Brake fluid level sensor

Connect an ohmmeter to each terminal of the brake fluid lev-

el sensor connector.

Check for continuity when the float is moved up and down.

The sensor is good if there is continuity when the float is be-

low the “MIN” mark, and if there is no continuity when the

float is above the “MAX” mark. If the sensor does not pass

this test, replace it.

Fuel-level warning lamp

1. Disconnect the connector from the fuel tank unit.

2. Connect the connector terminal “W/R” to the body ground.

3. Start the engine and check that the FUEL warning lamp il-

luminates.

4. If there is no illumination, check the fuse, warning lamp, and

wiring harness.

Alternator warning lamp

1. Start the engine, connect the connector terminal “W/B” to

a body ground.

2. Check that the alternator warning lamp illuminates.

3. If there is no illumination, check the warning lamps, wiring

harness and alternator. Replace or repair as necessary.

Engine oil pressure warning lamp

1. Disconnect the connector from the oil pressure switch.

2. Start the engine and connect the connector terminal “Y/R”

to a body ground.

3. Check that the “OIL” warning lamp illuminates. If it does

not, replace the sender switch or repair the wiring harness

if bulb is not burnt out.

T-61

Page 918 of 1164

T

I WARNING SYSTEM

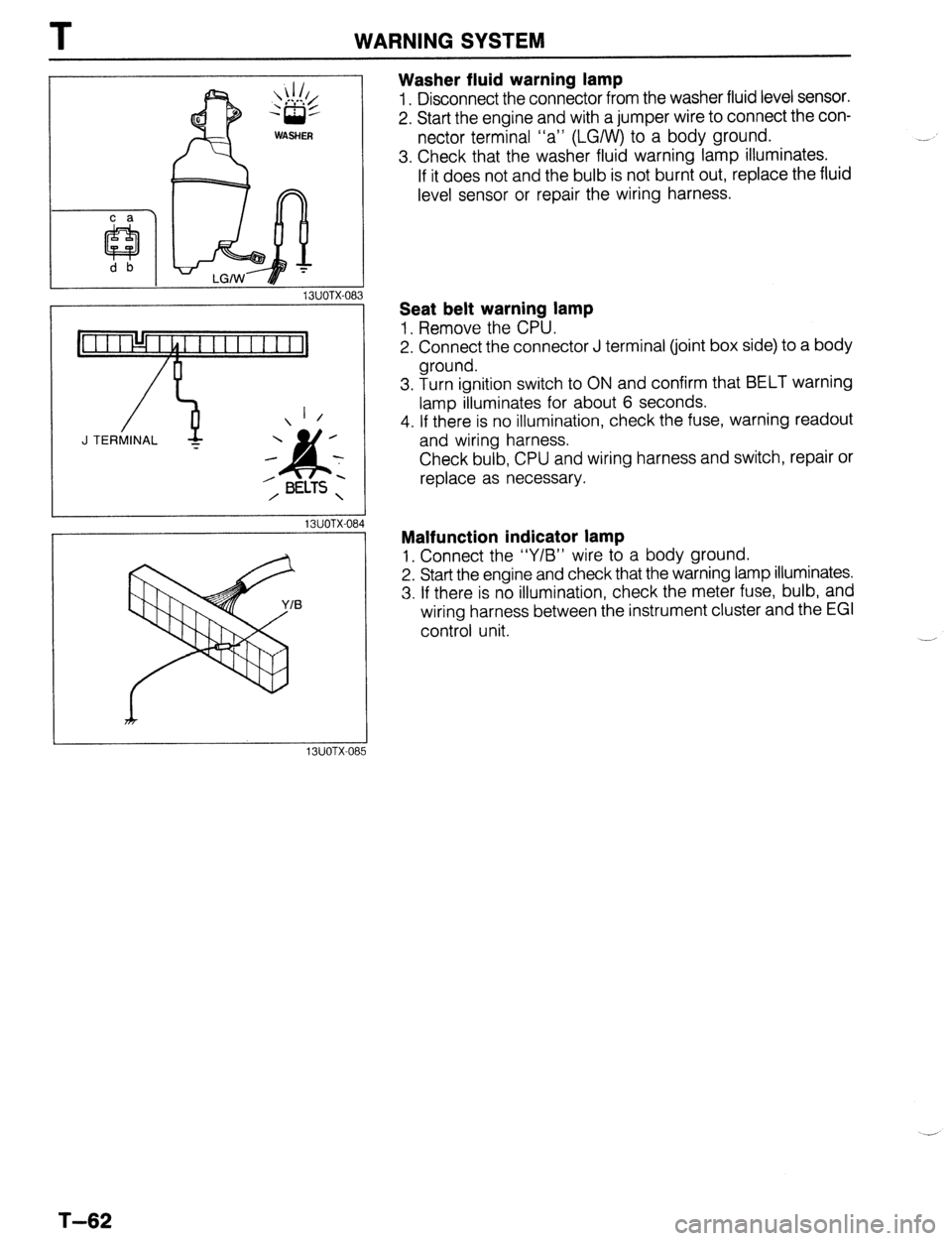

Washer fluid warning lamp

1. Disconnect the connector from the washer fluid level sensor.

2. Start the engine and with a jumper wire to connect the con-

nector terminal “a” (LGIW) to a body ground.

3. Check that the washer fluid warning lamp illuminates.

If it does not and the bulb is not burnt out, replace the fluid

level sensor or repair the wiring harness.

13UOTX-08

_-

1 /

J TERMINAL -

13UOTX-08

13UOTX-08

Seat belt warning lamp

1, Remove the CPU.

2. Connect the connector J terminal (joint box side) to a body

ground.

3. Turn ignition switch to ON and confirm that BELT warning

lamp illuminates for about 6 seconds.

4. If there is no illumination, check the fuse, warning readout

and wiring harness.

Check bulb, CPU and wiring harness and switch, repair or

replace as necessary.

Malfunction indicator lamp

1, Connect the “Y/B” wire to a body ground.

2. Start the engine and check that the warning lamp illuminates.

3. If there is no illumination, check the meter fuse, bulb, and

wiring harness between the instrument cluster and the EGI

control unit.

T-62

Page 922 of 1164

T INSTRUMENT CLUSTER

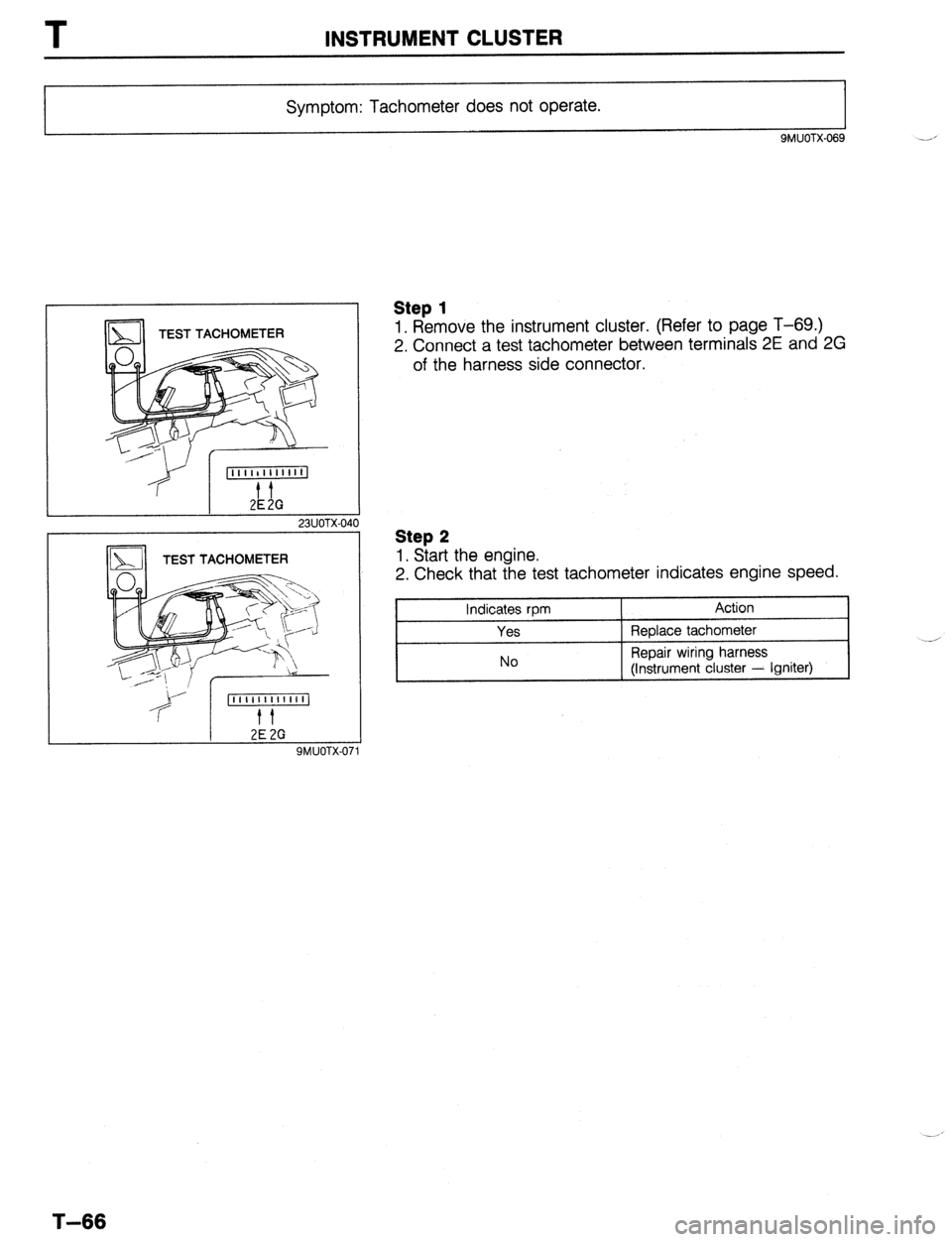

Symptom: Tachometer does not operate.

9MUOTX.069

TEST TACHOMETER

23UOTX-040

2E 2G SMUOTX-01

Step 1

1. Remove the instrument cluster. (Refer to page T-69.)

2. Connect a test tachometer between terminals 2E and 2G

of the harness side connector.

Step 2

1. Start the engine.

2. Check that the test tachometer indicates engine speed.

Indicates rpm

Yes

No Action

Replace tachometer

Repair wiring harness

(Instrument cluster - Igniter)

T-66

Page 927 of 1164

INSTRUMENT CLUSTER T

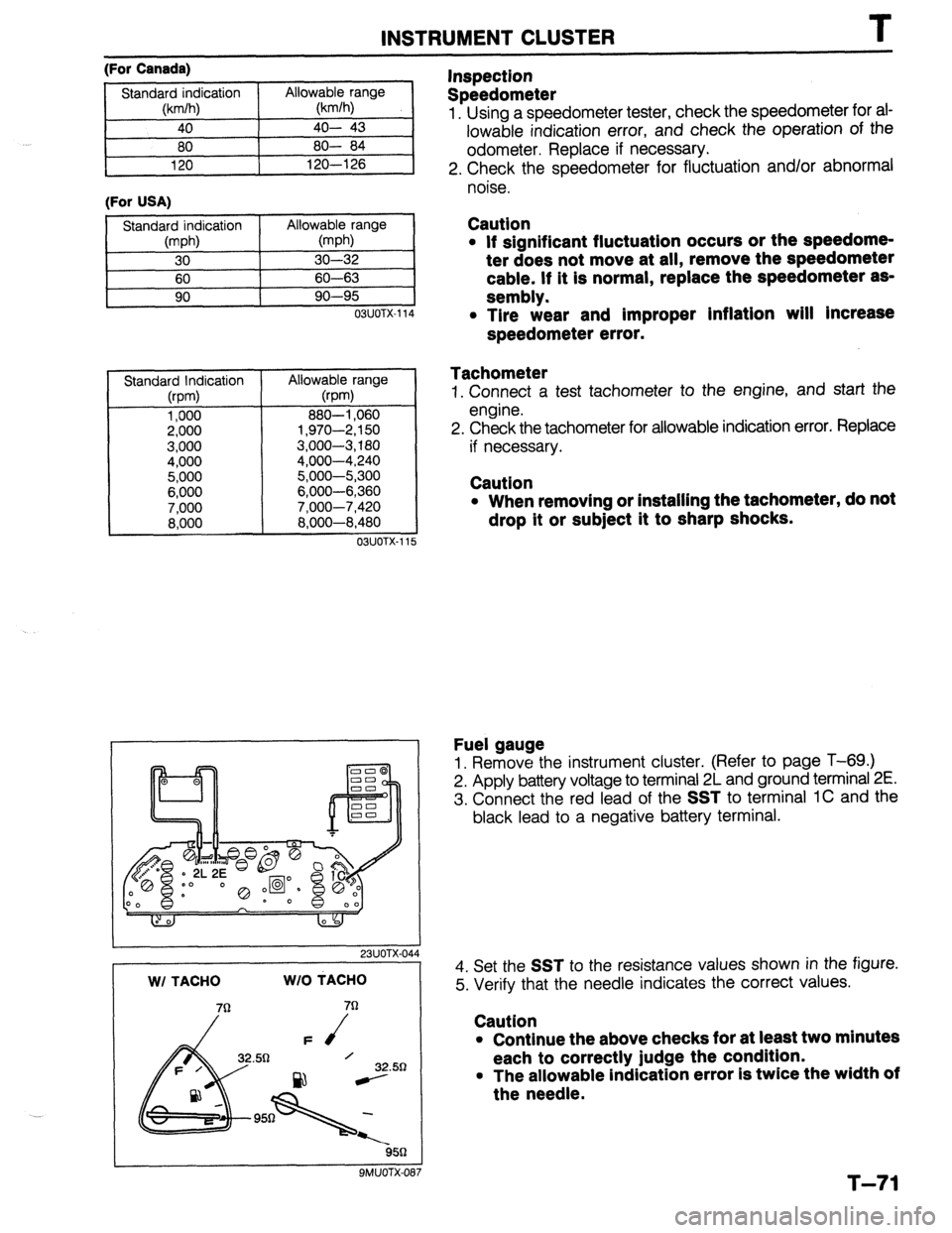

(For Canada)

(For USA)

11

OSUOTX-114

Standard Indication

(rpm)

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000 Allowable range

@pm)

880-l ,060

1,970-2,150

3,000-3,180

4,000-4,240

5,000-5,300

6,000-6,360

7.000-7.420

8:600-8:480

03UOTX-11 5

I 23UOTX-044 WI TACHO WIO MACHO

32.50

ssn

9MUOTX-087

Inspection

Speedometer

1. Using a speedometer tester, check the speedometer for ai-

lowable indication error, and check the operation of the

odometer. Replace if necessary.

2. Check the speedometer for fluctuation and/or abnormal

noise.

Caution

l If significant fluctuation occurs or the speedome-

ter does not move at all, remove the speedometer

cable. If it is normal, replace the speedometer as-

sembly.

l Tire wear and improper inflation will Increase

speedometer error.

Tachometer

1. Connect a test tachometer to the engine, and start the

engine.

2. Check the tachometer for allowable indication error. Replace

if necessary.

Caution

l When removing or installing the tachometer, do not

drop it or subject it to sharp shocks.

Fuel gauge

1. Remove the instrument cluster. (Refer to page T-69.)

2. Apply battery voltage to terminal 2L and ground terminal 2E.

3. Connect the red lead of the

SST to terminal 1C and the

black lead to a negative battery terminal.

4. Set the

SST to the resistance values shown in the figure.

5. Verify that the needle indicates the correct values.

Caution

l Continue the above checks for at least two minutes

each to correctly judge the condition.

l The allowable indication error is twice the width of

the needle.

T-71

Page 941 of 1164

CRUISE CONTROL SYSTEM T

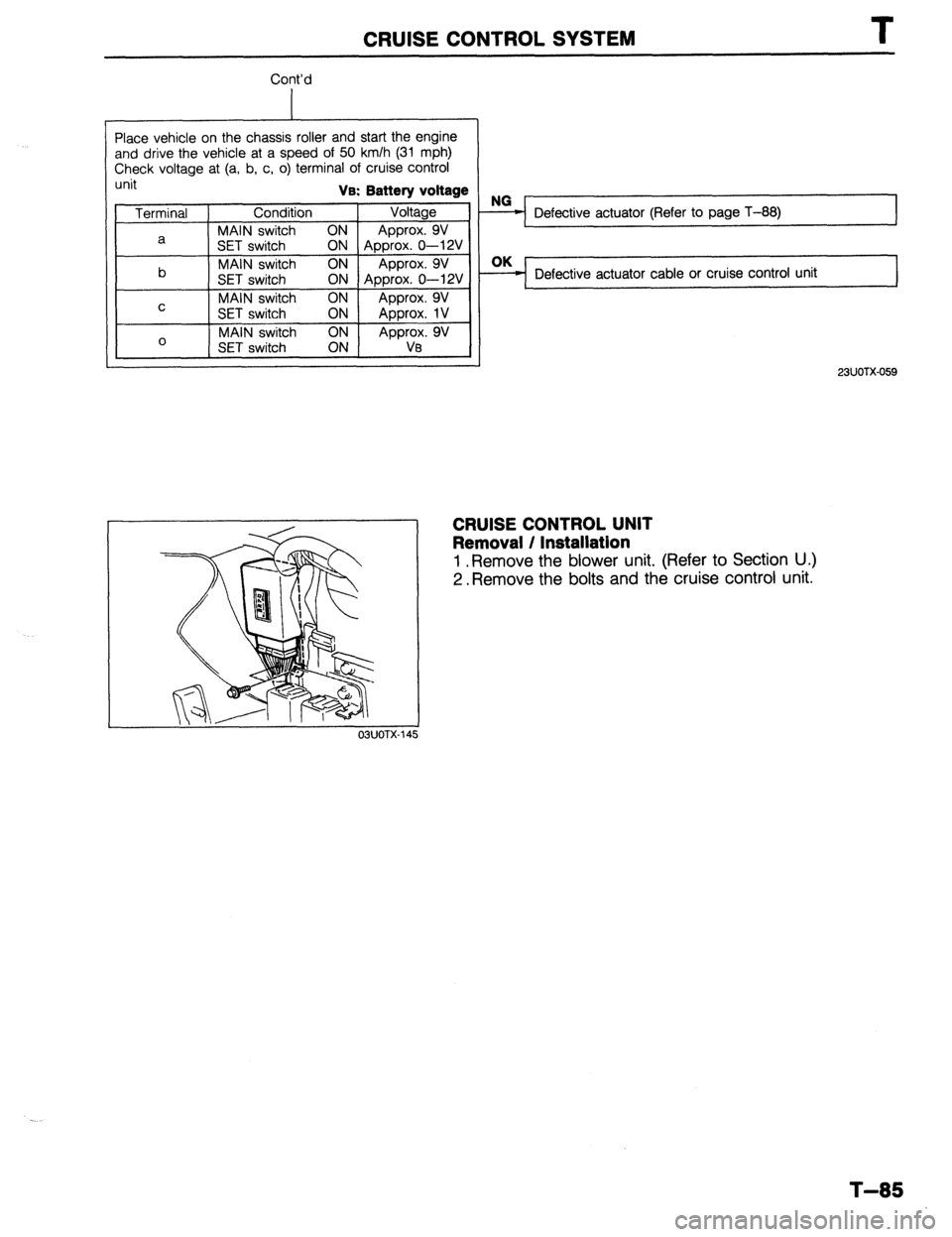

Cont’d

Place vehicle on the chassis roller and start the engine

and drive the vehicle at a speed of 50 km/h (31 mph)

Check voltage at (a, b, c, o) terminal of cruise control

unit Va: Battery voltage

Terminal Condition Voltage

MAIN switch ON

a Approx. 9V

SET switch

ON Approx. 0-12V

b MAIN switch ON Approx. 9V

SET switch ON Approx. 0-12V

MAIN switch ON

C Approx. 9V

SET switch ON

Approx. 1V

0 MAIN switch

Approx. 9V

SET switch Va

OBUOTX

Defective actuator (Refer to page T-88) I

Defective actuator cable or cruise control unit

23UOTX-059

CRUISE CONTROL UNIT

Removal / Installation

1 .Remove the blower unit. (Refer to Section U.)

2. Remove the bolts and the cruise control unit.

T-85

Page 960 of 1164

C

b l HEATER 6 AIR CONDITIONER 1 G

MAIN

I3 Fl

AD FAN

JB-06

4

B/R (F)

1,

1 I

t

G-07

REAR WIPER

IOA

-L/G (F) _fcoJI)

a-07

63

ENGINE

CONTROL UNIT

(SECTION 6-1~. 2bl A/C SWITCH 6 BLOWER SWITCH ILLUMINATION

LAMPS’REFER TO SECTION I-4

RESISTOR ASSEMBLY L/B

-1

r

BjG L)B

(AC9 (AC)

4NT

A/C SWITCH -L/B

4)

6 33

;~~l-bJG FAN

(SECTION B-3.

i-01 CONDENSER FAN (AC) -03 DIODE (AC) G-04 REFRIGERANT G-05 REFRIGERANT G-06 MAGNETIC CLUTCH (AC) G-07 IE) - (AC) CONNECTOR

PRESSURE SWITCH NO.2 (AC) PRESSURE SWITCH NO. 1 (AC)

I I I I

s-10 A/C SWITCH(ACl G-12 BLOWER MOTOR (F) G-13 RESISTOR ASSEMBLY (II

I

I j-14 BLOWER SWITCH (I)

Page 964 of 1164

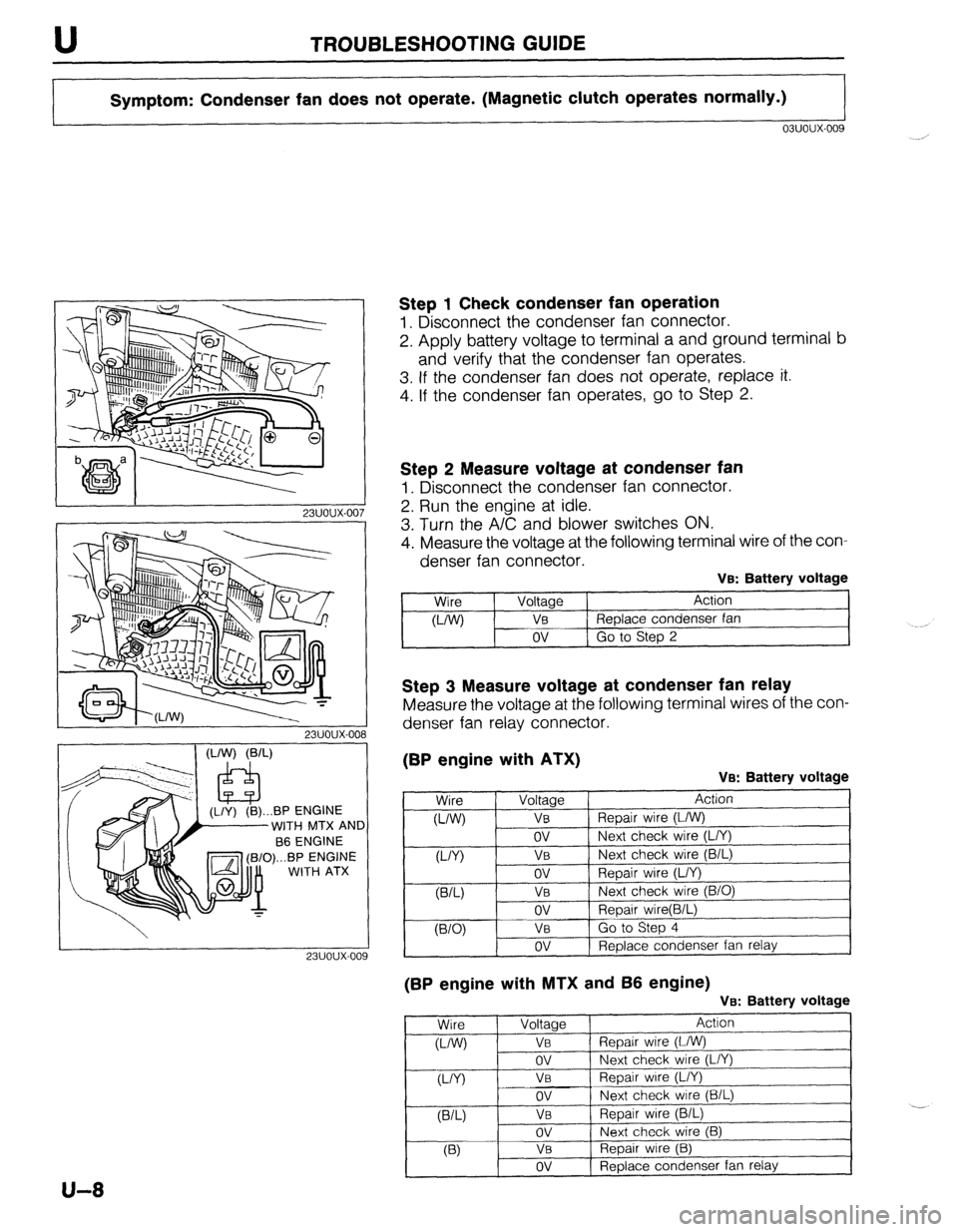

TROUBLESHOOTING GUIDE

Symptom: Condenser fan does not operate. (Magnetic clutch operates normally.)

03uoux-009

I 23UOlJX-007

WITH

MTX AND

fi==Tl (B/O)...BP ENGINE

-’ WITH ATX

Step 1 Check condenser fan operation

1. Disconnect the condenser fan connector.

2. Apply battery voltage to terminal a and ground terminal b

and verify that the condenser fan operates.

3. If the condenser fan does not operate, replace it.

4. If the condenser fan operates, go to Step 2.

Step 2 Measure voltage at condenser fan

1. Disconnect the condenser fan connector.

2. Run the engine at idle.

3. Turn the A/C and blower switches ON.

4. Measure the voltage at the following terminal wire of the con-

denser fan connector.

VB: Battery voltage

Wire

WV Voltage

VB

ov Action -

Replace condenser fan

Go to Step 2

Step 3 Measure voltage at condenser fan relay

Measure the voltage at the following terminal wires of the con-

denser fan relay connector.

(BP engine with ATX)

VB: Battery voltage

(BP engine with MTX and 66 engine)

Ve: Battery voltage

Wire Voltage Action

o-/W) VI3 Repair wire (L/W)

ov Next check wire (L/Y)

VY) VB Repair wire (L/Y)

ov Next check wire (B/L)

VW VB Repair wire (B/L)

ov Next check wire (B)

03 Va Repair wire (B)

ov Replace condenser fan relay ,

U-8