MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 681 of 1164

CONVENTIONAL BRAKE SYSTEM P

03UOPX-039

ARROW MARK

23UOPX-Old

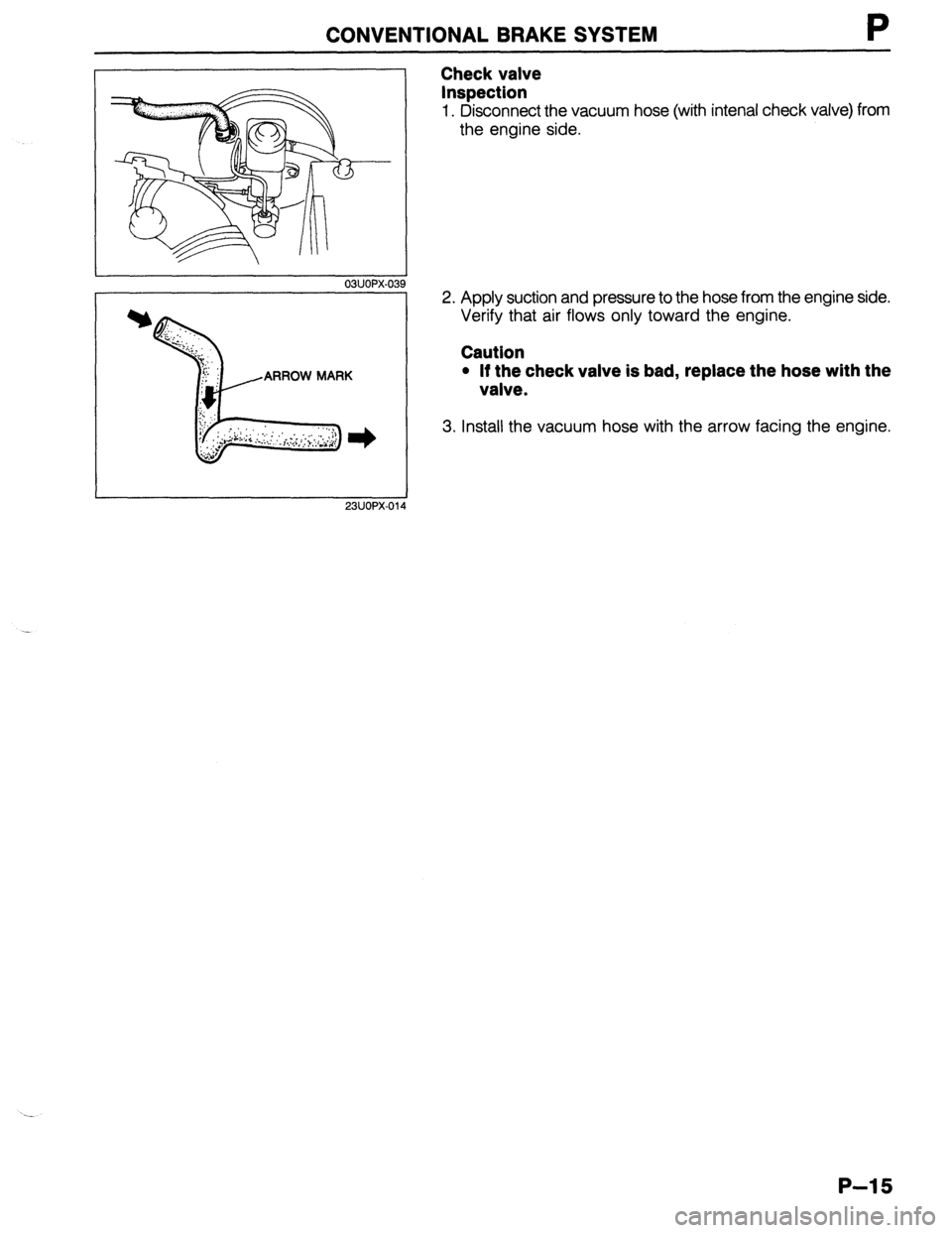

Check valve

Inspection

1. Disconnect the vacuum hose (with intenal check valve) from

the engine side.

2. Apply suction and pressure to the hose from the engine side.

Verify that air flows only toward the engine.

Caution

l If the check valve is bad, replace the hose with the

valve.

3. Install the vacuum hose with the arrow facing the engine.

P-15

Page 682 of 1164

P CONVENTIONALBRAKESYSTEM

Removal / Installation

1. Remove in the order shown in the figure, referring to Removal Note.

2. install in the reverse order of removal, referring to Installation Note.

(1.9-2.6, 14-19)

1.3-2.2, 9.4-16)

(1 .O-1.6, 7.2-12)

13-22 (1.3-2.2, 9.4-16)

N.m (m-kg, ft-lb)

23UOPX-003

1. Connector 3. Master cylinder 6. Nut

2. Brake pipe

Installation Note 7. Power brake unit

Removal Note . . page P-l 1 . . . . . . . . . . . . . . . . . S ,,,.. page P-l 1 8. Gasket

Installation Note

4. Vacuum hose

. . . . . . . . . . . . . . . . . . . . . . . page P-l 1 5. Cotter pin and clevis pin

Cautlon

Take the following steps after installation:

l Add fluid and bleed the air. (Refer to page P-6.)

l Check all parts for fluid leakage. (Refer to page P-8.)

l Adjust and check the brake pedal. (Refer to page P-8.)

l Make an on-vehicle check of the unit. (Refer to page P-13.)

13uow007

03UOPX-043

t

0

A

.--- -------_- --

m--v

K/

6 B I)

P-l 6

DUAL PROPORTIONING VALVE

Inspection

1. Connect two pressure gauges (9,810 kPa [lo0 kg/cm’,

1,422 psi]) to the brake pipes with adapters as shown in

the figure.

Adapter and flare nut tightening torque:

13-22 N,m (1.3-2.2 m-kg, 9.4-18 f&lb)

Note

l Disconnect and connect the brake pipes with SST.

2. Bleed the air from the brake system.

(Refer to page P-6.)

3. Depress the brake pedal until the master cylinder pressure

equals A; then record rear brake pressure A’.

4. Depress the brake pedal again, apply additional pressure

until the pressure equals B; then record pressure 6’.

Fluid pressure kPa (kg/cm*, psi)

A A’ B B’

Rear drum 2,453 2,256-2,649 5,886 284%3,434

brake

(25, 356) (23-27, 327-384) (60, 853) (29-35, 412-498) --.-,

Rear disc 2,453 2,256-2,649 5,886 3,188-3,777

brake (25, 356) (23-27, 327-384) (60, 853) (32.5-38.5, 462-547)

Page 683 of 1164

CONVENTIONAL BRAKE SYSTEM P

Caution

l Do not attempt to adjust the dual proportioning

valve.

l After the inspection, bleed the air from the brake

system and check for fluid leakage.

l If the measurements are not within specification,

replace the valve assembly.

03UOPX-045

13-22 (1.3-2.2, 9.4-16) TJ

R P @ 19-23 (1.9-2.3, 14-17)

Replacement

1. Remove in the order shown in the figure, referring to Removal Note.

2. install in the reverse order of removal, referring to Installation Note.

13-22 (1.3-2.2, 9.4-16)

_-. .--.. ^. uwurx-047 N-m (m-kg, R-lb)

23UOPX-oc

1. Brake pipe 2. Bolt

Removal I Installation Note . . . . . . . . . . . . . . . . . Below 3. Dual proportioning valve

Removal / Installation note

Brake pipe

Loosen and tighten the brake pipes with the SST.

P-17

Page 684 of 1164

CONVENTIONAL BRAKE SYSTEM

FRONT BRAKE (DISC)

Quick Inspection, On-vehicle

Disc pad

1. Jack up the front of the vehicle and support it with safety

stands.

2. Remove the wheels.

3. Verify the remaining thickness of the pads.

Thickness: 2.0mm (0.08 in) min.

Replacement

Disc pad

1. Remove in the order shown in the figure.

2. Install in the reverse order of removal, referring to

Installation Note.

23UOPX-oc

1. M-spring 4. Disc pad 5. Anti-squeak shim

2. W-pin Installation Note . . . . . . . . Below 6. Outer shim

3. Pad pin Inspection ,.,..,... page P-20 7. Inner shim

P-18

IBUOPX-01

Installation note

Disc pad

When installing the disc pads, push the piston fully inward with

the

SST and an old pad.

Page 685 of 1164

Removal / Installation

Caliper

1. Remove in the order shown in the figure.

2. Install in the reverse order of removal.

CONVENTIONAL BRAKE SYSTEM P

1

39-49 (4.0-5.0, 2! 3-36)

@ .-- . . -3

16-

‘(

N.m (m-kg, Mb)

23UOPX-023

1. Flexible hose 5. Caliper

2. Pad pin Disassembly / Inspection I

3. Disc pad assembly Assembly , . , , . , . . . . . . . . . . , . . . . . . . . . . . . . . . . . page P-21

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page P-20 6. Guide plate

7. Disc plate

Inspection . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page P-20 4. Bolt

Caution

Take the following steps after installation:

l Add fluid and bleed the air. (Refer to page P-6.)

l Check for fluid leakage. (Refer to page P-8.)

l Depress the brake pedal a few tlmes and check that

the rear brakes do not drag While rotating the wheel.

03UOPX-052 P-19

Page 686 of 1164

P CONVENTIONAL BRAKE SYSTEM

23UOPX-01. 5

84

03UOPX-055

Inspection

Check for the following and repair or replace parts as

necessary.

Disc pad assembly

1. Check for oil or grease on the facing, abnormal wear or

cracks, and deterioration or damage from heat.

2. Measure the thickness of the lining.

Specified thickness: 1Omm (0.39 in)

Minimum : 2.0mm (0.08 in)

3. Check visually for damage or wear of the guide plate.

Disc plate

1. Measure the thickness of the disc plate.

Standard: 22mm (0.87 in)

Minimum: 20mm (0.79 in)

2. Measure the runout at the outer edge of the contact sur-

face of the disc pad.

Runout: O.lmm (0.004 in) max.

Caution

l There must be no wheel bearing looseness.

l The measurement location is the outer edge of the

disc plate surface.

P-20

Page 687 of 1164

CONVENTIONAL BRAKE SYSTEM P

CALIPER

Disassembly / Inspection / Assembly

1. Disassemble in the order shown in the figure, referring to Disassembly Note.

2. Inspect all parts and depair or replace as necessary.

3. Assemble in the reverse order of disassembly.

1. Sleeve pin

2. Boot

3. Rubber cap and bleeder screw ..,.......... Below

4. Retaining ring

5. Dust seal

6. Piston

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . . page P-22

Inspect for damage, wear and rust 7. Piston seal

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . . page P-22

8. Caliper body

Inspect for damage, wear and rust

Disassembly note

Rubber cap and bleeder screw

Remove the rubber cap and remove the bleeder screw from

the brake caliper with the

SST.

P-21

Page 688 of 1164

P CONVENTIONAL BRAKE SYSTEM

I

13UOPX-023

Piston

Place a piece of wood in the caliper; then blow compressed

air through the hole to force the piston out of the caliper.

Caution

l Blow the compressed air slowly to prevent the pis-

ton from suddenly popping out.

1

03UOPX.058

Piston seal

Remove the piston seal from the brake caliper with the SST.

P-22

Page 689 of 1164

CONVENTIONAL BRAKE SYSTEM

REAR BRAKE (DISC)

Quick Inspection, On-vehicle

Disc pad

1. Jack up the rear of the vehicle and support it with safety

stands.

2. Remove the wheels.

3. Verify that the remaining thickness of the pads.

Thickness: l.Omm (0.04 in) min.

1 SUOPX-011

Replacement

Disc pad

1. Remove in the order shown in the figure, referring to Removal Note.

2. Install in the reverse order of removal, referring to Installation Note.

12-16 (1.2-l .6, 6.7-l 2

N.m (m-kg, &lb)

,,?I lftPY.rl17

1. Screw plug

2. Manual adjustment gear

Removal Note, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Below

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . . page P-24 _.,--. ,. ., . .

4. M-spring

5. Disc pad assembly

Inspection . , . , , . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . page P-25

6. Shim

3. Lock bolt 7. Guide plate

Removal note

Manual adjustment gear

Turn the manual adjustment gear counterclockwise with an

Allen wrench to pull the brake caliper piston inward. (Turn until

it stops)

03UOPX-062

P-23

Page 690 of 1164

CONVENTIONAL BRAKE SYSTEM

Installation note

Manual adjustment gear

1. Turn the manual adjustment gear clockwise until the brake

pads just touch the disc pIaTe.

2. Return the manual adjustment gear l/3-turn

Removal / Installation

Caliper

1. Jack up the rear of the vehicle and support it with safety stands.

2. Remove the wheels.

3. Remove in the order shown in the figure, referring to

Removal Note.

4. Install in the reverse order of removal, referring to Installation Note.

5. Tighten all nuts and bolts to the specified torques, referring to the figure.

@ 22-29 (2.2-3.0, 16-22)

23-30 (2.2-3.1, 16-

N.m (m-kg, R-lb)

23UOPX-00

1. Parking cable 7. Caliper

Removal I Inspection / Disassembly / Inspection /

Installation . . . . . . . . . . . . . . . . . . . . . . ,.,........ page P-32 Assembly ,.....*........................... page P-26

2. Connecting bolt 8. Disc pad assembly

3. Brake hose Replacement ,...,.,.,.,........*........... page P-23

4. Screw plug Inspection . . . . . . . ..*......................... page P-25

5. Manual adjustment gear 9. Bolt

Removal Note . . . . . . . . . . . . . . . ,,..,.,....... page P-23 10. Mounting support

Installation Note ,....,.,..,.,...,., ,...,., page P-24 11, Disc plate

6. Lock bolt Inspection .,...........*..................... page P-25

After installation:

(1) Add brake fluid and bleed air. (Refer to page P-6.)

(2) Adjust the parking brake lever stroke. (Refer to page P-31 .)

(3) Depress the brake pedal a few times and check that the rear brakes do not drag excessively while

rotating the wheel by hand.

P-24