MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 641 of 1164

MANUAL STEERING N

93GONX-OO! 3

63U 10X-09,

3

23UONX-052

13UOKX-01:

93GONX-01

Pinion

1. Gently grasp the serrated part of the pinion, and pull it out.

Rack

1. Remove the rack by taking it out in the direction indicated

by the arrow.

Caution

l If the rack is taken out in the opposite direction, the

inside surface of the rack bushing might be

damaged by the edge of the rack gear.

Mounting bracket and rubber

1. Remove the mounting bracket and rubber from the housing.

Inspection

Check the following points, replace the part if a problem is

found.

1. Cracking, damage, or deterioration of boots

2. Cracking, worn teeth, or damage to rack and pinion

3. Looseness, abnormal noise, or poor bearing operation in-

side the gear housing

4. Worn rack bushing inside the gear housing. Wear, normal

noise, or rough movement of the bearing on the pinon shaft.

Caution

l If replacement is necessary, replace the entire gear

housing assembly.

l Abnormal noise or rough movement of the bearing.

l If replacement is necessary, replace the entire pin-

ion and bearing assembly.

N-17

Page 642 of 1164

N MANUAL STEERING

5. Wear of sliding surface of pressure pad which contacts rack

6. Cracking or deformation of gear housing

7. Looseness or lack of smoothness in tie rod ball-joint

operation

8. Bent tie rod or tie rod ends

9. Damage to tie rod or tie rod end

23UONX-020

N-18

Page 643 of 1164

MANUAL STEERING N

Assembly

Assemble in the order shown in the figure, referring to Assembly Note.

REPLACE 1 J REPLACE

REPLACE

N.m (m-kg, ft-lb)

7% lilNXA7

----. .,. --

1. Gear housing 11. Pressure pad plate

Assembly Note... . . . . . . . . . . . . . . . . . . . . . . . . page N-20 12. Spring

2. Mounting bracket and rubber 13. Adjusting cover

Assembly Note. . . . . . . . . . . ,, ,....,.... ,, . . page N-20 Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-21

3. Bushing 14. Locknut

4. Rack Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-21

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-20 15. Washer

5. Pinion gear Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-22

Assembly Note. . . . . . . . . . . . . . . . . . . . . . . . . . . page N-20 16. Tie rod

6. Snap ring Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . . . . page N-21

Assembly Note... . . . . . . . . . . . . . . . . . . . . . . . . page N-20 17. Boot

7. Snap ring cap Assembly Note... . . . . . . . . . . . . . . . . . . . . . . . . page N-22

8. Oil seal 18. Boot wire

Assembly Note.. . . . . . . . . . ,.. . . . . . . . . . . . . . page N-20 19. Boot clip

9. Pinion protector 20. Locknut

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page N-21 21. Tie rod end

IO. Pressure pad Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . . . . page N-22

Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . . . . page

N-21

N-19

Page 644 of 1164

MANUAL STEERING

Assembly note

Pinion gear and gear housing

1. Fill or coat with grease.

Before assembly, coat (of fill) the following parts with grease

(lithium base, NLGI No.2).

(1) Pinion bearing and teeth

(2) Inside the gear housing

1 93GONX-013

23UONX-05 3

93GONX-015

N-20

23UONX-02:

23UONX-02:

Mounting bracket and rubber

1. Push the mounting rubber on until it just contacts the end

of the housing.

Rack

1. Carefully install the rack in the direction of the arrow.

Caution

l If the rack is installed from the opposite direction,

the inner surface of the rack bushing might be

damaged by the edge of the rack gear.

Snap ring

1. Install the new snap ring with facing the chamfer side of the

snap ring upward.

Oil seal

1. Press the new oil seal with the SST as shown in the figure.

Note

l Before installing, apply a coating of general purpose

grease to the oil seal.

Page 645 of 1164

MANUAL STEERING N

93GONX-018

23UONX-02

I 23UONX-02

23UONX-026

23UONX-02

Pinion protector

1. Press the pinion protector onto the gear housing with the

SST as shown in the figure.

Pressure pad and adjustment cover

1. Install so that the pressure pad correctly contacts the rack.

2. Apply a coat of sealant to the threads of the adjusting cover.

Adjusting cover and locknut

1. Apply sealant to the adjusting cover.

2. After tightening the adjusting cover to a torque of 4.4-6.4

N-m (45-65 cm-kg, 39-56 ft-lb), loosen it about

5O -35” from that position. Add then tighten the locknut

securely.

Locknut tightening torque:

39-49 N-m (4.0-5.0 m-kg, 29-36 ft-lb)

2. Measure the pinion torque with the SST.

Pinion torque: Neutral position f 90’

0.9-l .3 N*m (9-13 cm-kg, 7.6-l 1.3 in-lb)

[Pull scale reading: 900-1,300 g, 31.6-45.9 oz]

Any other position

1.5 N-m or less (15 cm-kg, 13 in-lb or less)

[Pull scale reading:

1,500 g or less (52.95 02 or less)]

Tie rod

1. Attach new washers to the left and right tie rods, and then

screw them onto the rack.

2. Using a wrench, tighten the left and right tie rod to the speci-

fied torque.

Tightening torque:

108-128 N-m (1 l-13 m-kg, 80-94 ft-lb)

N-21

Page 646 of 1164

MANUAL STEERING

Washer

1. Align the washer with the rack groove, and then crimp the

washer.

93GONX-07

23UONX-02

23UONX-03

Boot

1. Install the boot and then wrap a new wire two times around

it and twist it 4 or 4.5 times.

Caution

l Be sure that the boot is not twisted or dented.

Tie rod end

1. Install the tie rod ends and align them with the marks made

before disassembly.

N-22

Page 647 of 1164

ENGINE SPEED SENSING POWER STEERING N

ENGINE SPEED SENSING POWER STEERING

PREPARATION

SST

19 6032 306

Nrench, plug For

removal and

installation of

Plug 49 8032 312

Protector, slipper

seal For

installation of seal

ring

$9 B032 314

Yipper seal

ormer For

form of seal ring 49 F032 303

Handle

19 8032 315

nstaller, oil seal For

installation of oil

seal 49 8032 309

Installer body,

pinion seal For

installation of

oil seal

49 B032 316

Support block,

Pul For

removal of oil

seal & bearing 49 8032 310

Protector, pinion

seal For

installation of

oil seal

49 8032 317

Remover, bearing

& oil seal For

removal of oil

seal & bearing 49 8032 311

Protector, slipper

seal For

installation of

pinion shaft

49 GO30 797

Handle For

installation of

pinion seal 49 8032 320

Wrench For

removal and

installation of

adjustment cover

locknut

49 0180 5108 For 49 8032 321 For

measurement of hermetic

Attachment,

preload ,+&--I pinion torque Adapter

Q inspection

^

49 8032 305

Holder, power

steering pump For

installation of oil

N-23

Page 648 of 1164

N ENGINE SPEED SENSING POWER STEERING

19 1232 670A

Gauge set,

Dower steering

49 HO32 301

wrench

49 8032 304

Adapter

49 8032 307

Wrench, outer

box

49 8032 308

Remover body,

rod seal

49 8032 319

Protector body,

rod seal

49 9200 020

Tension gauge,

V-ribbed belt For

measurement of

fluid pressure

For

removal of

tie-rod

For

measurement of

fluid pressure

For

removal and

installation of

outer box

For

removal of oil

seal

For

installation of

inner guide 81 oil

seal

For

measurement of

drive belt tension 49 1232 673

Valve body

(Part of

49 1232 670A)

49 1232 672

Gauge

(Part of

49 1232 670A)

49 HO02 671

Adapter

49 8032 313

Protector, outer

box

49 8032 318

Guide, rod seal

49 0118 850C

Puller, ball joint

I

-

For

measurement of

fluid pressure

For

measurement of

fluid pressure

For

measurement of

fluid pressure

For

installation of

outer box

For

installation of

inner guide & oil

seal

For

removal of

tie rods end

23UONX-0.

N-24

Page 649 of 1164

ENGINE SPEED SENSING POWER STEERING N

TROUBLESHOOTING GUIDE

Adjust or replace

Repair or replace Shimmy (Steering

wheel vibrates

left/right)

N-25

Page 650 of 1164

ENGINE SPEED SENSING POWER STEERING

23UONX-03

03UONX-032

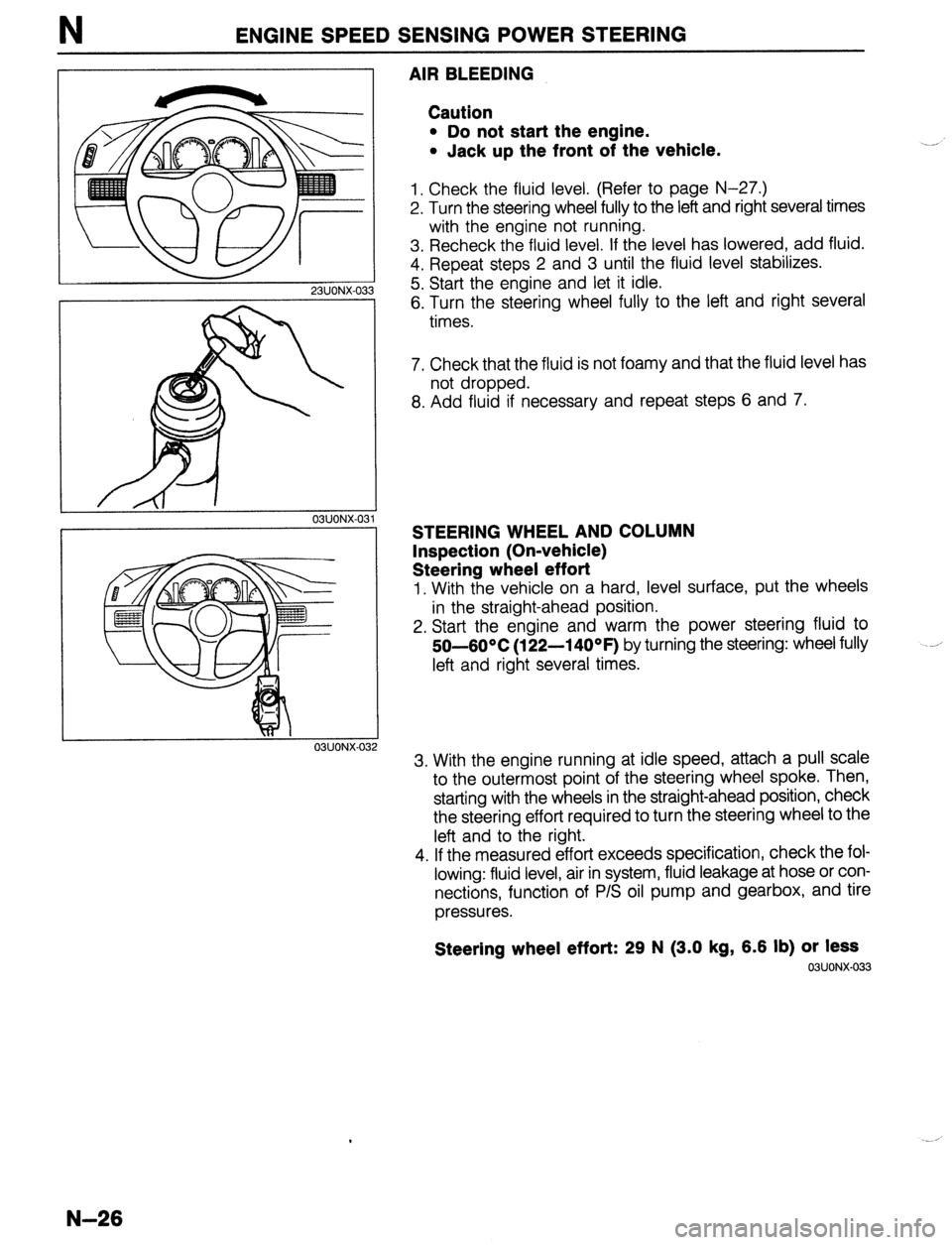

AIR BLEEDING

Caution

l Do not start the engine.

l Jack up the front of the vehicle.

1. Check the fluid level. (Refer to page N-27.)

2. Turn the steering wheel fully to the left and right several times

with the engine not running.

3. Recheck the fluid level. If the level has lowered, add fluid.

4. Repeat steps 2 and 3 until the fluid level stabilizes.

5. Start the engine and let it idle.

6. Turn the steering wheel fully to the left and right several

times.

7. Check that the fluid is not foamy and that the fluid level has

not dropped.

8. Add fluid if necessary and repeat steps 6 and 7.

STEERING WHEEL AND COLUMN

Inspection (On-vehicle)

Steering wheel effort

1. With the vehicle on a hard, level surface, put the wheels

in the straight-ahead position.

2. Start the engine and warm the power steering fluid to

50-60°C

(122-14OOF) by turning the steering: wheel fully

left and right several times.

3. With the engine running at idle speed, attach a pull scale

to the outermost point of the steering wheel spoke. Then,

starting with the wheels in the straight-ahead position, check

the steering effort required to turn the steering wheel to the

left and to the right.

4. If the measured effort exceeds specification, check the fol-

lowing: fluid level, air in system, fluid leakage at hose or con-

nections, function of P/S oil pump and gearbox, and tire

pressures.

Steering wheel effort: 29 N (3.0 kg, 6.6 lb) or less 03UONX-033

N-26