MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 701 of 1164

WHEELS AND TIRES

OUTLINE ..................................................

SPECIFICATIONS ....................................

TROUBLESHOOTING

GUIDE.. .................... Q- 2

WHEELS AND TIRES ................................. Q- 3

SPECIAL NOTES ABOUT WHEELS

AND TIRES .......................................... Q- 3

NOTES REGARDING TIRE REPLACEMENT. Q- 3

INSPECTION I ADJUSTMENT.. .................. Q- 3

REMOVAL / INSTALLATION.. .................... Q- 6

TIRE ROTATION .....................................

WHEEL BALANCE ADJUSTMENT ............. :: ;

13UOQX-001

Page 702 of 1164

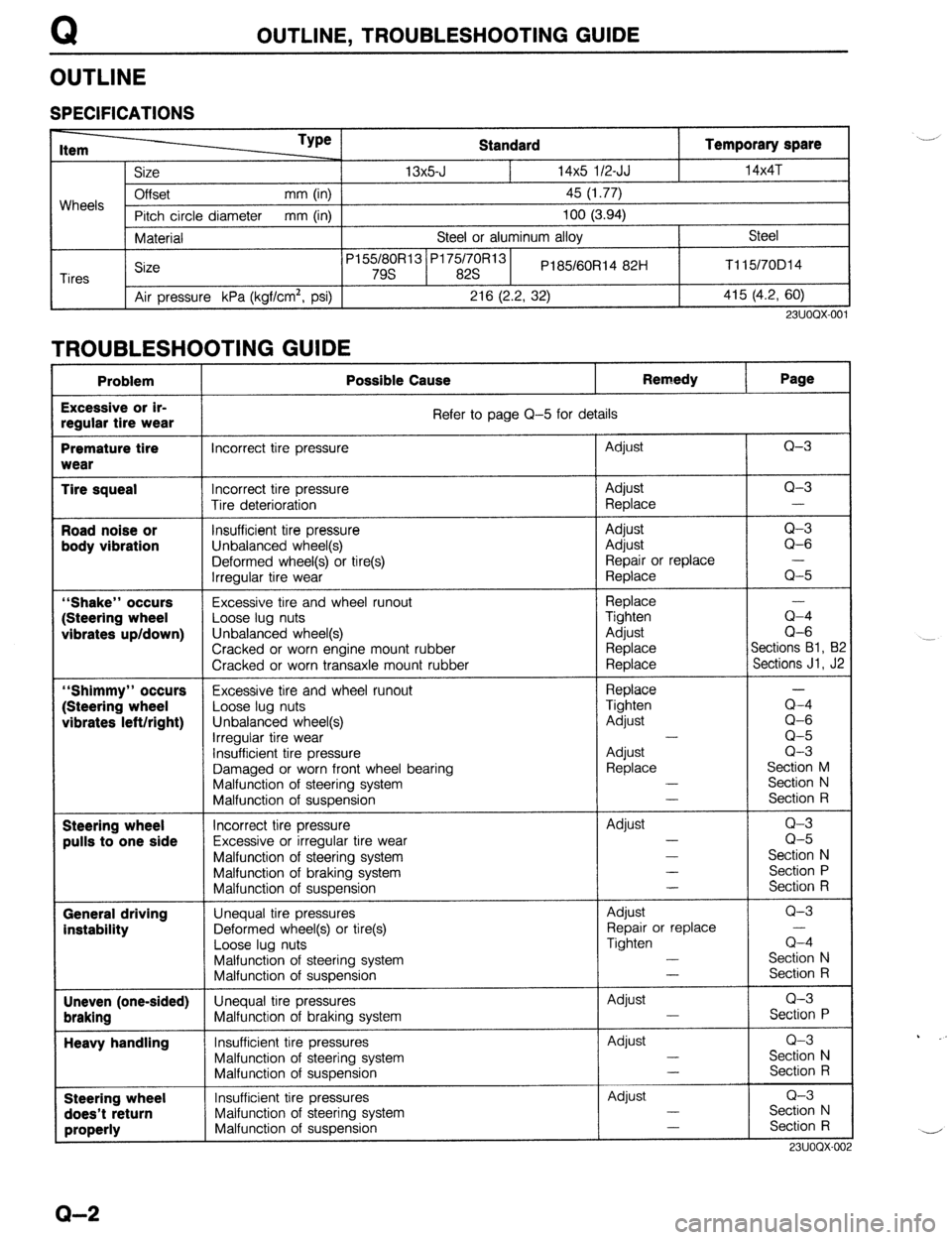

Q OUTLINE, TROUBLESHOOTING GUIDE

OUTLINE

SPECIFICATIONS

Wheels

Tires Standard Temporary spare __/

Size 13x5-J 14x5 l/2-JJ l4x4T

Offset mm (in)

45 (1.77)

Pitch circle diameter mm (in)

100 (3.94)

Material Steel or aluminum alloy Steel

Size P155/80R13’P175/70R131

PI 85/60Rl4 82H Tll5/70D14

79s 82s

Air pressure kPa (kgflcm’, psi)

216 (2.2, 32) 415 (4.2, 60)

23UOQX-001

TROUBLESHOOTING GUIDE _____ -_- ____ _ __.- -. -.-.--

Problem Possible Cause Remedy Page

Excessive or ir-

regular tire wear Refer to page Q-5 for details

Premature tire incorrect tire pressure Adjust Q-3

wear

Tire squeal Incorrect tire pressure Adjust Q-3

Tire deterioration Replace -

Road noise or Insufficient tire pressure Adjust Q-3

body vibration

Unbalanced wheel(s) Adjust Q-6

Deformed wheel(s) or tire(s) Repair or replace

Irregular tire wear Replace Q-5

“Shake” occurs Excessive tire and wheel runout

Replace

(Steering wheel Loose lug nuts

Tighten a-4

vibrates up/down) Unbalanced wheel(s)

Adjust Q-6

Cracked or worn engine mount rubber

Replace Sections Bl, B:

Cracked or worn transaxle mount rubber

Replace Sections Jl, J2

“Shimmy” occurs Excessive tire and wheel runout

Replace

(Steering wheel

Loose lug nuts Tighten a-4

vibrates left/right) Unbalanced wheel(s)

Adjust Q-6

irregular tire wear -

Q-5

insufficient tire pressure

Adjust Q-3

Damaged or worn front wheel bearing

Replace Section M

Malfunction of steering system -

Section N

Malfunction of suspension -

Section R

Steering wheel Incorrect tire pressure Adjust Q-3

pulls to one side Excessive or irregular tire wear -

Q-5

Malfunction of steering system -

Section N

Malfunction of braking system -

Section P

Malfunction of suspension -

Section R

General driving Unequal tire pressures Adjust Q-3

instability Deformed wheel(s) or tire(s) Repair or replace

Loose lug nuts Tighten Q-4

Malfunction of steering system -

Section N

Malfunction of suspension -

Section R

Uneven (one-sided) Unequal tire pressures

Adjust Q-3

braking Malfunction of braking system -

Section P

Heavy handling Insufficient tire pressures Adjust Q-3

Malfunction of steering system -

Section N

Malfunction of suspension -

Section R

Steering wheel Insufficient tire pressures Adjust Q-3

does’t return Malfunction of steering system -

Section N

properly Malfunction of suspension -

Section R

731100x-or . _. -,

Q-2

Page 703 of 1164

WHEELS AND TIRES

WHEELS AND TIRES

SPECIAL NOTES ABOUT WHEELS AND TIRES

1. Do not use wheels or tires other than the specified types.

2. Aluminum wheels are easily scratched. When washing them, use a soft cloth, never a wire brush. If the

vehicle is steam cleaned, do not allow boiling water to contact the wheels.

3. If alkaline compounds (such as saltwater or road salts) get on aluminum wheels, wash them as soon as

possible to prevent damage. Use only a neutral detergent.

9MUOQX-004

NOTES REGARDING TIRE REPLACEMENT

Note the following points when tires are to be removed from or mounted onto the wheels.

1. Be careful not to damage the tire bead, the rim bead, or the edge of the rim.

2. Use a wire brush, sandpaper, or cloth to clean and remove all rust and dirt from the rim edge and the

rim bead.

3. When cleaning aluminum wheels, use a soft cloth, never a wire brush or sandpaper.

4. Remove any pebbles, glass, nails, and other foreign items embedded in the tire tread.

5. Be sure the air valve is installed correctly.

6. Apply a soapy solution to the tire bead and the edge of the rim.

7. After mounting a tire onto a wheel, inflate the tire to 250-300 kPa (2.55-3.06 kg/cm2, 35.55-42.66

psi). Check to be sure that the bead is seated correctly onto the rim and that there are no air leaks. Then

reduce the pressure to the specified level.

8. If a tire iron is used to change a tire on an aluminum wheel, be sure to use a piece of rubber between

the iron lever and the wheel to avoid damage to the wheel. Work should be done on a rubber mat, not

on a hard or rough surface.

03UOQX-004

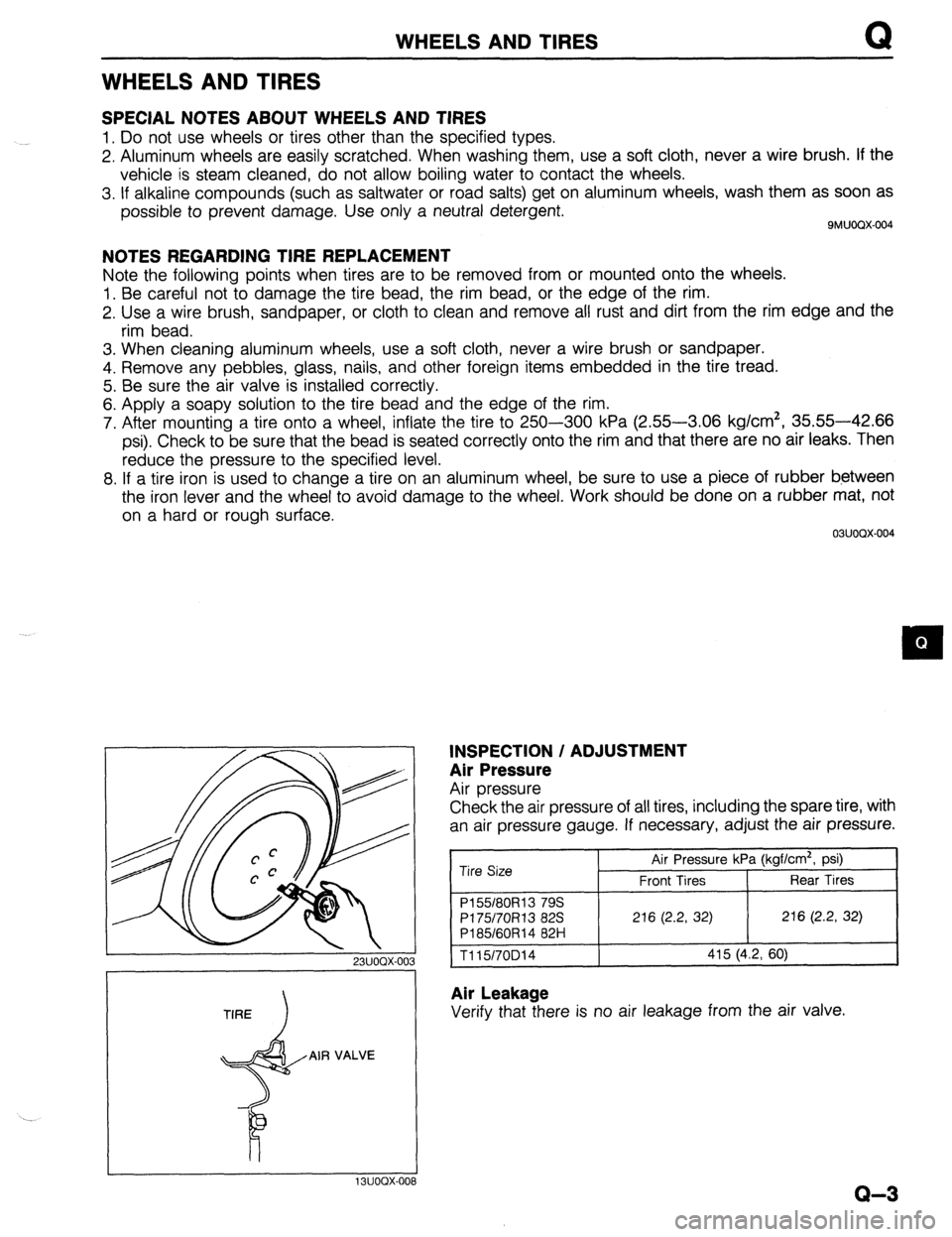

23UOOX-003

TIRE

I

AIR VALVE

INSPECTION / ADJUSTMENT

Air Pressure

Air pressure

Check the air pressure of all tires, including the spare tire, with

an air pressure gauge. If necessary, adjust the air pressure.

Tire Size Air Pressure kPa (kgf/cm2, psi)

Front Tires Rear Tires

P155180R13 79s

PI 75/70R13 82s 216 (2.2, 32) 216 (2.2, 32)

P185/60R14 82H

1115/70D14 415 (4.2, 60)

Air Leakage

Verify that there is no air leakage from the air valve.

I I 13UOOX-008

Q-3

Page 704 of 1164

WHEELS AND TIRES

WEAR INDICATOR WEAR IbiDICATOR

13UOQX-00s

13UOQX-011 0

23UOQX-004

Tire Wear

1. Check the remaining tread.

Remaining tread

Standard tires: 1.6mm (0.063 in) min.

Snow tires: 50% of tread ’ _,I’

2. The tire should be replaced if the wear indicators are

exposed.

Inspection (Tire and Wheel)

The wheel or tire should be replaced if any crack, damage,

deformation or other problem is found.

Wheel and Tire Runout

1. Jack up the vehicle and place it on safety stands.

2. Set the probe of a dial indicator against the wheel, and meas-

ure the runout through one full revolution.

Runout:

_..’

Horizontal Aluminum wheel: 2.0 (0.079), Steel wheel: 2.5 (0.098)

Vertical 1.5 (0.059)

3. Replace the wheel if necessary.

Caution

l Adjust wheel balance after replacement of a wheel

or tire.

Lug Nut

1. Verify that the lug nuts are tightened to the specified torque.

Tightening torque:

66-l 16 N*m (9-12 m-kg, 65-67 ft-lb)

Q-4

Page 705 of 1164

WHEELS AND TIRES

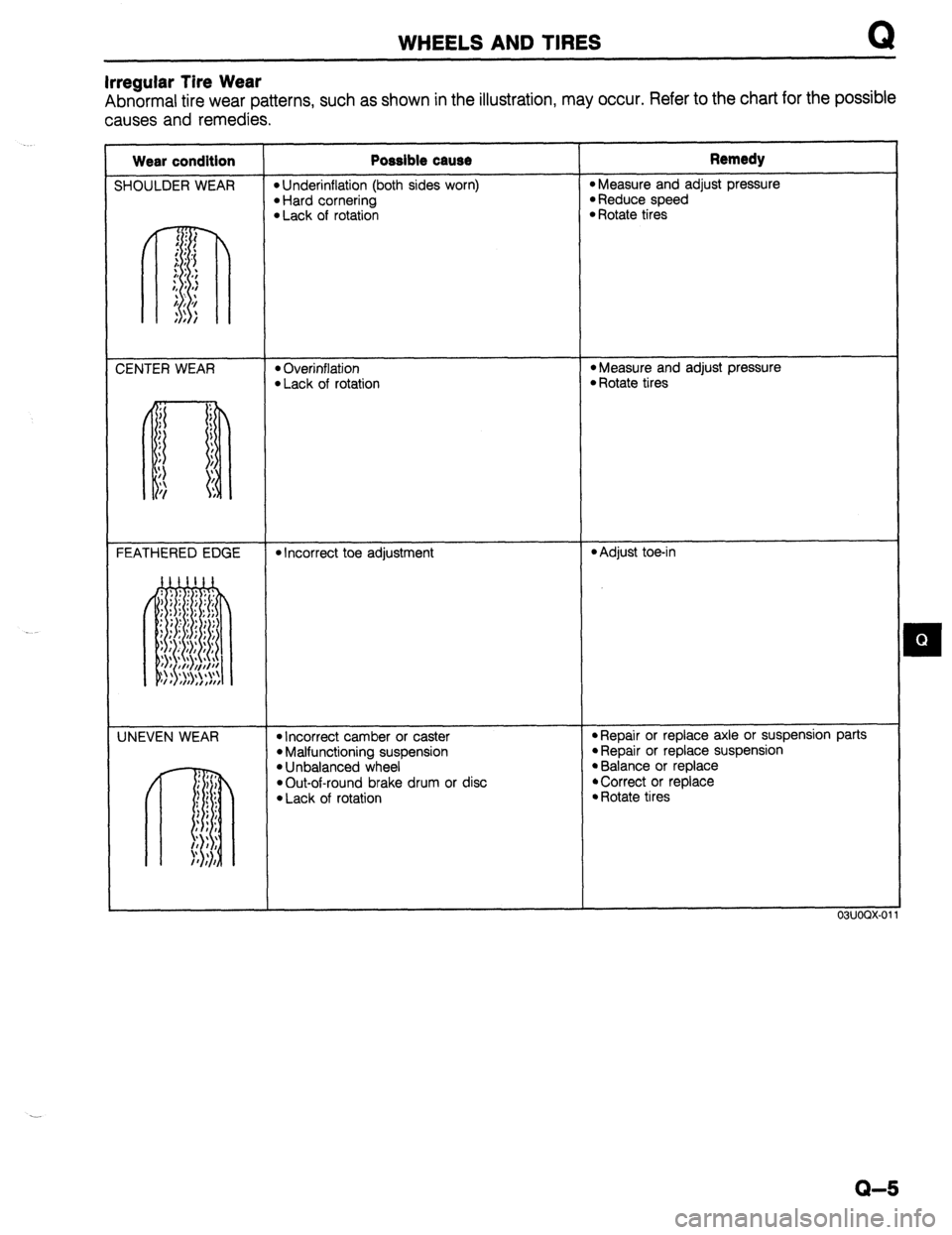

Irregular Tire Wear

Abnormal tire wear patterns, such as shown in the illustration, may occur. Refer to the chart for the possible

causes and remedies.

Wear condition

SHOULDER WEAR Possible cause l Underinflation (both sides worn) l Hard cornering l Lack of rotation Remedy

l Measure and adjust pressure l Reduce speed l Rotate tires

CENTER WEAR

l Overinflation l Lack of rotation *Measure and adjust pressure l Rotate tires

FEATHERED EDGE

l Incorrect toe adjustment l Adjust toe-in

UNEVEN WEAR

l Incorrect camber or caster l Malfunctioning suspension l Unbalanced wheel

*Out-of-round brake drum or disc

l Lack of rotation *Repair or replace axle or suspension parts

l Repair or replace suspension l Balance or replace

*Correct or replace

l Rotate tires

03UOQX-01

Q-5

Page 706 of 1164

WHEELS AND TIRES

L 13UOQX-005

FRONT

13UOQX-006

G=a I) OUTSIDE

BALANC

WEIGHT

REMOVAL / INSTALLATION

1. The wheel-to-hub contact surfaces must be clean.

2. Tighten the lug nuts to the specified torque.

Tightening torque:

88-l 18 N-m (9-12 m-kg, 85-87 ft-lb)

Caution

l When reinstalling a wheel, retighten the lug nuts to

the specified torque after about 1,000 km (820 miles)

driving.

TIRE ROTATION

To prolong tire life and assure uniform tire wear, rotate the tires

from every 3,000 km (1,860 miles) to every 6,000 km (3,720

miles).

Caution

l Do not include “TEMPORARY USE ONLY” spare tire

in rotation.

l Use the best tires on the front axle.

l After rotating the tires, adjust each tire to the speci-

fied air pressure. (Refer to page Q-3.)

WHEEL BALANCE ADJUSTMENT

If a wheel becomes unbalanced or if a tire is replaced or

repaired, the wheel must be rebalanced to within specification.

Maximum unbalance (at rim edge)

13 inch wheel: 11 g (0.39 oz)

14 inch wheel: 10 g (0.35 or)

Caution

l Do not use more than two balance weights on the

inner or outer side of the wheel.

l If the total weight exceeds 1OOg (3.5 oz) perslde,

rebalance after moving the tire around on the rim.

l Attach the balance weights tightly on the wheel.

l Select suitable balance weights for steel or alumi-

num alloy wheels.

l Do not use an on-car balancer on automatic trans-

axle models; it may cause transaxle damage.

.__’

Q-6

Page 707 of 1164

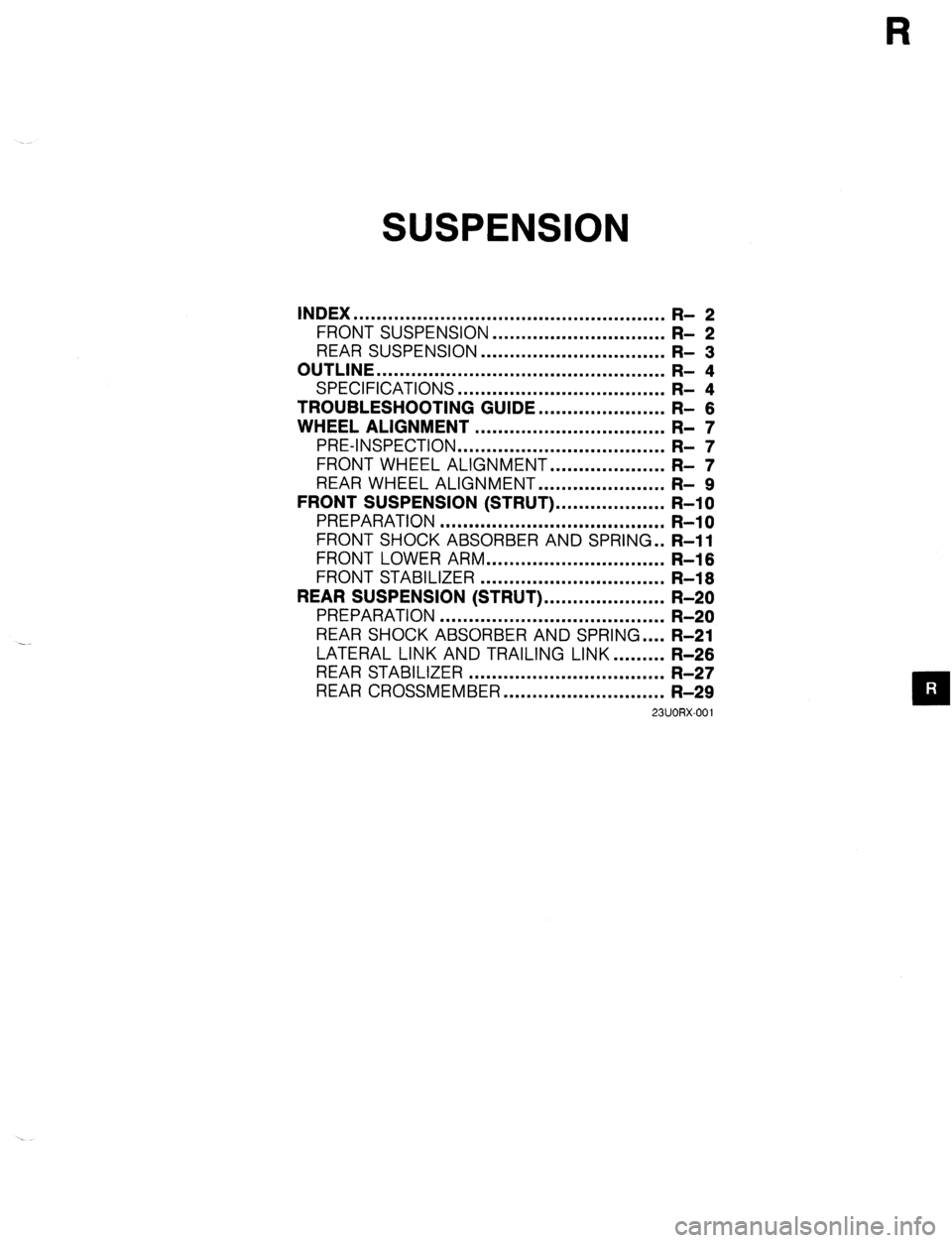

R

SUSPENSION

INDEX ...................................................... R- 2

FRONT SUSPENSION ..............................

R- 2

REAR SUSPENSION ................................ R- 3

OUTLINE .................................................. R- 4

SPECIFICATIONS ....................................

TROUBLESHOOTING GUIDE.. .................... ;I ;

WHEEL ALIGNMENT ................................. R- 7

PRE-INSPECTION ....................................

FRONT WHEEL ALIGNMENT.. .................. ;I ;

REAR WHEEL ALIGNMENT.. .................... R- 9

FRONT SUSPENSION (STRUT). .................. R-l 0

PREPARATION ....................................... R-l 0

FRONT SHOCK ABSORBER AND SPRING . . R-11

FRONT LOWER ARM

............................... R-l 6

FRONT STABILIZER ................................

R-l 6

REAR SUSPENSION (STRUT). .................... R-20

PREPARATION ....................................... R-20

REAR SHOCK ABSORBER AND SPRING .... R-21

LATERAL LINK AND TRAILING LINK.. ....... R-26

REAR STABILIZER .................................. R-27

REAR CROSSMEMBER ............................ R-29

23UORX-001

Page 708 of 1164

R INDEX

INDEX

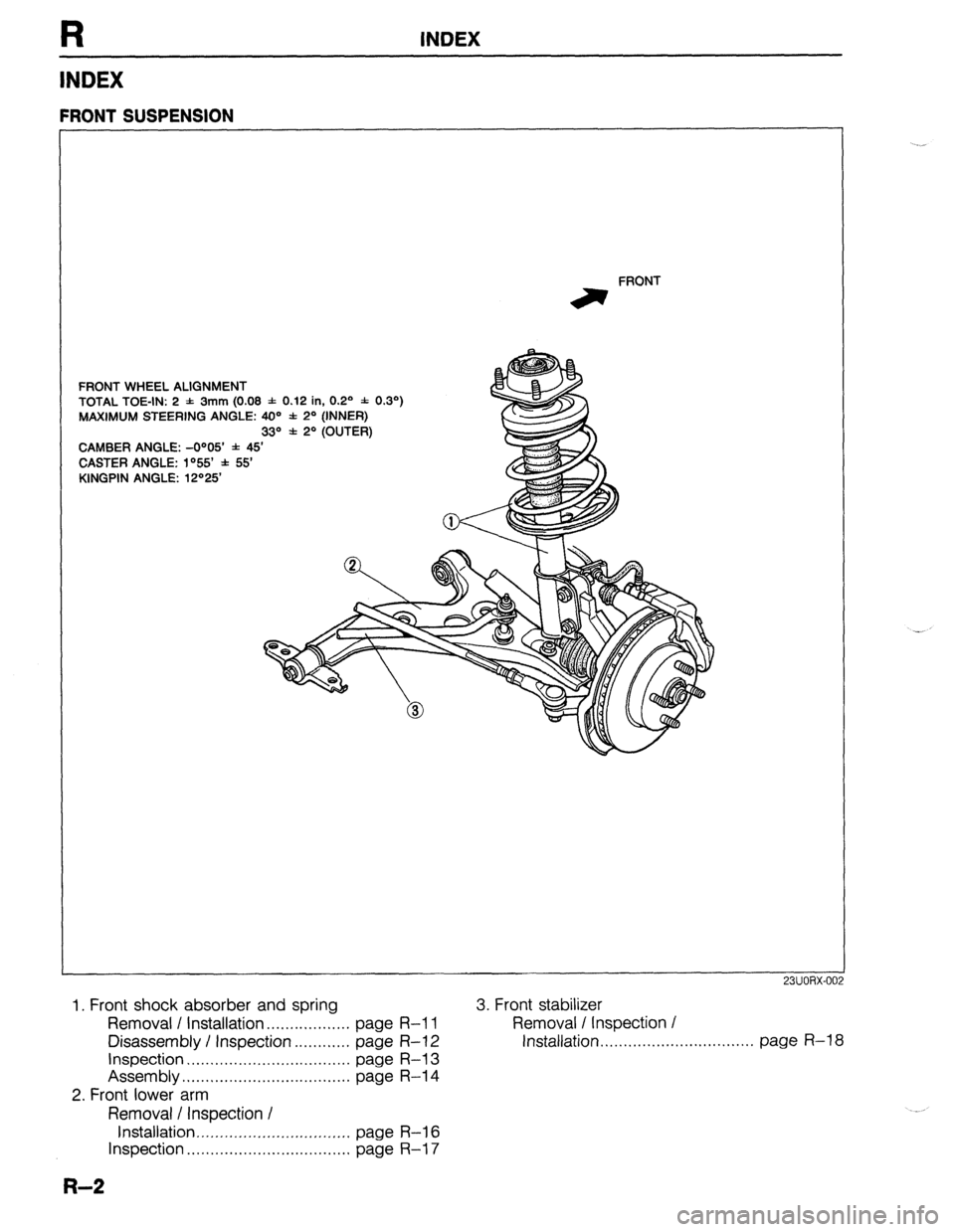

FRONT WHEEL ALIGNMENT

TOTAL TOE-IN: 2 -1: 3mm (0.08 f 0.12 in, 0.2’ * 0.3’)

MAXIMUM STEERING ANGLE: 40=’ * 2’ (INNER)

33“ f 2O (OUTER)

CAMBER ANGLE: -O”05’ * 45’

CASTER ANGLE: lo55 f 55

KINGPIN ANGLE: 12“25 FRONT

irr

FRONT SUSPENSION

1. Front shock absorber and spring

Removal I Installation . . . . . . . . . . . . . . . . . . page R-l 1

Disassembly / Inspection . . . . . . . . . . . . page R-l 2

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page R-l 3

Assembly . . . . . . 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page R-l 4

2. Front lower arm

Removal / Inspection I

Installation ,,...,.......,...........,.._..,. page R-l 6

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page R-l 7

R-2

3. Front stabilizer

Removal / Inspection /

Installation, . . . . . . ,. . . . . . . . . . . . . . . . . . . . . . . . . page R-l 8

Page 709 of 1164

INDEX

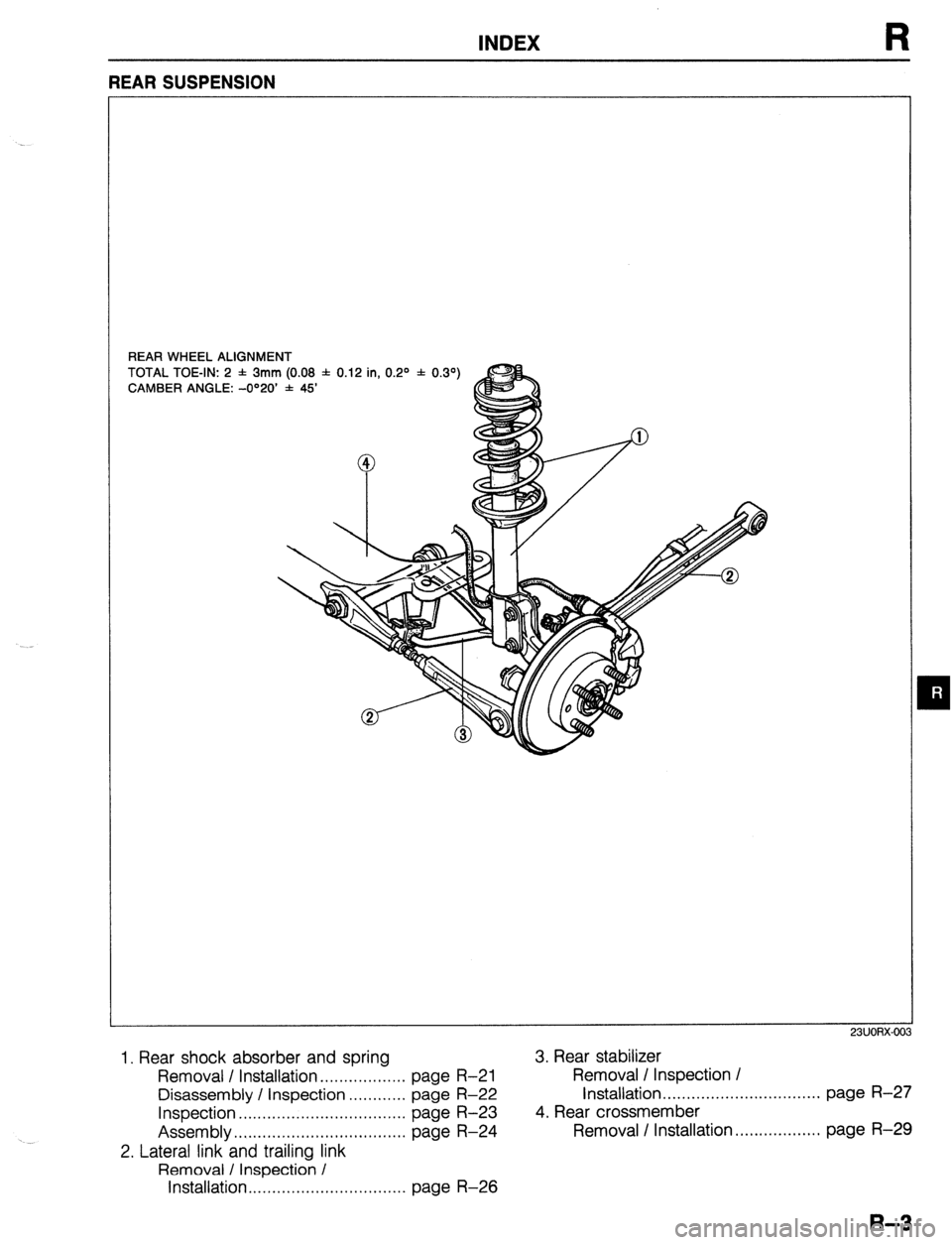

REAR WHEEL ALIGNMENT

TOTAL TOE-IN: 2 f 3mm (0.08 f 0.12 in, 0.2O * 0.39

CAMBER ANGLE: -O”20’ * 45’

m

1. Rear shock absorber and spring 3. Rear stabilizer

Removal / Installation . . . . . . . . . . . . . . . . . . page R-21 Removal / Inspection /

Disassembly / Inspection . . . . . . . . . . . . page

R-22 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . ...*... page R-27

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page R-23 4. Rear crossmember

Assembly.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page R-24 Removal I Installation. . . . . . . . . . . . . . . . . . page R-29

2. Lateral link and trailing link

Removal / Inspection /

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page R-26

Page 710 of 1164

R OUTLINE

OUTLINE

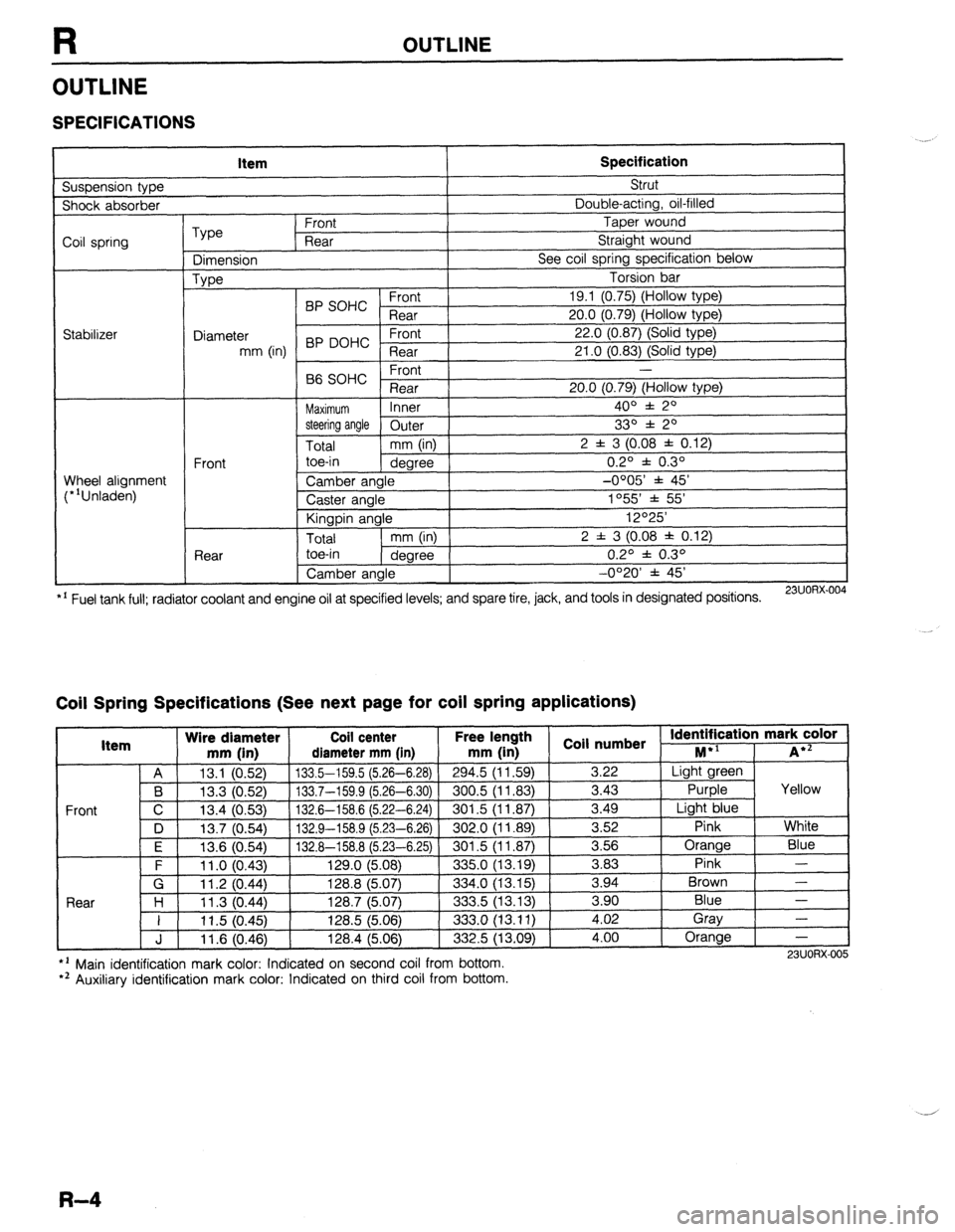

SPECIFICATIONS

Suspension type Item Specification Strut

Shock absorber Double-acting, oil-filled

Coil spring

Stabilizer Type Front Taper wound

Rear Straight wound

Dimension See coil spring specification below

Type Torsion bar

BP SOHC Front 19.1 (0.75) (Hollow type)

Rear 20.0 (0.79) (Hollow type)

Diameter 22.0 (0.87) (Solid type)

mm (in) BP DOHC ;eTrt

21 .O (0.83) (Solid type)

P ,

-

66 SOHC rronr

Rear 20.0 (0.79) (Hollow type)

Maximum Inner 400 f 20

steering angle

Outer 330 f 20

Total mm (in) 2 f 3 (0.08 f 0.12)

Front toe-in

degree 0.2O f 0.3O

Wheel alignment

(*‘Unladen) Camber angle -0005’ f 45’

Caster angle 1055 * 55’

Kingpin angle 12O25’

Total mm (in) 2 f 3 (0.08 * 0.12)

Rear toe-in

degree 0.2O f 0.3O

Camber angle -0°20’ f 45’

*’ Fuel tank full; radiator coolant and engine oil at specified levels; and spare tire, jack, and tools in designated positions.

23UORX.004

Coil Spring Specifications (See next page for coil spring applications)

I Item Wire diameter Coil center Free lel.=-. .

mm iin1 rliamotor mm [in mm (in 1 coil numbs

Front

nath

1 _ . . *St Identification mark color +l

., . . . . I...,

-*.....-.“, * . . . . . ,..-, -....- I--‘, M iA*=

A 13.1 (0.52) 133.5-159.5 (5.26-6.28)

294.5 (11.59) 3.22 Light green

B 13.3 (0.52) 133.7-159.9 (5.26-6.30) 300.5 (11.83)

3.43 Purple Yellow

C 13.4 (0.53)

132.6-158.6 (5.22-6.24) 301.5 (11.87) 3.49

Light blue

D 13.7 (0.54)

132.9-158.9 (5.23-6.26) 302.0 (11.89) 3.52

Pink White

I F I 12f3 Kl5Al I 1.17 A-l!% 8 f!i PR-Fi 751

I RrIl .5 II 1 6x71 I 3.56 Orange

Blue

3 83 Pink -

Brown - .“._ \“.- .,

. “W.., ~ - -. - \-. -- -. - -, -- .-

\’ .‘-‘I t

F 11 .o (0.43) 129.0 (5.08)

335.0 (13.19) -.--

G 11.2 (0.44) 128.8 (5.07)

334.0 (13.15) 3.94

Rnnr l-4

1 I ? 07 AA 1387 /5n7

.?m !i 113 1% 3 an Blue - I I I I .” \v.-7, I&V., \V.“., ---.., \.-. .-, I 11.5 (0.45) 128.5 (5.06)

333.0 (13.11) i:oi Gray

-

J 11.6 (0.46) 128.4 (5.06)

332.5 (13.09) 4.00 Orange

-

l ’ Main identification mark color: Indicated on second coil from bottom.

*’ Auxiliary identification mark color: Indicated on third coil from bottom. 23UORX-005

R-4